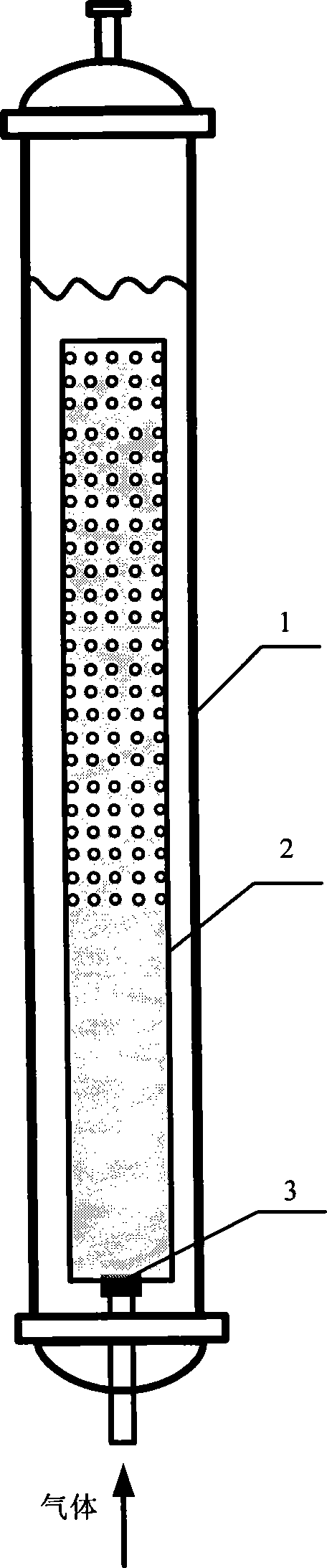

Air-lift type circular current reactor

A loop reactor and airlift technology, applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting liquids and gaseous media, can solve the problem of reducing the gas-liquid contact area and increasing the volume of the reactor , Reactor utilization efficiency decline and other issues, to achieve the effect of improving efficiency and strengthening gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

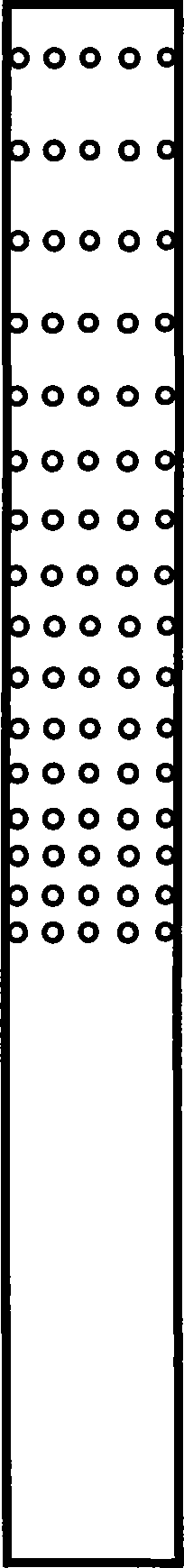

[0034] Example 1 This example is about the hydrodynamic conditions in a 180L loop reactor. The height of the reactor tower is 3000mm, and the inner diameter is 270mm. The height of the guide tube is 2200mm, the inner diameter is 210mm, and the distance from the lower edge of the guide tube to the bottom of the reactor is 100mm. The opening section of the diversion cylinder is cylindrical, with a height of 1300mm, and 1120 circular holes with a diameter of 5mm are evenly opened, and the total area of the holes is 61% of the cross-sectional area of the diversion cylinder. After the reactor is filled with water containing 0.5% ethanol, the overall gas holdup of the reactor under different superficial gas velocities (compared with the reactor with the same structure but without openings in the draft tube) is shown in Table 1. The distribution of the rate along the axial direction (at the gas velocity u G =1.44cm·s -1 ) is shown in Figure 6 (compared with a reactor with the ...

Embodiment 2

[0037] Example 2 This example is the effect of the opening area on the hydrodynamic conditions in the reactor in a 180L loop reactor. The structural parameters and experimental system of the reactor are the same as in Example 1. The ratio of the total opening area to the cross-sectional area of the guide cylinder (S p / S t ) is 61%, 32%, 16% (uniform distribution), superficial gas velocity u G =1.44cm·s -1 , the overall gas holdup of the reactor is shown in Table 2, and the distribution of the annulus gas holdup along the axial direction is shown in Table 2. Figure 7 , see S p / S t <0.3, the distribution effect of gas holdup becomes significantly worse.

[0038] The overall gas holdup of the reactor when the opening area is different in table 2

[0039] S p / S t / %

Embodiment 3

[0040] Example 3 This example is about the effect of the height of the opening section on the hydrodynamic conditions in the reactor in a 180L loop reactor. Other structural parameters and experimental system of the reactor are the same as in Example 1, and the superficial gas velocity u G=1.44cm·s -1 , the height of the opening section H p When they are 800mm, 1300mm, and 1600mm respectively, the corresponding ratio to the total height of the guide tube (H p / H t ) are 0.36, 0.59, 0.73, the overall gas holdup of the reactor is shown in Table 3, and the distribution of the annulus gas holdup along the axial direction is shown in Table 3. Figure 8 , see H p / H t Not bigger is better, in this embodiment when H p =1600mm, at the bottom of the hole section, not only does no gas flow out of the guide tube, but the gas in the annulus descends to the bottom of the hole section, and then flows into the guide tube from the hole, resulting in the gas contained in the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com