One-component room temperature vulcanized silicone rubber and preparation method

A room temperature vulcanization and silicone rubber technology, which is applied in the field of silicone rubber, can solve the problems of complex vulcanized silicone rubber preparation process, water, electricity, heat consumption, poor storage stability, etc., and achieve shortened production process and production process time, mechanical Improved performance and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

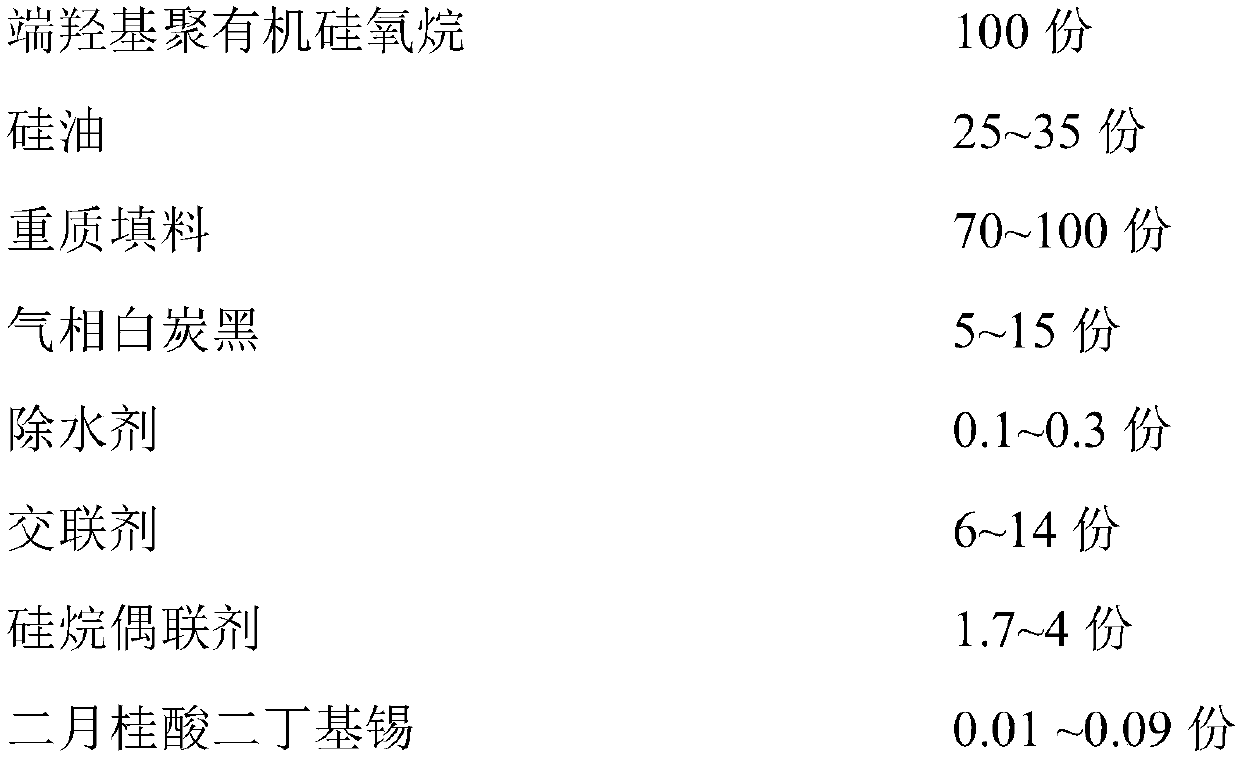

[0034] The embodiment of the present invention provides a one-component room temperature vulcanized silicone rubber, which uses polyorganosiloxane with a functionality of 80,000 terminal hydroxyl groups. The one-component room temperature vulcanized silicone rubber includes the following components in parts by mass:

[0035]

[0036]

[0037] A preparation method of simple room temperature vulcanized silicone rubber, characterized in that it comprises the following steps:

[0038] In terms of parts by mass, add 100 parts of hydroxyl-terminated polyorganosiloxane, 25 parts of silicone oil 100cps, 70 parts of heavy filler, and 5 parts of fumed silica into a planetary stirring tank, stir and mix for about 40 minutes, and then add vinyl trimethoxy 0.1 part of base silane; 9 parts of cross-linking agent; 2 parts of silane coupling agent; 0.05 part of dibutyltin dilaurate Continue mixing, stirring for 30 minutes under the condition of vacuum greater than -0.095MPa, and discharg...

Embodiment 2

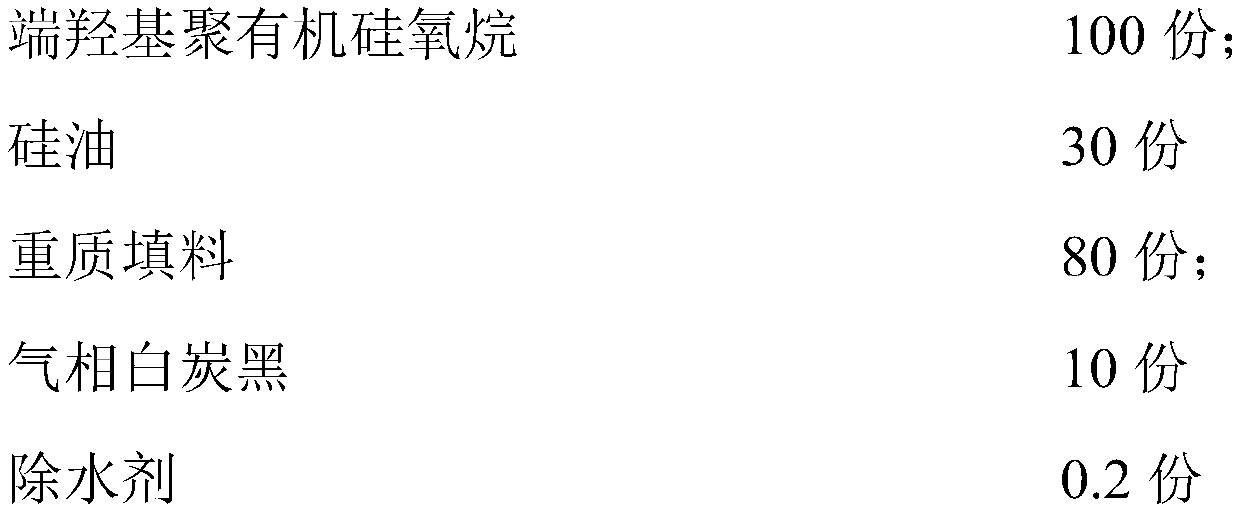

[0040] The one-component room temperature vulcanizing silicone rubber provided in this example is polyorganosiloxane with a functionality of 50,000 terminal hydroxyl groups. The one-component room temperature vulcanizing silicone rubber includes the following components in parts by mass:

[0041]

[0042] In above-mentioned embodiment, the preparation method of room temperature vulcanized silicone rubber comprises the following steps:

[0043] In terms of parts by mass, add 100 parts of hydroxyl-terminated polyorganosiloxane, 30 parts of silicone oil 100cps, 80 parts of heavy filler, and 10 parts of fumed silica into a planetary stirring tank and stir for about 40 minutes, then add vinyl trimethoxy 0.2 parts of base silane; 10 parts of crosslinking agent; 3 parts of silane coupling agent; 0.05 parts of dibutyltin dilaurate Continue mixing, stirring for 30 minutes under the condition of vacuum greater than -0.095MPa, and discharging.

Embodiment 3

[0045] The one-component room temperature vulcanizing silicone rubber provided in this example is a polyorganosiloxane with a functionality of 120,000 terminal hydroxyl groups. The one-component room temperature vulcanizing silicone rubber includes the following components in parts by mass:

[0046]

[0047]The preparation method of the room temperature vulcanized silicone rubber in the above-mentioned embodiment comprises the following steps: in parts by mass, 100 parts of hydroxyl-terminated polyorganosiloxane, 35 parts of silicone oil 100 cps, 100 parts of heavy filler, and 5 parts of fumed silica are added Stir and mix in the planetary stirring tank for about 40 minutes, then add 0.3 parts of vinyltrimethoxysilane; 12 parts of crosslinking agent phenyltributanoneximosilane; 4 parts of silane coupling agent; 0.1 part of dibutyltin dilaurate and continue mixing , Stir for 30 minutes under the condition that the vacuum degree is greater than -0.095MPa, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com