Blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enriching air blasting

A technology of vanadium-titanium magnetite and oxygen-enriched blast, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as difficulty in strengthening smelting, poor air permeability, and sticky slag, so as to improve high-temperature droplet performance and reduce hazards , the effect of increasing smelting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

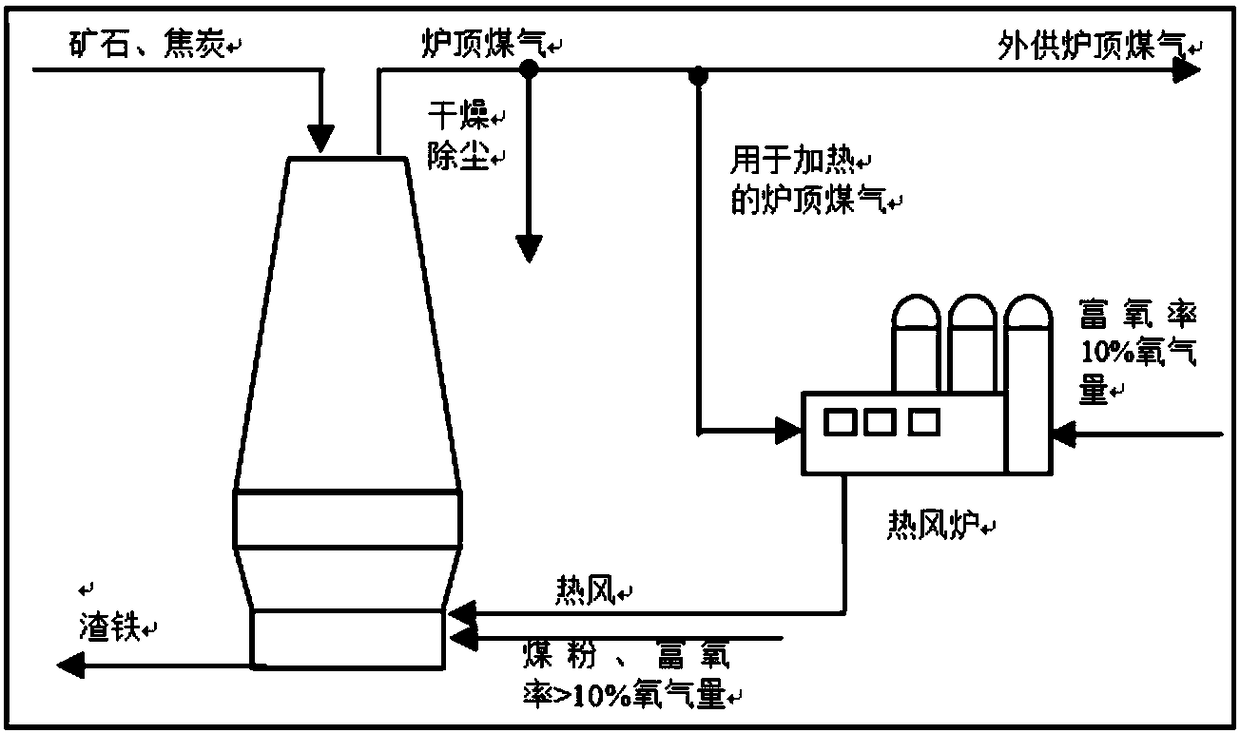

[0030] The blast oxygen enrichment rate is 5%: at a certain 2000m 3 80% vanadium-titanium sinter, 15% vanadium-titanium pellets and 10% lump ore are used as raw materials for the blast furnace; coke and ore are fed into the blast furnace by the blast furnace roof distribution equipment; After being heated by the heating furnace, it is blown into the blast furnace; the pulverized coal is blown into the blast furnace through the coal gun through the direct blowing pipe; The remaining part is externally supplied for power generation; the process is as follows figure 1 As shown, its production technical indicators are as follows:

[0031] Oxygen consumption: 51m 3 / tHM;

[0032] Coke ratio: 390kg / tHM;

[0033] Coal ratio: 137kg / tHM;

[0034] Blast humidity: 3.5%;

[0035] Air volume: 1024.1 m 3 / tHM;

[0036] Composition of bosh gas: CO: 40.5%, H 2 : 6.3%, N 2 : 53.2%;

[0037] Bosh gas volume: 1378.7 m 3 / tHM;

[0038] Bosh gas volume index: 62.7;

[0039] Theoretical...

Embodiment 2

[0044] The blowing oxygen enrichment rate is 10%: the implementation steps are the same as the implementation column 1, and its production technical indicators are as follows:

[0045] Oxygen consumption: 88m 3 / tHM;

[0046] Coke ratio: 360kg / tHM;

[0047] Coal ratio: 169kg / tHM;

[0048] Blast humidity: 4.8%;

[0049] Air volume: 880.1 m 3 / tHM;

[0050] Composition of bosh gas: CO: 45.5%, H 2 : 8.4%, N 2 : 46.1%;

[0051] Bosh gas volume: 1258.51 m 3 / tHM;

[0052] Bosh gas volume index: 63.17;

[0053] Theoretical combustion temperature: 2218°C;

[0054] Top gas composition (dry): CO: 26.8%, H 2 : 4.6%, CO 2 : 26.3%, N 2 : 42.2%;

[0055] Furnace top gas volume: 1376.5m 3 / tHM;

[0056] Utilization factor: 2.56t / ( m 3 · d), the utilization factor increased by 30%.

Embodiment 3

[0058] The blast oxygen enrichment rate is 15%: at a certain 1000m 3 80% vanadium-titanium sintered ore, 15% vanadium-titanium pellets and 10% lump ore are used as raw materials for the blast furnace. Coke and ore are fed into the blast furnace by the blast furnace roof distribution equipment; the oxygen enrichment rate is 10%. The cold air pipe in front of the blower is directly mixed into the blast furnace after being heated by the heating furnace, and the remaining 5% oxygen enrichment rate is blown into the blast furnace through the oxygen coal gun equipment; the injection coal powder is injected into the blast furnace through the direct blowing pipe of the oxygen coal gun; The slag and iron are discharged from the blast furnace through the iron gate; part of the furnace top gas is used for combustion and heating in the hot blast stove after drying and dust removal, and the remaining part is used for external power generation; the process is as follows figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com