Preparation method of textured plating layer electrode wire

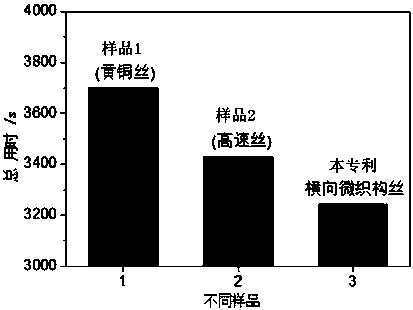

A coating electrode wire and texturing technology, applied in electrode manufacturing, electric processing equipment, coating, etc., can solve the problems of poor wire ductility, increase the manufacturing cost of electrode wire, etc. The effect of extended time and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

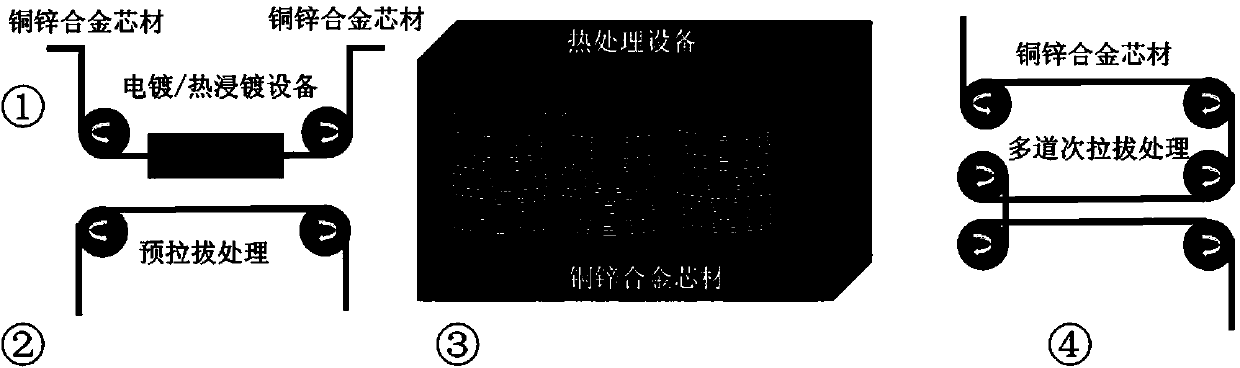

[0036] like Figure 1-Figure 4 As shown, the preparation method of the textured coating electrode wire provided in this embodiment is carried out according to the following steps:

[0037] Step (1), preparation of zinc coating on the surface of the copper-zinc alloy core material: firstly, the cleaned zinc alloy core material (Cu / Zn: 60 / 40) is electroplated / hot-dipped, and the thickness is obtained by adjusting the galvanizing process 5μm zinc coating;

[0038] Step (2), pre-drawing treatment: select the above-mentioned coated electrode wire as the initial material, and use cold drawing technology to perform pre-drawing treatment to obtain an electrode wire blank with a diameter of 0.5 mm;

[0039] Step (3), diffusion heat treatment: Diffusion heat treatment is carried out on the electrode wire blank processed in step (2) by discontinuous heat treatment, and the selected treatment process is 150°C-200°C and 300°C-400°C two-stage temperature, 250 minutes Processing time for t...

Embodiment 2

[0046] The preparation method of the textured coated electrode wire provided in this embodiment is carried out according to the following steps:

[0047] Step (1), preparation of zinc coating on the surface of the copper-zinc alloy core material: firstly, the cleaned zinc alloy core material (Cu / Zn: 60 / 40) is electroplated / hot-dipped, and the thickness is obtained by adjusting the galvanizing process 10μm zinc coating;

[0048] Step (2), pre-drawing treatment: select the above-mentioned coated electrode wire as the initial material, and use cold drawing technology to perform pre-drawing treatment to obtain an electrode wire blank with a diameter of 0.8 mm;

[0049] Step (3), diffusion heat treatment: conduct diffusion heat treatment on the wire electrode blank treated in step (2) by means of discontinuous heat treatment, the selected treatment process is 150°C-200°C and 300°C-400°C two-stage temperature, 300 minutes Processing time for thermal diffusion processing. After the...

Embodiment 3

[0054] The preparation method of the textured coated electrode wire provided in this embodiment is carried out according to the following steps:

[0055] Step (1), preparation of zinc coating on the surface of the copper-zinc alloy core material: first, the cleaned zinc alloy core material (Cu / Zn: 63 / 37) is subjected to electroplating / hot-dip plating, and the thickness is obtained by adjusting the galvanizing process 5μm zinc coating;

[0056] Step (2), pre-drawing treatment: select the above-mentioned coated electrode wire as the initial material, and use cold drawing technology to perform pre-drawing treatment to obtain an electrode wire blank with a diameter of 0.5 mm;

[0057] Step (3), diffusion heat treatment: Diffusion heat treatment is performed on the wire electrode blank treated in step (2) by discontinuous heat treatment, and the selected treatment process is 150°C-200°C and 300°C-400°C two-stage temperature, 400 minutes Processing time for thermal diffusion proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com