Raman spectrum quantitative determination method applicable to carbon sources in blast furnace gas dust

A quantitative detection method, blast furnace gas ash technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of heavy workload, laborious, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

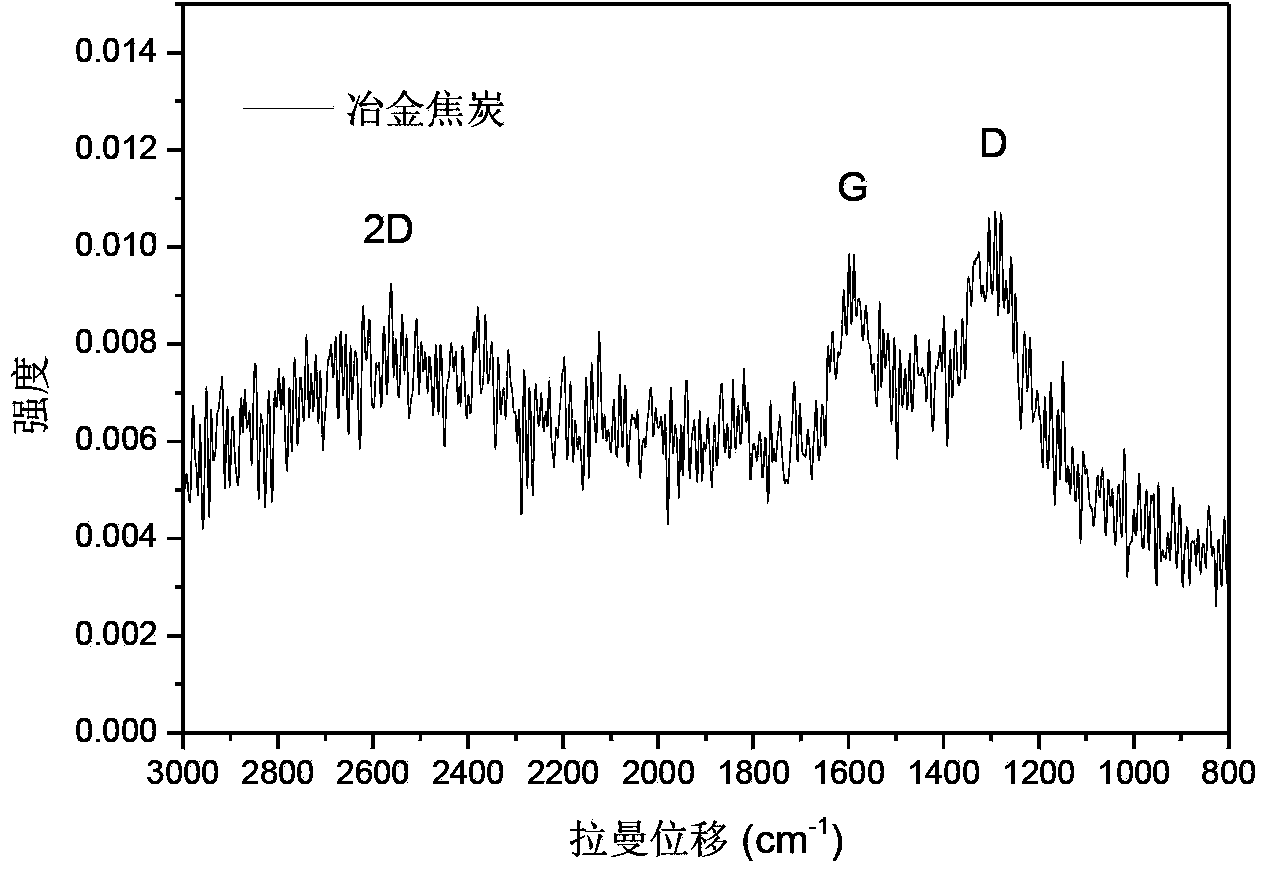

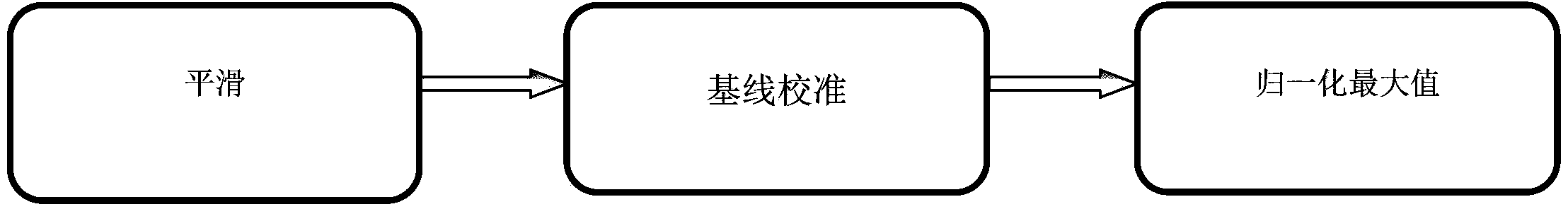

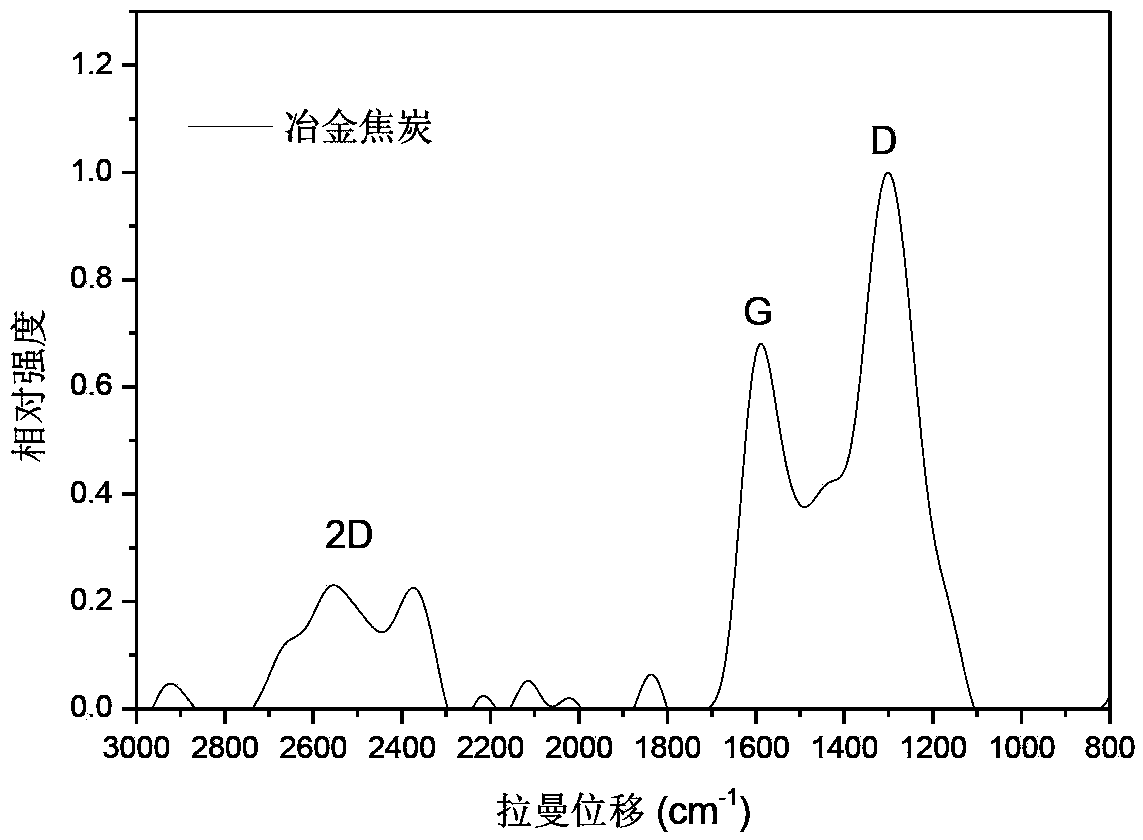

Embodiment 1

[0037] 1) Grind the collected coal samples and coke samples to a particle size range of 150-202um, dry the ground coal powder samples and spread them on a corundum porcelain boat, place them in a tube furnace, and pass them into Nitrogen forms an inert atmosphere, and then starts the heating process to produce coal char and coke that have been heat-treated at different high temperatures. This is to better reflect the difference in carbon structure of samples under different conditions in the Fourier transform Raman spectrum. Due to the different heat treatment temperatures, different durations have no difference in the final sample spectra. That is, the heat treatment lasting for 30 minutes has completely affected the carbon structure of the carbonaceous material, and a longer heating time has no effect on the carbon structure. The heat treatment process of this technology is to raise the temperature in the heating furnace to a temperature range of 800-2000 ° C at a certain h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com