Low NOx liquid state slag-off double-eddy flow coal-powder combustor

A technology of pulverized coal burner and liquid slag discharge, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of insufficient pulverized coal combustion, affecting the service life of the burners, etc., and reduce smoke and dust emissions. Quantity, extended service life, and the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the 10-ton chain grate steam boiler burner as an example, such as figure 1 , 2 , 3 is a structural schematic diagram of a water-cooled low NOx liquid slagging double swirl pulverized coal burner. The water-cooled low NOx liquid slagging double swirl pulverized coal burner is composed of Device 5 and combustion chamber 30 form:

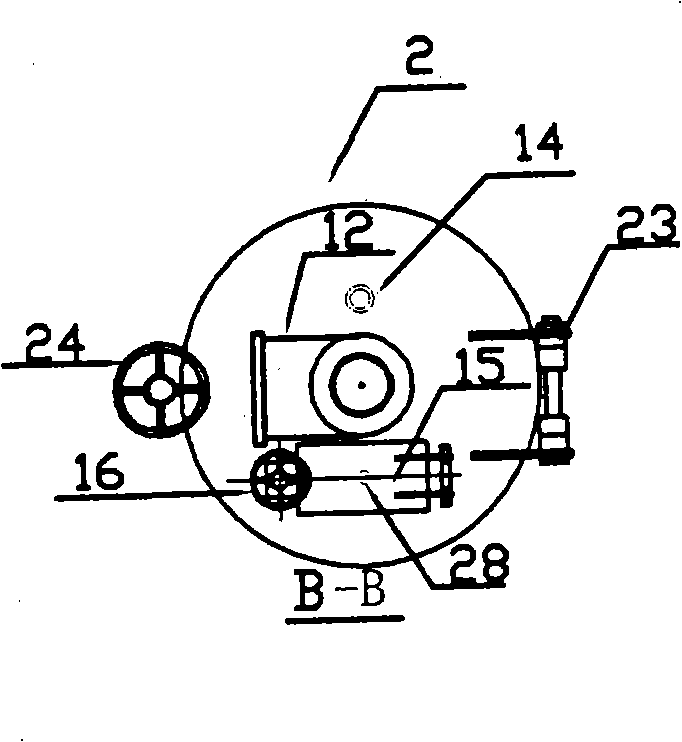

[0030] The adjustable combustion device 5 is composed of a rear end cover 2, a cone 6, an adjustment screw outer casing 7, a nozzle adjustment screw 8, a diffuser 9, a primary air axial flow generator 10, a cone adjustment control panel 11, and a fuel pipe. 12. Ignition device 13, igniter 14, fire viewing door 15, fire viewing door locking control panel 16, rear end cover hinge 23 and rear end cover locking control panel 24, primary air / coal powder injection pipe 25 and flame detection The sensor 28 constitutes.

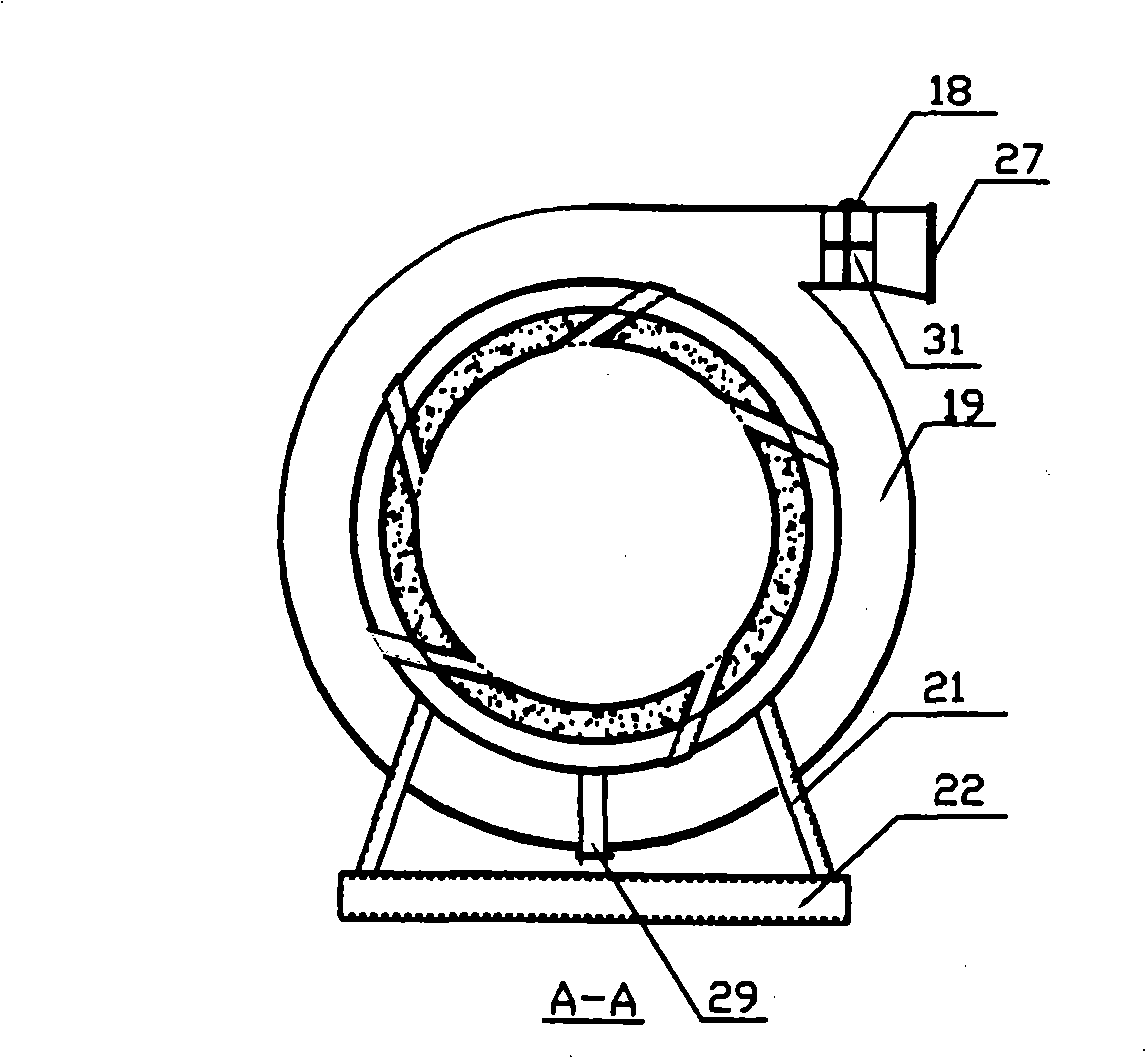

[0031] The combustion chamber 30 is a cylindrical combustion chamber, which consists of a cooling water channel 1, a secondar...

Embodiment 2

[0037] Take the 10-ton chain grate steam boiler burner as an example, such as Figure 5 , 6 As shown, it is a structural schematic diagram of an air-cooled low NOx liquid slagging double swirl pulverized coal burner. The air-cooled low NOx liquid slagging double swirl pulverized coal burner consists of an adjustable injection Composition of device 5 and combustion chamber 30: the adjustable combustion device 5 is the same as that of embodiment 1, the only difference of combustion chamber 30 is that secondary air heat exchange fins are provided between combustion chamber housing 20 and secondary air chamber 19 33. Other parts are the same as in Example 1.

[0038] The second example of the present invention: reform the boiler, install the air-cooled low NOx liquid slagging double-swirl pulverized coal burner, the reformed boiler is the SZL10-1.25-AII chain grate boiler produced by Jiangsu Nantong Boiler Factory, and the boiler is 05 years old Factory put into operation, boile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com