Organic composite type foodstuff, fruit and vegetables antistaling agent and preparation method thereof

A fruit and vegetable preservative, composite technology, applied in the field of organic composite food fruit and vegetable preservatives and its preparation, to achieve the effects of low production cost, simple manufacturing process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

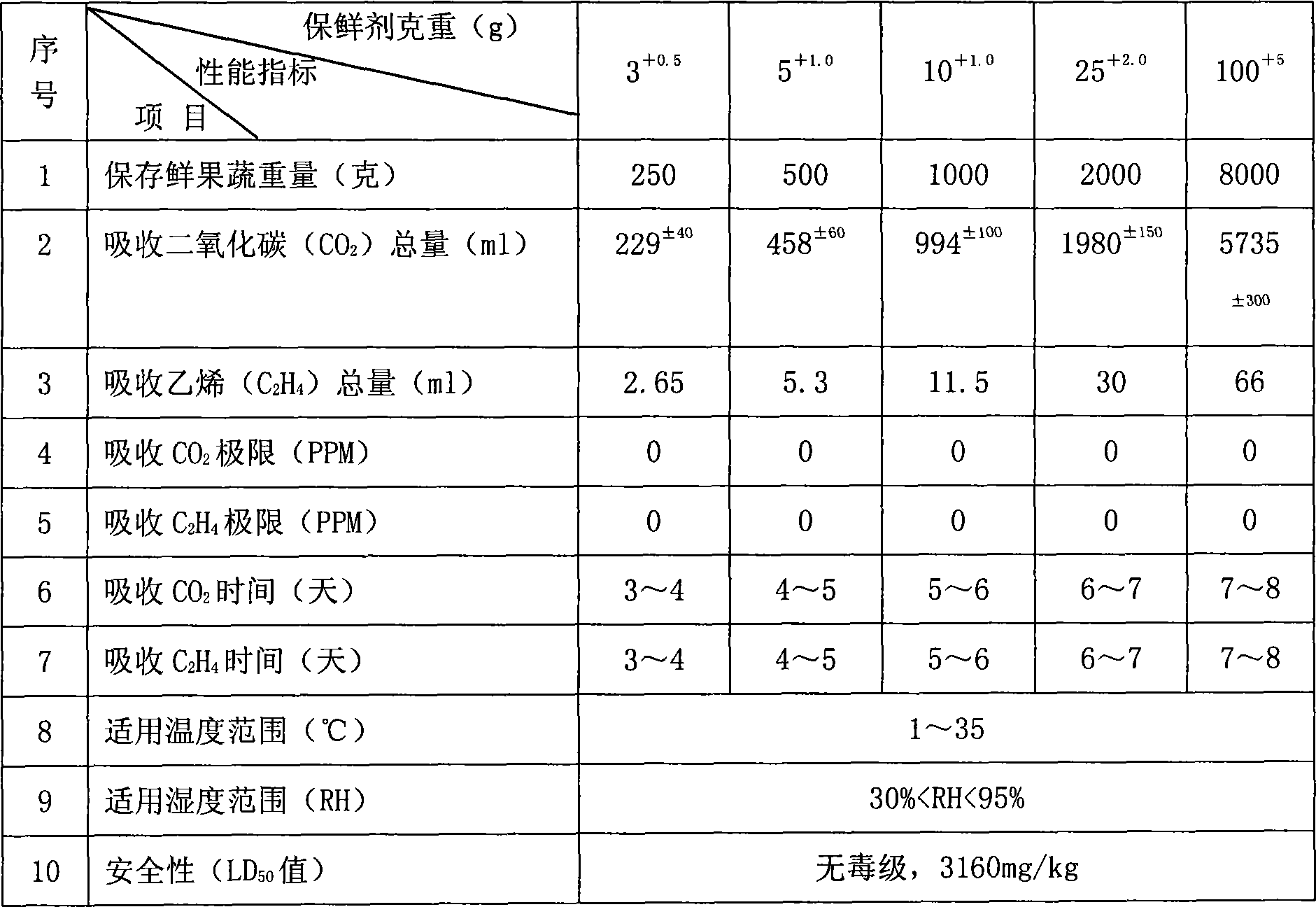

[0026] Embodiment 1: Configuration embodiment of organic composite preservative

[0027] Components and content: 20-80% calcium oxide, 5-20% potassium permanganate, 10-30% vermiculite, 1-10% superabsorbent resin, 2-20% diatomaceous earth, the sum of each component is 100%.

[0028] Preparation method: Grind and mix calcium oxide and potassium permanganate, then add vermiculite, superabsorbent resin and diatomaceous earth in turn, after mixing and stirring evenly, use paper-plastic packaging that meets certain air permeability requirements. .

[0029] Air permeability of paper and plastic packaging: the requirement is 40-70ml / min·30.5cm 2 ·220mm H 2 O column, such as three-layer composite packaging of PET / coated paper / PE or PA / coated paper / PE.

Embodiment 2

[0030] Embodiment 2: sealing sample of fresh betel nut

[0031] Weigh 45% calcium oxide and 8% potassium permanganate and crush them into 20 meshes, mix them, then add 27% vermiculite, 8% superabsorbent resin and 12% diatomaceous earth in turn, mix and stir evenly and use PET / Laminated paper / PE three-layer composite packaging is made into a small package, and the small package containing the preservative is placed in a high-barrier food-grade composite film bag containing fresh betel nuts (6g of preservative for every 500g of fresh betel nuts), seal.

[0032] The fresh betel nuts packaged with preservative are kept fresh at normal temperature (temperature 20-24°C, humidity 58-78%RH), refrigerated (temperature 5°C, humidity 55%RH) and high-temperature and high-humidity (temperature 26-32%RH). , Humidity 65~78%RH) fresh-keeping storage, observe the mold of fresh betel nut, yeast breeding time and mildew, fermentation, browning period, the results are as follows:

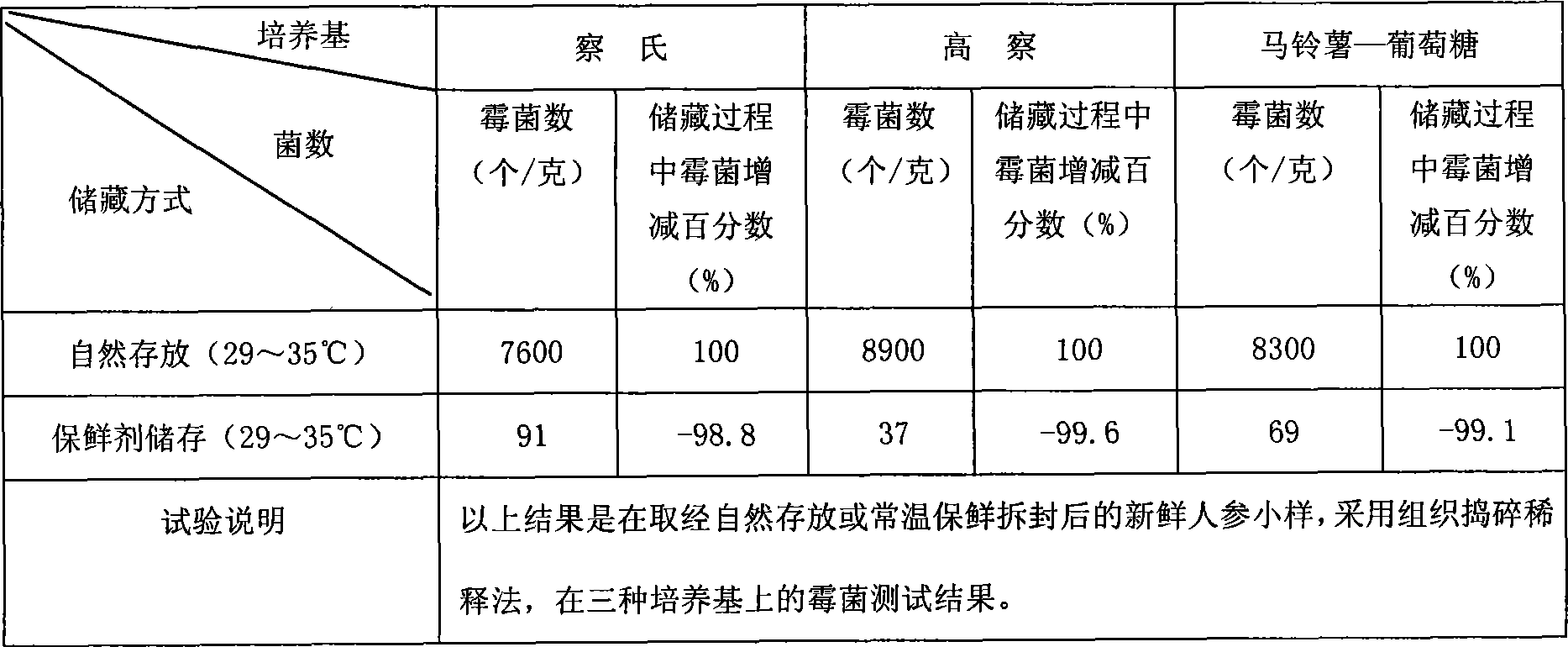

[0033] Norm...

Embodiment 3

[0036] Embodiment 3: fresh chestnut sealing sample

[0037] Weigh 56% calcium oxide and 12% potassium permanganate and crush them into 20 meshes, mix them, then add 15% vermiculite, 3% superabsorbent resin and 14% diatomaceous earth in turn, and use PA / coated paper / PE three-layer composite packaging is made into a small package, and the small package containing the preservative is placed in a high-barrier food-grade composite film bag containing fresh chestnuts (6g of preservative for every 500g of fresh chestnuts), seal.

[0038] Store fresh chestnuts packaged with preservatives at high temperature and high humidity (temperature 26-34°C, humidity 60-75% RH), observe the mildew, softening and browning period of fresh chestnuts and high temperature and high humidity (temperature 26-75% RH). 34 ℃, humidity 60 ~ 75% RH) natural storage and no preservative natural refrigeration (temperature 5 ℃, humidity 50% RH) storage conditions were delayed at least 90 days or more and 45 day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Ph value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com