Method for reducing nitrogen oxides in flue gas of medium and small sized industrial coal burning boiler through combination with wet-method sulfur removing technology

A technology for coal-fired boilers and flue gas, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low solubility and difficult removal of nitrogen oxides, and achieve high removal efficiency and equipment renovation investment. Small, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described below through specific examples, but the present invention is not limited thereto.

[0062] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

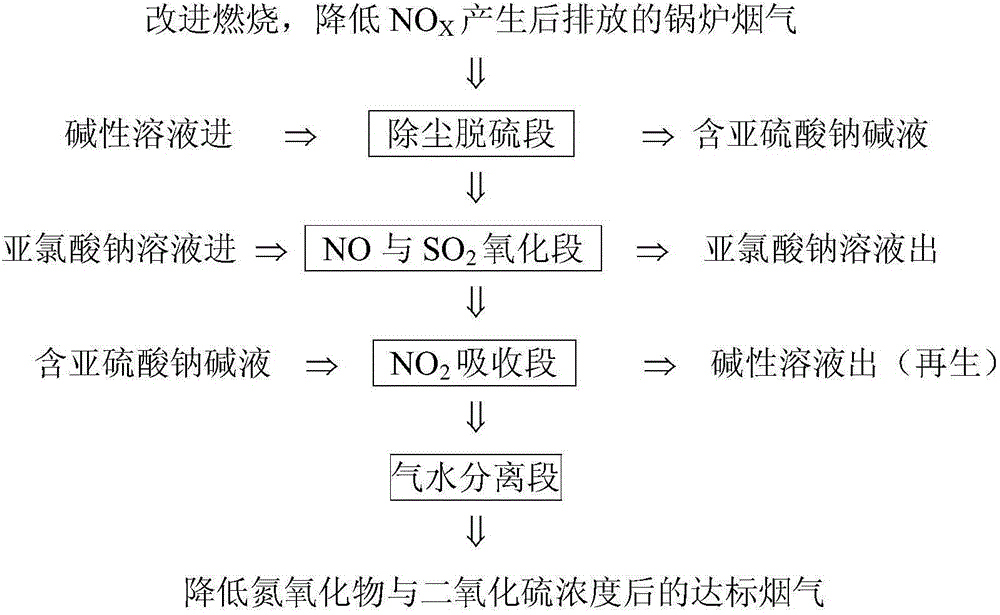

[0063] The technical solution of the present invention is to provide a method for removing nitrogen oxides from flue gas of a coal-fired boiler by using an oxidation method combined with a double-alkali desulfurization technology.

[0064] First, low nitrogen oxides (NOx) were achieved by controlling the oxygen content in the coal-fired boiler furnace. X ) combustion to reduce NO X The total amount is generated, and then the generated flue gas is introduced into the series tower purification system, and after dust removal and primary desulfurization pretreatment, the NO in the flue gas is oxidized to NO und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com