Friction stir butt welding device for large-thickness titanium-nickel dissimilar material and machining method of friction stir butt welding device

A technology of friction stir welding and friction stir, which is applied in the direction of metal processing equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of affecting the performance and application range of weldments, the upper and lower fillets are not effectively connected, and the structure of hybrid robots Complicated problems, to achieve the effect of improving welding efficiency, reducing axial pressure and increasing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

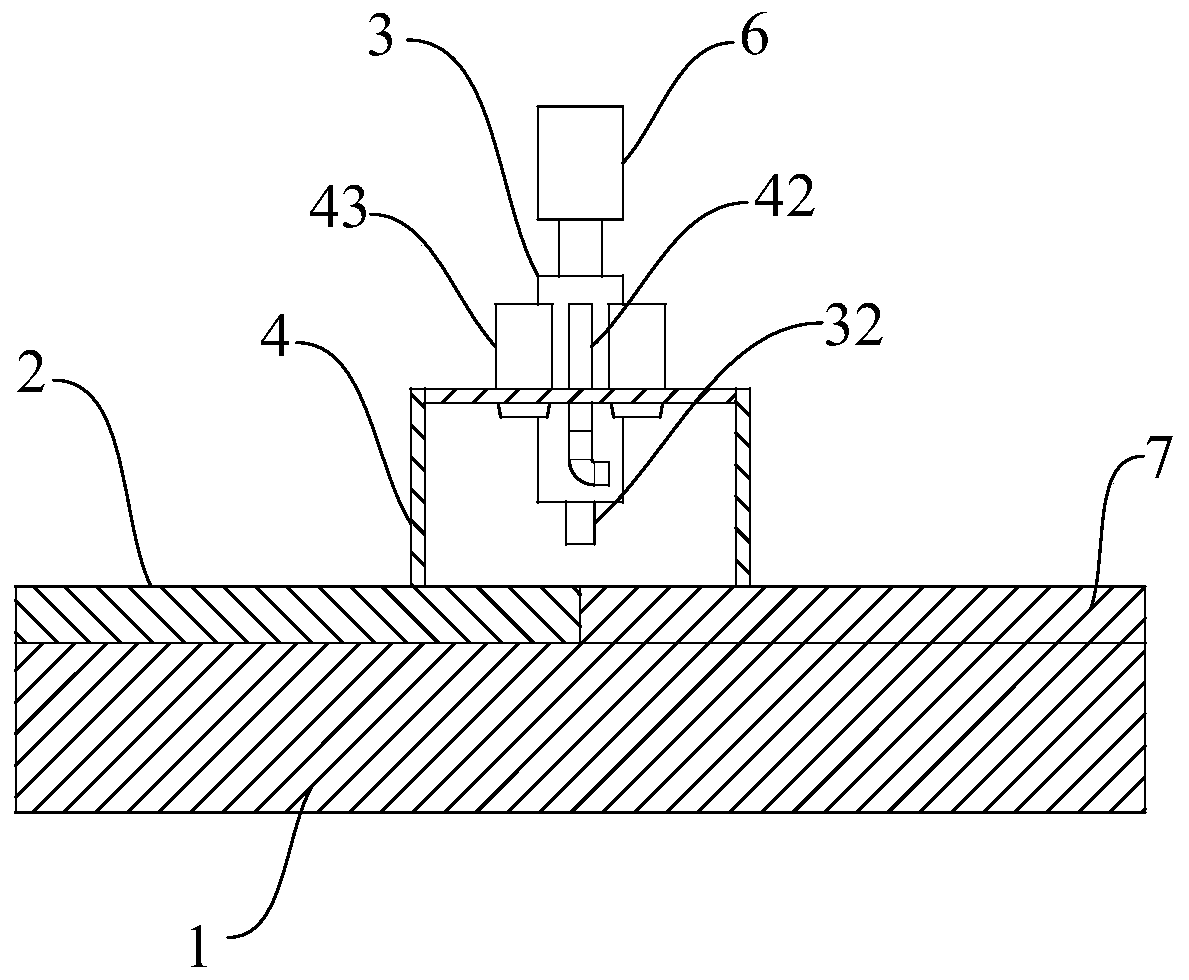

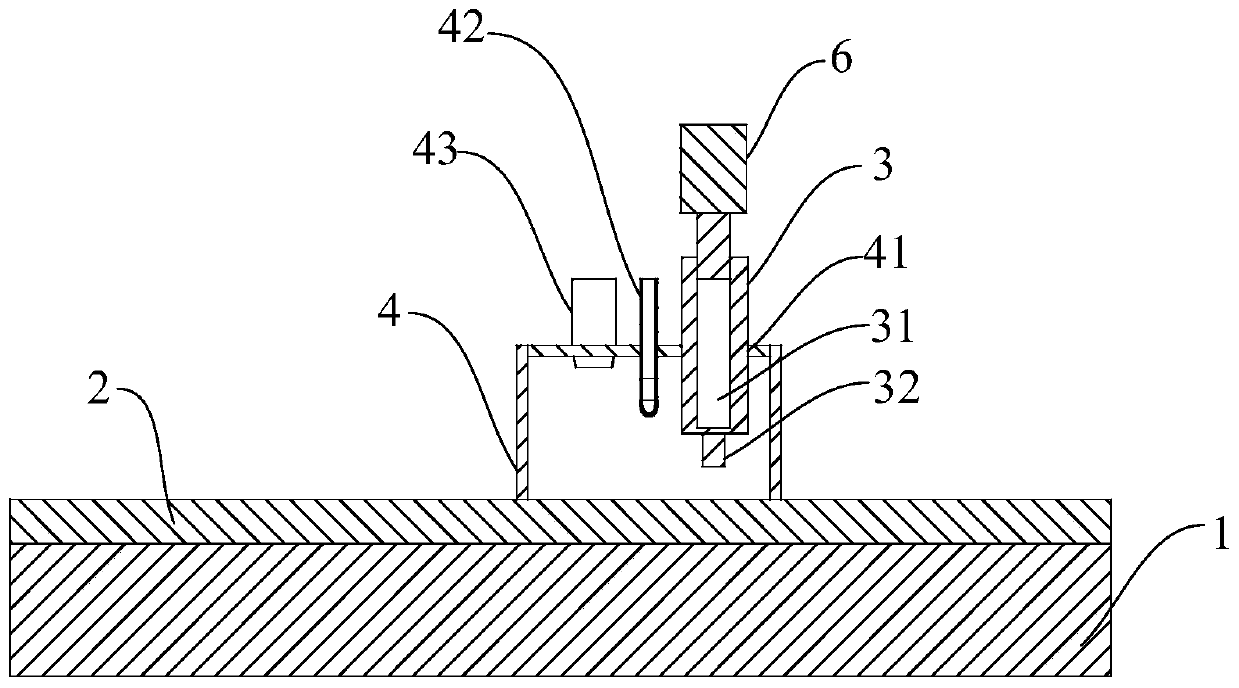

[0043] like figure 1 and 2 As shown, a friction stir butt welding device for large-thickness titanium-nickel dissimilar materials includes a workbench, a friction stir welding mechanism and a laser heating mechanism. The surface of the workbench is provided with a heat shield 1, and the heat shield 1 The surface is used to place the alloy plate to be welded. By setting the heat shield 1, the temperature gradient in the thickness direction of the weld can be reduced, so that the bottom of the weld can also have sufficient softening effect, thereby increasing the material flow in the bottom area during the welding process And the flow rate, so that the dissimilar materials of titanium and nickel at the bottom can also be fully mixed, reducing various welding defects at the bottom, and improving the quality of the weld. The workbench also includes a fixed clamping device, which is convenient for fixing the heat shield 1 and the alloy plate to be welded on the surface of the work...

Embodiment 2

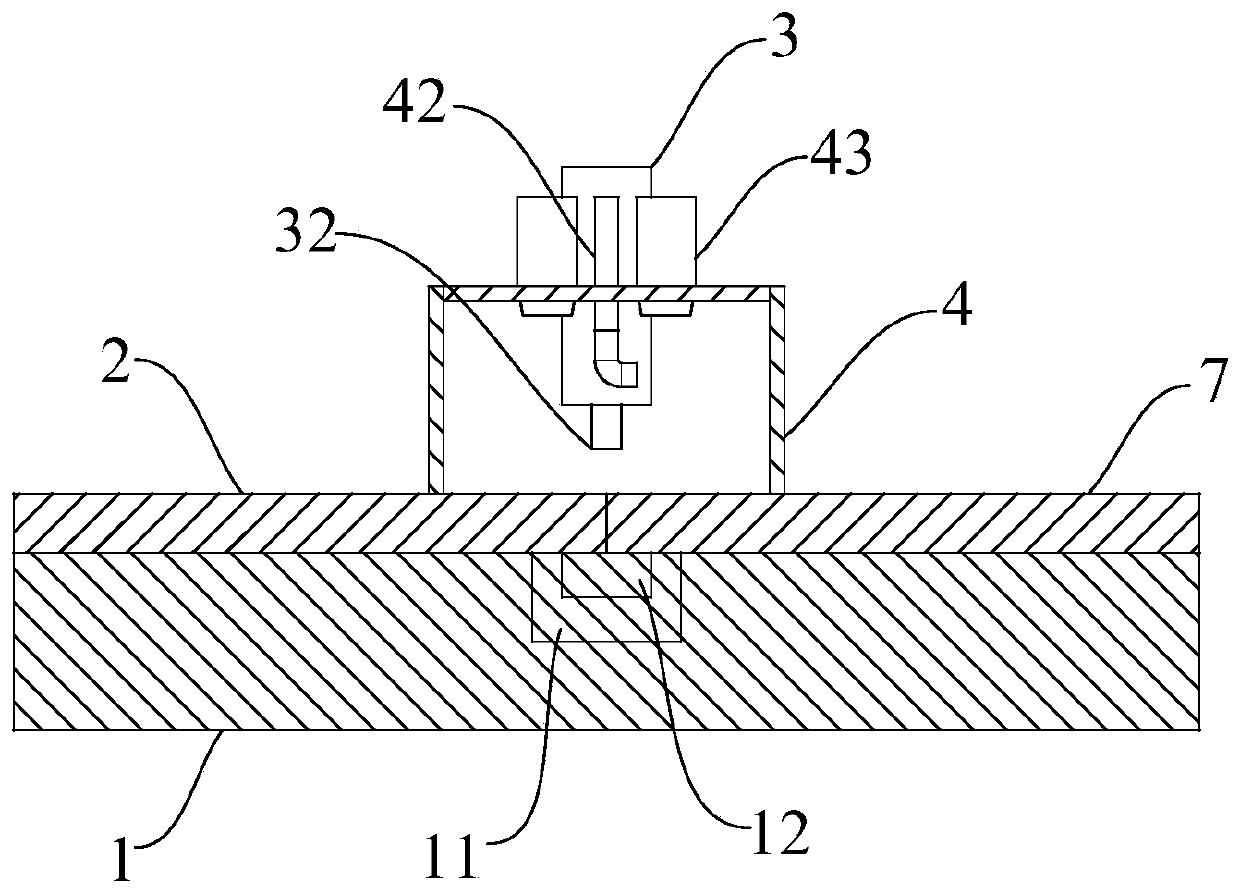

[0048] like image 3 and 4 As shown, a friction stir butt welding device for large-thickness titanium-nickel dissimilar materials differs from Example 1 in that a hollow placement groove 31 is arranged inside the stirring head 3, and a hollow placement groove 31 is arranged inside the placement groove 31 There is a copper core electrode 34 that matches with it. The side surface of the copper core electrode 34 is wrapped with an insulating sleeve 33, and its bottom is in contact with the stirring pin 32 at the bottom of the stirring head 3. The input end of the copper core electrode 34 is connected to the set It is connected to one end of the pulse power supply outside the friction stir welding equipment; the surface of the heat shield 1 is provided with an insulating groove corresponding to the interface of the workpiece to be welded, and an elastic insulating heat insulating pad 11 matching with it is arranged in the insulating groove , the upper surface of the elastic insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com