Chemically foamed thermoplastic elastomer (TPE) material and preparation method thereof

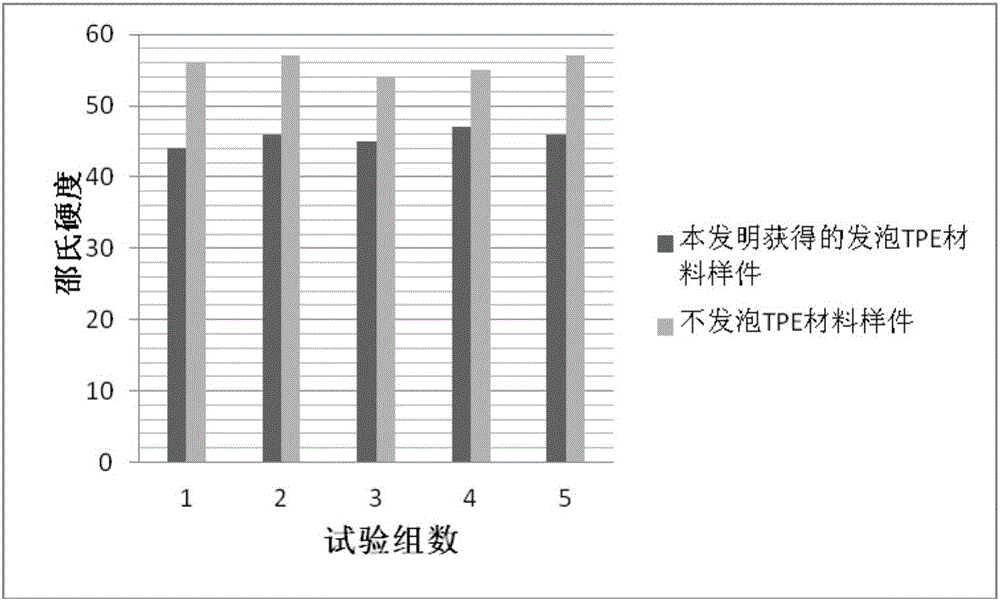

A chemical foaming and chemical foaming agent technology, applied in the field of polymer materials, can solve the problems of upper limit of use temperature, solvent resistance, poor oil resistance, large compression deformation and high density, and achieves good fluidity and reduced surface hardness. , The obvious effect of injection molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

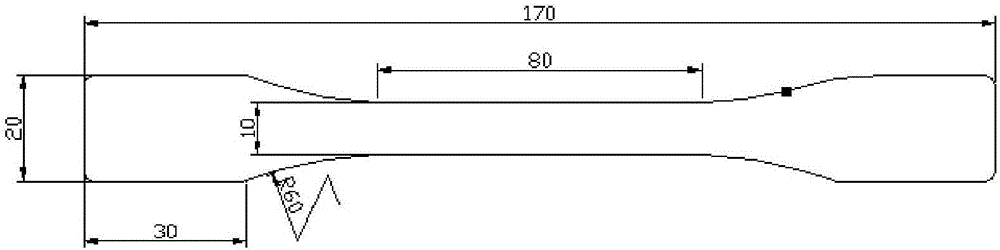

Image

Examples

Embodiment 1

[0040] A preparation method of a chemically foamed TPE material, comprising the steps of:

[0041] 1) according to the parts by weight of each raw material:

[0042]

[0043] Select hydrogenated styrene-butadiene-styrene block copolymer (SEBS), paraffin oil, polypropylene (PP), anti-scratch additives, antioxidants and chemical foaming agents for subsequent use;

[0044] 2) First mix hydrogenated styrene-butadiene-styrene block copolymer (SEBS, powder) and paraffin oil in a high-speed mixer at 500r / min for 5min, and then place it for 20min;

[0045] 3) Add polypropylene (PP), anti-scratch additives and antioxidants to the mixer in step 2) and mix at 1000r / min for 5min; obtain a premix;

[0046] 4) Add the premixed material obtained in step 3) into a twin-screw extruder to extrude and granulate, the extrusion temperature is 180-210°C, the head temperature is 200°C, and the masterbatch (non-foaming TPE material );

[0047] 5) Add the masterbatch and chemical foaming agent o...

Embodiment 2

[0052] A preparation method of a chemically foamed TPE material, comprising the steps of:

[0053] 1) according to the parts by weight of each raw material:

[0054]

[0055]

[0056] Select hydrogenated styrene-butadiene-styrene block copolymer (SEBS), paraffin oil, polypropylene (PP), anti-scratch additives, antioxidants and chemical foaming agents for subsequent use;

[0057] 2) First mix hydrogenated styrene-butadiene-styrene block copolymer (SEBS, powder) and paraffin oil in a high-speed mixer at 500r / min for 5min, and then place it for 20min;

[0058] 3) Add polypropylene (PP), anti-scratch additives and antioxidants to the mixer in step 2) and mix at 1000r / min for 5min; obtain a premix;

[0059] 4) Add the premixed material obtained in step 3) into a twin-screw extruder to extrude and granulate. The extrusion temperature is 180-210°C, and the head temperature is 200°C to obtain a non-foaming TPE material (masterbatch );

[0060] 5) Add the masterbatch and chemi...

Embodiment 3

[0065] A preparation method of a chemically foamed TPE material, comprising the steps of:

[0066] 1) according to the parts by weight of each raw material:

[0067]

[0068] Select hydrogenated styrene-butadiene-styrene block copolymer (SEBS), paraffin oil, polypropylene (PP), anti-scratch additives, antioxidants and chemical foaming agents for subsequent use;

[0069] 2) First mix hydrogenated styrene-butadiene-styrene block copolymer (SEBS, powder) and paraffin oil in a high-speed mixer at 500r / min for 5min, and then place it for 20min;

[0070] 3) Add polypropylene (PP), anti-scratch additives and antioxidants to the mixer in step 2) and mix at 1000r / min for 5min; obtain a premix;

[0071] 4) Add the premixed material obtained in step 3) into a twin-screw extruder to extrude and granulate. The extrusion temperature is 180-210°C, and the head temperature is 200°C to obtain a non-foaming TPE material (masterbatch );

[0072] 5) Add the masterbatch and chemical foaming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com