A method of using a glove box with a purification system

A purification system and glove box technology, applied in the field of glove boxes, can solve the problems of unscientific reduction gas flow control, unreasonable purification column structure design, unscientific height-diameter ratio design, etc., so as to increase the reduction time, frequency and cost. , the effect of reducing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

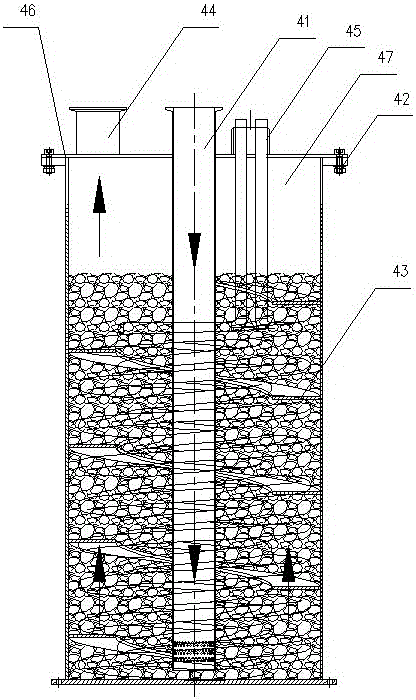

[0040] Example 1, such as Figure 1-3 As shown, a glove box with a purification system includes a main box body 1, a transition compartment 2, a glove operation port 3, a purification system 4, and a power system 6. The main box body 1, the transition compartment 2 are respectively provided with valves and are connected Air extraction and inflation interface; the purification system 4 includes a sealing cover 46, a purification cylinder 47, the sealing cover 46 and the purification cylinder 47 are connected by bolts 42; the purification cylinder 47 is fixedly provided with a main air passage 41 and a heater 45; the purification cylinder 47 The inner wall is provided with a spiral air passage 43, and the purification cylinder 47 is filled with purification materials.

Embodiment 2

[0041] In Embodiment 2, the clearance between the spiral air passage 43 and the bottom of the purification cylinder 47 in the embodiment 1 is 30 mm, and the upward angle of the spiral air passage is 15°.

Embodiment 3

[0042] Example 3, a method of using a glove box with a purification system:

[0043] The first step: purification system 4 reduction;

[0044] First connect the purification gas source 5, heat the purification material, heating time 100min; pass in reducing gas for 2 minutes, gas flow rate 10L / min; hold the pressure for 15 minutes and then vacuum for 15 minutes; then pass the gas flow automatic controller in two stages Reducing gas, the total time is 120min; the first stage is 30min, the gas flow rate is 10L / min; the second stage is 90min, the gas flow rate is 10L / min; the above procedure is cycled 4 times;

[0045] Step 2: Put in materials, experimental instruments or tools;

[0046] Open the outer door of the transition compartment 2 and put the materials to be placed on the material platform in the transition compartment 2, then open the inner door of the main box 1 and add the materials to be placed into the main box 1; close the main box 1. Transition cabin 2 doors;

[0047] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com