Novel process for refining oil-tea camellia seed crude oil

Camellia oleifera seed crude oil, a new process technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems that product quality cannot be effectively improved, soluble impurities cannot be effectively removed, and the production cost of camellia oleifera seed oil is high. Effect of degumming and production efficiency, increase of by-product income, and effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

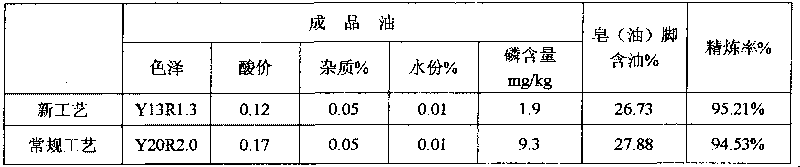

Image

Examples

Embodiment 1

[0021] The specific technological process of the present embodiment is as follows:

[0022] First, the crude camellia seed oil to be refined is filtered to remove impurities, so that the quality of the crude camellia seed oil after removal of impurities is: acid value 3.5, phospholipid content 1.05%, moisture 0.2%, and impurities 0.18%.

[0023] Second, add 85% phosphoric acid accounting for 0.12% of the total weight of camellia seed crude oil to the crude camellia seed oil after impurity removal, and enter the acid reaction tank after being mixed by a knife mixer, and the reaction time is 80 minutes;

[0024] Third, heat the crude camellia seed oil after the acid reaction to 50°C, then add 15Be of NaOH solution and centrifugally mix it (the amount of alkali added is calculated according to the formula: 1×0.713×Q / 1000, Q is the flow rate of the crude camellia seed oil T / h.), after fully mixing, stir slowly, and carry out low-temperature alkali refining reaction time after 20m...

Embodiment 2

[0030] The specific technological process of the present embodiment is as follows:

[0031] First, the crude camellia seed oil to be refined is filtered to remove impurities, so that the quality of the crude camellia seed oil after removal of impurities is: acid value 3.5, phospholipid content 1.05%, moisture 0.2%, and impurities 0.18%.

[0032] Second, add 85% phosphoric acid accounting for 0.13% of the total weight of the camellia seed crude oil to the crude camellia seed oil after impurity removal, and enter the acid reaction tank after being mixed by a knife mixer, and the reaction time is 90 minutes;

[0033] Third, heat the crude camellia seed oil through the acid reaction to 55°C, then add 15Be of NaOH solution and centrifugally mix it (the amount of alkali added is calculated according to the formula: 1×0.713×Q / 1000, Q is the flow rate of the crude camellia seed oil T / h.), after fully mixing, stir slowly, and carry out low-temperature alkali refining reaction time aft...

Embodiment 3

[0039] The specific technological process of the present embodiment is as follows:

[0040] First, the crude camellia seed oil to be refined is filtered to remove impurities, so that the quality of the crude camellia seed oil after removal of impurities is: acid value 3.5, phospholipid content 1.05%, moisture 0.2%, and impurities 0.18%.

[0041] Second, add 85% phosphoric acid accounting for 0.15% of the total weight of camellia seed crude oil to the crude camellia seed oil after impurity removal, and enter the acid reaction tank after being mixed by a knife mixer, and the reaction time is 100min;

[0042] Third, heat the crude camellia seed oil after the acid reaction to 60°C, then add 15Be of NaOH solution and centrifugally mix it (the amount of alkali added is calculated according to the formula: 1×0.713×Q / 1000, Q is the flow rate of the crude camellia seed oil T / h.), after fully mixing, stir slowly, and carry out low-temperature alkali refining reaction time after 20min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com