Biomass cyclone dust removal burner

A cyclone dust removal and burner technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve the problems of large combustion smoke and dust, complex structure, and insufficient combustion, and achieve improved combustion rate, improved dust removal performance, and furnace Effect of Fire Purity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

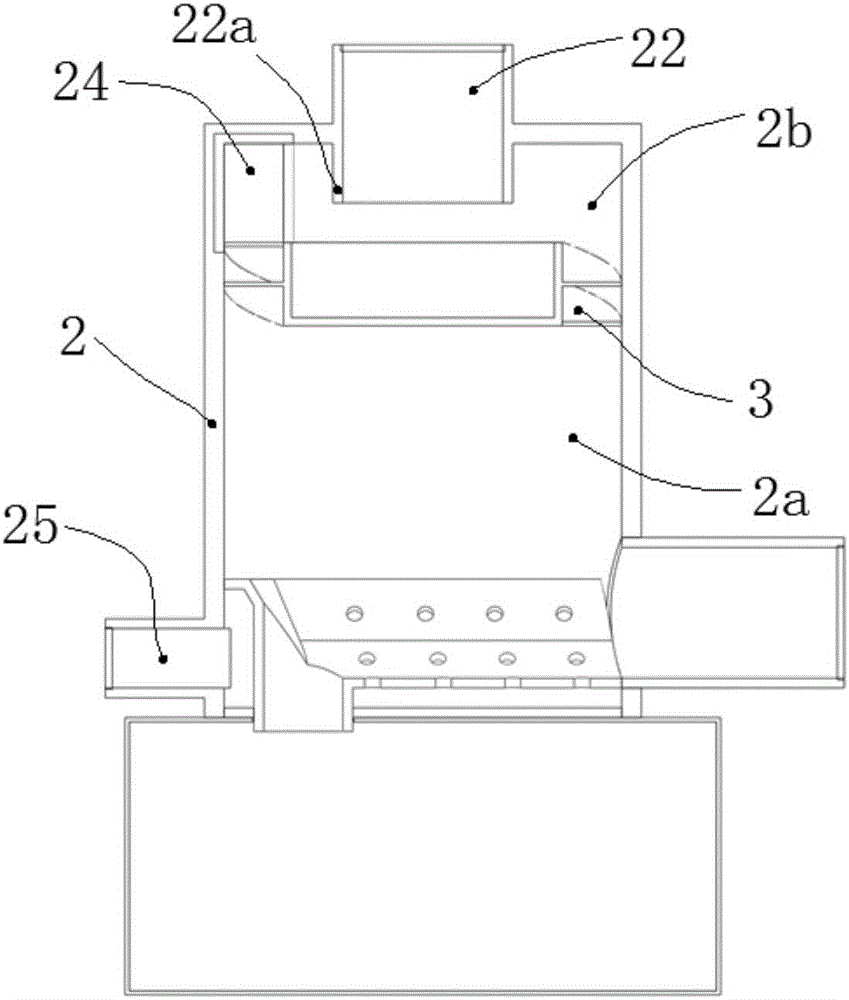

[0038] Image 6 It is the simulation effect diagram of the overflow interception of 30 micron dust particles in the present invention, Figure 7It is the simulation effect diagram of the overflow of 30 micron dust particles after the general burner is burned in the prior art. The above two simulation effect diagrams use professional three-dimensional simulation software. It can be compared from the diagrams that the dust retention effect of the present invention is very obvious.

[0039] In the same way, Figure 8 It is the simulation effect diagram of the overflow interception of 50 micron dust particles in the present invention, Figure 9 It is the simulation effect diagram of the overflow of 50 micron dust particles after the general burner is burned in the prior art. It can be compared from the figure that the present invention has a 100% interception effect on 50 micron dust particles.

[0040] Figure 10 It is the actual combustion diagram of biomass material wood in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com