Method for preparing graphene nano-sheet based on crystalline flake graphite

A technology of graphene nanosheets and graphite flakes, which is applied in the field of graphene, can solve the problems of complex production process, low yield of graphene, and amorphization by mechanical ball milling of solid-state media, and achieve simple process, high oxidation degree, and control side effects. The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

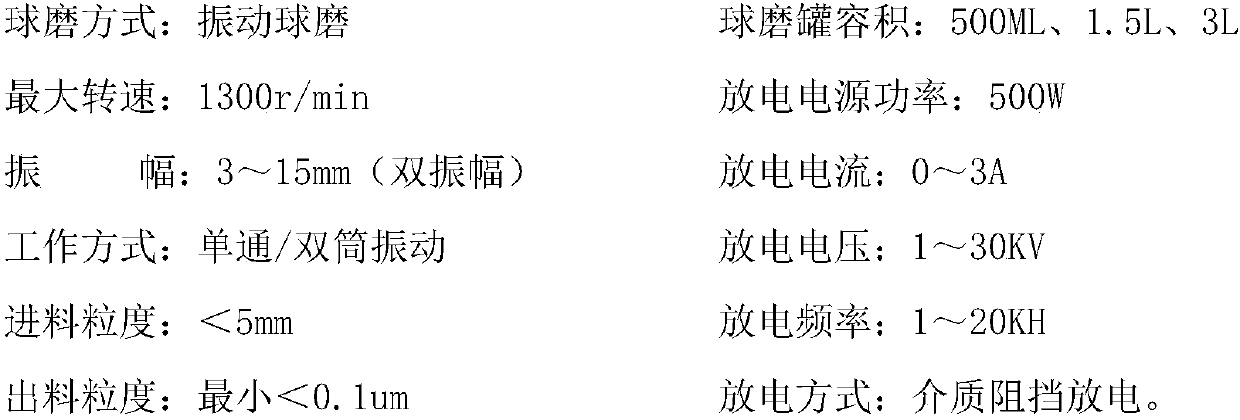

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method that prepares graphene nanoplate based on flake graphite, comprises the following steps:

[0032] S1. Preparation of oxidized flake graphite: add flake graphite and sodium nitrate to concentrated sulfuric acid, and gradually add KMnO while keeping it below 20°C 4 , keep stirring at low temperature for 1h, then raise the temperature to 35°C and stir for 30min, then raise the temperature to 65°C, add hydrogen peroxide dropwise, keep for 40min, wash by repeated centrifugation and filtration, and then vacuum dry to obtain graphite oxide flakes;

[0033] S2. Pre-stripping: place the oxidized flake graphite obtained in step S1 in a heating furnace, raise the temperature from room temperature to 260-305°C, the heating rate is 9.0°C / min, and keep feeding Ar gas at 3000ml / min to obtain Expanded graphene nanosheets, the expanded graphene nanosheets have an expansion factor of 235 times and a specific surface area of ...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method that prepares graphene nanoplate based on flake graphite, comprises the following steps:

[0041] S1. Preparation of oxidized flake graphite: add flake graphite and sodium nitrate to concentrated sulfuric acid, and gradually add KMnO while keeping it below 20°C 4 , kept stirring at low temperature for 2 hours, then raised the temperature to 40°C and stirred for 30 minutes, then raised the temperature to 80°C, added hydrogen peroxide dropwise, kept for 40 minutes, washed by repeated centrifugation and filtration, and then vacuum-dried to obtain graphite oxide flakes;

[0042] S2. Pre-stripping: place the oxidized flake graphite obtained in step S1 in a heating furnace, raise the temperature from room temperature to 260-305°C, the heating rate is 9.0°C / min, and keep flowing Ar gas at 3000ml / min, The expanded graphene nanosheets were obtained. The expanded graphene nanosheets had an expansion factor of 300 times...

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, the difference is that in step S3, the ball milling medium GeO 2 , the graphene nanosheets prepared in this example have about 6 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com