Gas-liquid stirring reactor for synthesizing acrylic acid and ester through acetylene carbonylation method

A gas-liquid stirring and carbonylation technology, which is applied in the fields of carbon monoxide or formate reaction preparation, chemical/physical/physical-chemical stationary reactors, and chemical methods for reacting liquid and gaseous media, etc., and can solve engineering scale-up applications. Restrictions, poor gas-liquid distribution, large equipment investment, etc., to achieve the effect of improved gas-liquid mass transfer, good fluid mixing effect, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

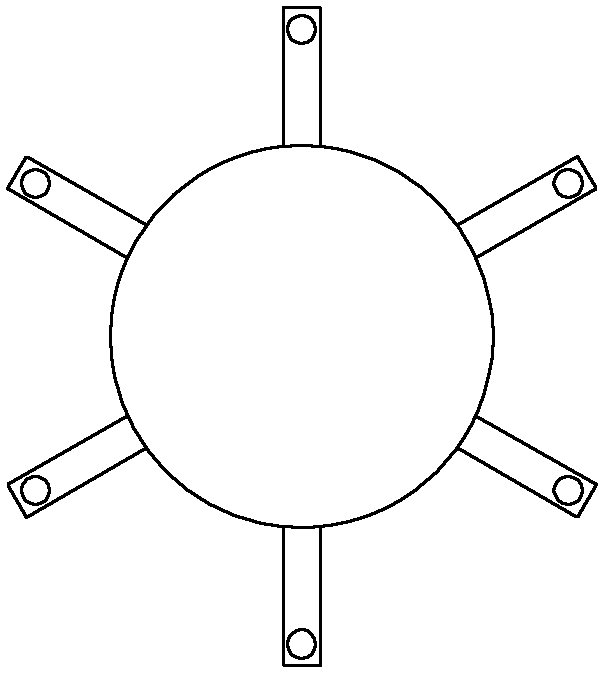

[0028] Such as figure 1 As shown, a gas-liquid stirring reactor for synthesizing acrylic acid and esters by acetylene carbonylation, the reactor includes: kettle body 1, stirring shaft 2, axial flow stirring paddle 3, radial flow stirring paddle 4, gas distributor 5, baffle Plate 6, guide tube 7, the kettle body 1 has a steam heating jacket, the middle of the kettle body 1 is cylindrical, its top and bottom are ellipsoidal, and the side wall of the kettle body 1 is with The steam heating jacket side wall has a jacket steam inlet 13 on the upper part, a jacket steam outlet 14 on the lower part, and a waste liquid discharge port 12 on the bottom of the kettle body 1 . The side wall of the kettle body 1 is provided with a liquid inlet 8, a liquid outlet 10 and a gas outlet 11, and the bottom of the kettle body 1 is provided with a gas inlet 9, which is connected to the gas distributor 5, and the gas distributor 5 It is an annular pipe with evenly distributed openings or a diverg...

Embodiment 2

[0034] Using the present invention as figure 1 The reactor structure shown, the material of the reactor is high pressure resistant, high temperature and anti-corrosion stainless steel material, the kettle body has a steam heating jacket, the diameter of the reactor body T=300mm, the total height H=2.3×T=700mm, The bottom of the kettle and the top of the kettle are also elliptical, with a height of H3=0.3×T=90mm, a volume of about 45L, a liquid level of H4=1.5×T=450mm, and a volume of about 30L; a double-layer is installed on a vertical stirring shaft in the center of the kettle. Stirring paddle, the upper end of the stirring shaft protrudes out of the top cover of the reactor through sealing measures to connect with the power unit, and the lower end is fixed through the groove in the center of the bottom of the reactor. 0.45×T=135mm, the distance C2 from the liquid surface is 0.5×T=150mm, the paddle type of the axial flow stirring paddle in the lower layer is a four-blade 45° ...

Embodiment 3

[0037] Using the present invention as figure 1 The reactor structure shown, the material of the reactor is high pressure resistant, high temperature and anti-corrosion stainless steel material, the kettle body has a steam heating jacket, the diameter of the reactor body T=400mm, the total height H=2.5×T=1000mm, The bottom of the kettle and the top of the kettle are also oval, with a height of H3=0.3×T=120mm, a volume of about 120L, a liquid level of H4=1.5×T=600mm, and a volume of about 70L; a double-layer is installed on a vertical stirring shaft in the center of the kettle. Stirring paddle, the upper end of the stirring shaft protrudes out of the top cover of the reactor through sealing measures to connect with the power unit, and the lower end is fixed through the groove in the center of the bottom of the reactor. 0.45×T=180mm, the distance C2 from the liquid surface is 0.55×T=220mm, the paddle type of the axial flow stirring paddle in the lower layer is a four-blade 45° ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com