Method for reducing sintered solid fuel consumption

A technology of solid fuel and fuel consumption, applied in the field of sintering process in the metallurgical industry, can solve the problems of high control difficulty and cost, poor fuel consumption reduction effect, and reduced quality of sintered ore, so as to improve the quality of sintered ore, low cost, fuel The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

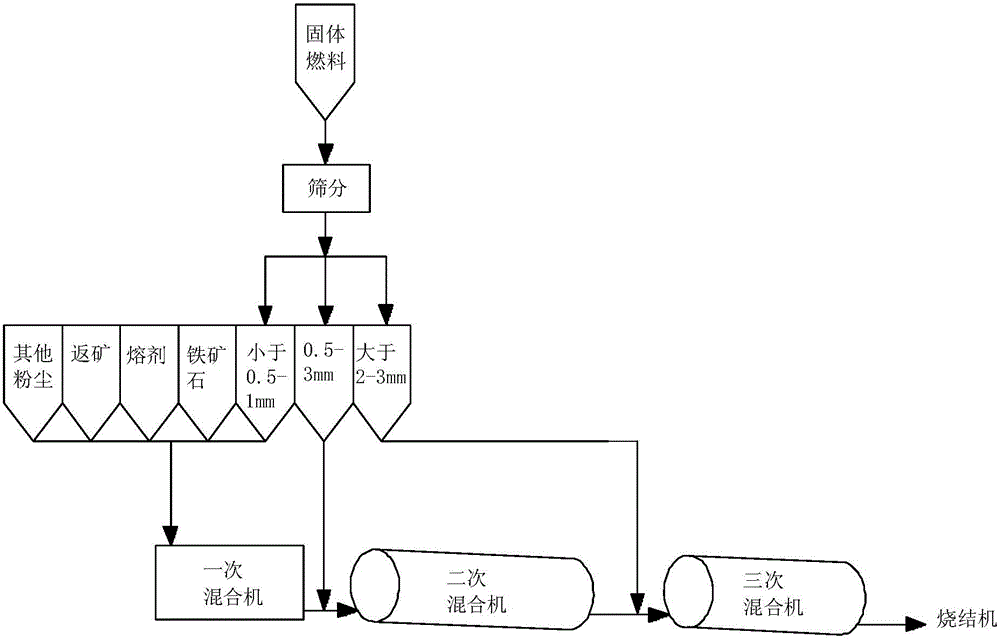

[0043] Embodiment 1 and embodiment 3 adopt the method of this three times mixing. Embodiment 1 is to sieve into three particle fractions greater than 2mm, 0.5-2mm, and less than 0.5mm. Embodiment 3 is sieved into three particle fractions greater than 3mm, 0.5-3mm and less than 0.5mm.

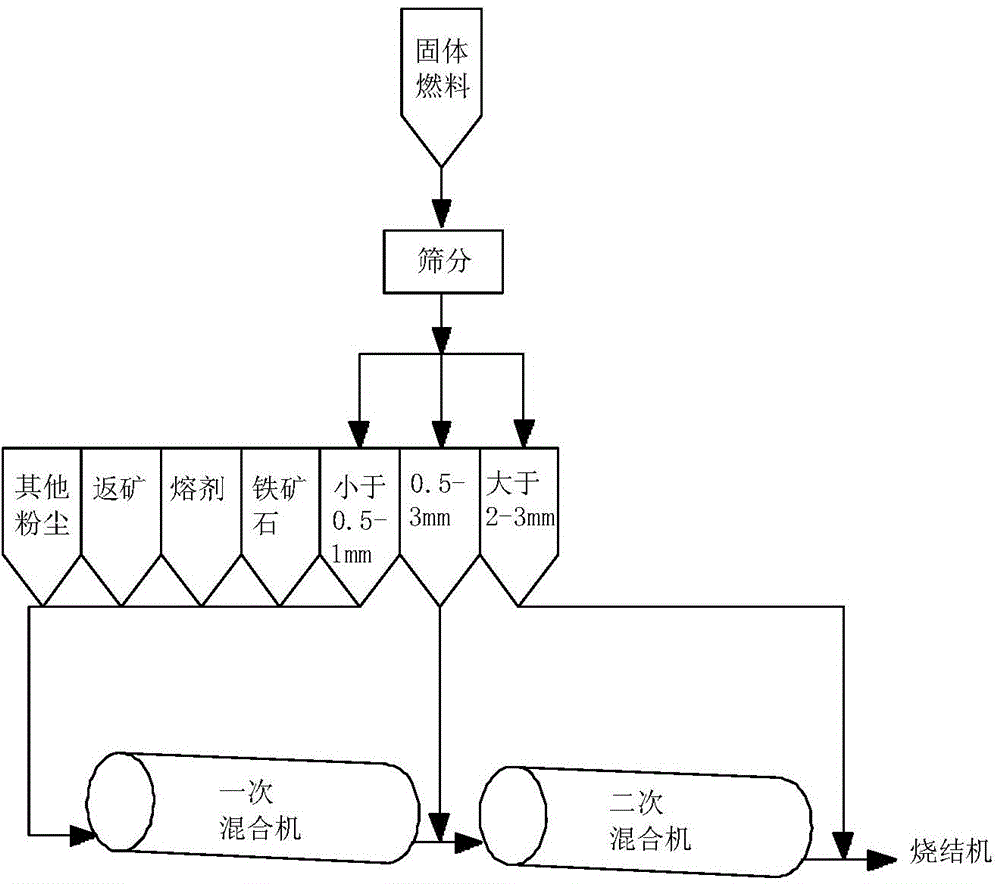

[0044] see figure 2 , another technical scheme of the method for reducing the fuel consumption of sintered solids in the present invention, which comprises the following steps:

[0045] 1) Sieve the solid fuel for sintering into three grades larger than 2.0-3.0mm, 0.5-3.0mm and smaller than 0.5-1.0mm with 2-3mm and 0.5-1.0mm sieves, and put them into three fuel silos respectively ;

[0046] 2) Batching solid fuel with particle size of less than 0.5-1.0mm and sintering raw materials such as iron ore, flux, return ore and other dust, and adding them to a primary mixer for mixing;

[0047] 3) Transport the mixture mixed by the primary mixer and the solid fuel of 0.5-3.0mm particle size to the ...

Embodiment 2

[0049] Embodiment 2 and 4 adopt figure 2 secondary mixing method. Example 2 is sieved into fractions greater than 2mm, 1-2mm and less than 1mm. Example 4 is sieved into fractions greater than 3mm, 1-3mm and less than 1mm.

[0050] The control example adopts three-stage mixing, but without particle size sieving.

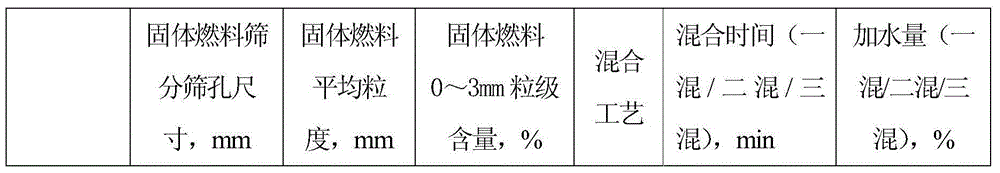

[0051] The parameter setting of embodiment is as shown in table 1:

[0052] Table 1 embodiment parameter setting

[0053]

[0054]

[0055] Table 2 Implementation Results

[0056]

[0057] See Table 2 according to the implementation results of the embodiment parameters listed in Table 1. Using the scheme of Example 1, compared with the control example, the yield is increased by 2.37%, the utilization factor is increased by 11.94%, the drum index is increased by 1.5%, and the solid fuel consumption is reduced by 5.48%. Adopting the scheme of Example 4, compared with the comparative example, the utilization coefficient is increased by 4.48%, the yield an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com