Cu-S-Se ternary thermoelectric material and preparation method thereof

A thermoelectric material, cu-s-se technology, applied in ion sintering process, Cu-S-Se ternary thermoelectric material and preparation field, can solve the problem of low Seebeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

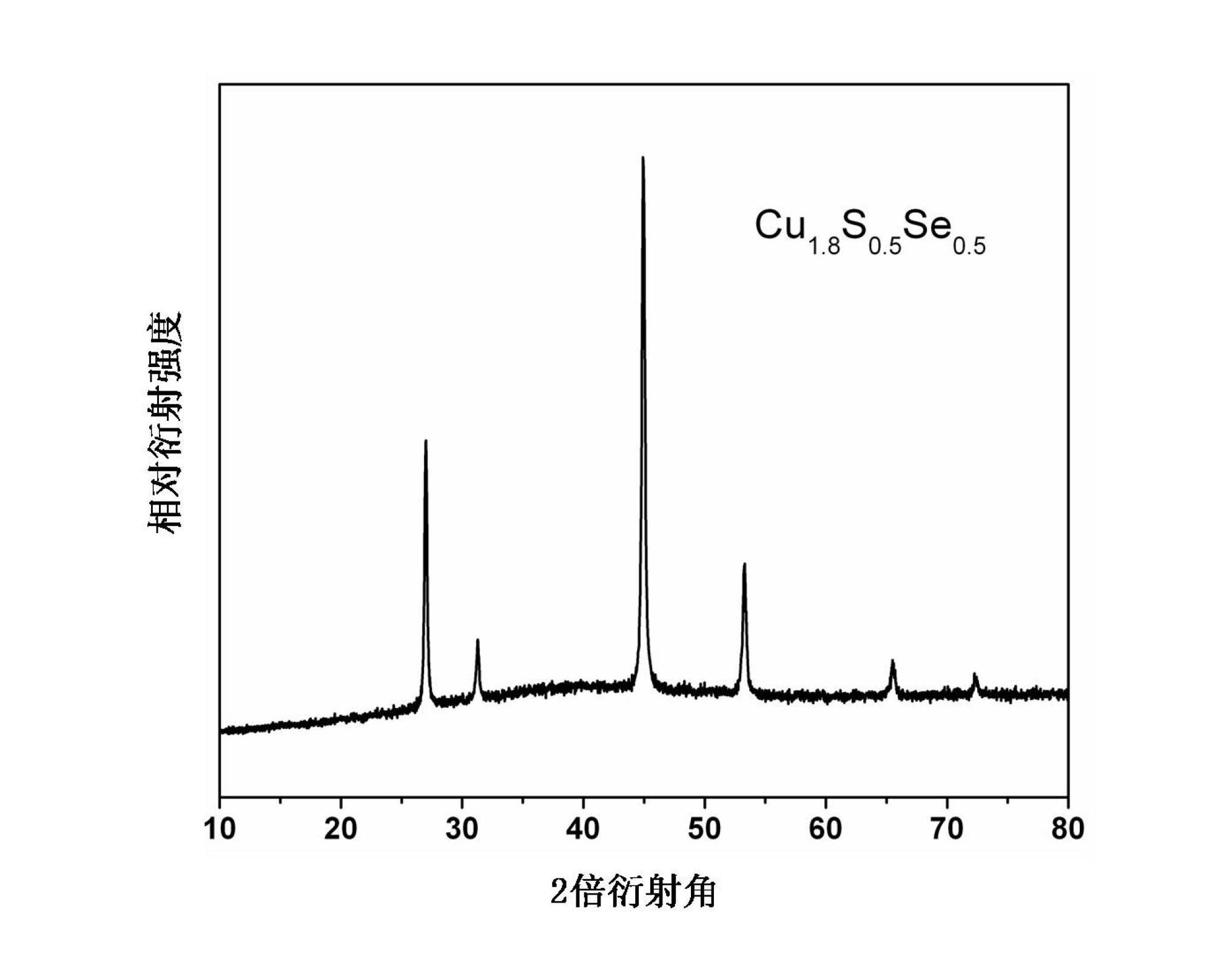

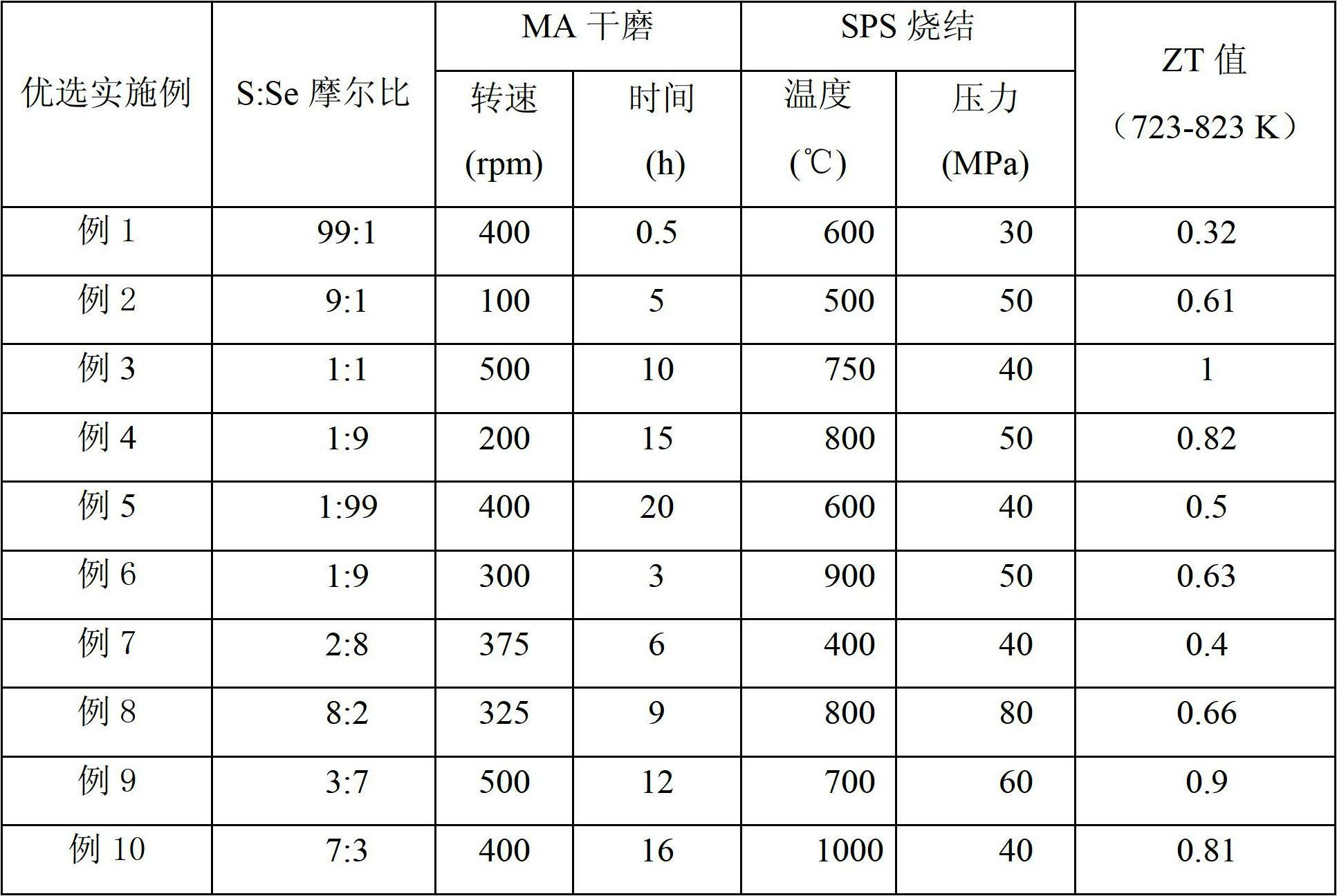

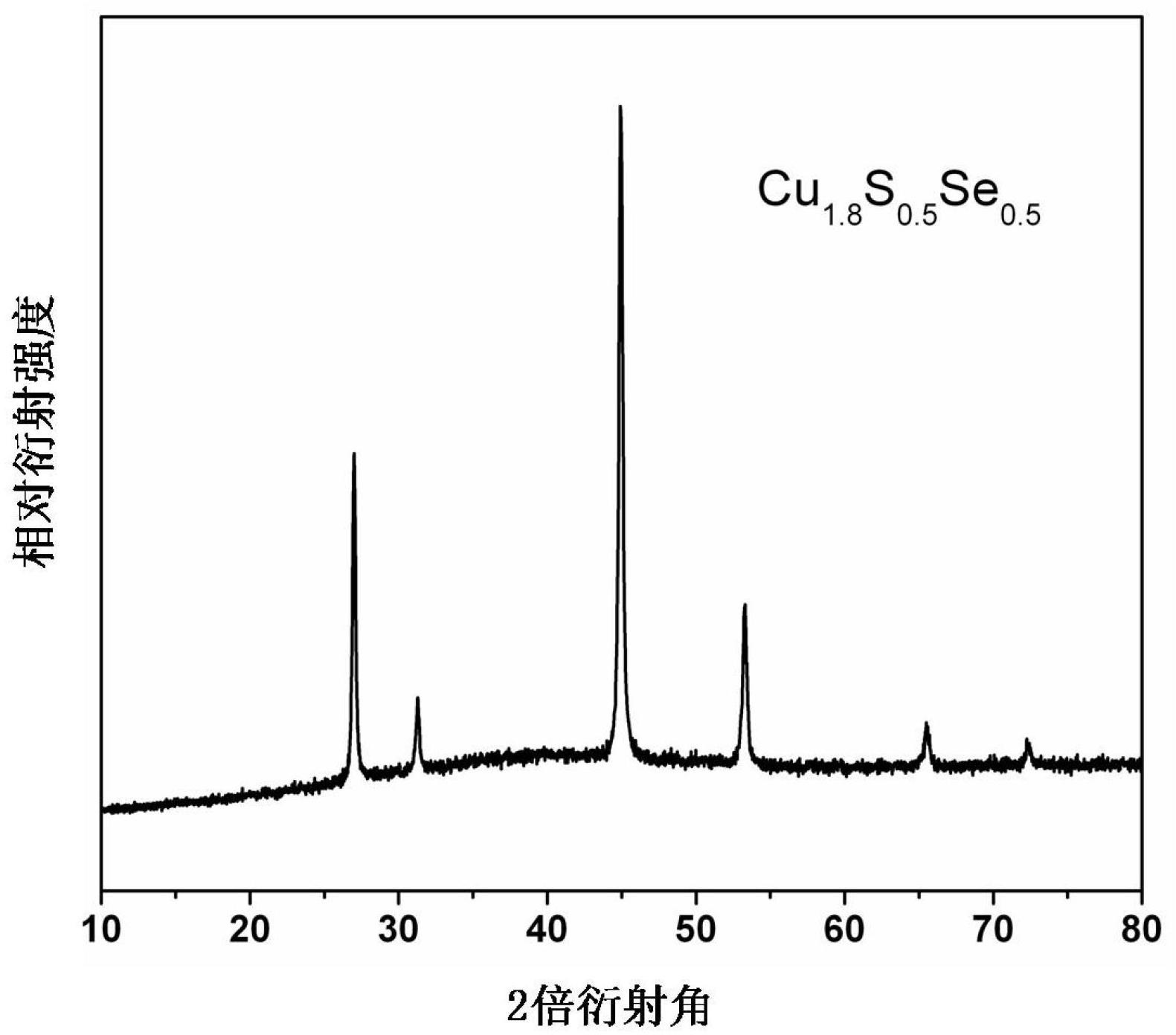

[0009] Cu was first prepared by mechanical alloying method 1.8 S 1-x Se x (0.01≤x≤0.99) ternary nano powder, the method is to mix Cu powder (mass percentage greater than 99.5%), S powder (mass percentage greater than 99.5%) and Se powder (mass percentage greater than 99.5%), according to the general chemical formula Cu 1.8 S 1-x Se x (0.01≤x≤0.99) After proportioning, mix them into a planetary ball mill, and carry out mechanical alloying under the protection of inert gas argon to obtain Cu 1.8 S 1-x Se x alloy powder. The powder is subjected to spark plasma sintering to obtain a bulk thermoelectric material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com