Method for preparing acrylic resin modified graphene oxide leather tanning agent

A technology of acrylic resin and oxidized stone, which is applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, tanning treatment, etc. It can solve formaldehyde pollution, formaldehyde content, Carcinogenic, shortage and other problems, to achieve good application prospects, eliminate pollution, soft hand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

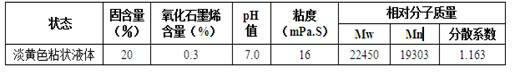

Examples

preparation example Construction

[0020] The preparation method of the present invention firstly uses concentrated sulfuric acid, sodium nitrate and potassium permanganate etc. to oxidize flake graphite to prepare graphene oxide, and the effect of oxidation is to introduce hydroxyl, carboxyl, epoxy groups etc. on the structure of graphene At the same time, the graphite expands and the interlayer distance becomes larger. Then use methacrylic acid and acrylic acid to enter between graphene oxide sheets for in-situ intercalation compounding and polymerization reaction, so that graphene oxide, methacrylic acid and acrylic acid form copolymers, and acrylic resin modified graphene oxide leather tanning is obtained. agent.

[0021] The preparation method of acrylic resin modified graphene oxide leather tanning agent of the present invention is realized by the following steps:

[0022] Step 1: Preparation of graphene oxide:

[0023] Slowly add 50 parts by weight of concentrated sulfuric acid to a mixture of 5 parts ...

Embodiment 1

[0028] Step 1: Preparation of graphene oxide:

[0029] Slowly add 50 parts by weight of concentrated sulfuric acid to a mixture of 5 parts by weight of graphite powder with a particle size of less than 30 microns and 5 parts by weight of sodium nitrate under stirring, and control the temperature of the system to <20°C. Slowly add 18 parts by weight of potassium permanganate; then react at 50°C for 30 minutes, then slowly add 280 parts of deionized water, heat up to 100°C for 4 hours; then drop the temperature to 70°C and add 20 parts by weight, mass A hydrogen peroxide solution with a fraction of 30% was reacted for 30 minutes, washed with deionized water, adjusted to a pH of 6, dispersed by ultrasonic waves for 30 minutes to obtain a graphene oxide aqueous solution, and the graphene oxide content was controlled at 0.4%;

[0030] Step 2: Preparation of acrylic resin modified graphene oxide:

[0031] Take 60 parts by weight of graphene oxide aqueous solution, add 8 parts by we...

Embodiment 2

[0033] Step 1: Preparation of graphene oxide:

[0034] Slowly add 50 parts by weight of concentrated sulfuric acid to a mixture of 5 parts by weight of graphite powder with a particle size of less than 30 microns and 5 parts by weight of sodium nitrate under stirring, and control the temperature of the system to <20°C. Slowly add 18 parts by weight of potassium permanganate; then react at 50°C for 30 minutes, then slowly add 280 parts of deionized water, heat up to 100°C for 4 hours; then drop the temperature to 70°C and add 20 parts by weight, mass A hydrogen peroxide solution with a fraction of 30% was reacted for 30 minutes, washed with deionized water, adjusted to a pH of 6, dispersed by ultrasonic waves for 30 minutes to obtain a graphene oxide aqueous solution, and the graphene oxide content was controlled at 0.4%;

[0035] Step 2: Preparation of acrylic resin modified graphene oxide:

[0036] Take 70 parts by weight of graphene oxide aqueous solution, add 10 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com