A pipe welding method

A welding method and pipeline technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as easy cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are for more clearly illustrative of the technical solutions of the present invention, and therefore only examples are exemplified, and the scope of protection of the present invention is not limited thereto.

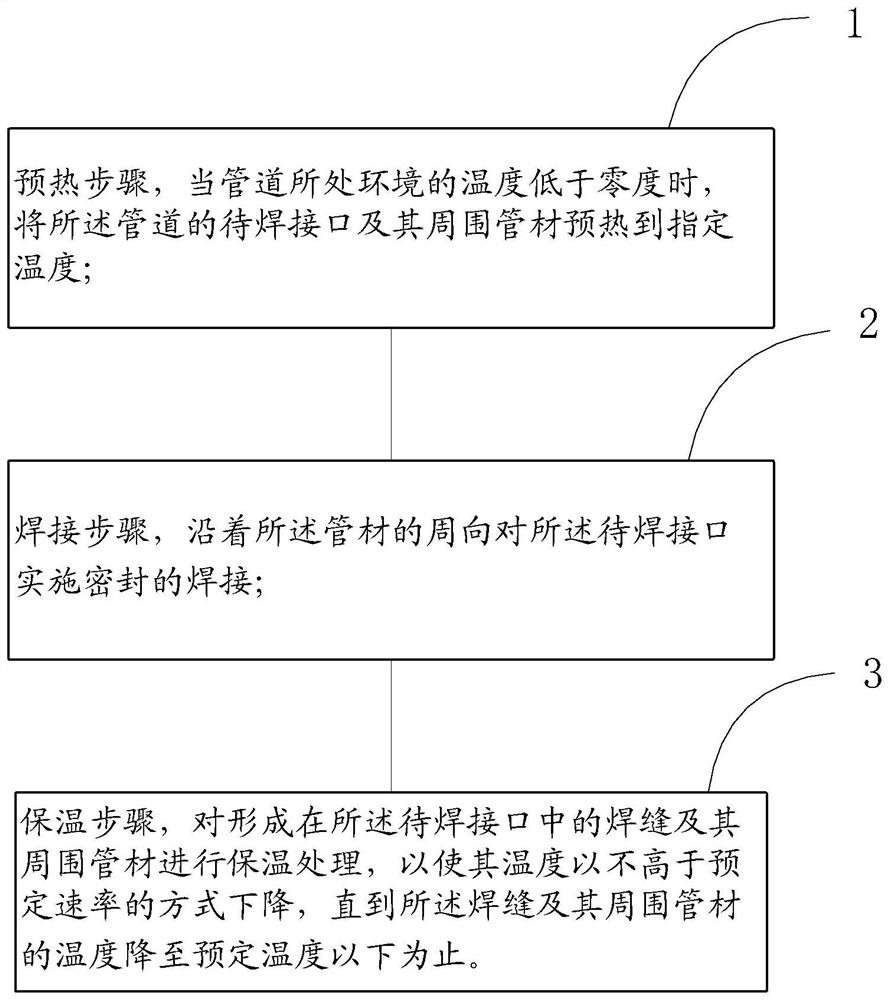

[0020] like figure 1 As shown, the welding method 100 of the embodiment of the present invention, including:

[0021] Preheat step 1, when the temperature in which the environment is located is lower than zone, preheat the pipe welded interface and its surrounding tubes to the specified temperature;

[0022] Specifically, the construction personnel need to determine the designated temperature and preheating range of the pipe preheating through the temperature in the pipeline, generally specifying the temperature of 50 to 300 ° C, the preheating range is welded heat affected area (in the welding heat cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com