Solid oxide fuel cell composite cathode and preparation method thereof

A technology of solid oxide and composite cathode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of severe sintering, decrease in electrode porosity, performance attenuation, etc., and achieve high porosity, good thermal stability, and high electrical The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of electrolyte material Sm 0.2 Ce 0.8 o 1.9 For the porous framework, SrCoO 3 The powder suspension is the composite cathode of the impregnating liquid.

[0025] Proceed as follows:

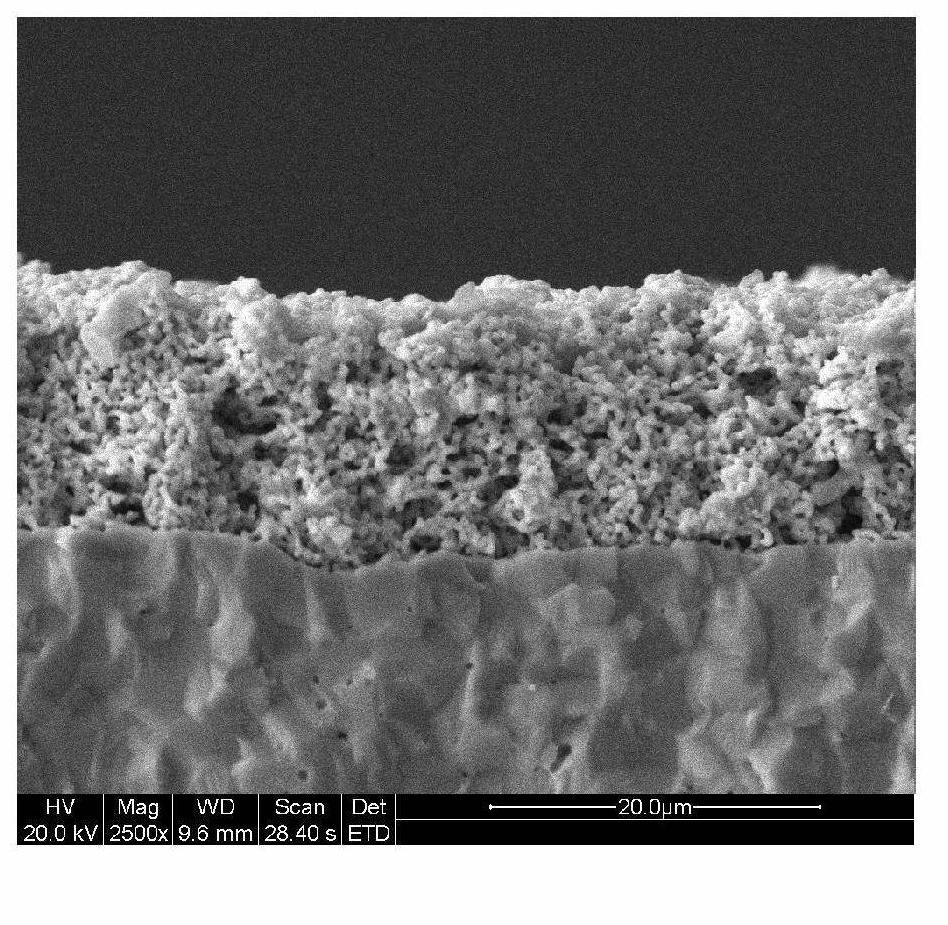

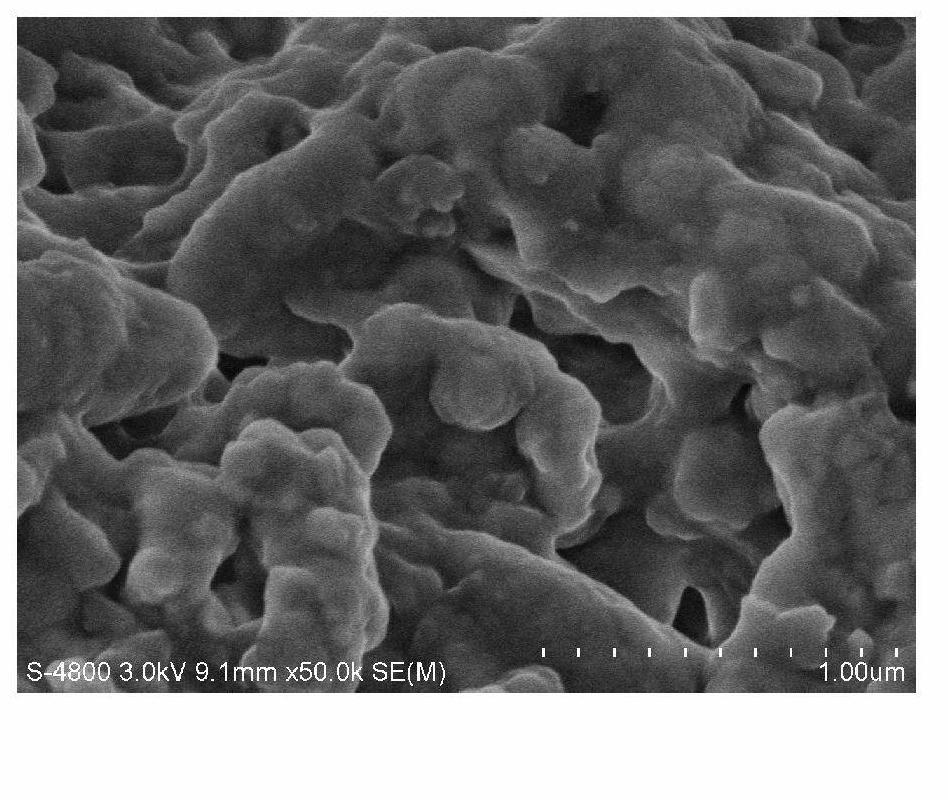

[0026] (1) Preparation of three-dimensional porous electrolyte framework: the electrolyte material Sm 0.2 Ce 0.8 o 1.9 To make a porous skeleton, see the published literature for detailed manufacturing steps of the skeleton: F.Zhao, R.R.Peng, C.R.Xia, Fuel Cells Bull.2(2008) 12-16. The firing temperature of the skeleton in this example is 1250°C / 5h , to obtain a three-dimensional porous electrolyte framework with a thickness of 20 μm and a porosity of 50%.

[0027] figure 1 Sm shown 0.2 Ce 0.8 o 1.9 The electrolyte material is a microscopic morphology diagram of a porous skeleton; it can be seen from the figure that the skeleton prepared by this method has an ideal effect, the pore size distribution in the skeleton is relatively uniform, and the pore size ...

Embodiment 2

[0032] Example 2: Preparation of Sm 0.2 Ce 0.8 o 1.9 The electrolyte material is a porous framework, Co(NO 3 ) 3 and Sr(NO 3 ) 3 The solution is the compound cathode of the immersion liquid.

[0033] Proceed as follows:

[0034] (1) Preparation of three-dimensional porous electrolyte framework: the electrolyte material Sm 0.2 Ce 0.8 o 1.9 To make a porous skeleton, the manufacturing steps of the skeleton are the same as in Example 1, except that the firing temperature of the skeleton in this example is 1300°C / 5h, and a three-dimensional porous electrolyte skeleton with a thickness of 15 μm and a porosity of 45% is obtained.

[0035] (2) Prepare a nitrate solution for impregnating the cathode material: Sr(NO 3 ) 3 and Co(NO 3 ) 2 ·6H 2 O is mixed into deionized water according to the molar ratio of metal ions Sr and Co as 1:1, then glycine is added according to the molar ratio of total metal ions to glycine as 1:2, and finally the concentration of the solution is ...

Embodiment 3

[0039] Embodiment 3: prepare with BaZr 0.1 Ce 0.7 Y 0.2 o 3-δ The electrolyte material is a porous framework, Co(NO 3 ) 3 The solution is the compound cathode of the immersion liquid.

[0040] Proceed as follows:

[0041] (1) Preparation of three-dimensional porous electrolyte framework: the electrolyte material BaZr 0.1 Ce 0.7 Y 0.2 o 3-δ Do porous skeleton, the manufacture step of skeleton in the present embodiment and the Sm in embodiment 1 0.2 Ce 0.8 o 1.9 The steps for making a skeleton are the same. In this example, the firing temperature of the skeleton was 1400°C / 4h, and a three-dimensional porous electrolyte skeleton with a thickness of 30 μm and a porosity of 40% was obtained.

[0042] (2) Prepare a nitrate solution for impregnating the cathode material: Co(NO 3 ) 2 ·6H 2 O was added to deionized water, and then a certain amount of glycine was added to make the molar ratio of Co metal ions to glycine 1:2, and the concentration of the solution was adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com