Device for measuring thermal coefficient

A technology of thermal conductivity and thermal insulation device, applied in the field of thermal conductivity measurement device, can solve the problems of insufficient thermal insulation performance, leaving air, affecting measurement accuracy, etc., to improve measurement accuracy and reliability, improve operability, and improve measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

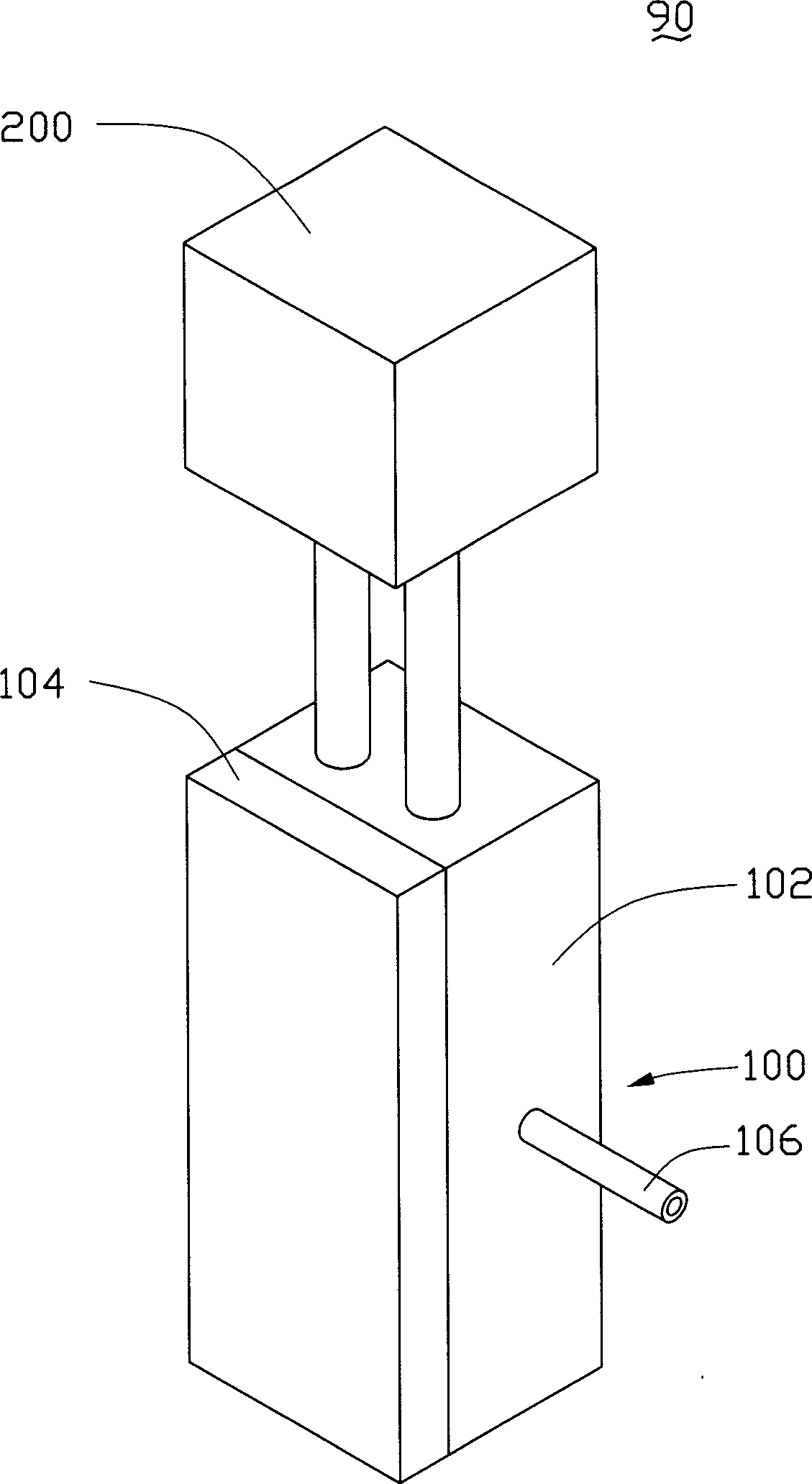

[0024] see figure 1 , that is, a schematic perspective view of the first embodiment of the thermal conductivity measuring device 90 provided by the present invention. The device includes a thermal insulation device 100 and a presser 200 . The heat-insulated container 100 is a square airtight container, which has a movable upper cover 104, which can be opened or closed, so that items can be put in or taken out. In addition, an exhaust tube 106 penetrates the outer wall 102 of the heat insulating container 100 , so that one end thereof extends into the heat insulating container 100 , and the other end is connected to a vacuum device (not shown). The inside of the heat insulating container 100 may be evacuated.

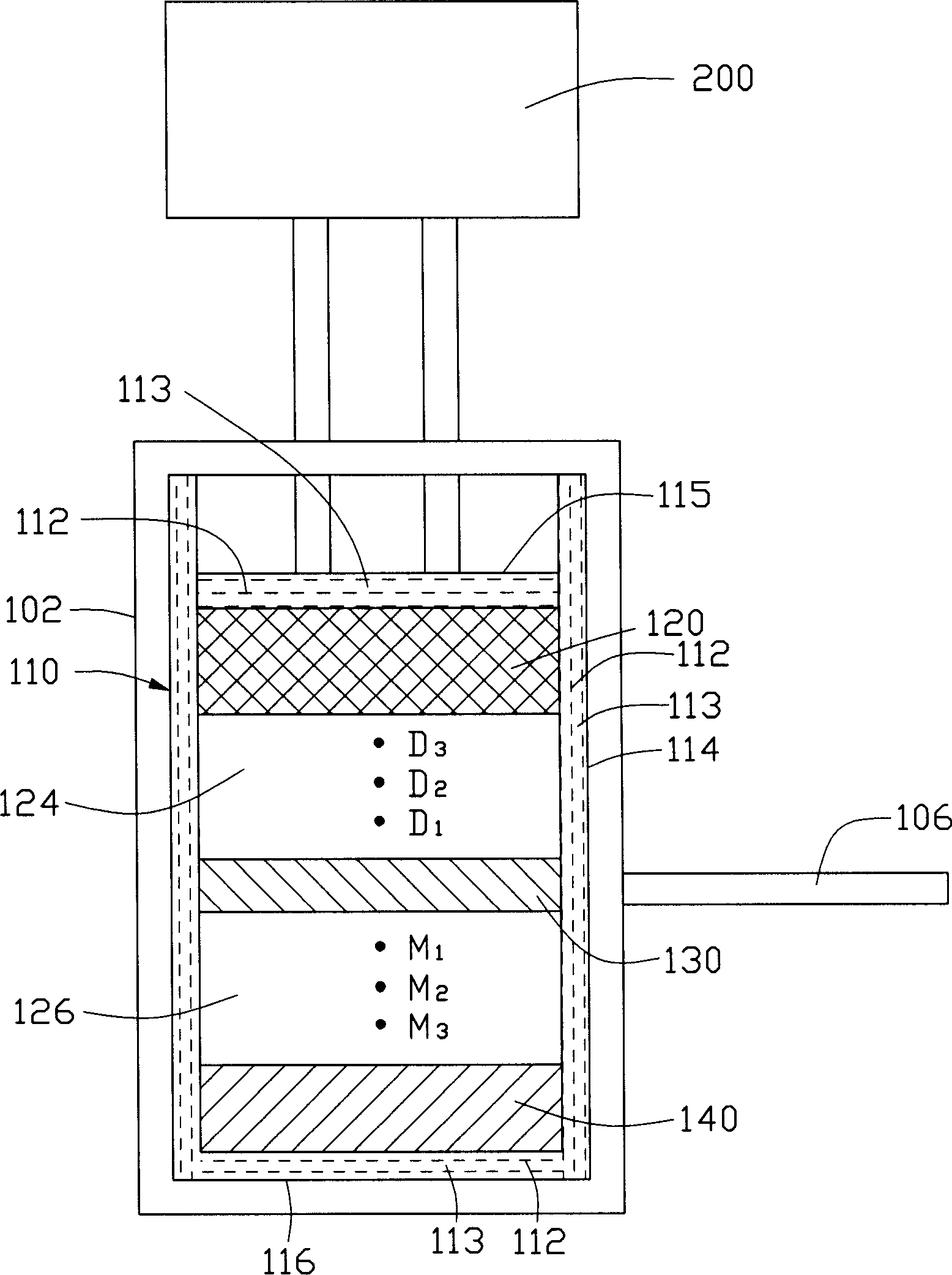

[0025] see figure 2 , the heat-insulating container 100 has a double-layer structure, the inner layer is a thermal insulation layer 110, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com