Production method of anti-dezincification and unleaded lead-cast brass ingot

A production method and anti-dezincification technology, which is applied in the field of copper alloys for the bathroom and kitchen industry, can solve the problems of weakening the anti-dezincification corrosion performance of duplex brass, so as to improve the anti-dezincification corrosion performance, increase the absorption rate of elements, and prevent The effect of oxidation burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

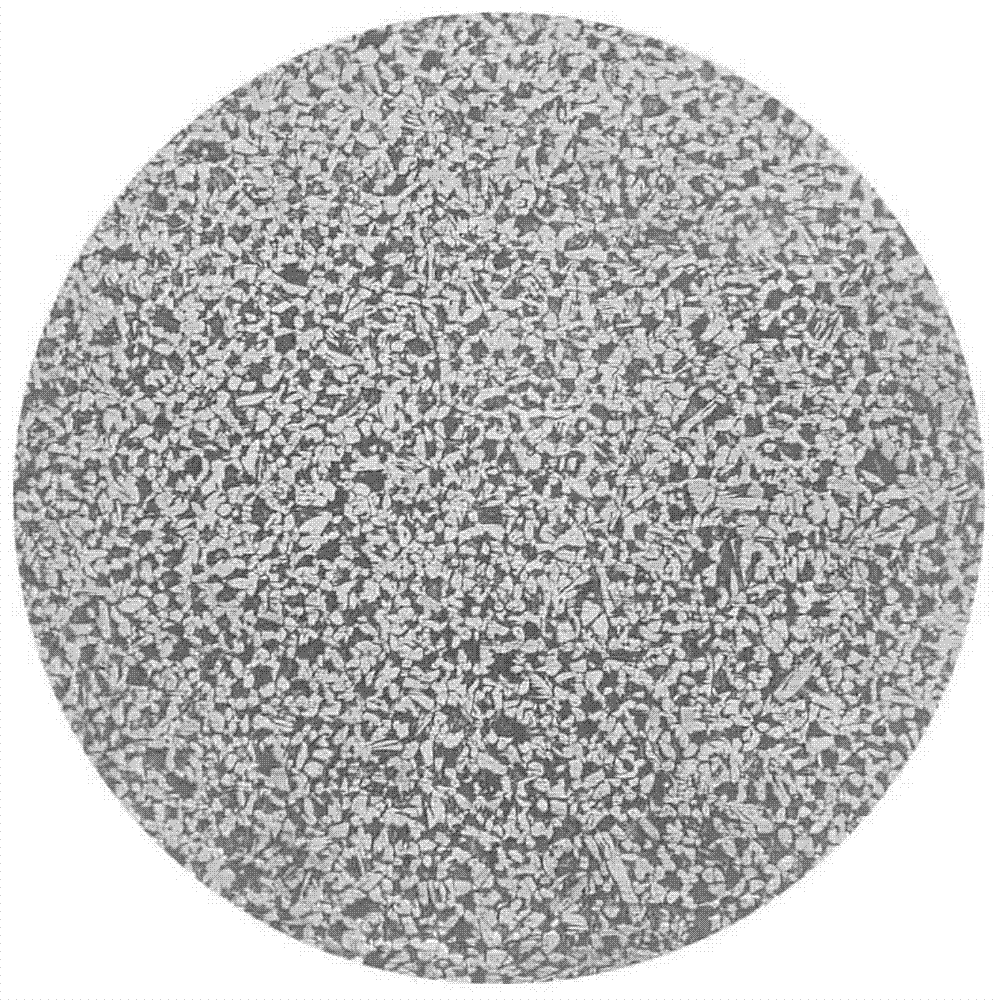

Image

Examples

Embodiment 1

[0023] An anti-dezincification lead-free lead-cast brass ingot consists of the following raw materials in mass percentage: Cu61%, Bi0.5%, As0.07%, Al0.5%, Sn0.08%, Pb0.06%, Zn37.75% and total 0.04% impurities.

[0024] The production method of the above-mentioned anti-dezincification lead-free casting brass ingot includes the step of casting the above-mentioned brass liquid in the mass percentage into a brass ingot, and the step of casting the brass ingot includes:

[0025] 1) First add 150kg of pure copper rice into the cored power frequency furnace. The total amount of pure copper rice in the power frequency furnace is 7.5% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.08% tin ingot, 0.5% bismuth ingot and 0.5% aluminum ingot accounted for the total raw material, fully stirred and allowed to stand for 10 minutes;

[0026] 2) Add the red copper plate required for the batching of the furnace. The red copper plate is standard cath...

Embodiment 2

[0038] An anti-dezincification lead-free lead-cast brass ingot is composed of the following raw materials in mass percentage: Cu62%, Bi0.7%, As0.1%, Al0.7%, Sn0.15%, Pb0.09%, Zn36.12% and a total of 0.14% impurities.

[0039] The production method of the above-mentioned anti-dezincification lead-free casting brass ingot includes the step of casting the above-mentioned brass liquid in the mass percentage into a brass ingot, and the step of casting the brass ingot includes:

[0040] 1) First add 200kg of pure red copper rice into the cored power frequency furnace. The total amount of pure red copper rice in the power frequency furnace is 10% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.15% tin ingot, 0.7% bismuth ingot and 0.7% aluminum ingot accounted for the total raw material, fully stirred and allowed to stand for 10 minutes;

[0041] 2) Add the red copper plate required for the furnace ingredients. The red copper plate is sta...

Embodiment 3

[0050] An anti-dezincification lead-free lead-cast brass ingot consists of the following raw materials in mass percentage: Cu63%, Bi0.9%, As0.12%, Al0.8%, Sn0.24%, Pb0.02%, Zn34.84% and a total of 0.08% impurities.

[0051] The production method of the above-mentioned anti-dezincification lead-free casting brass ingot includes the step of casting the above-mentioned brass liquid in the mass percentage into a brass ingot, and the step of casting the brass ingot includes:

[0052] 1) First add 300kg of pure copper rice into the cored power frequency furnace. The total amount of pure copper rice in the power frequency furnace is 15% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.24% tin ingot, 0.9% bismuth ingot and 0.8% aluminum ingot accounted for the total raw material, fully stirred and allowed to stand for 10 minutes;

[0053] 2) Add the red copper plate required for the batching of the furnace. The red copper plate is standard ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com