Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Raise the overpotential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel catalyst mixtures

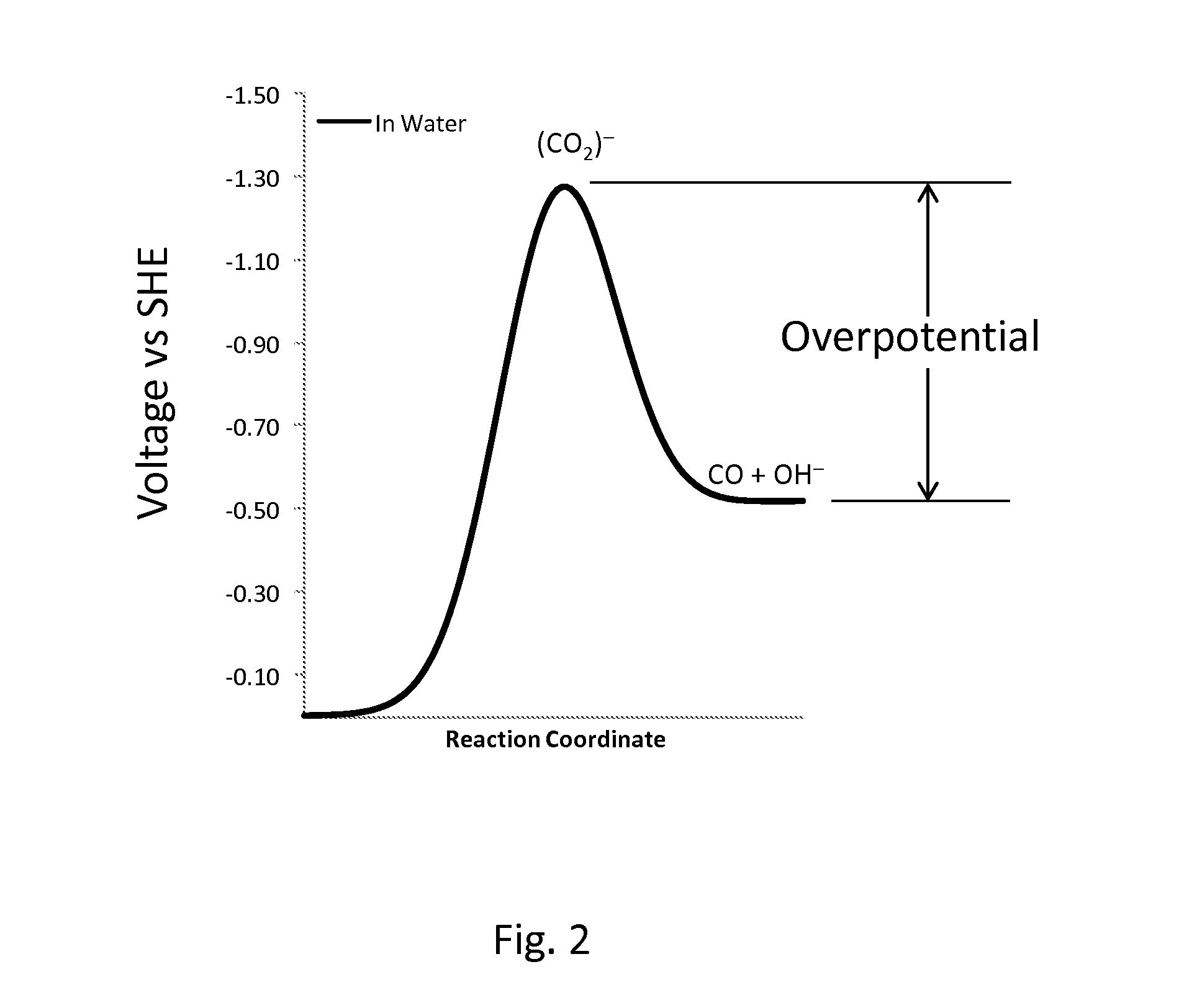

InactiveUS20110237830A1Low rateRaise the overpotentialOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical reactionCompound (substance)

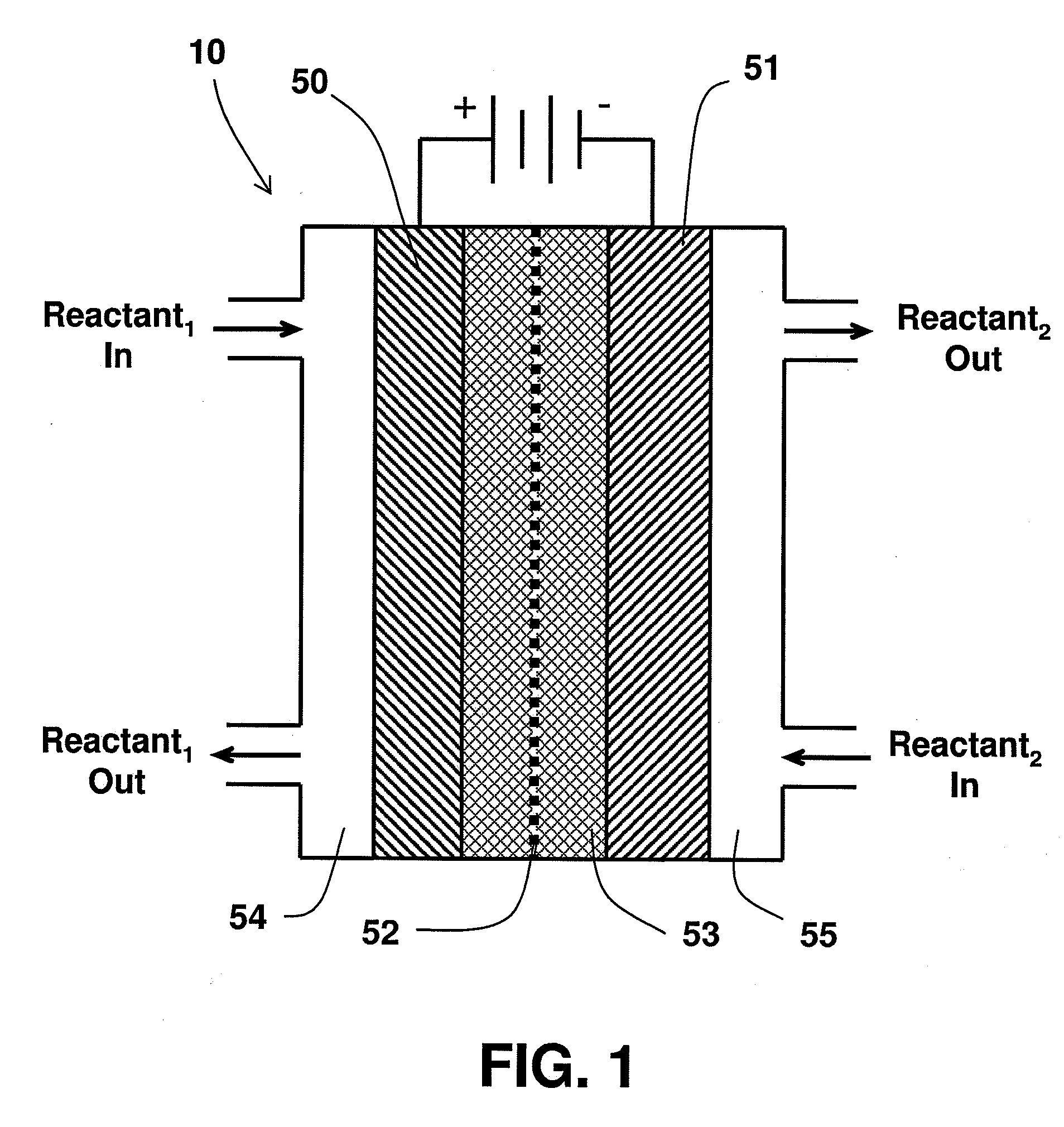

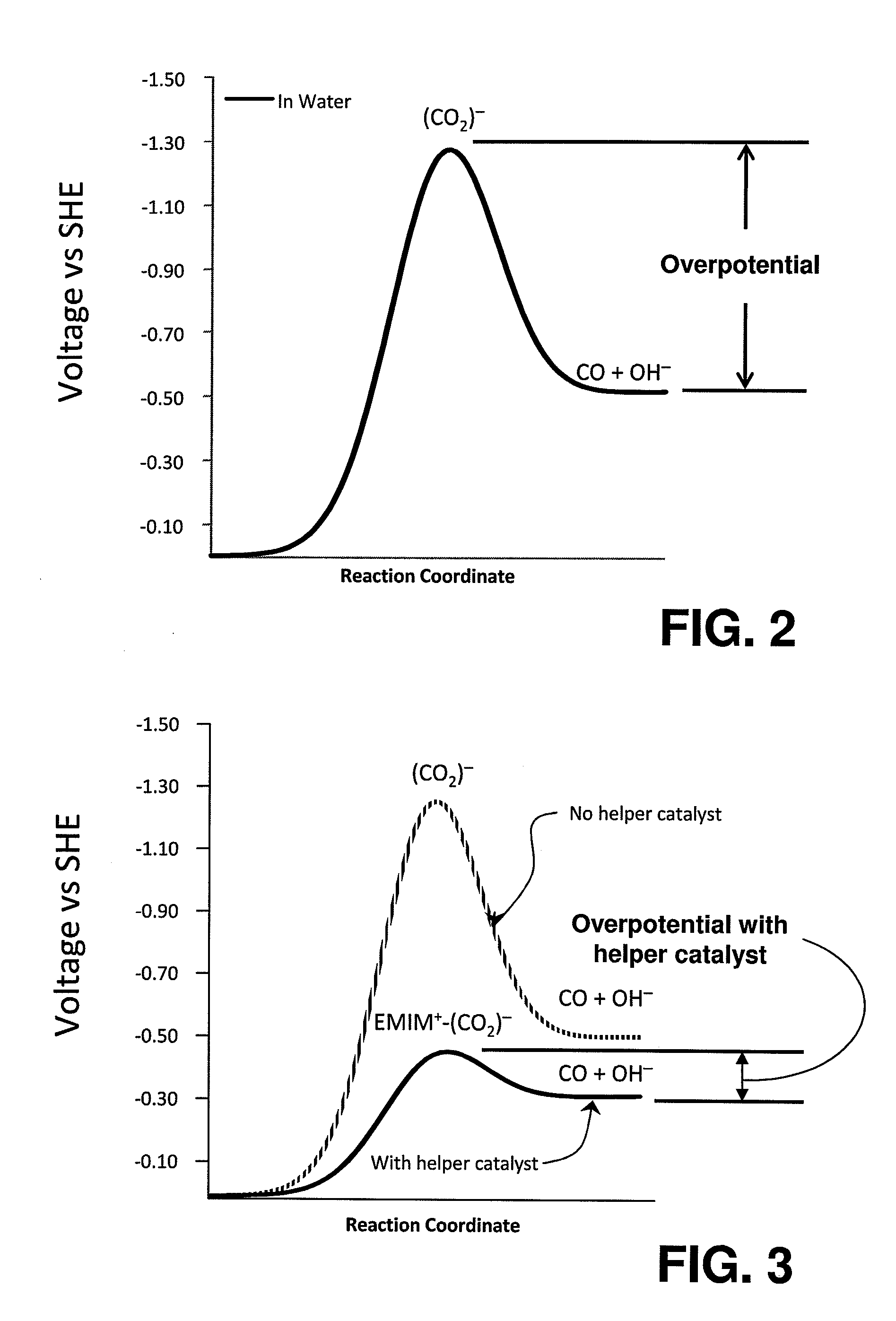

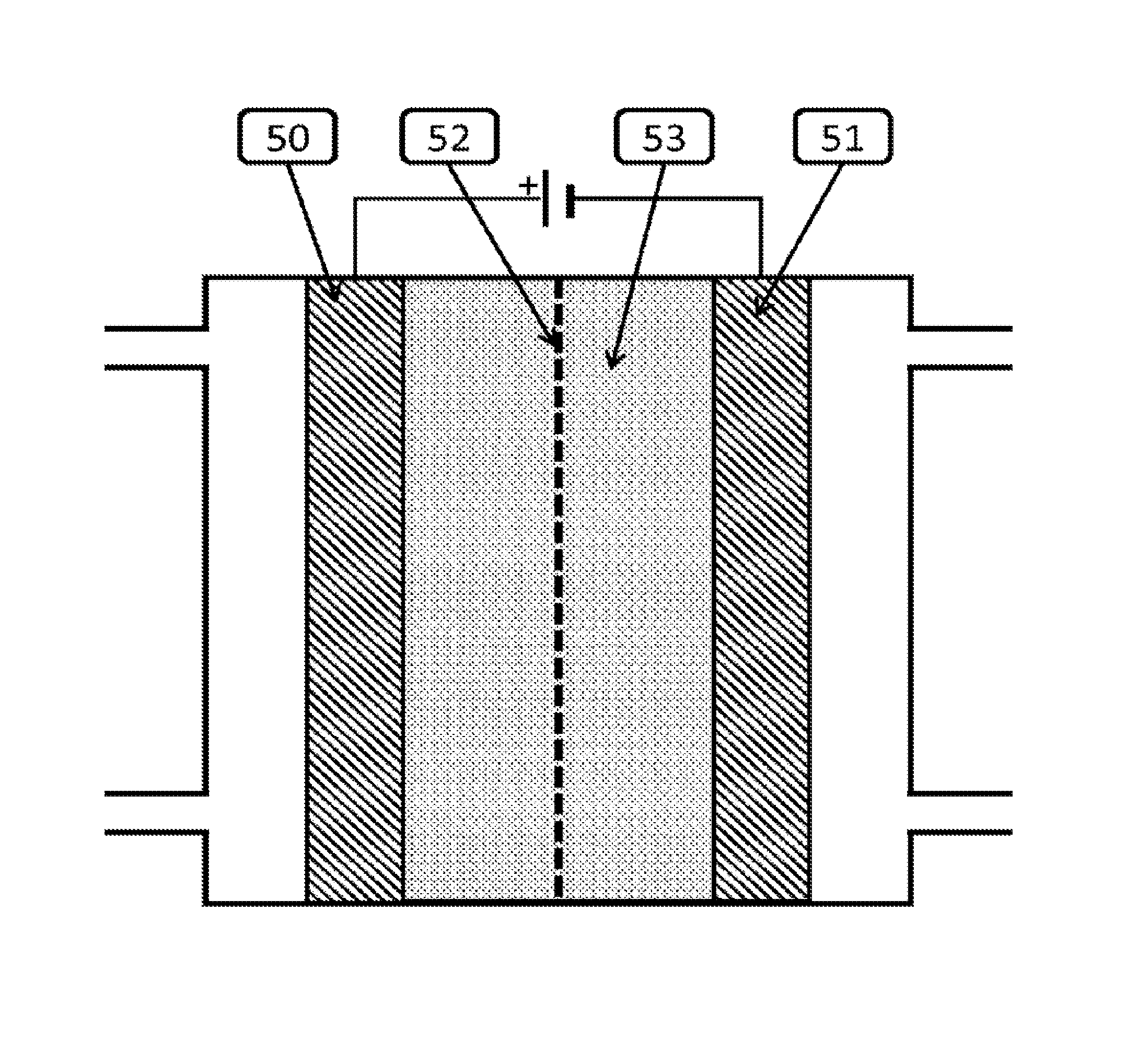

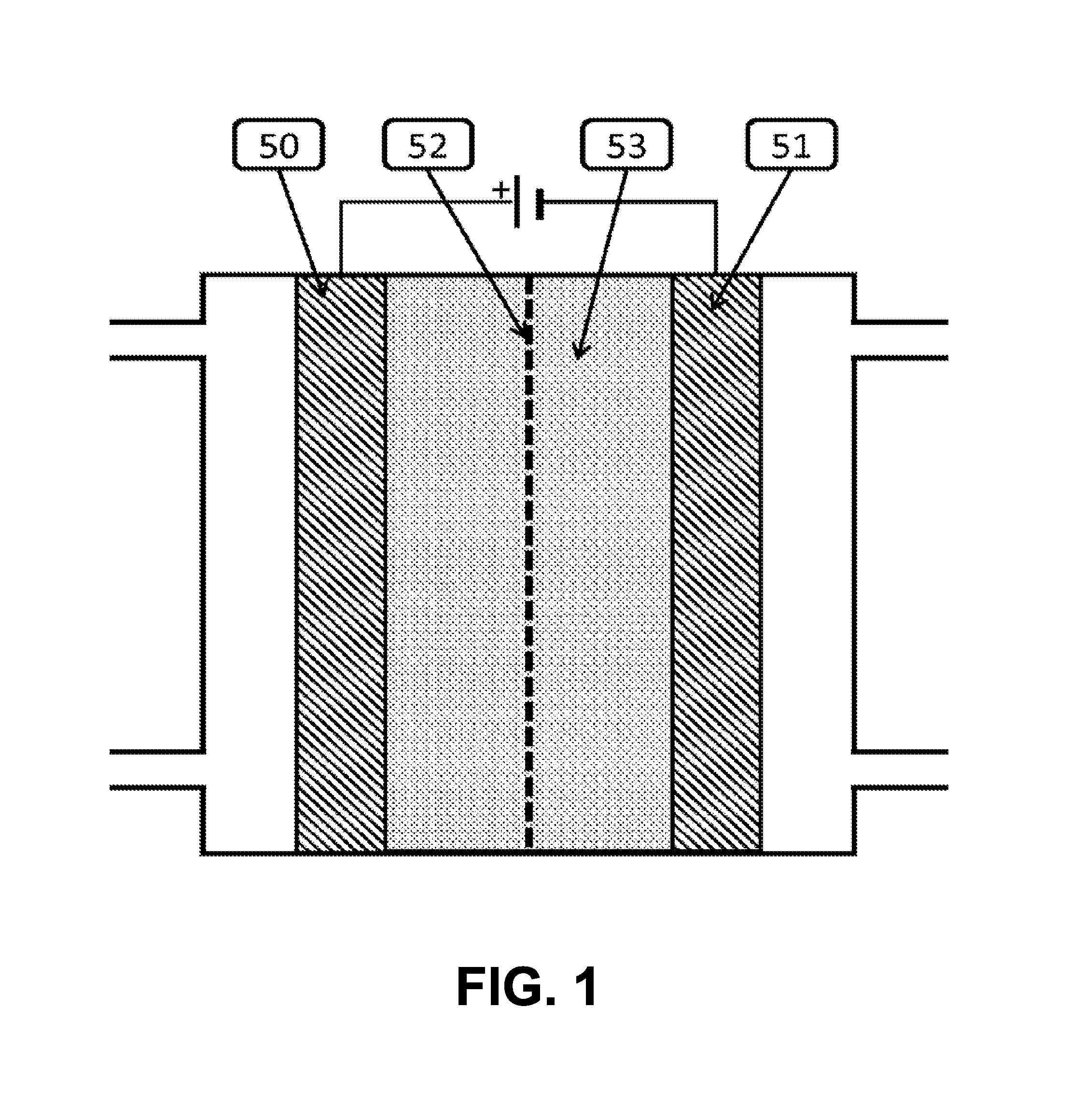

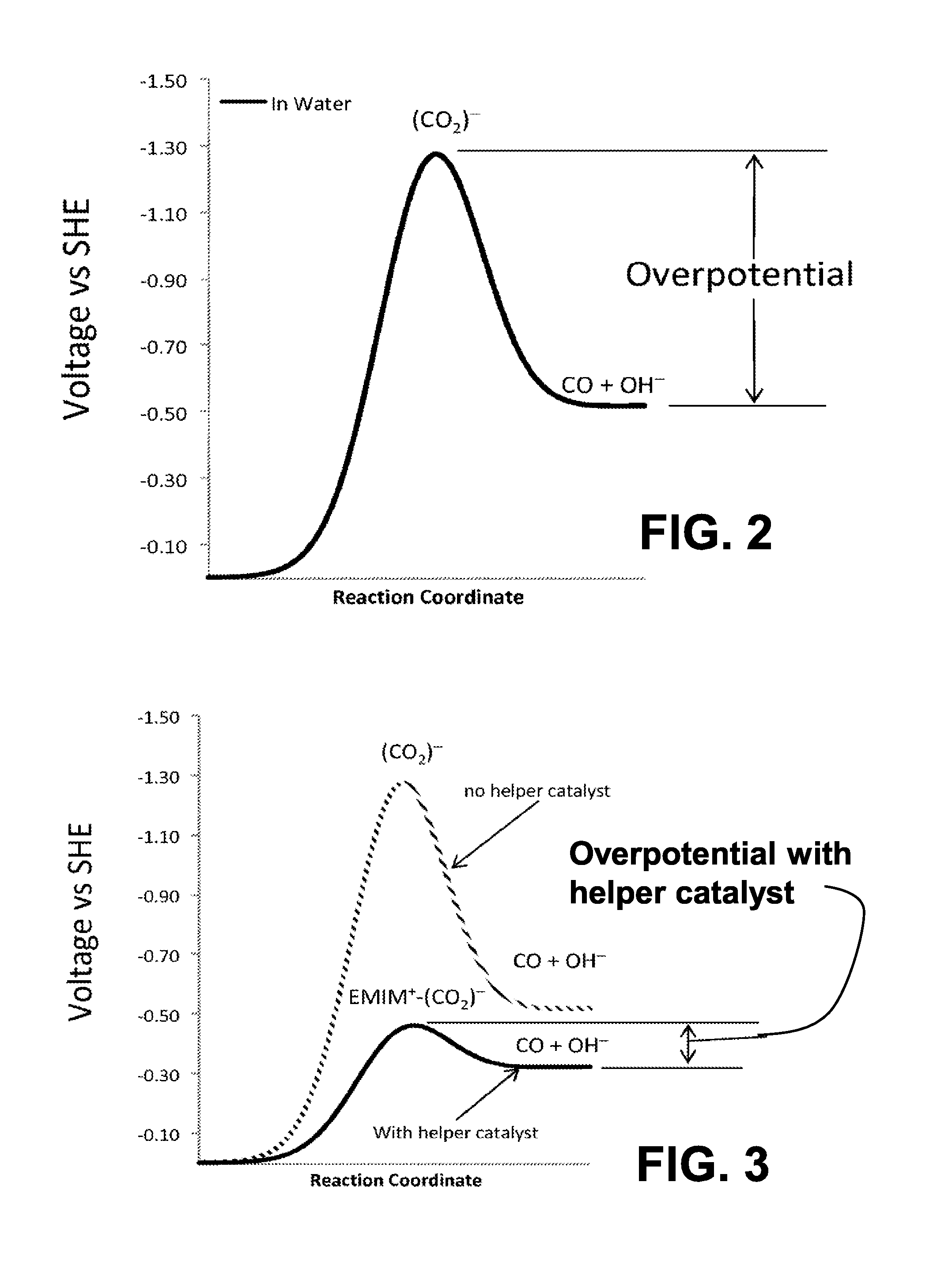

Catalysts comprised of at least one catalytically active element and at least one helper catalyst are disclosed. The catalysts may be used to increase the rate, the selectivity or lower the overpotential of chemical reactions. These catalysts may be useful for a variety of chemical reactions including in particular the electrochemical conversion of carbon dioxide to formic acid.

Owner:DIOXIDE MATERIALS

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

Novel Catalyst Mixtures

ActiveUS20120308903A1Raise the overpotentialLow rateWeather/light/corrosion resistanceCell electrodesChemical reactionCompound (substance)

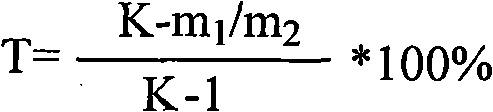

Catalysts that include at least one catalytically active element and one helper catalyst can be used to increase the rate or lower the overpotential of chemical reactions. The helper catalyst can simultaneously act as a director molecule, suppressing undesired reactions and thus increasing selectivity toward the desired reaction. These catalysts can be useful for a variety of chemical reactions including, in particular, the electrochemical conversion of CO2 or formic acid. The catalysts can also suppress H2 evolution, permitting electrochemical cell operation at potentials below RHE. Chemical processes and devices using the catalysts are also disclosed, including processes to produce CO, OH−, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, O2, H2, (COOH)2, or (COO−)2, and a specific device, namely, a CO2 sensor.

Owner:DIOXIDE MATERIALS

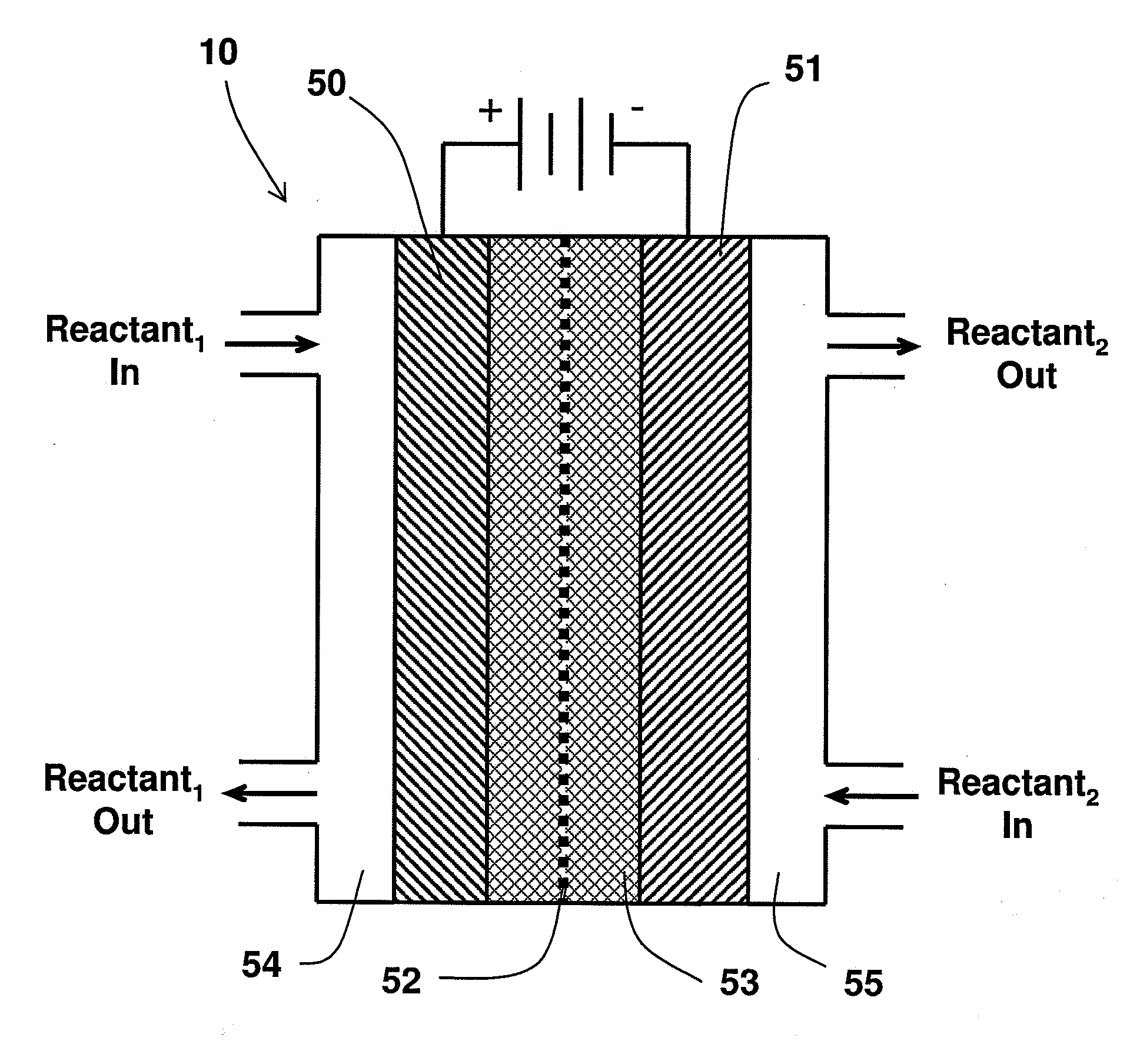

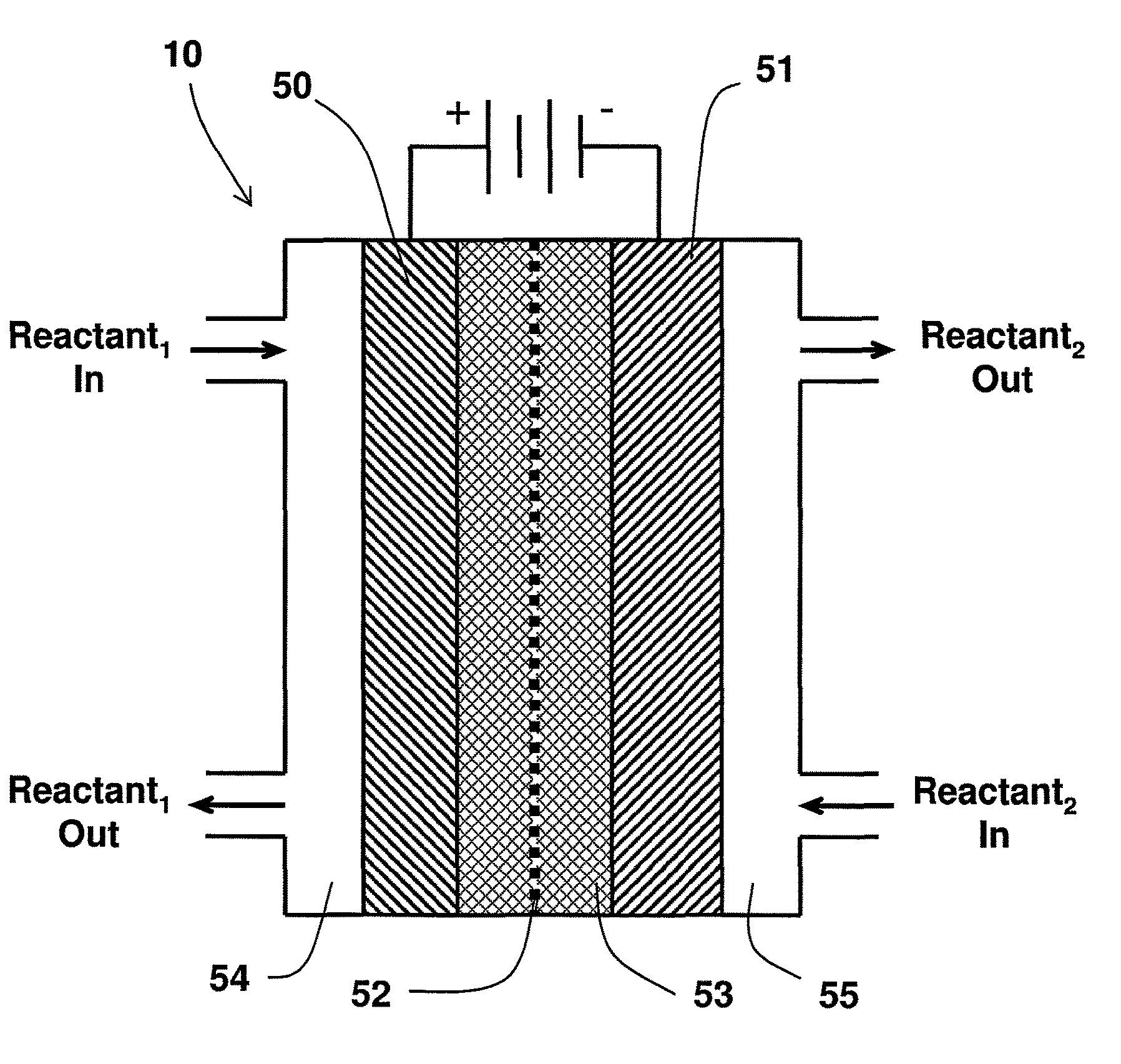

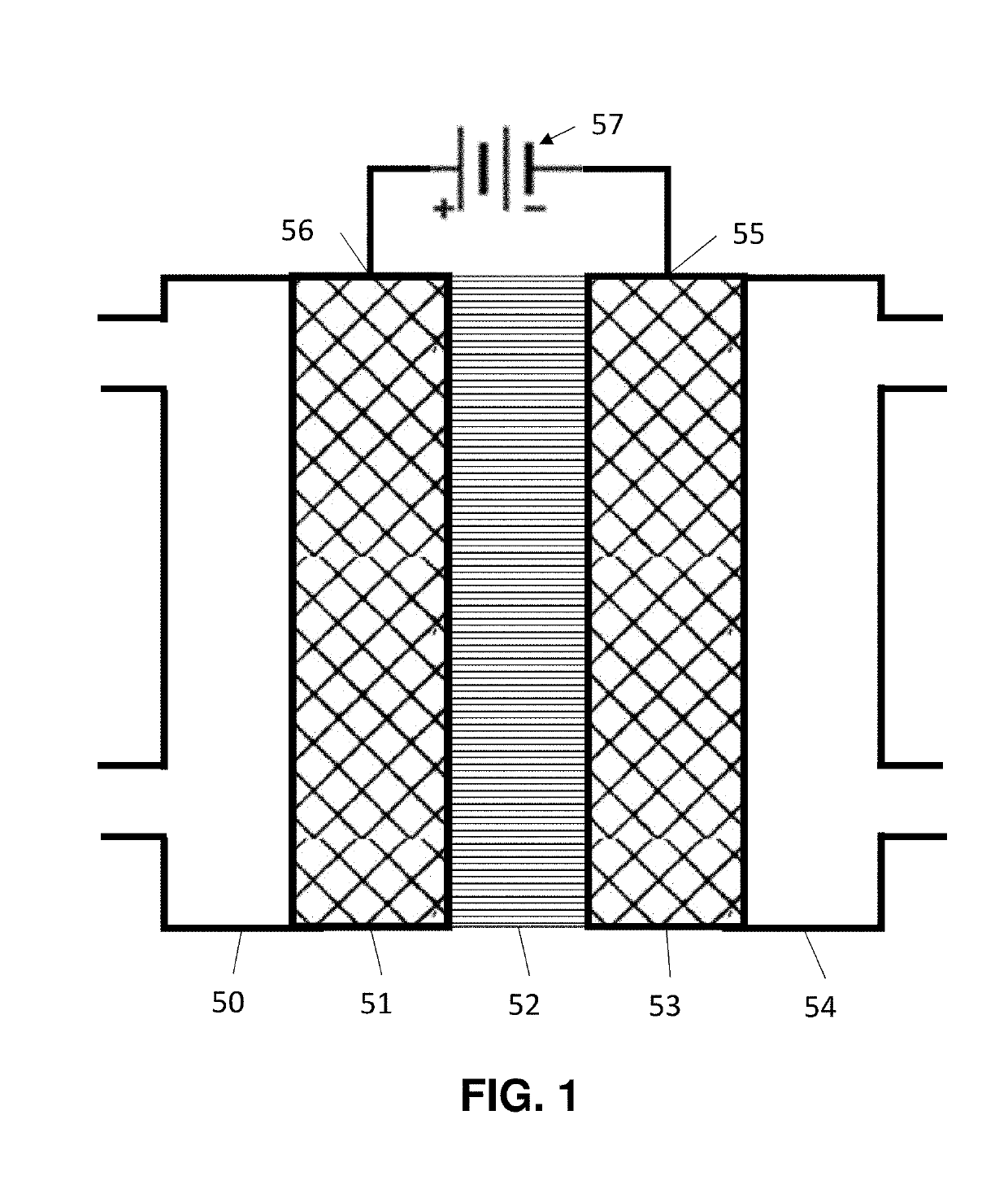

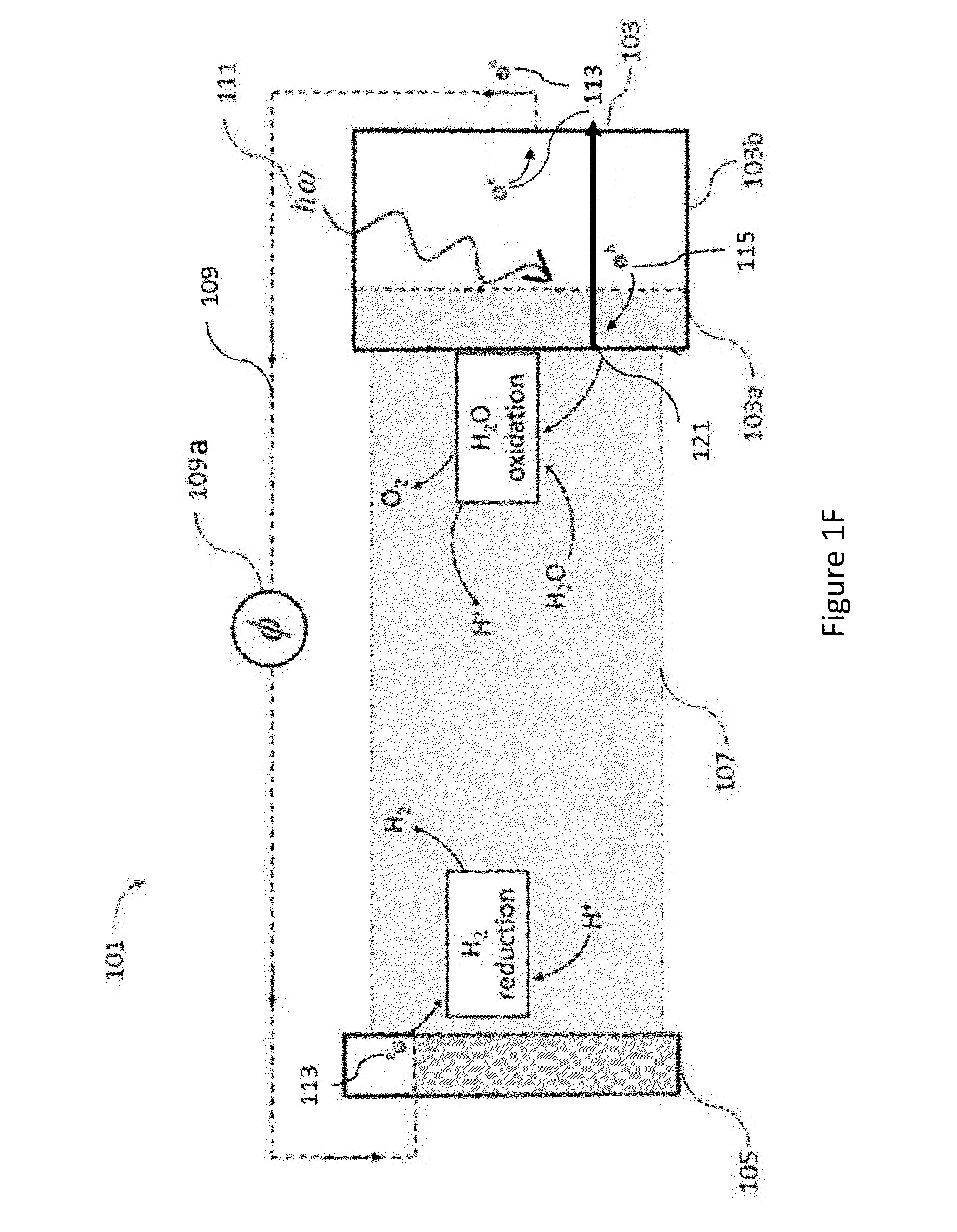

Devices And Processes For Carbon Dioxide Conversion Into Useful Fuels And Chemicals

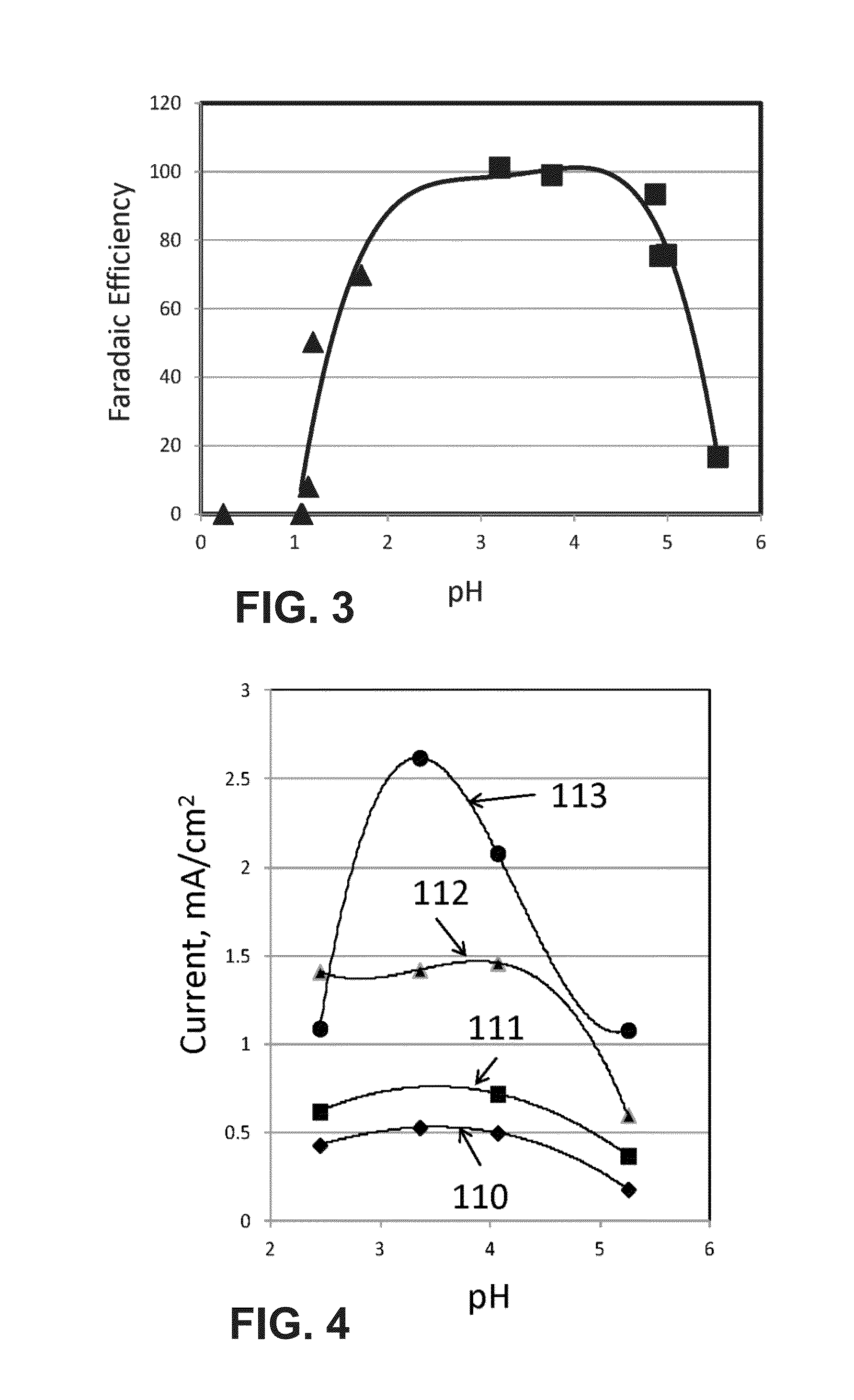

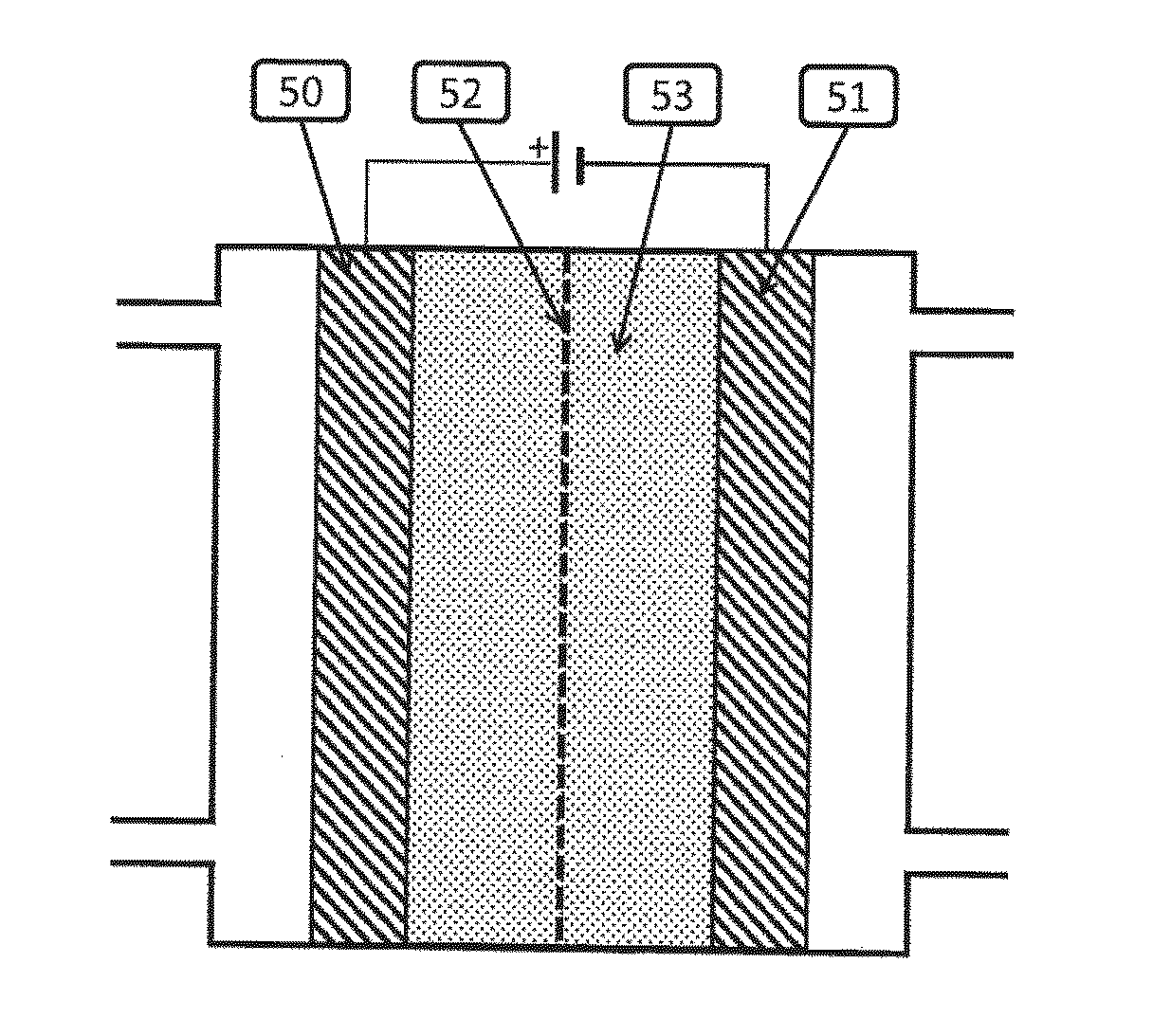

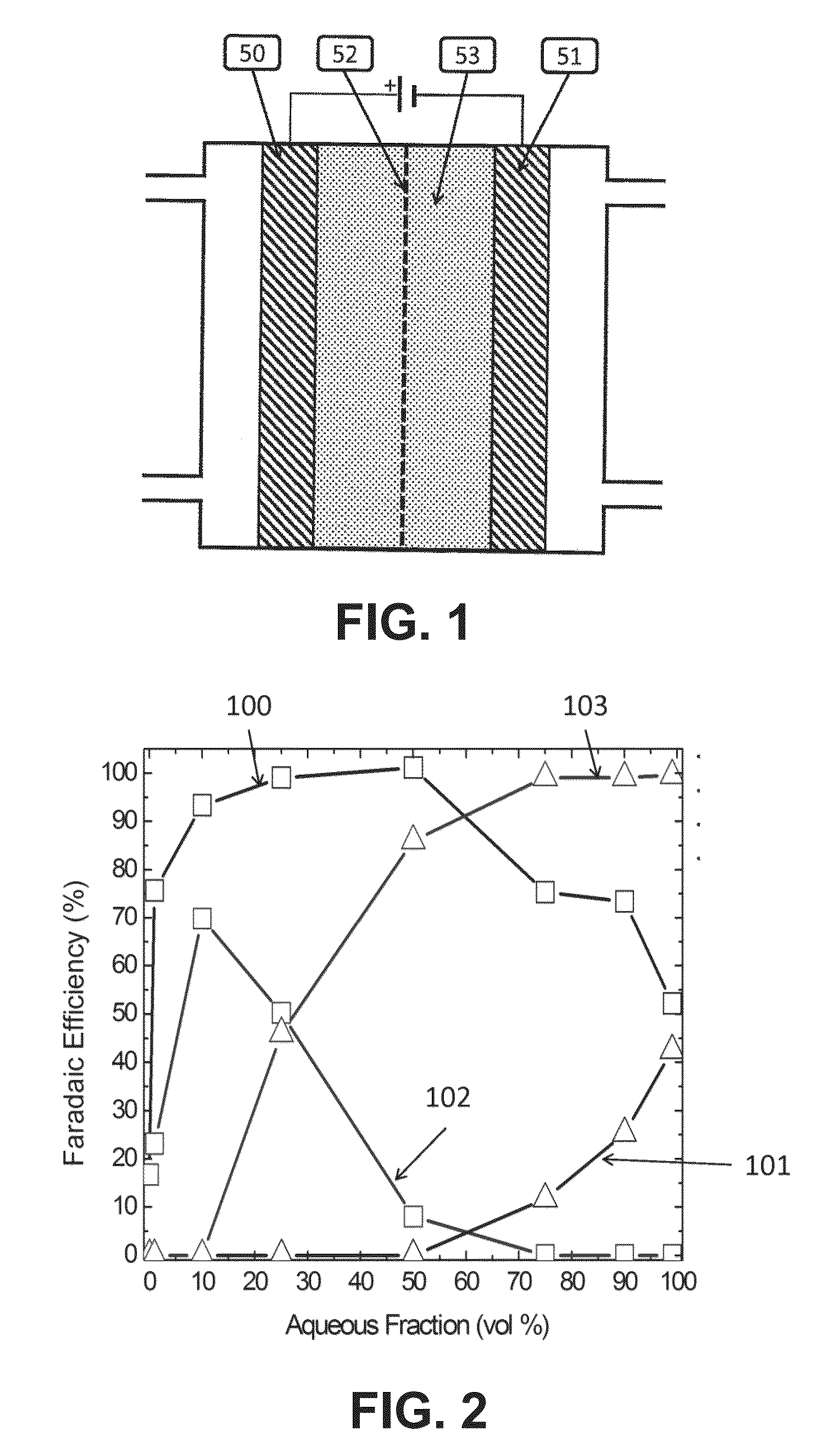

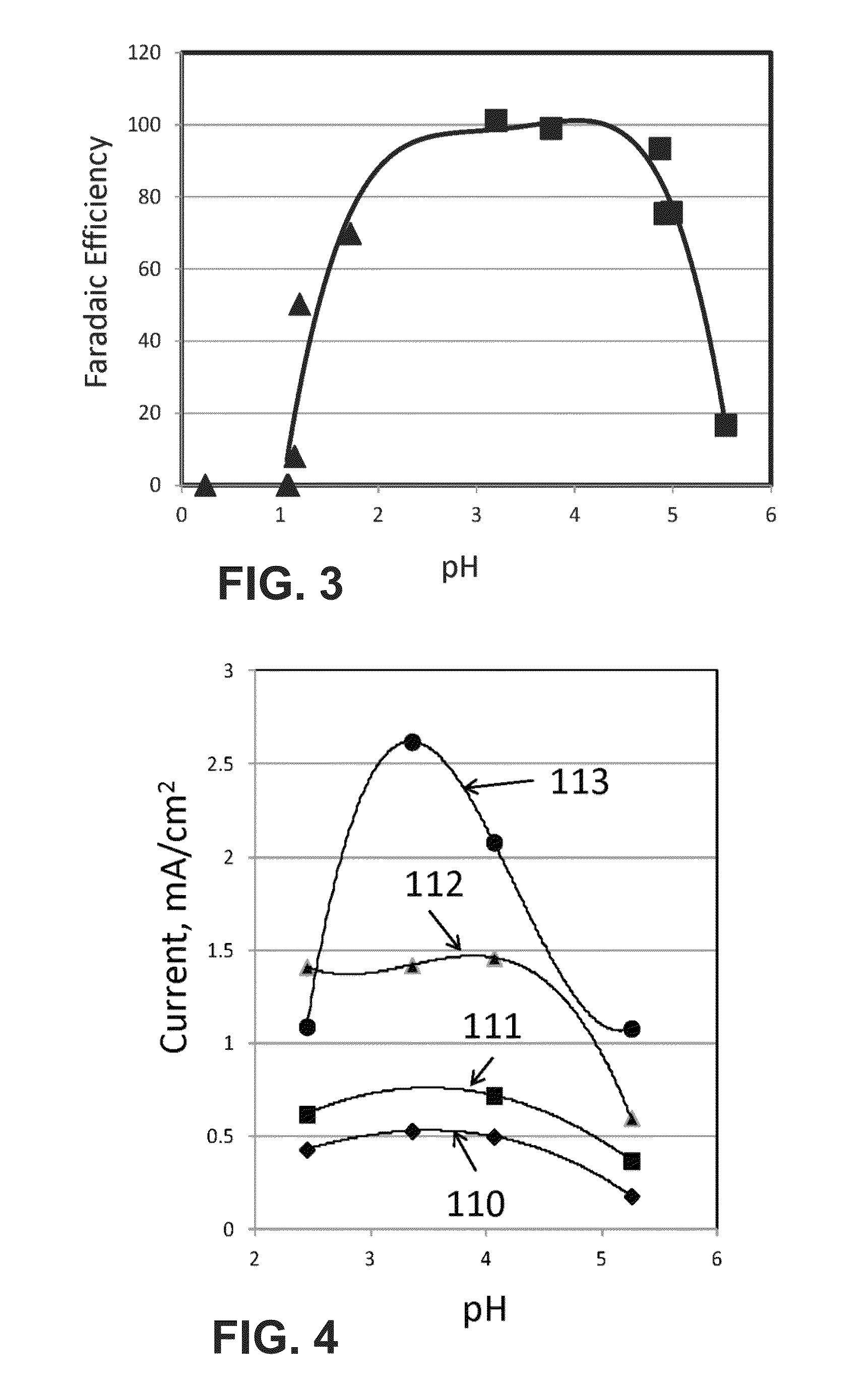

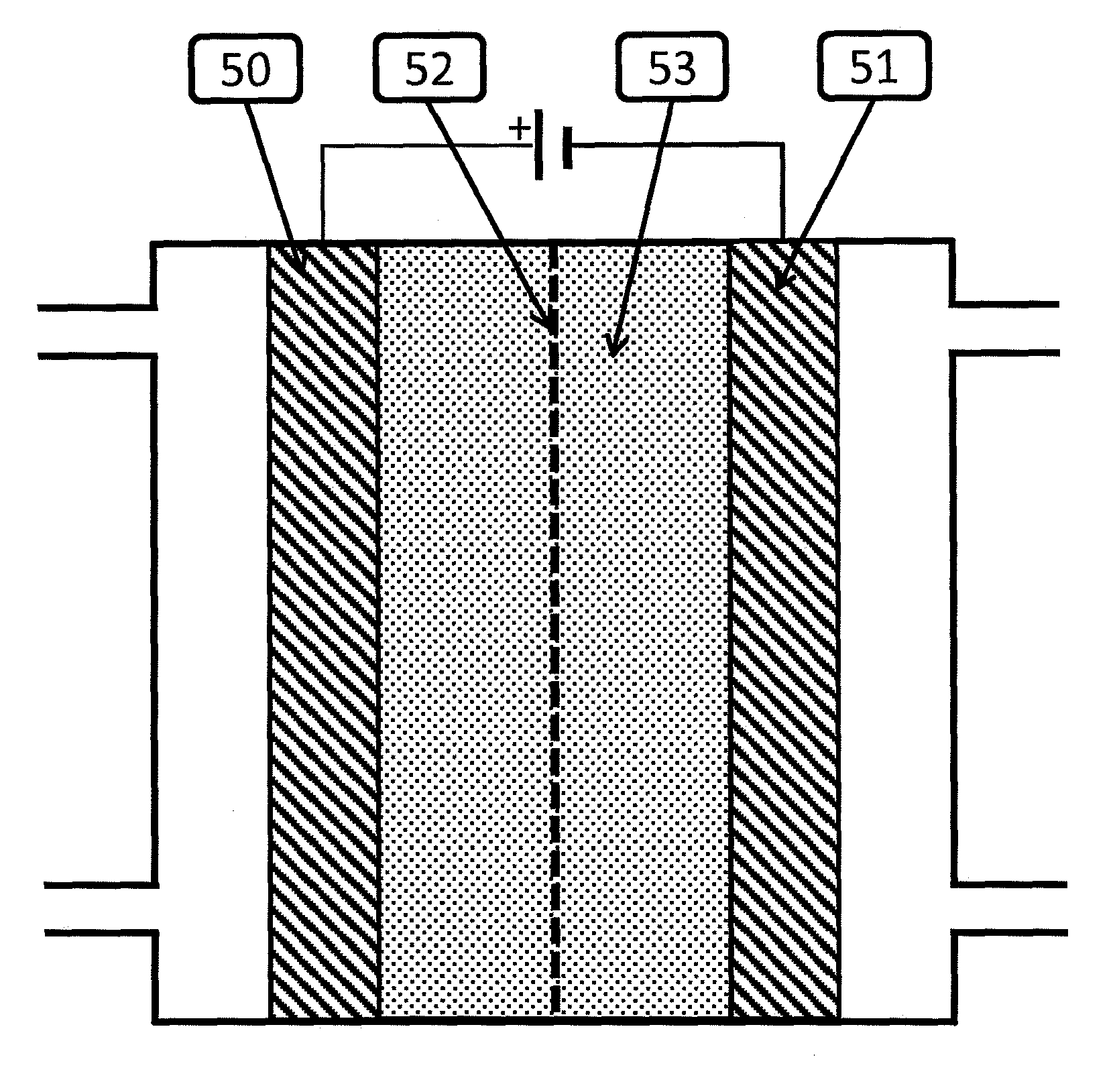

ActiveUS20140093799A1Low rateRaise the overpotentialCellsElectrolytic organic productionOrganic acidCompound (substance)

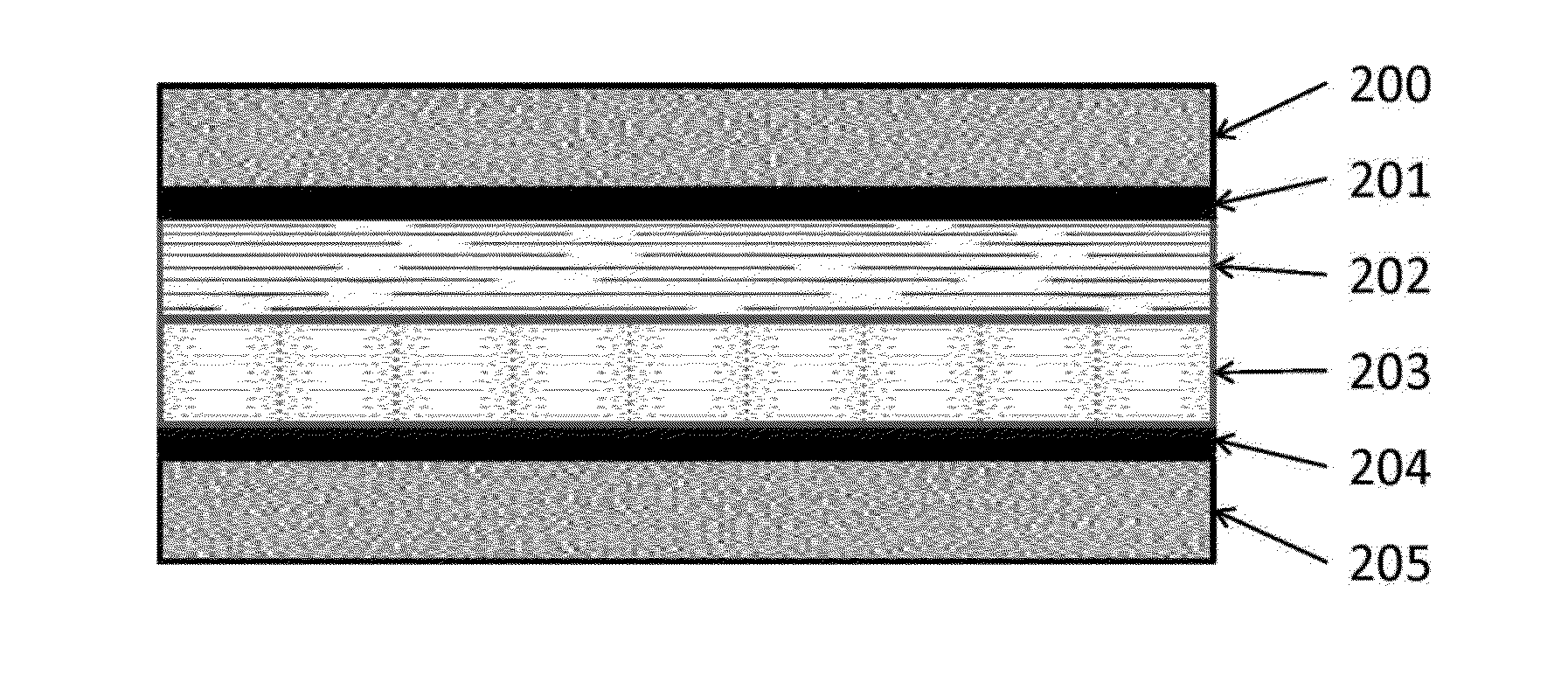

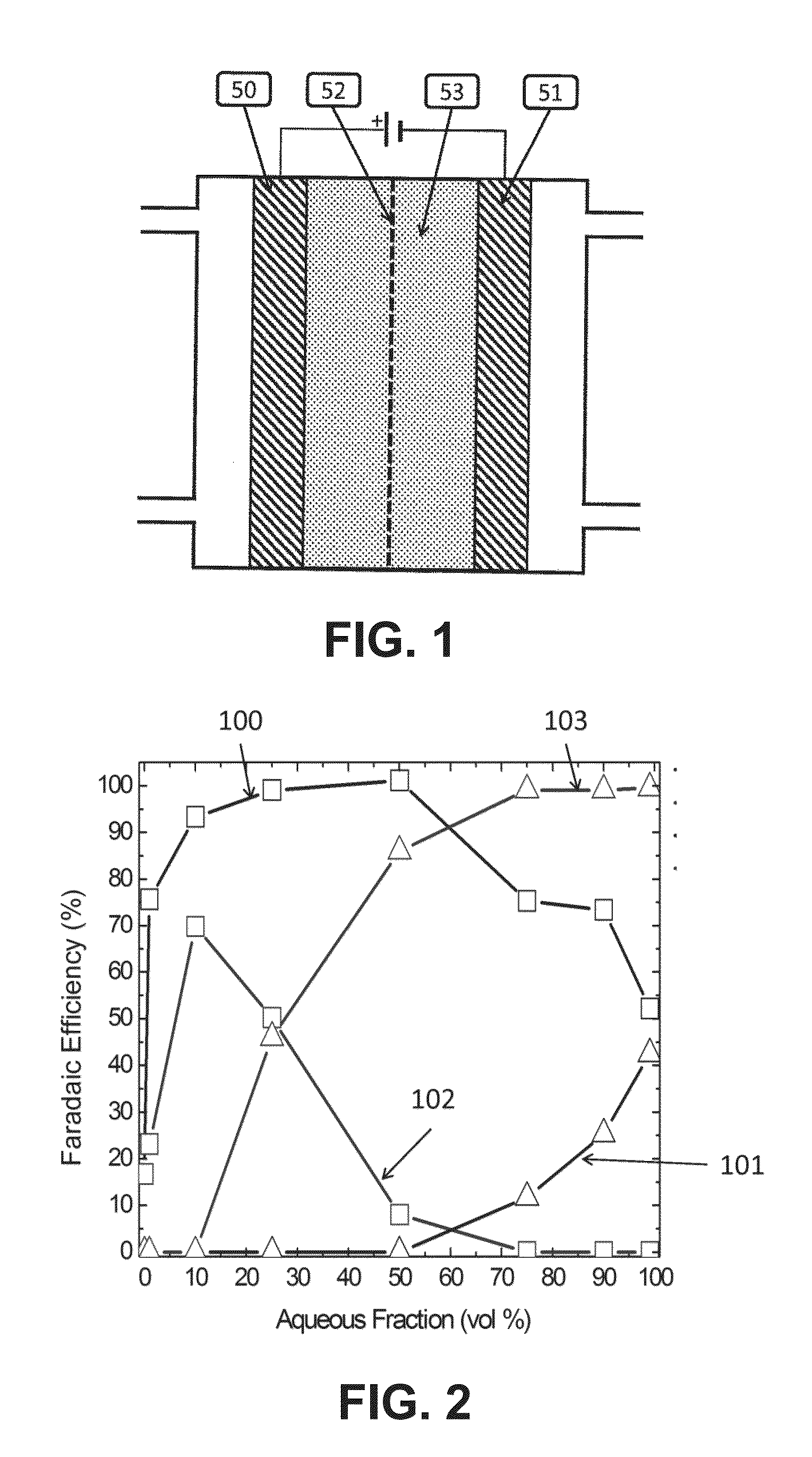

Electrochemical devices for converting carbon dioxide to useful reaction products include a solid or a liquid with a specific pH and / or water content. Chemical processes using the devices are also disclosed, including processes to produce CO, HCO−, H2CO, (HCO2), H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, acrylic acid, diphenyl carbonate, other carbonates, other organic acids and synthetic fuels. The electrochemical device can be a CO2 sensor.

Owner:DIOXIDE MATERIALS

Electrocatalysts For Carbon Dioxide Conversion

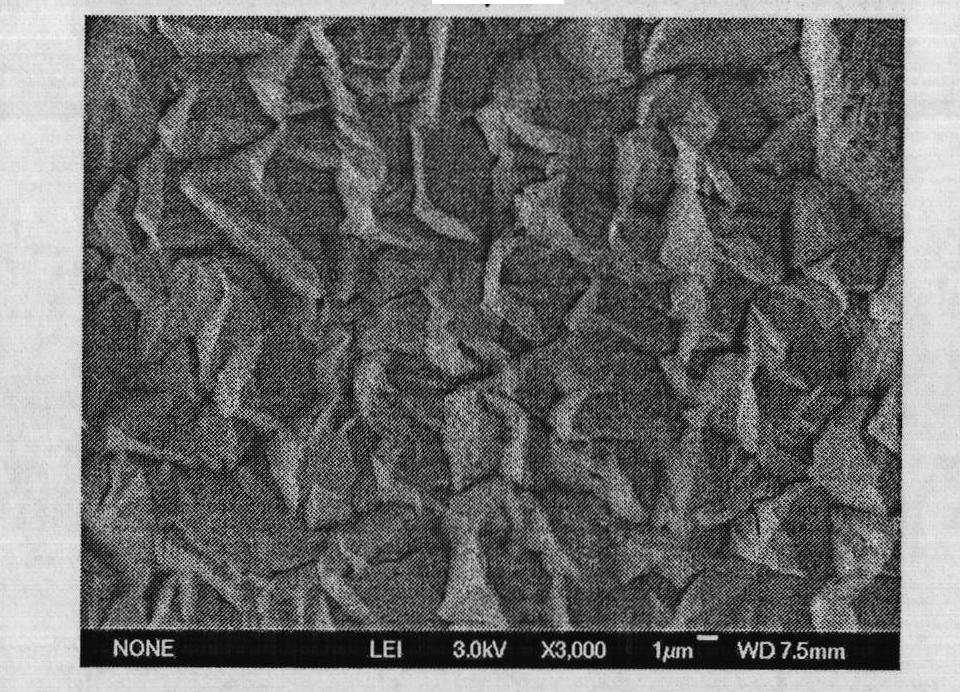

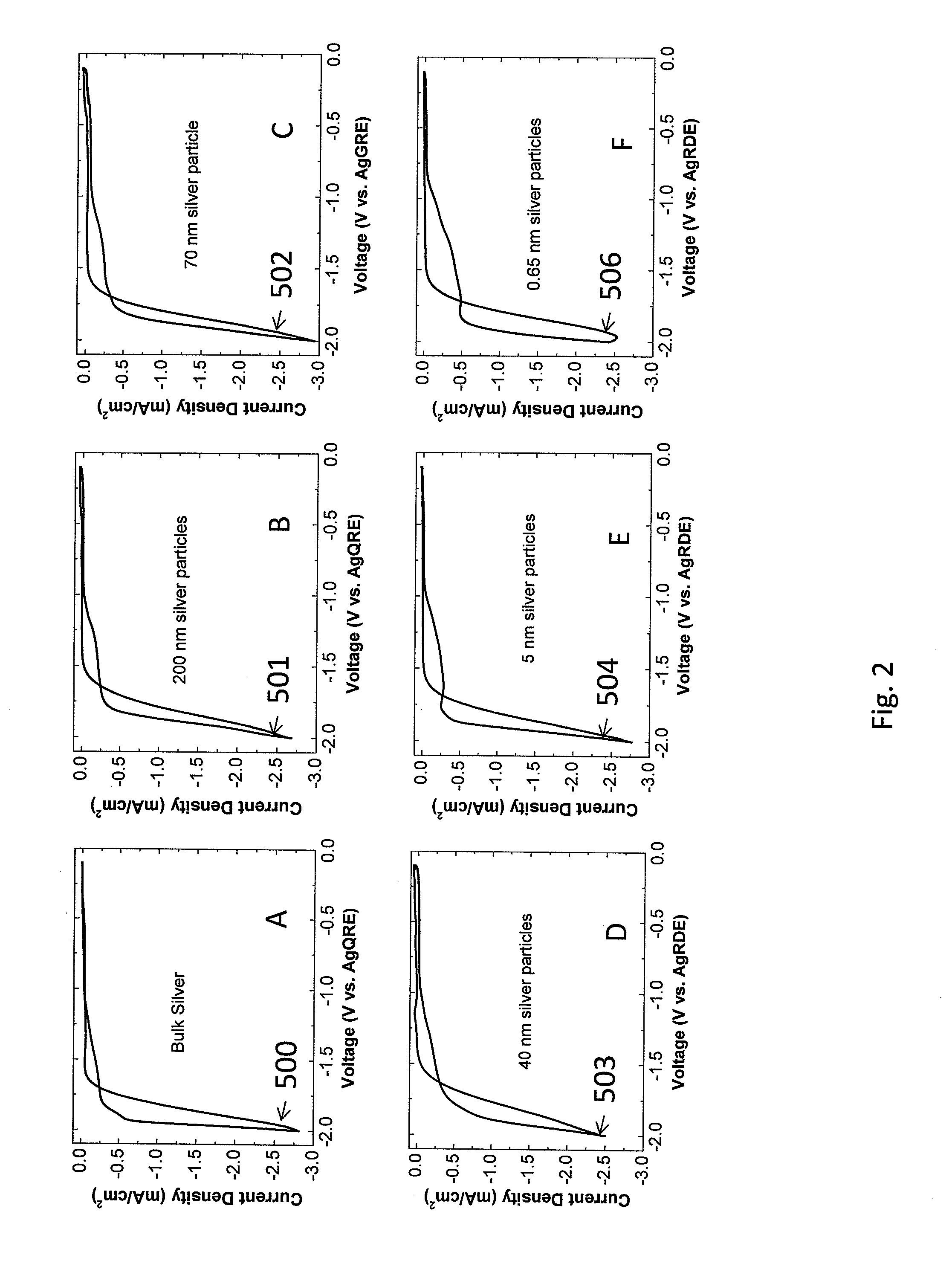

ActiveUS20130157174A1Raise the overpotentialLow rateOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCompound (substance)Chemical process

Electrocatalysts for carbon dioxide conversion include at least one catalytically active element with a particle size above 0.6 nm. The electrocatalysts can also include a Helper Catalyst. The catalysts can be used to increase the rate, modify the selectivity or lower the overpotential of electrochemical conversion of CO2. Chemical processes and devices using the catalysts also include processes to produce CO, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, or (COO−)2, and a specific device, namely, a CO2 sensor.

Owner:DIOXIDE MATERIALS

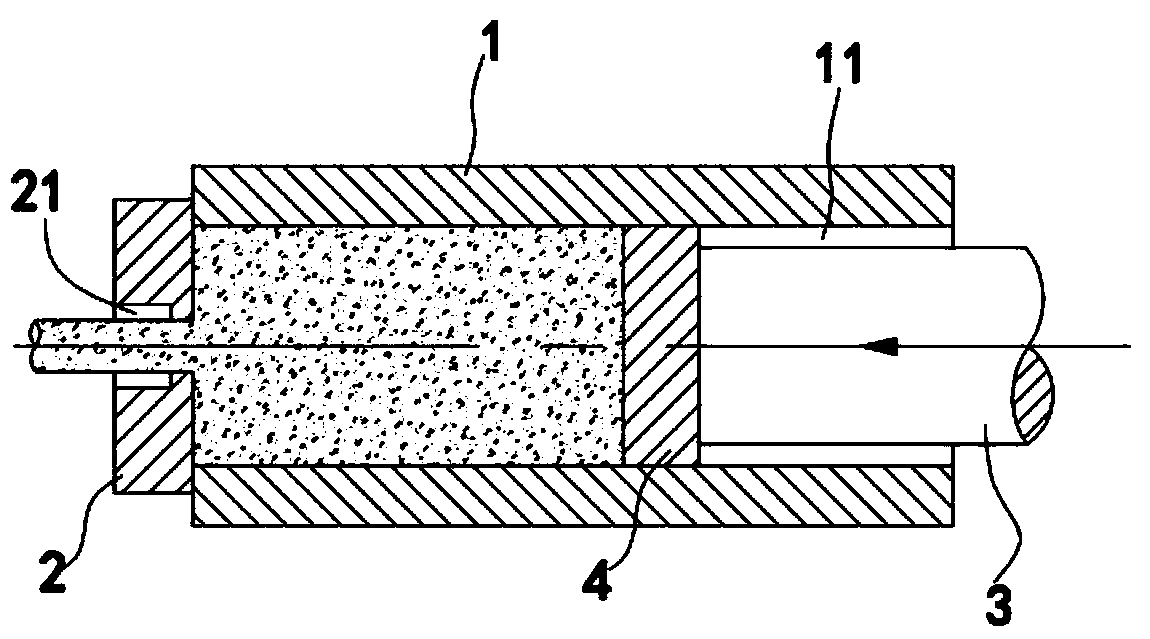

Method and apparatus for treating high concentrated organic wastewater by hydrothermal electrical catalytic oxidation

InactiveCN1654344ARelieve pressureLow costCatalyst carriersWater/sewage treatment by heatingHigh concentrationReaction temperature

The present invention is hydrothermal and electric catalytic oxidation process and apparatus for treating high concentration organic waste water. The present invention features that high concentration organic waste water is treated electrolytically at temperature from room temperature to 250 deg.c and pressure of 0.5-7 MPa while oxygen containing air is led in to eliminate organic compound and nitrous compound from waste water and to make them become CO2, N2, water or inorganic salt inside an intermittent or continuous electrolytic reactor. The present invention combines wet catalytic oxidation and high temperature electrolysis, and has relatively low reaction temperature and pressure, high organic waste water treating efficiency and low cost.

Owner:YUNNAN UNIV

Catalyst mixtures

ActiveUS8956990B2Raise the overpotentialLow rateCell electrodesCarbon monoxideChemical reactionCompound (substance)

Catalyst mixtures include at least one Catalytically Active Element and, as a separate constituent, one Helper Catalyst. The catalysts can be used to increase the rate, modify the selectivity or lower the overpotential of chemical reactions. These catalysts are useful for a variety of chemical reactions including, in particular, the electrochemical conversion of CO2. Chemical processes employing these catalysts produce CO, OH−, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, O2, H2, (COOH)2, or (COO−)2. Devices using the catalysts include, for example, a CO2 sensor.

Owner:DIOXIDE MATERIALS

Devices and processes for carbon dioxide conversion into useful fuels and chemicals

ActiveUS9181625B2Raise the overpotentialLow rateCellsNoble metal coatingsOrganic acidCompound (substance)

Owner:DIOXIDE MATERIALS

Electrocatalysts for carbon dioxide conversion

ActiveUS9012345B2Raise the overpotentialLow rateMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsChemical processCarbon dioxide

Owner:DIOXIDE MATERIALS

Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

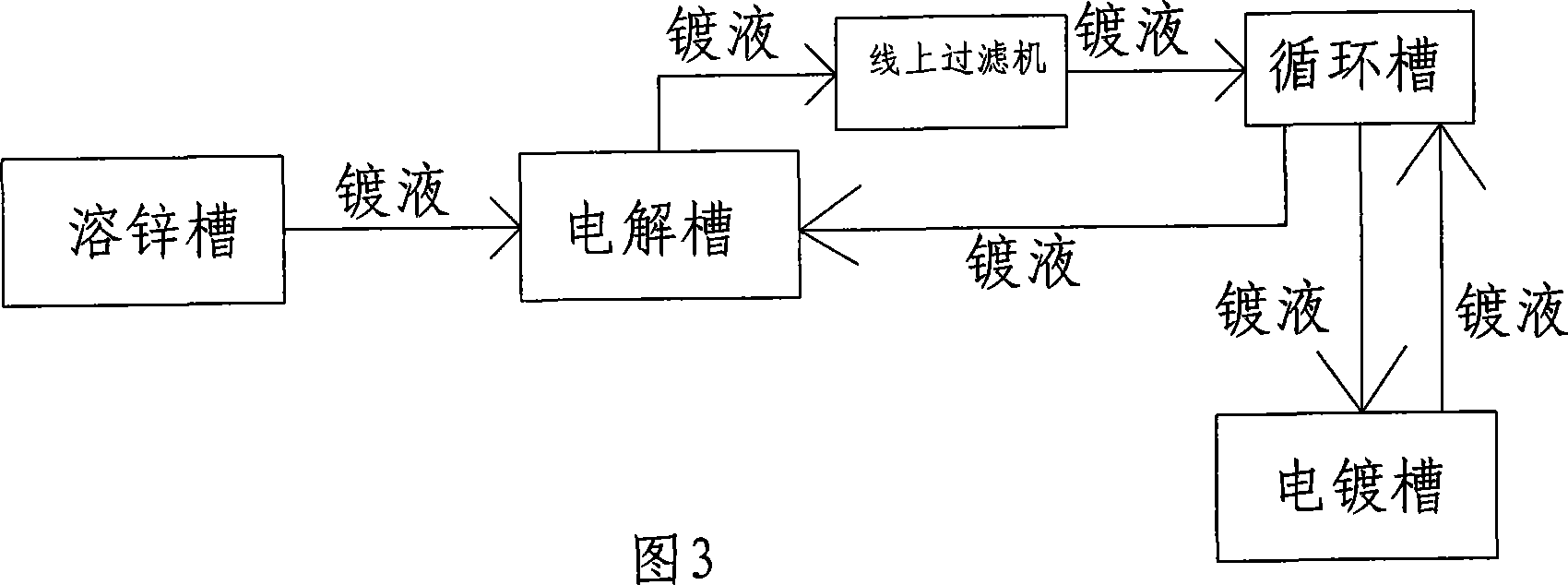

The invention provides a technical method for controlling and raising the PH value of galvanizing solution on a fingerprint resistant continuous and automatic production line of the electro-galvanizing and roller coating of a rolled plate; the galvanizing solution rich in zinc ions enters a galvanizing bath from a dezincification bath; the technique is characterized in that: after entering the galvanizing bath from the dezincification bath, the galvanizing solution enters a circulating tank after going through an on-line filtering machine and then enters the galvanizing bath from the circulating tank; the galvanizing solution in the galvanizing bath returns to the galvanizing bath through the circulating tank; and the galvanizing solution is electrolyzed by the current density of 0.1A / dm<2> to 0.3A / dm<2> in an electrobath. The electrobath is internally provided with three anodes and two cathodes at intervals. The technical proposal has the advantages of not only removing hazardous metal impurities, but also increasing dezincification speed, particularly properly raising the PH value, increasing the overpotential of hydrogen, reducing hydrogen evolution, fining electro-galvanizing layers and reducing electric energy consumption, thereby greatly improving product quality.

Owner:长江润发(江苏)薄板镀层有限公司

Electrolytic reduction process of preparing bivalent europium

InactiveCN1453395AImprove electrical efficiencyGood strengthCellsPhotography auxillary processesIon-exchange membranesChemistry

The electrolytic reduction process for preparing bivalent europium includes using net coated with titanium or plated with noble metal as anode, titanium net or porous titanium plate as cathode, RE solution containing europium chloride as cathode solution, hydrochloric acid or hydrochloric acid plus sodium chloride solution as anode solution, and ion exchange film to separate the anode chamber andthe cathode chamber. The electrolytic reduction process is performed under the said conditions to prepare bivalent europium. The present invention has the advantages of reasonable electrolytic system, high reduction current efficiency, etc.

Owner:GRIREM ADVANCED MATERIALS CO LTD

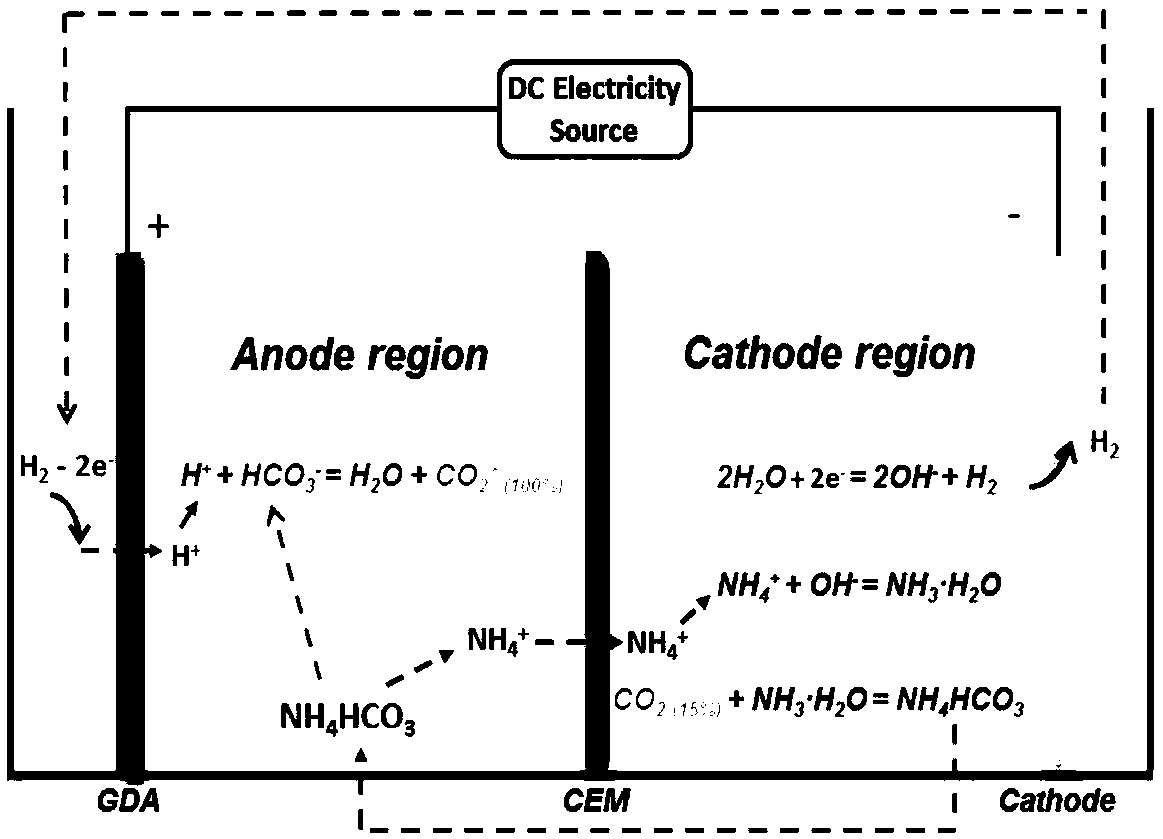

Riboflavin promoting low concentration CO2 electrochemical trapping method

ActiveCN108728860AReduce overpotentialReduce energy consumptionCellsCarbon compoundsHigh concentrationTrapping

The invention provides a riboflavin promoting low concentration CO2 electrochemical trapping method, and belongs to the technical field of CO2 electrochemical trapping. The method comprises the following steps that a cation-exchange membrane is placed in an electrolytic cell; a FMN solution and a potassium acid carbonate solution are added in acathode zone; a FMNH2 solution and a potassium acid carbonate solution are added in an anode zone; direct current is applied between the anode electrode and the cathode electrode; two electrons are obtained in the cathode electrode by the FMN; two protons are received in a KHCO3 solution to form the FMNH2 solution in the reduction state; generated CO32-enters the solution and is used for absorbing low concentration CO2; the FMNH2 releases electrons at the anode electrode and returns to a oxidized state FMN; and the protons leave the FMNH2 to react with KHCO3 in the solution to release high concentration CO2. Low concentration CO2 trapping is achieved; when electric current density is at 10mAcm-2, the average voltage for trapping the CO2 is 0.065V, energy consumption of trapping one ton of the CO2 is about 80KWh, while energy consumption of trapping one ton of the CO2 by an existing chemical absorption method of MES regeneration is 370-510 KWh, so that energy saving is more than 75%.

Owner:SICHUAN UNIV

Catalyst mixtures

ActiveUS9566574B2Raise the overpotentialLow rateWeather/light/corrosion resistanceCell electrodesElectrochemical cellFormic acid

Catalysts that include at least one catalytically active element and one helper catalyst can be used to increase the rate or lower the overpotential of chemical reactions. The helper catalyst can simultaneously act as a director molecule, suppressing undesired reactions and thus increasing selectivity toward the desired reaction. These catalysts can be useful for a variety of chemical reactions including, in particular, the electrochemical conversion of CO2 or formic acid. The catalysts can also suppress H2 evolution, permitting electrochemical cell operation at potentials below RHE. Chemical processes and devices using the catalysts are also disclosed, including processes to produce CO, OH−, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, O2, H2, (COOH)2, or (COO−)2, and a specific device, namely, a CO2 sensor.

Owner:DIOXIDE MATERIALS

Novel Catalyst Mixtures

ActiveUS20130023404A1Low rateLow conversion efficiencyCell electrodesCarbon monoxideCompound (substance)Chemical process

Catalyst mixtures include at least one Catalytically Active Element and, as a separate constituent, one Helper Catalyst. The catalysts can be used to increase the rate, modify the selectivity or lower the overpotential of chemical reactions. These catalysts are useful for a variety of chemical reactions including, in particular, the electrochemical conversion of CO2. Chemical processes employing these catalysts produce CO, OH−, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, O2, H2, (COOH)2, or (COO−)2. Devices using the catalysts include, for example, a CO2 sensor.

Owner:DIOXIDE MATERIALS

Methanol gasoline multi-phase corrosion inhibitor and methanol gasoline prepared from same

ActiveCN106147887AReduce oxidationReduce conductanceOrganic chemistryLiquid carbonaceous fuelsCarcinogenMorpholine

The invention discloses a methanol gasoline multi-phase corrosion inhibitor which is prepared by mixing the following components: a methylnaphthalene biquinoline quaternary ammonium salt, a morpholine derivative, propargyl alcohol and a leveling agent. The invention further discloses methanol gasoline which is prepared from the methanol gasoline multi-phase corrosion inhibitor. The methanol gasoline is prepared from the following components: the methanol gasoline multi-phase corrosion inhibitor, methanol, gasoline, naphtha and butanol. The methanol gasoline multi-phase corrosion inhibitor disclosed by the invention is free of raw material 'which is harmful to vehicle reliability and aftertreatment systems', also free of suspected carcinogens such as nitrite and benzene, relatively good in corrosion inhibition function on metal surfaces, and excellent in electric-chemical corrosion inhibition function on gas-liquid-gas-liquid multi-phase systems; the raw materials can meet national standard requirements and are beneficial to security, environment-friendliness and healthy consumption; the corrosion of methanol gasoline to metals can be remarkably alleviated by using a small amount of the corrosion inhibitor (which accounts for 0.1-0.2% of the total weight of finished product oil).

Owner:福建中源新能源股份有限公司

Secondary battery anode piece and preparation method thereof

InactiveCN102148376AIncrease profitExtended service lifeElectrode manufacturing processesElectrode carriers/collectorsOxygenActive layer

The invention discloses a secondary battery anode piece, comprising a substrate layer and an active layer covering the substrate layer, wherein the active layer contains the following components in parts by weight: 100 parts of spherical nickel, 0.5 to 5 parts of bonding agent and 0.1 to 10 parts of additive which is at least one of LiOH, Li2CO3 and Na3PO4. As the anode piece is added with at least one additive of LiOH, Li2CO3 and Na3PO4, the advantages of raising the utilization rate of active substances, increasing the overpotential of an oxygen evolution reaction, reducing the occurrence of the oxygen evolution reaction and improving charging efficiency are achieved, and thus, the service life of the secondary battery of the anode piece is obviously prolonged and the high-current discharging capacity of the same is obviously improved. The invention further provides a preparation method of the secondary battery anode piece.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

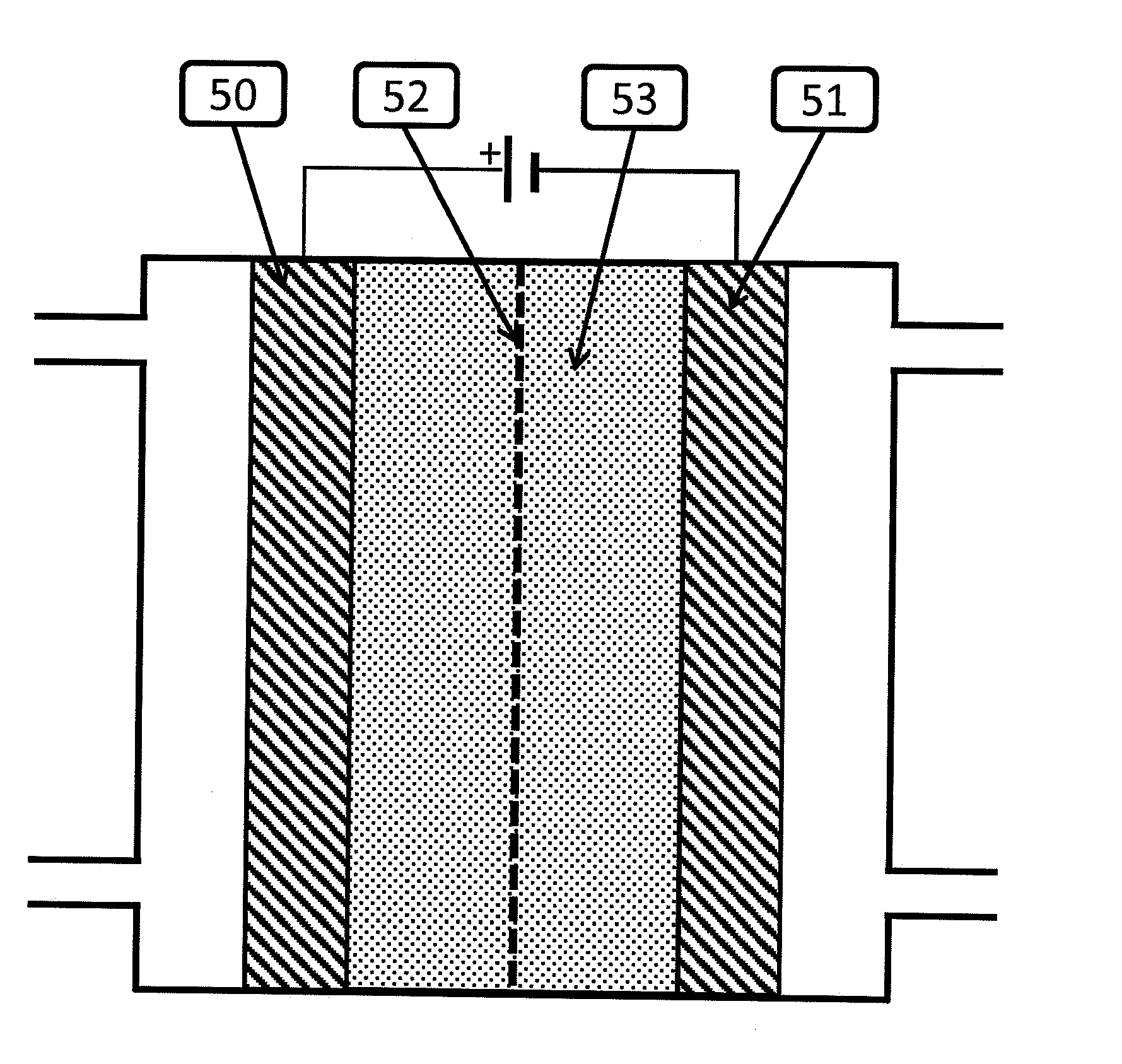

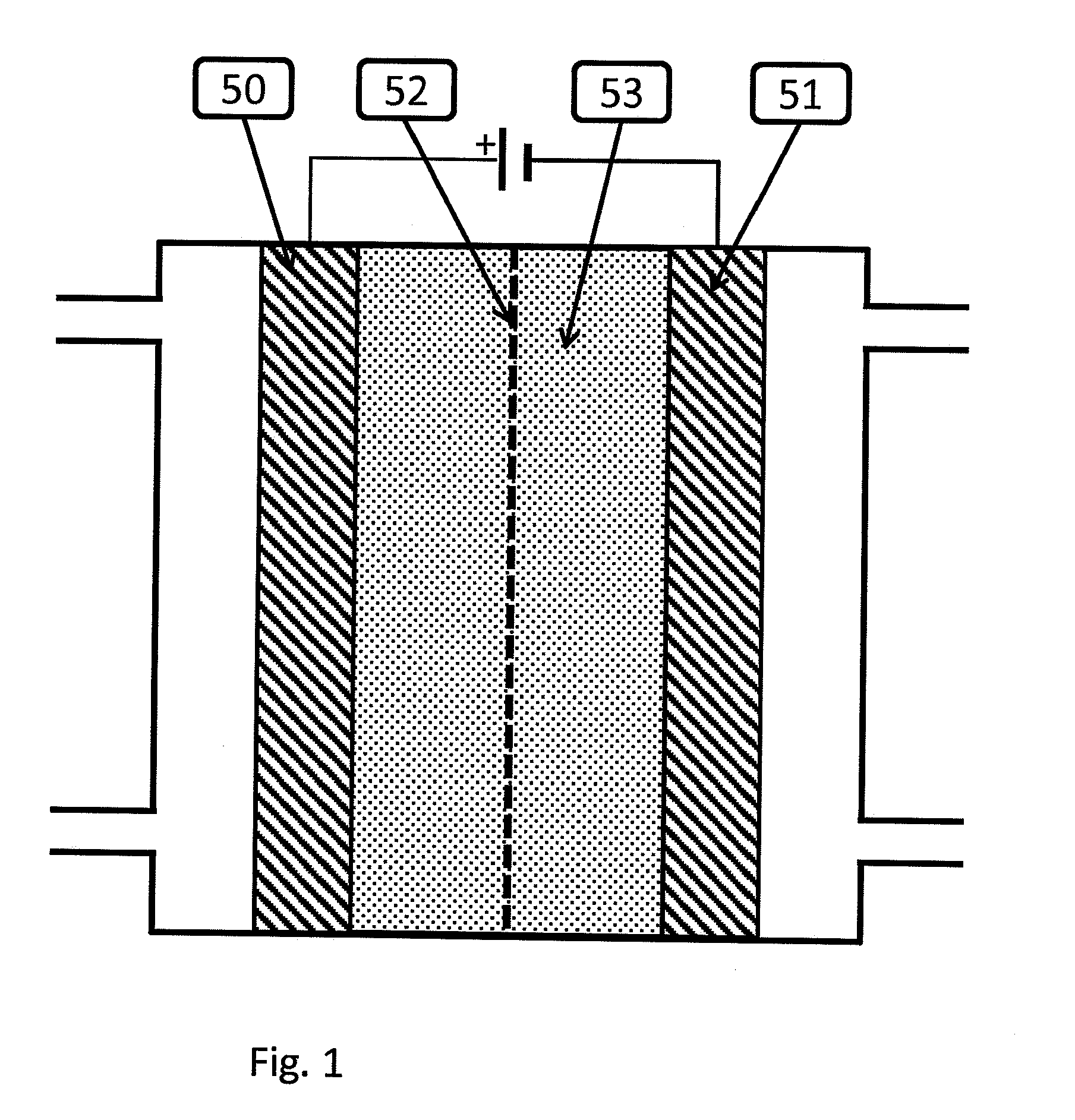

Devices For Electrocatalytic Conversion Of Carbon Dioxide

An electrocatalytic device for carbon dioxide conversion includes a cathode with a Catalytically Active Elementa metal in the form of supported or unsupported particles or flakes with an average size between 0.6 nm and 100 nm. The reaction products comprise at least one of CO, HCO−, H2CO, (HCOO)−, HCOOH, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, and CF3COOH.

Owner:DIOXIDE MATERIALS

Electrocatalytic process for carbon dioxide conversion

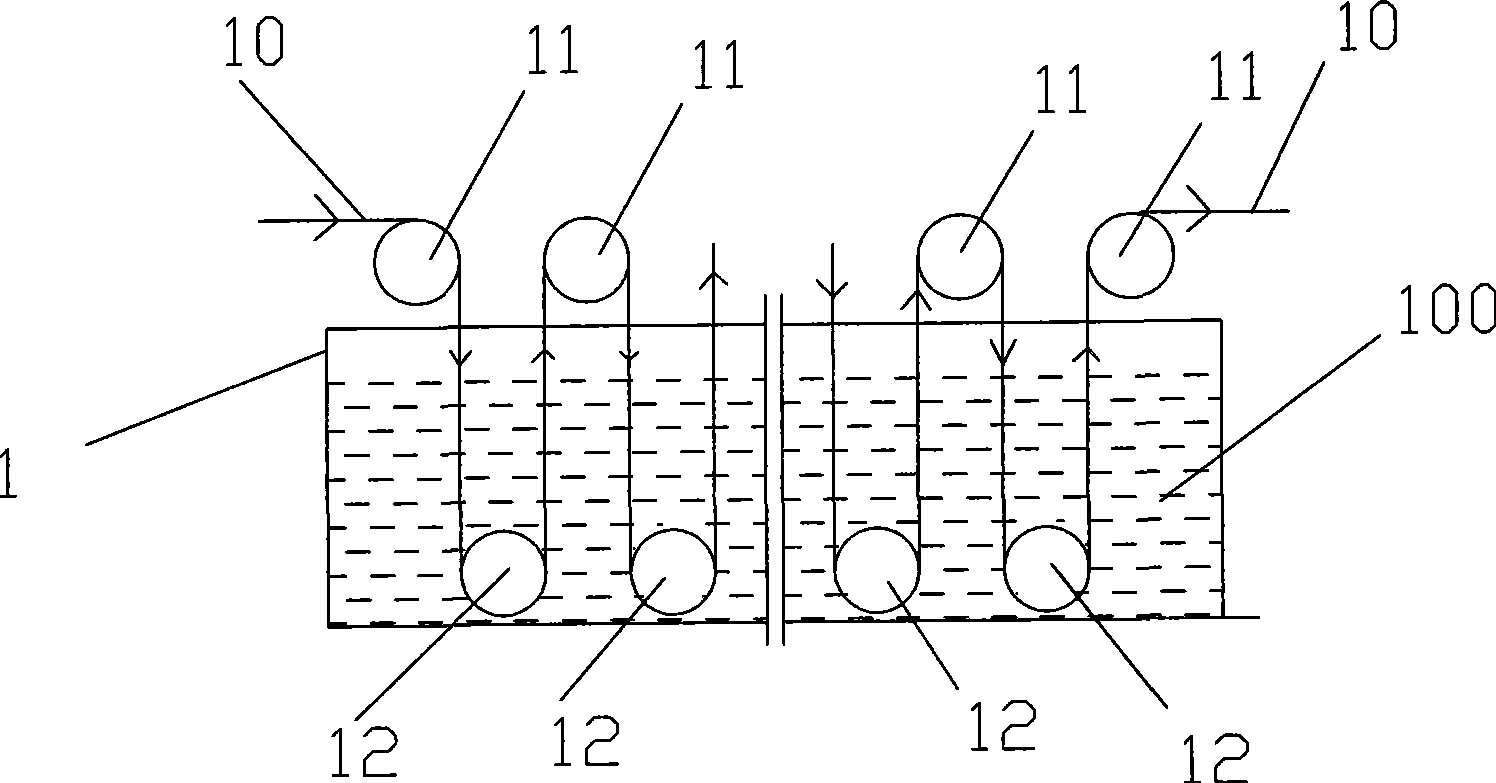

ActiveUS10975480B2Raise the overpotentialLow rateElectrolytic organic productionCarbon monoxideElectrical batteryElectrochemistry

An electrocatalytic device for carbon dioxide conversion includes an electrochemical stack comprising a series of cells with a cathode with a Catalytically Active Element metal in the form of supported or unsupported particles or flakes with an average size between 0.6 nm and 100 nm. The reaction products comprise at least one of CO, HCO−, H2CO, (HCOO)−, HCOOH, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, and CF3COOH.

Owner:DIOXIDE MATERIALS

Magnesium battery

The invention discloses a magnesium battery. With a magnesium alloy as a negative material, on the basis of the total weight of the magnesium alloy, the magnesium alloy contains the following components in percentage: 0.01%-0.3% of Er, 0.05%-0.5% of Sn, 0.01%-0.03% of Y, 0.01%-0.1% of Ce, 0.1%-0.5% of Nd and 0.02%-0.2% of In. Alloy elements of destroying the structure of a magnesium oxide film are added to a magnesium electrode, so that falling of a corrosion product can be effectively promoted; the self-corrosion speed is lowered; and the utilization rate of a magnesium negative electrode is greatly improved.

Owner:黄静 +2

Inhibitor for controlling electric dipole corrosion

An inhibitor which can control the corrosion of the galvanic couple is made up of the aliphatic polyoxyethylene ether 1-70%; the propiolic alcohol 0.01-30%; the water 0-70%; diaminoethane 0-30%; the ethanol 0-70%. It has the good effect of controlling the corrosion of the galvanic couple.

Owner:YANGTZE UNIVERSITY

Electrocatalytic Process for Carbon Dioxide Conversion

ActiveUS20190211463A1Low rateLow conversion efficiencyCellsHydrocarbon from carbon oxidesAverage sizeMetal

An electrocatalytic device for carbon dioxide conversion includes an electrochemical stack comprising a series of cells with a cathode with a Catalytically Active Element metal in the form of supported or unsupported particles or flakes with an average size between 0.6 nm and 100 nm. The reaction products comprise at least one of CO, HCO−, H2CO, (HCOO)−, HCOOH, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, and CF3COOH.

Owner:DIOXIDE MATERIALS

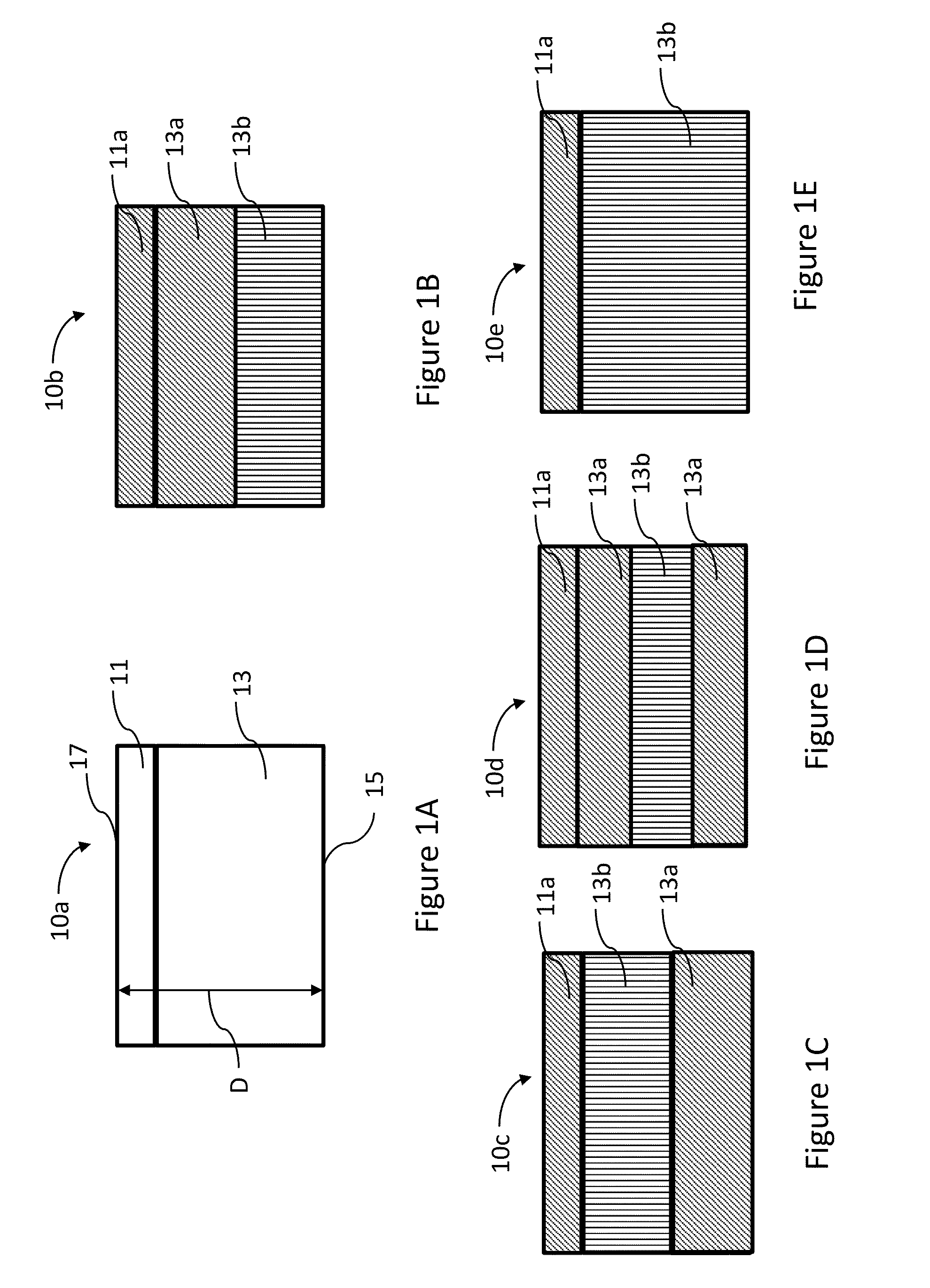

Non-uniform doping of photoelectrochemical cell electrodes

ActiveUS20160194768A1High photoactivityHigh catalytic activityCellsLight-sensitive devicesDopantPhotoelectrochemical cell

The present invention provides a photo-electrochemical (PEC) cell electrode having a surface portion and a bulk portion composed of the same material, wherein at least one of the bulk portion and the surface portion of the electrode is doped with at least one dopant, and wherein said doping is non-uniform along an axis perpendicular to the surface portion. The non-uniform doping can include different concentrations and / or types of the dopants in the bulk portion and in the surface portion of the electrode. There is further provided a PEC cell comprising said electrode and an electrolyte, wherein the surface portion of the electrode faces the electrolyte.

Owner:TECHNION RES & DEV FOUND LTD

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

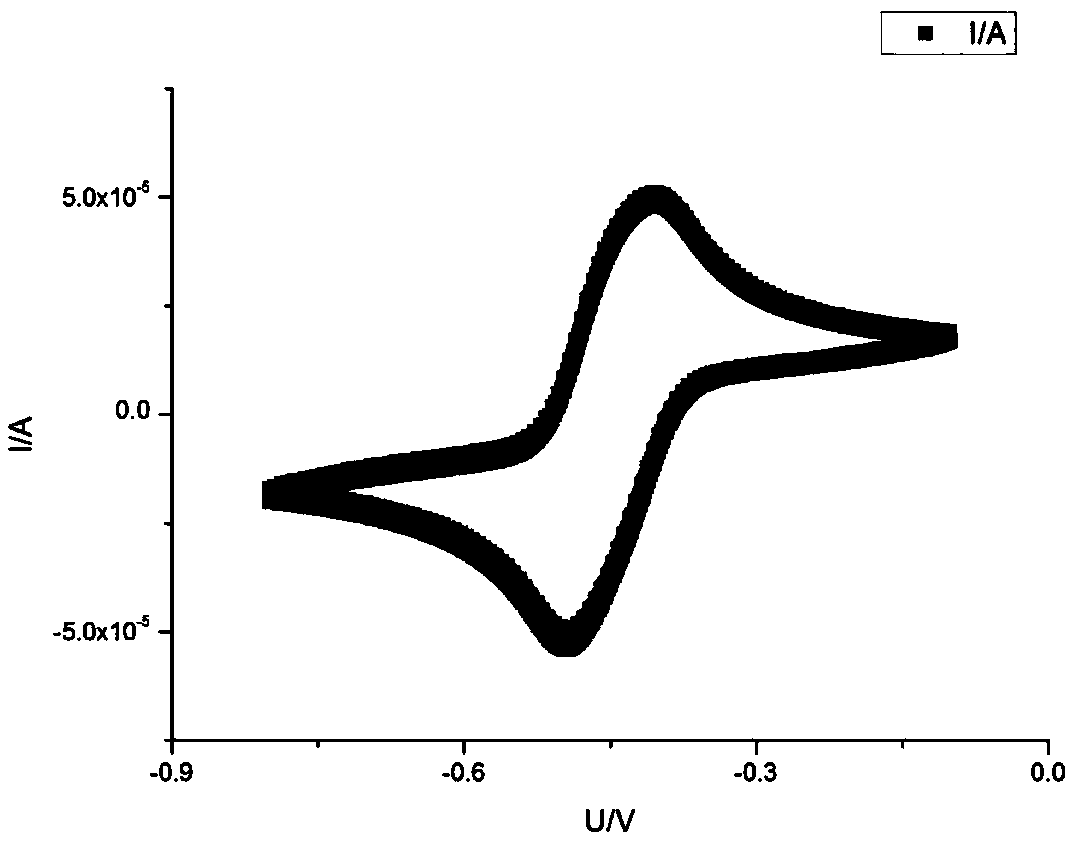

Additives for recycling copper

ActiveCN107747109ARaise the overpotentialPromote polarizationElectrolysis componentsPhotography auxillary processesDuctilityCrystallite

The invention provides additives for recycling copper, and relates to the technical field of material preparation. The additives comprise 10-50 ppm of a brightener, 10-30 ppm of a leveling agent and 5-20 ppm of a surface active agent. By adding the additives including the brightener, the leveling agent and the surface active agent in etching liquid, the overpotential is improved, polarization is increased, the electrode reaction speed is reduced, and a fine-grain and bright copper clad layer is finally obtained. Therefore, a copper layer with a bright and flat surface, high purity, a compact structure and ductility is obtained through recycling.

Owner:SHENZHEN JECH TECH +1

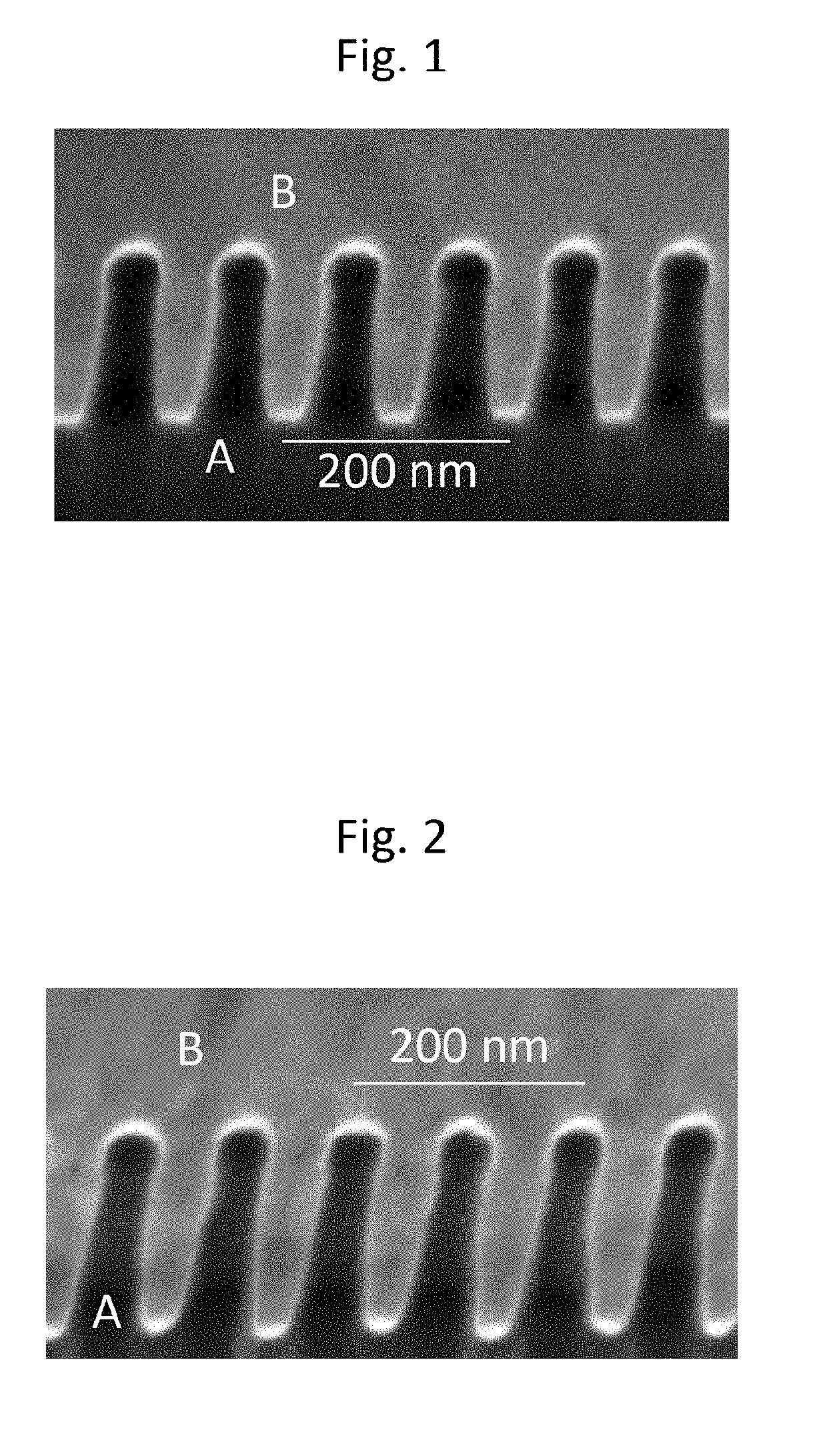

Acidic aqueous composition for electrolytic copper plating

ActiveUS20190203369A1Improve plating qualityRaise the overpotentialOrganic chemistrySemiconductor devicesElectrolysisCopper plating

The present invention relates to an acidic aqueous composition (plating bath) for electrolytic copper plating (electrolytic deposition of copper), the composition comprising(i) copper (II) ions,(ii) one or more than one compound of Formula (Ia)(iii) one, two, three or more than three further compounds, which are different from the compound of Formula (Ia),with the definitions given below, the use of the acidic aqueous composition according to the invention for electrolytic copper plating, the use of the compound of Formula (Ia) in an acidic aqueous composition for electrolytic metal plating, a method of electrolytic copper plating using the acidic aqueous composition according to the invention, and specific compounds derived from Formula (Ia) for an acidic aqueous composition for electrolytic metal plating.

Owner:ATOTECH DEUT GMBH

Electrocatalytic Process For Carbon Dioxide Conversion

ActiveUS20170259206A1Low rateConversion efficiency is lowProductsGas treatmentChemistryCarbon dioxide

An electrocatalytic process for carbon dioxide conversion includes combining a Catalytically Active Element and a Helper Polymer in the presence of carbon dioxide, allowing a reaction to proceed to produce a reaction product, and applying electrical energy to said reaction to achieve electrochemical conversion of said carbon dioxide reactant to said reaction product. The Catalytically Active Element can be a metal in the form of supported or unsupported particles or flakes with an average size between 0.6 nm and 100 nm. The reaction products comprise at least one of CO, HCO−, H2CO, (HCO2)−, H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, and CF3COOH.

Owner:DIOXIDE MATERIALS

Production method of anti-dezincification and unleaded lead-cast brass ingot

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

Lead crystal accumulator

InactiveCN101369673AExtend your lifeExtended service lifeLead-acid accumulatorsCell electrodesHigh rateAlloy

The invention discloses an accumulator, specifically a lead accumulator. An electrode plate in the invention is implemented by taking lead as substrate, lead, stibium, arsenic, copper, sulphur alloys as plate materials with electrolyte replacing fluoro-sulphuric acid solution with silicate. Advantages of the invention lie in that the lead accumulator has long service life, great high-rate charging and discharging performance, rapid charge, great deep discharging performance, great low temperature resistance performance and environment protection features. Products of the invention can be widely applicable for various bicycle dynamos, automobiles and so on.

Owner:HANGZHOU QILINPU ELECTRIC AUTOMOBILE PROD

Preparation method of high-hardness Cu-SiC nanometer compound plating layer and special device thereof

InactiveCN101717977BHigh content of nanoparticlesEvenly distributedElectrolytic coatingsNanoparticleCrystal structure

Owner:HUAIHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com