Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Elongation at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

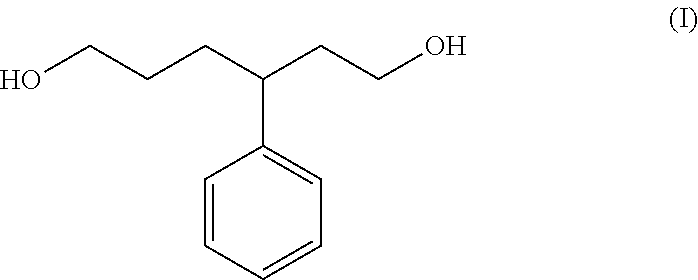

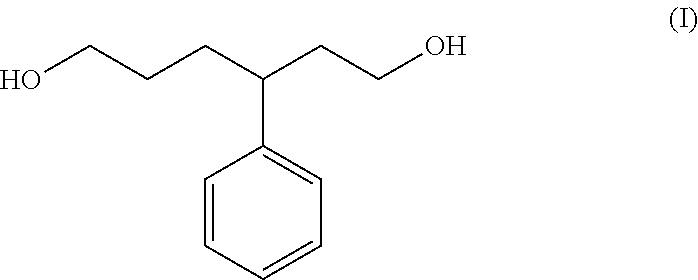

Polyoxyalkylenepolyols and process for producing ring-opened polymer

InactiveUS6531566B1Improve responseImprove adhesionOrganic compound preparationOther chemical processesPolyolHydrogen

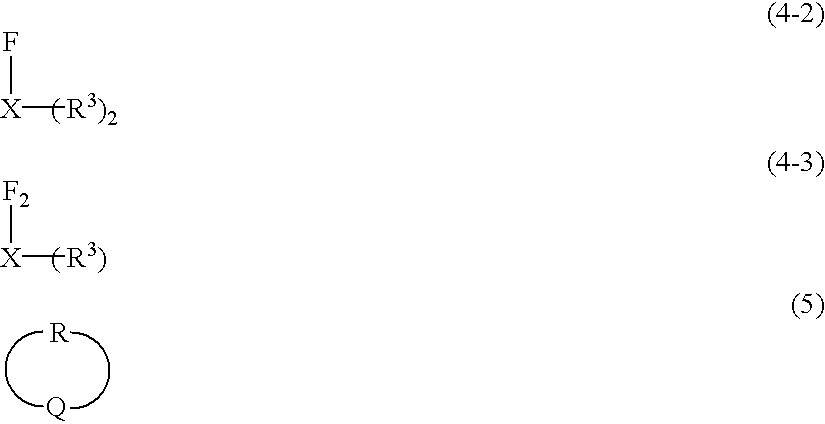

A polyoxyalkylene polyol or monool (I) of the general formula (1) below, in which not less than 40% of the terminally located hydroxyl-containing groups, namely -AO-H groups, are primary hydroxyl-containing groups of the general formula (2) below, or;a method of producing ring-opening polymerization products, by subjecting a heterocyclic compound to ring-opening addition polymerization with an active hydrogen-containing compound, using as a catalyst tris(pentafluorophenyl)borane, tris(pentafluorophenyl)aluminum, etc.

Owner:SANYO CHEM IND LTD

Crosslinking agents

A polyorganosiloxane containing the units (HR2Si-O1 / 2) HM units, (Si-O4 / 2) Q units, (R1Si-O3 / 2) T units and (R2Si-O2 / 2) D units in a ratio of from 2:1:0:0 to 6:4:2:2, or (HR2Si-O1 / 2) HM units, (R1Si-O3 / 2) T units, (R2Si-O2 / 2) D units and (R2(R1O)Si-O1 / 2) in a ratio HM:T:D:alkoxyM of from 1:2:0:0 to 3:4:2:2 is described, where R are identical or different, non-halogenated or halogenated hydrocarbon radicals having from 1 to 18 carbon atoms per radical, or are OR1, where R1 is a monovalent, unsubstituted or substituted hydrocarbon radical having from 1 to 8 carbon atoms, and in each molecule there are at least 3 Si-bonded hydrogen atoms. The polyorganosiloxanes are particularly useful as crosslinking agents in addition curable elastomer formulations.

Owner:WACKER CHEM GMBH

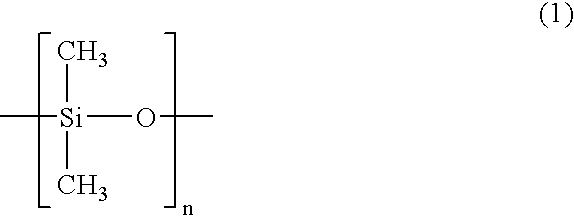

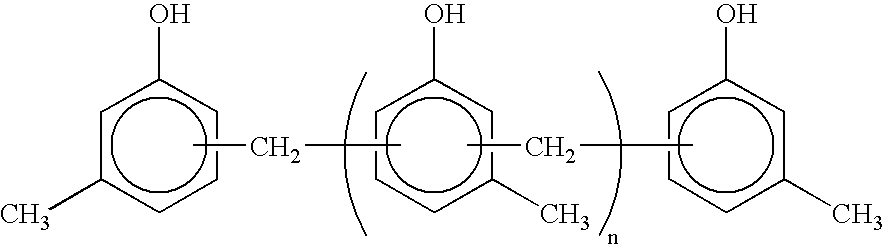

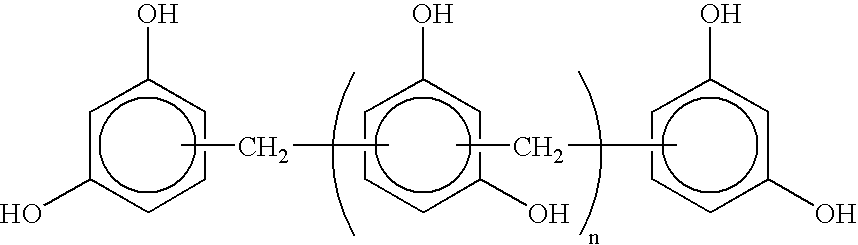

Rubber composition and tire using same

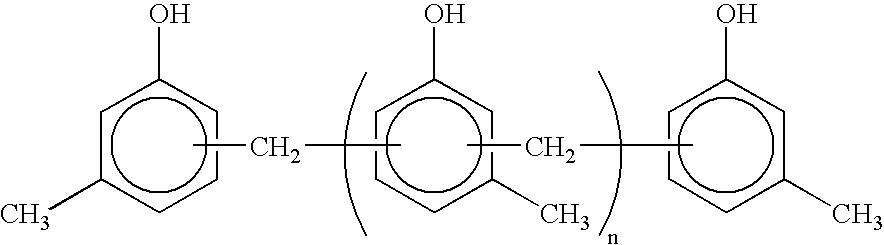

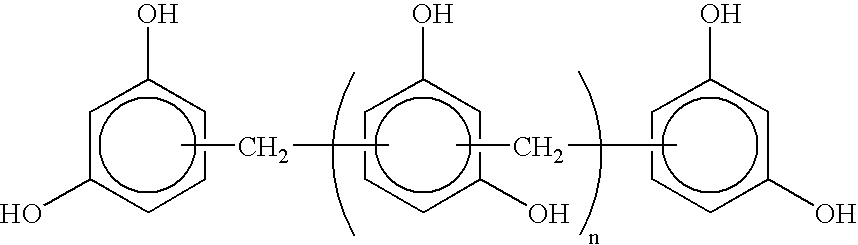

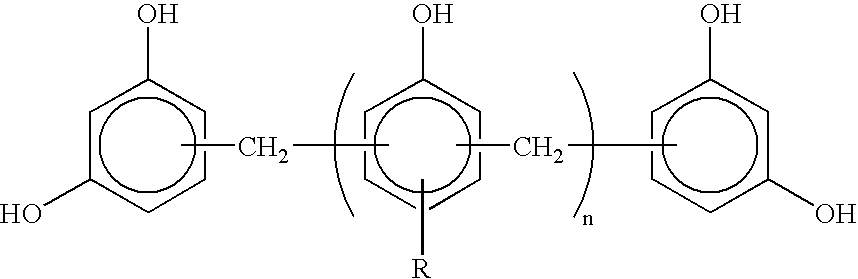

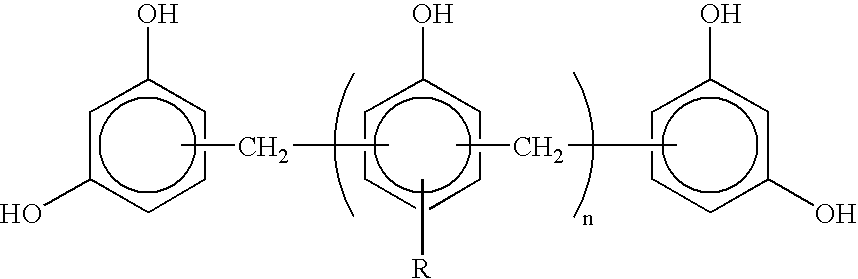

InactiveUS20080009570A1Solve the lack of hardnessReduce consumptionOrganic chemistrySpecial tyresPolymer scienceCresol

The present invention provides a rubber composition with superior properties with respect to processability, low fuel consumption, complex modulus, and durability, and tires prepared by using the rubber composition. The rubber composition of the present invention comprises: 2 to 2.9 parts by weight of (B) sulfur, 0.6 to 10 parts by weight of (C) at least one compound selected from the group consisting of a cresol resin, a resorcin condensate, and a modified resorcin condensate, and 10 to 55 parts by weight of (D) a carbon black and / or silica, based on 100 parts by weight of (A) a rubber component comprising a natural rubber and / or isoprene rubber and at least two kinds of synthetic rubbers selected from the group consisting of butadiene rubber, modified butadiene rubber, styrene-butadiene rubber, and modified styrene-butadiene rubber. The tire of the present invention is prepared by using the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

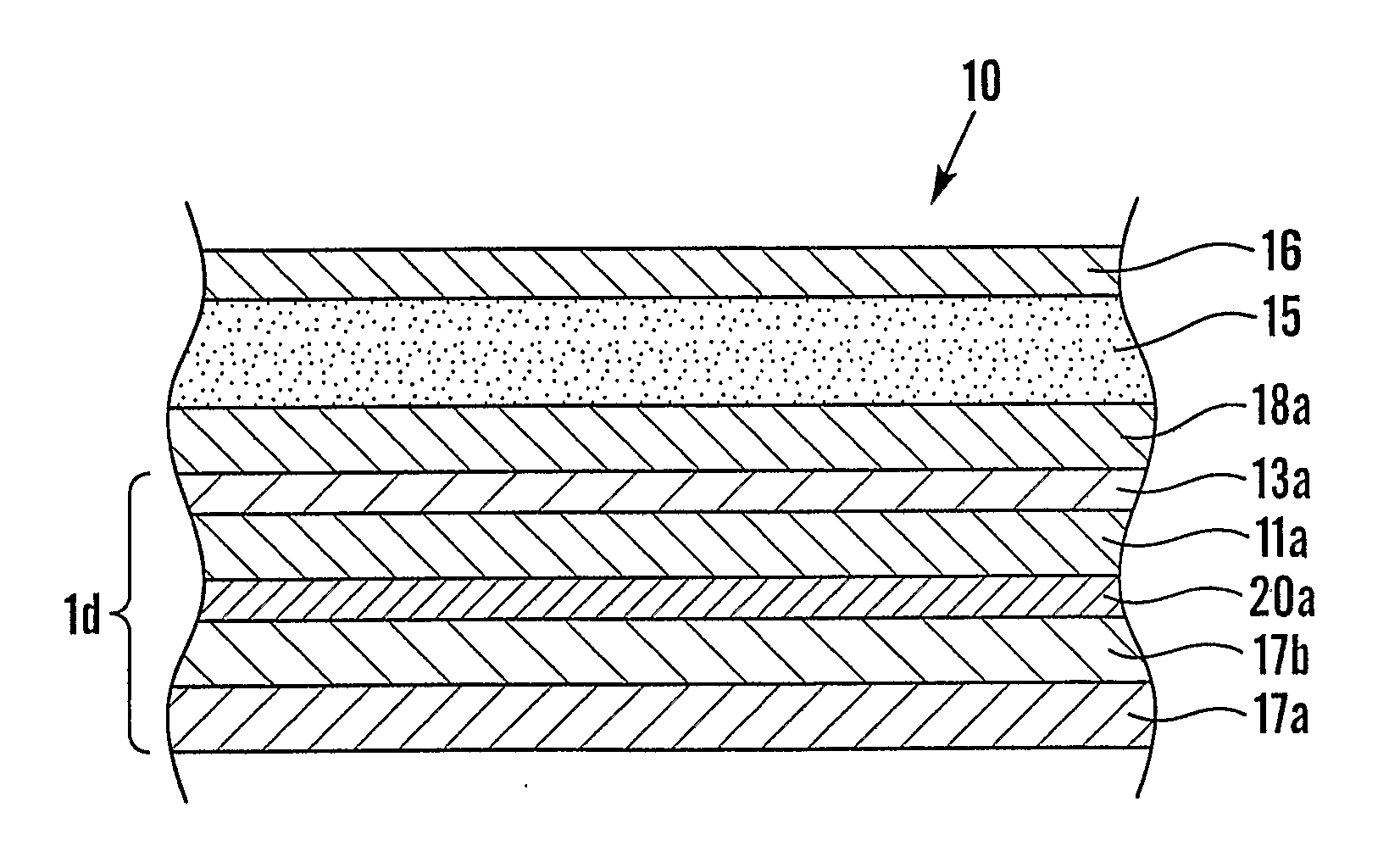

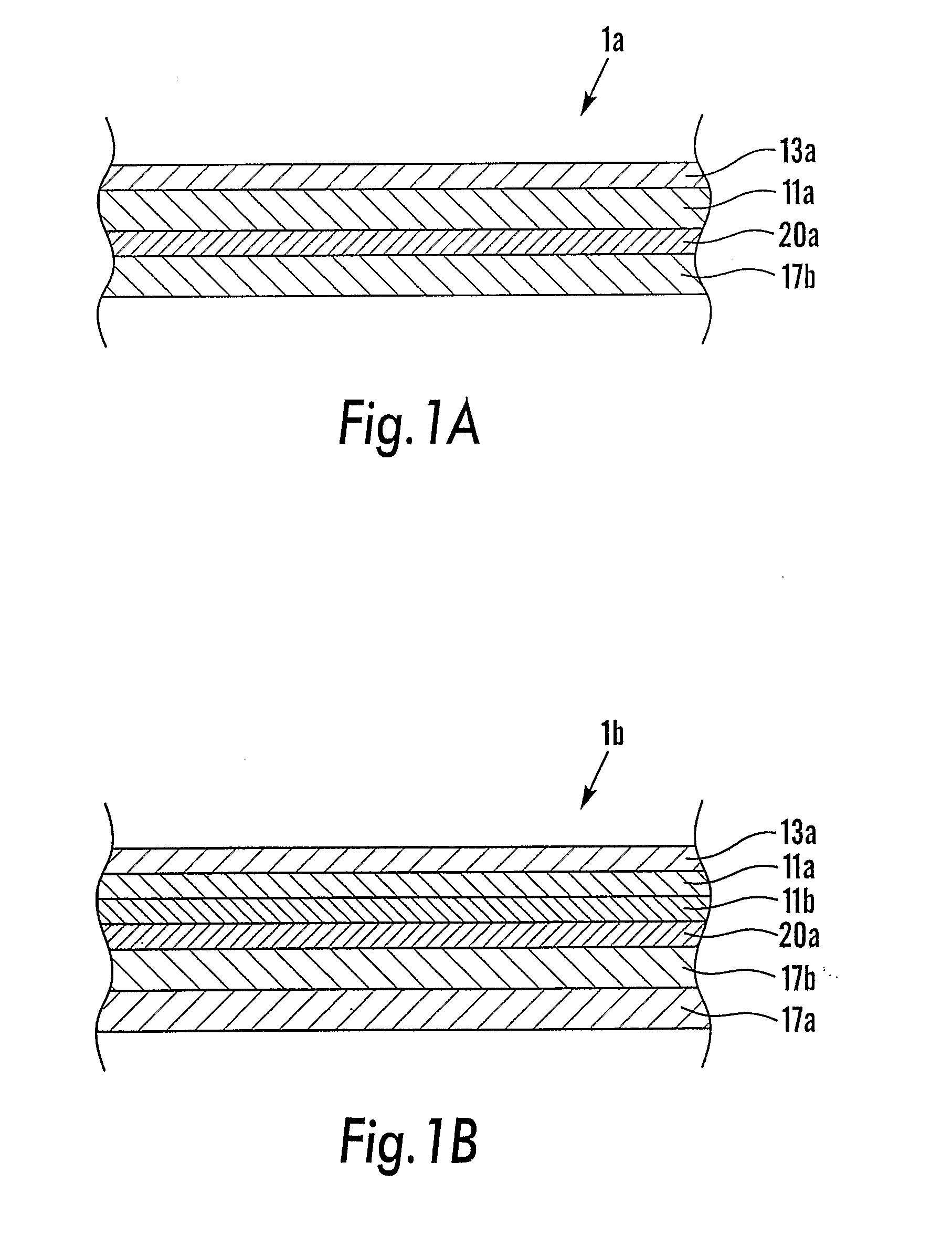

Endless belt for electrophotographic apparatus

ActiveUS20050196202A1Large elongationIncreased durabilitySynthetic resin layered productsElectrographic process apparatusPolyamide-imideCarboxylic acid

An endless belt for use as an intermediate transfer belt or a transfer-sheet transfer belt in an electrophotographic apparatus using electrophotographic technologies such as a full-color LBP (Laser Beam Printer) or a full-color PPC (Plane Paper Copier). At least a base layer of the belt comprises a modified polyamide imide resin formed by copolymerizing: (A) an aromatic isocyanate compound; (B) an aromatic polycarboxylic acid anhydride; and (C) a polymer having carboxylic acids at both terminals thereof.

Owner:TOKAI RUBBER IND LTD

Polylactic acid anti-bacterial-activity packaging material and preparation method thereof

InactiveCN104212136AEasy to processAvoid the effects of antimicrobial activityAdditive ingredientAntibacterial activity

The invention discloses a polylactic acid anti-bacterial-activity packaging material and a preparation method thereof and belongs to the technical field of macromolecule. The anti-bacterial-activity packaging material includes, in a blending manner, a matrix resin and natural anti-bacterial plant essential oil, wherein the matrix resin accounts 100 parts by weight and the natural anti-bacterial plant essential oil accounts 2-10 parts by weight. The matrix resin is blended by polylactic acid and polytrimethylenecarbonate with a weight ratio of the polylactic acid to the polytrimethylenecarbonate being (60-90):(40-10). The natural anti-bacterial plant essential oil includes clove essential oil, cinnamon essential oil, fennel essential oil and lemongrass essential oil, thyme essential oil or origanum vulgare essential oil. The ingredients are blended in a double-screw extruder and are prepared into the novel polylactic acid anti-bacterial-activity packaging material through a film blowing machine. The material has a certain tensile strength and a certain elongation at break, can be biologically degraded completely, has an excellent anti-bacterial activity and can be widely applied in the field of packaging.

Owner:KUNMING UNIV OF SCI & TECH

Blended rubber of silicon rubber and high density polyethylene and preparation method thereof

InactiveCN101824223AImprove liquidityEnhance aggregation abilityManufacturing cost reductionPolymer science

The invention relates to a blended rubber of silicon rubber and high density polyethylene. The blended rubber is prepared from the following raw materials in part by weight: 55 to 75 parts of silicon rubber, 25 to 40 parts of high density polyethylene, 3 to 8 parts of silane coupling agent, 30 to 40 parts of white carbon black, 30 to 40 parts of plasticizer, and 2.0 to 10 parts of vulcanizing agent. The formula of the blended rubber provided by the invention effectively improves the liquidity of the high density polyethylene, enhances the polymerization capacity of the silicon rubber and the high density polyethylene, reduces the viscosity of material blended rubber, and improves excellent performance of the blended rubber. The prepared blended rubber is particularly applied to preparing thin silica gel plates, electric fittings, mold pressing arresters, insulators for overhead power transmission lines, shades for isolating switches, and other products. The method for preparing the blended rubber can effectively reduce the manufacturing cost and further optimize the performance of the rubber.

Owner:仝国磊

Rubber composition and tire using same

InactiveUS7737209B2Solve the lack of hardnessReduce consumptionOrganic chemistrySpecial tyresPolymer scienceCresol

The present invention provides a rubber composition with superior properties with respect to processability, low fuel consumption, complex modulus, and durability, and tires prepared by using the rubber composition. The rubber composition of the present invention comprises: 2 to 2.9 parts by weight of (B) sulfur, 0.6 to 10 parts by weight of (C) at least one compound selected from the group consisting of a cresol resin, a resorcin condensate, and a modified resorcin condensate, and 10 to 55 parts by weight of (D) a carbon black and / or silica, based on 100 parts by weight of (A) a rubber component comprising a natural rubber and / or isoprene rubber and at least two kinds of synthetic rubbers selected from the group consisting of butadiene rubber, modified butadiene rubber, styrene-butadiene rubber, and modified styrene-butadiene rubber. The tire of the present invention is prepared by using the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

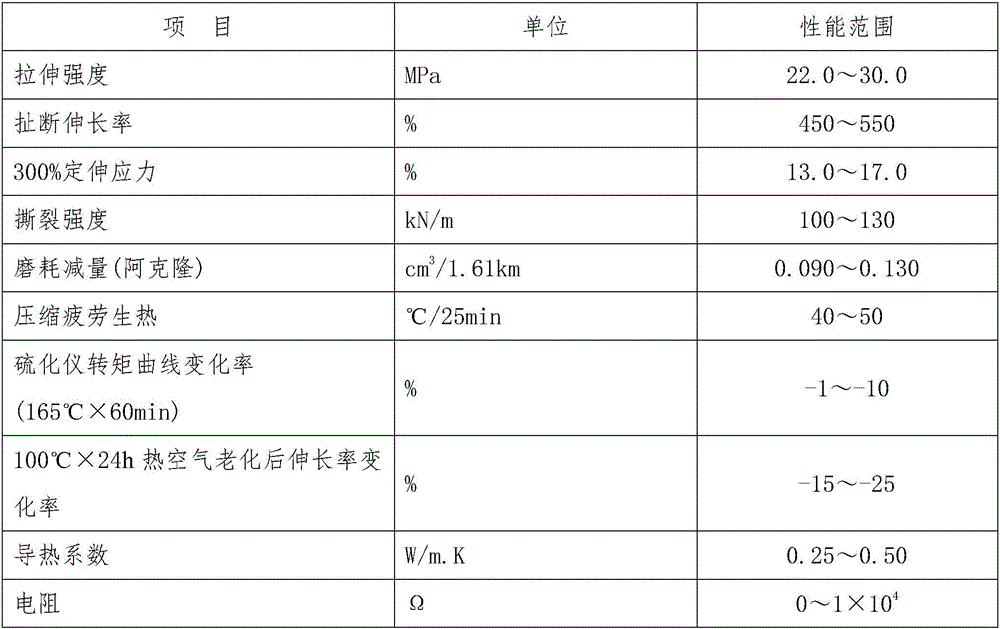

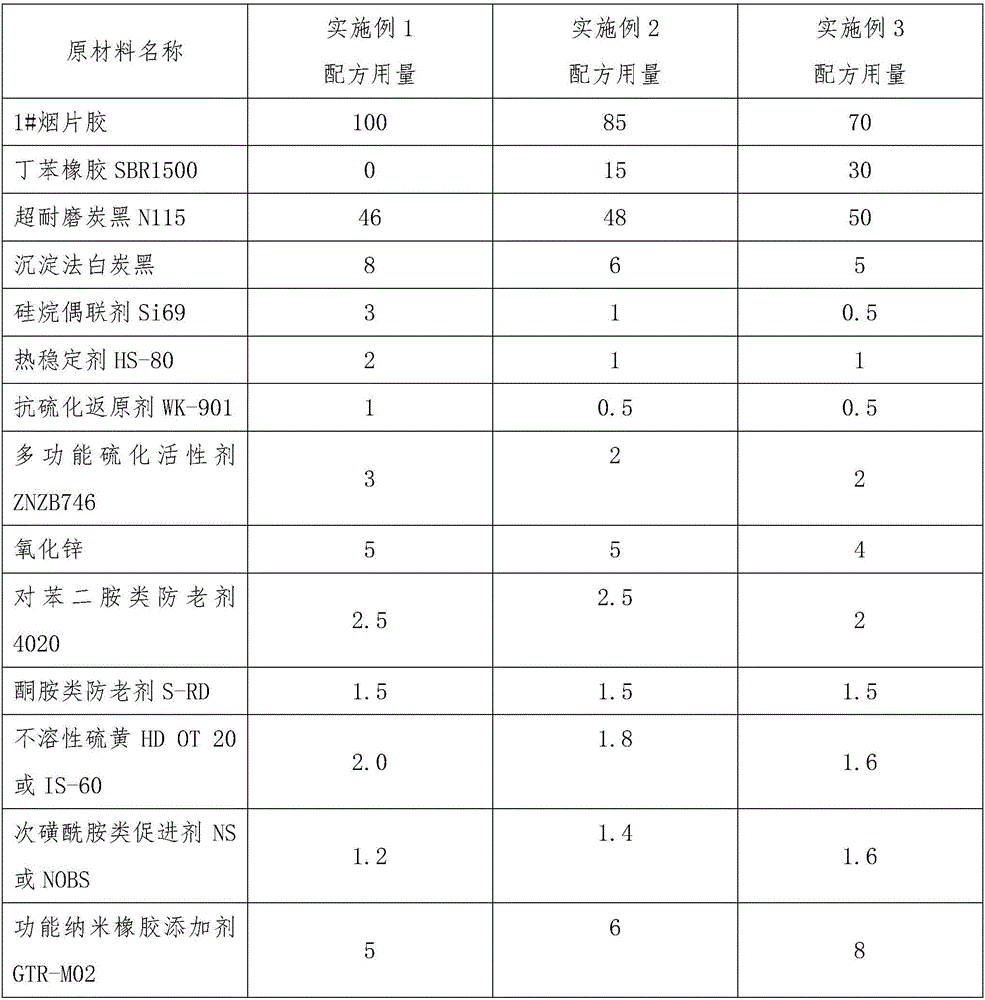

Heat-conducting high-heat-conductivity aircraft tire tread rubber

ActiveCN105713246AGood thermal and electrical conductivityGood wear resistanceSpecial tyresP-PhenylenediamineButadiene-styrene rubber

The invention relates to a heat-conducting high-heat-conductivity aircraft tire tread rubber which is prepared from the following raw materials in parts by weight: 70-100 parts of 1# bacon rubber, 30-0 parts of styrene-butadiene rubber (SBR) 1500, 46-52 parts of super-wear-resistance carbon black N115, 5-8 parts of precipitated white carbon black, 0.5-3 parts of silane coupling agent Si69, 1-2 parts of heat stabilizer HS-80, 0.5-1.0 part of anti-reversion agent WK-901, 1-3 parts of multifunctional vulcanization activator ZNZB746, 3-5 parts of zinc oxide, 1-3 parts of p-phenylenediamine anti-aging agent 4020, 1-2 parts of ketoamine anti-aging agent S-RD, 1.5-2.5 parts of insoluble sulfur HD OT 20 or IS-60, 0.8-2.0 parts of sulfenamide accelerator NS or NOBS and 3-10 parts of functional nano rubber additive GTR-M02. The tread rubber has the characteristics of favorable heat conductivity, favorable electric conductivity, favorable wear resistance and high heat stability, and has the advantages of higher tensile strength, higher elongation at break and higher 300% stress at definite elongation.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Rubber Composition and Pneumatic Tire Using Same

ActiveUS20180186975A1Improve wear resistanceHigh tensile strengthSpecial tyresPolymer scienceButadiene-styrene rubber

The present technology provides a rubber composition containing a diene rubber including a styrene-butadiene copolymer component including at least one type of styrene-butadiene copolymer and a reinforcing filler. The bonded styrene content is from 5 to 50 wt. %. The total amount of styrene of an ozone decomposed component S1 including one styrene-derived unit and an ozone decomposed component S1V1 including one styrene-derived unit and one 1,2-bonded butadiene-derived unit is less than 80 wt. % of the amount of bonded styrene. The total amount of styrene of the decomposed component S1V1 is less than 10 wt. % of the amount of bonded styrene. The integrated intensity of an ozone decomposed component S1V2 including one styrene-derived unit and two 1,2-bonded butadiene-derived units is less than 15% of the integrated intensity of all decomposed components including styrene-derived units. The vinyl content of a butadiene portion is not less than 50%.

Owner:YOKOHAMA RUBBER CO LTD

Polyvinyl chloride mixture and preparation method therefor

ActiveUS20160115307A1Low elongationPoor toughnessLiquid surface applicatorsCoatingsPolyvinyl chloridePolymer chemistry

The present invention discloses a polyvinyl chloride mixture and a preparation method thereof. The mixture comprises the following components in parts be weight: (a) polyvinyl chloride resin of 100 parts and (b) a toughening modifier of 2-20 parts, the toughening modifier being rubber powder whose elongation at break is 1601%-2200% and which contains the percentage of chlorine of 5-45 wt %. The elongation at break of the polyvinyl chloride mixture of the present inventions is greatly improved, and the defect of low elongation at break of the polyvinyl chloride product is substantially solved accordingly; therefore, the application scope of polyvinyl chloride surely will be greatly widened.

Owner:SHANDONG RIKE CHEM

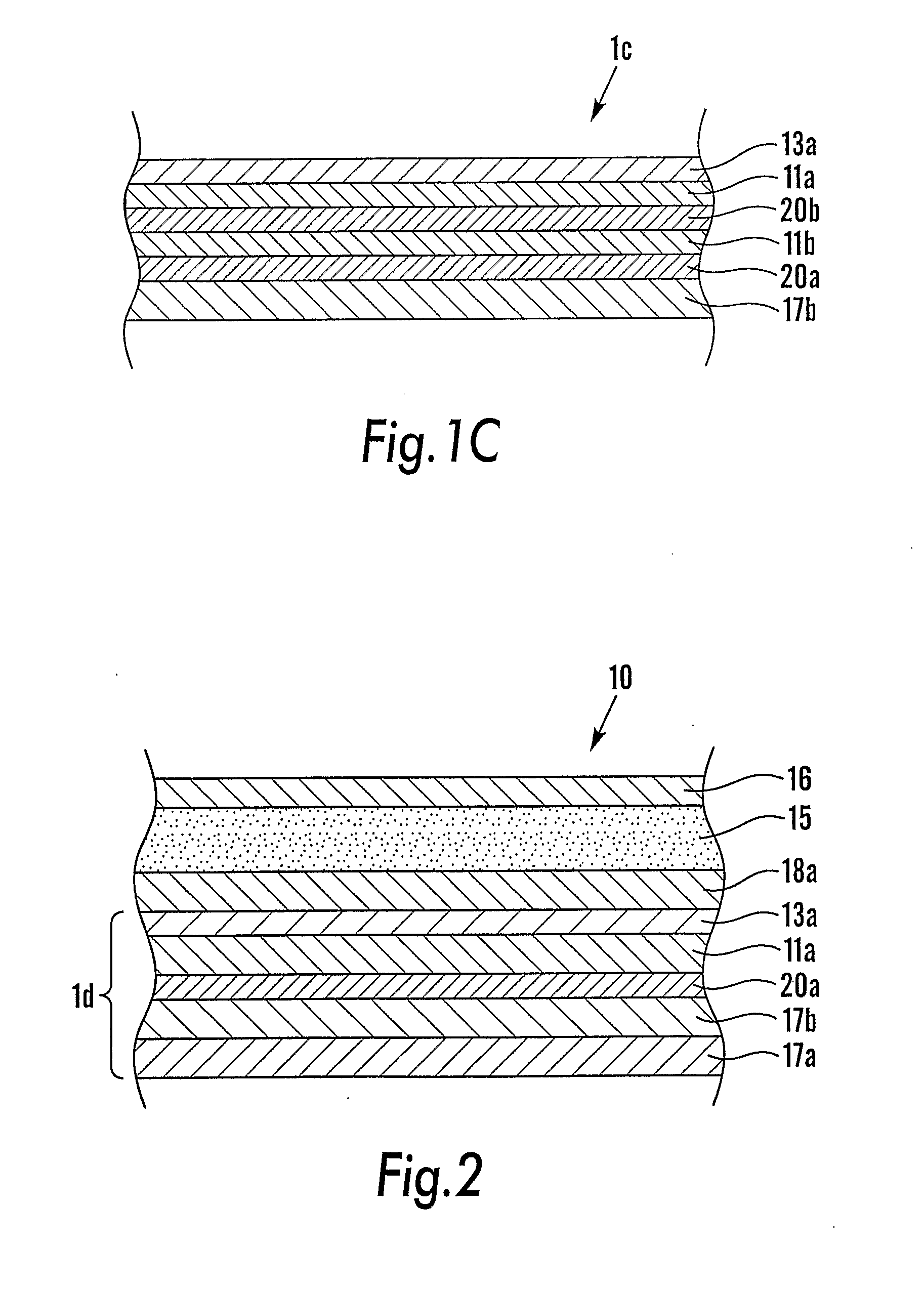

Polymer Film, a Packaging Laminate Comprising the Polymer Film, a Packaging Container Formed from the Packaging Laminate and a Process for the Production of the Polymer Film

InactiveUS20070254147A1High oxygen barrierGuaranteed uptimeSynthetic resin layered productsPaper/cardboard layered productsPolyolefinEngineering

A polymer film comprising a gas barrier coating of SiOx directly coated onto a first side of a polymer carrier layer. The film also comprises a heat sealable polyolefin layer arranged on a second side of the polymer carrier layer. The invention also relates to a packaging laminate comprising the polymer film and to a packaging container produced from such a packaging laminate. The invention further relates to a process for the production of the polymer film.

Owner:TETRA LAVAL HLDG & FINANCE SA

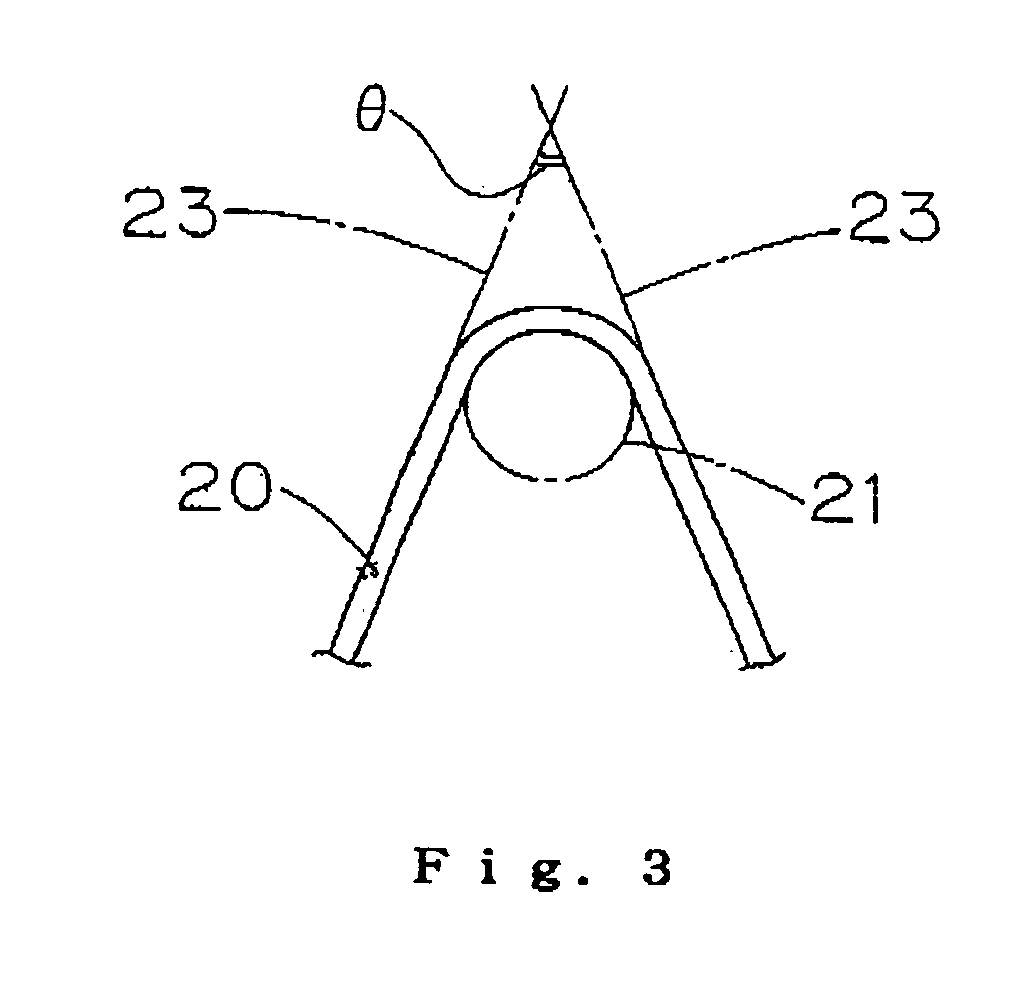

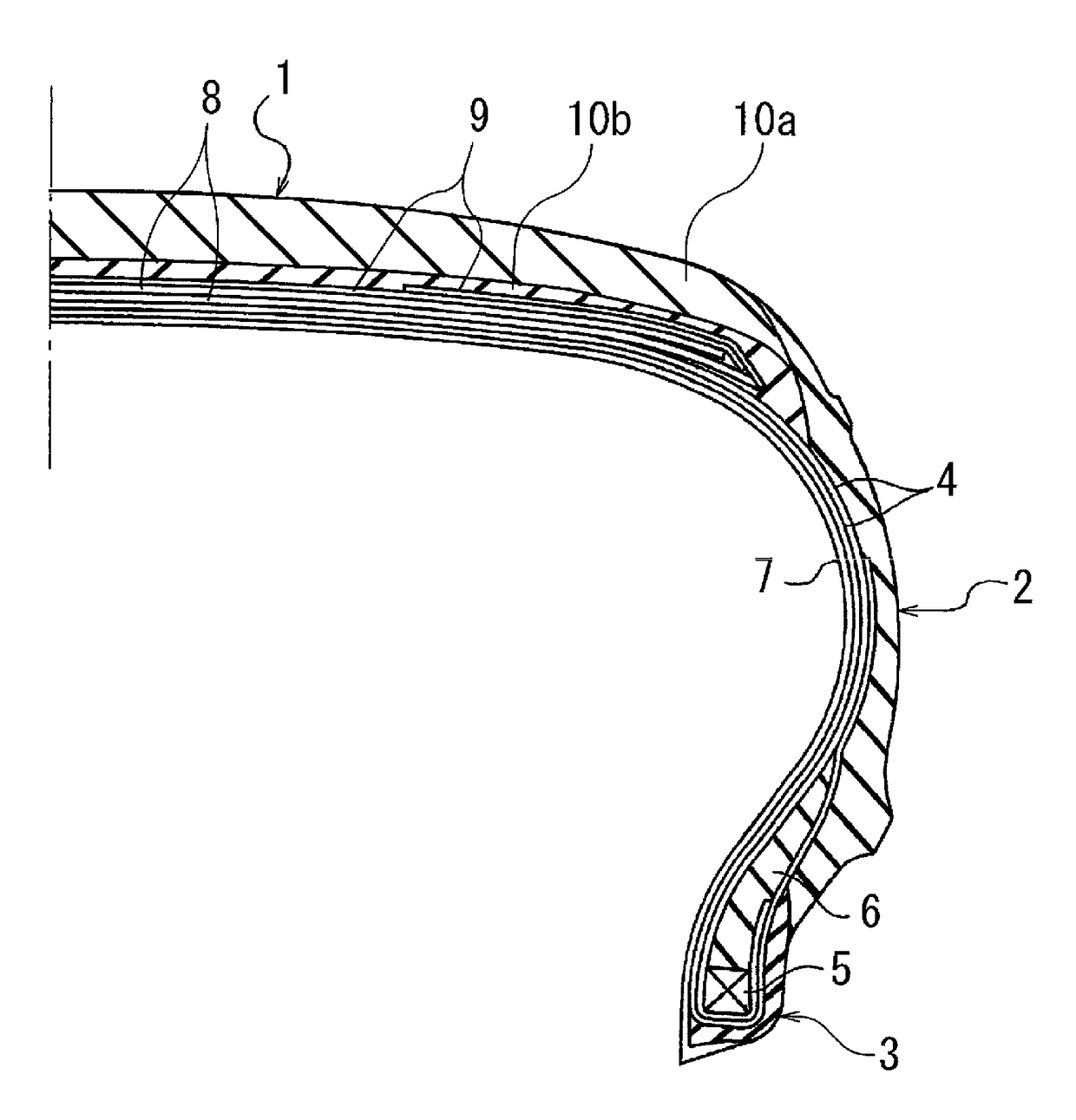

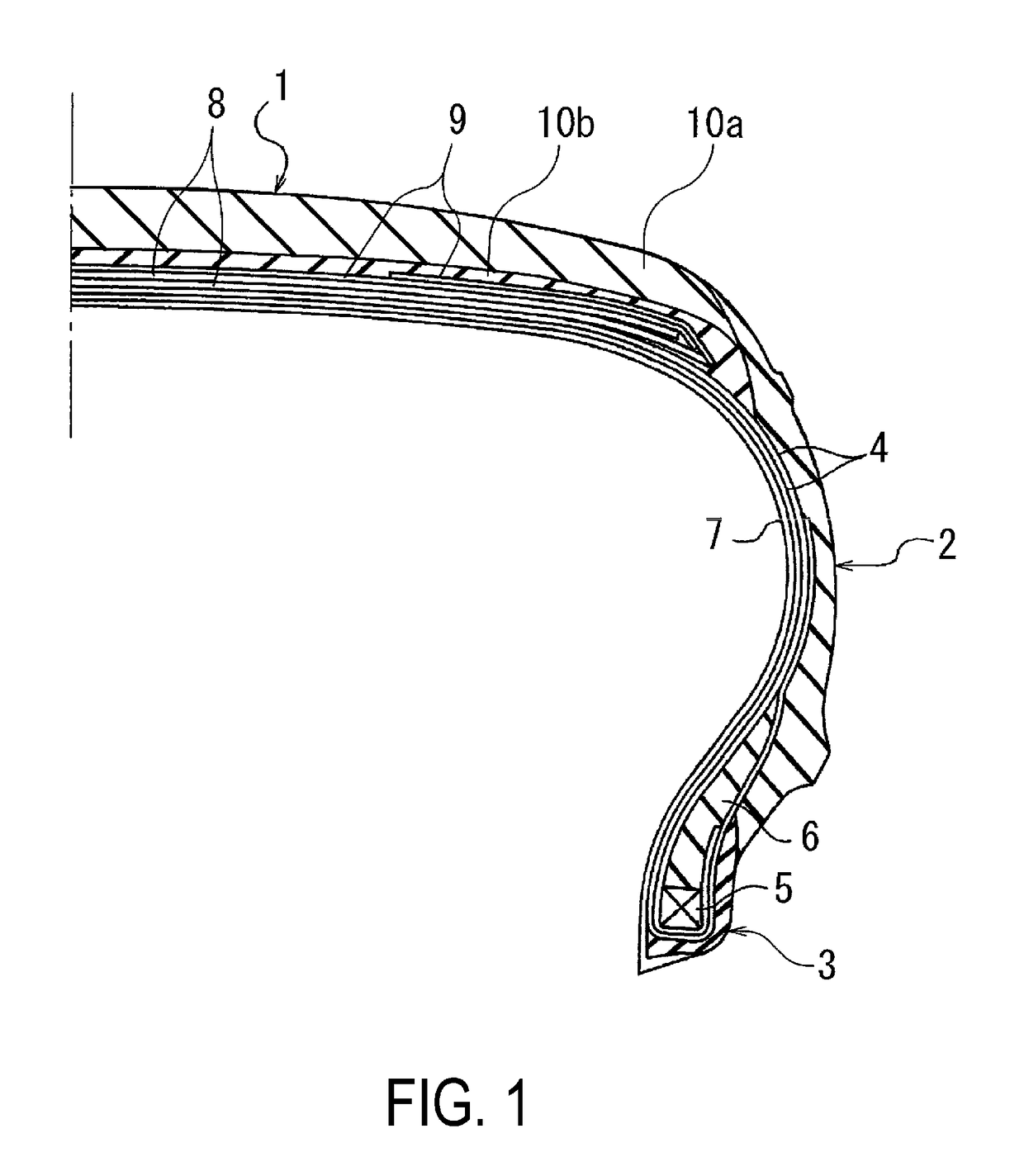

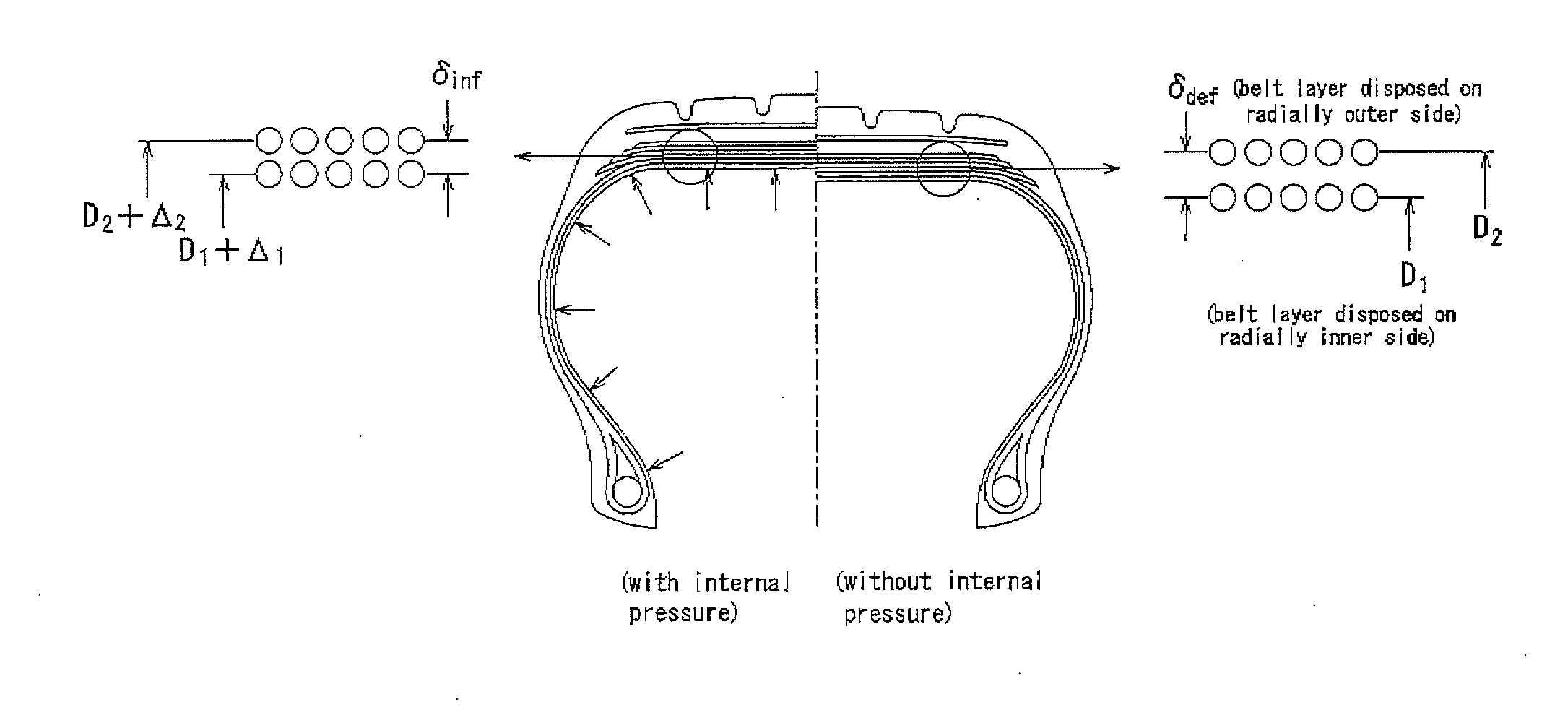

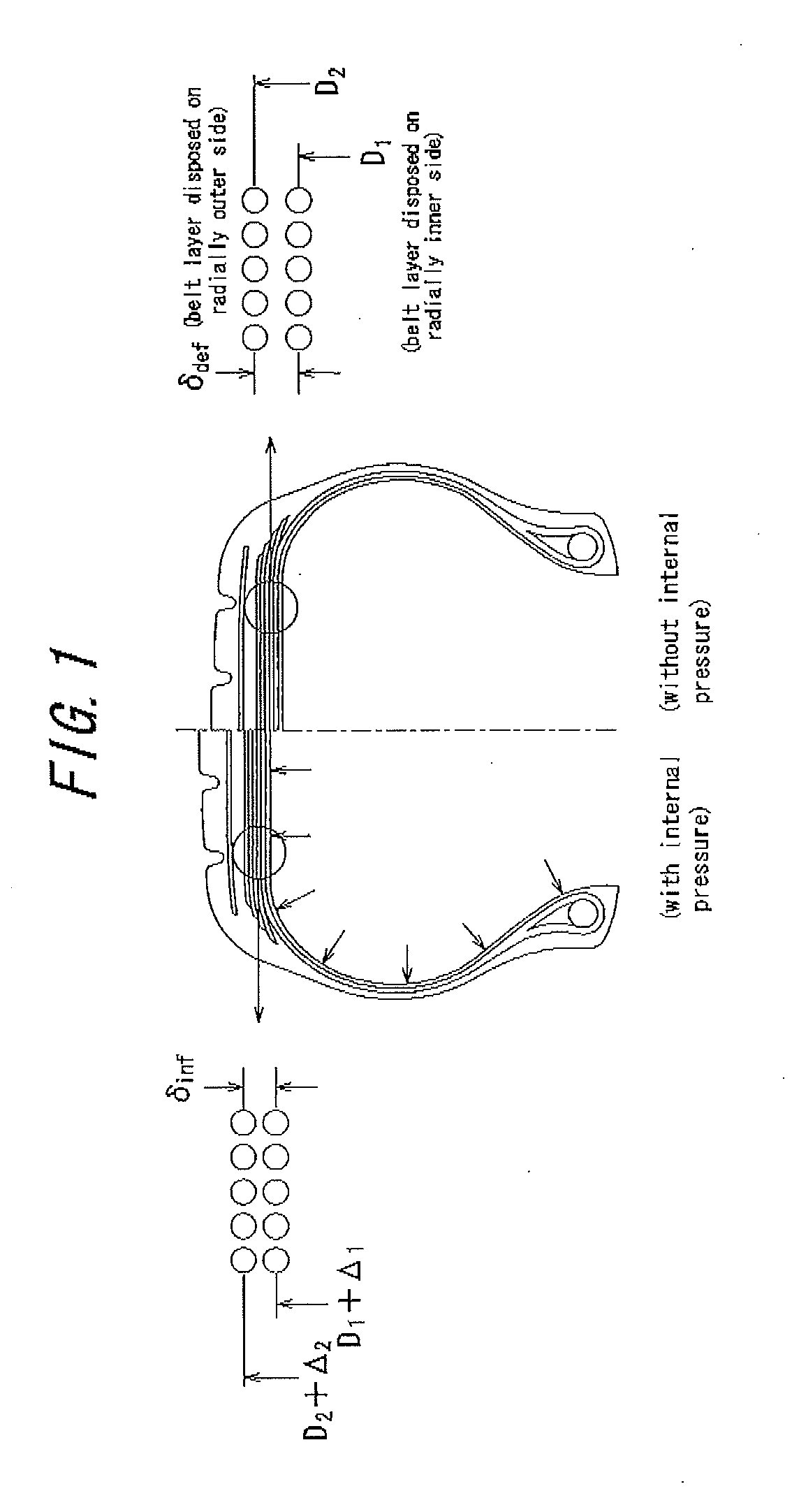

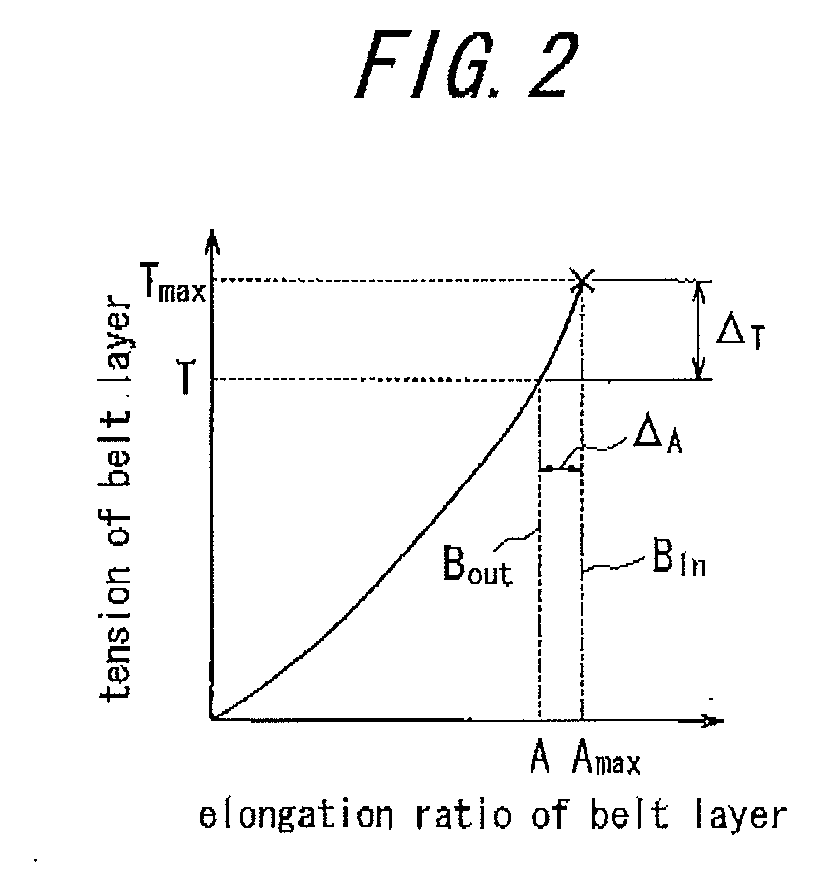

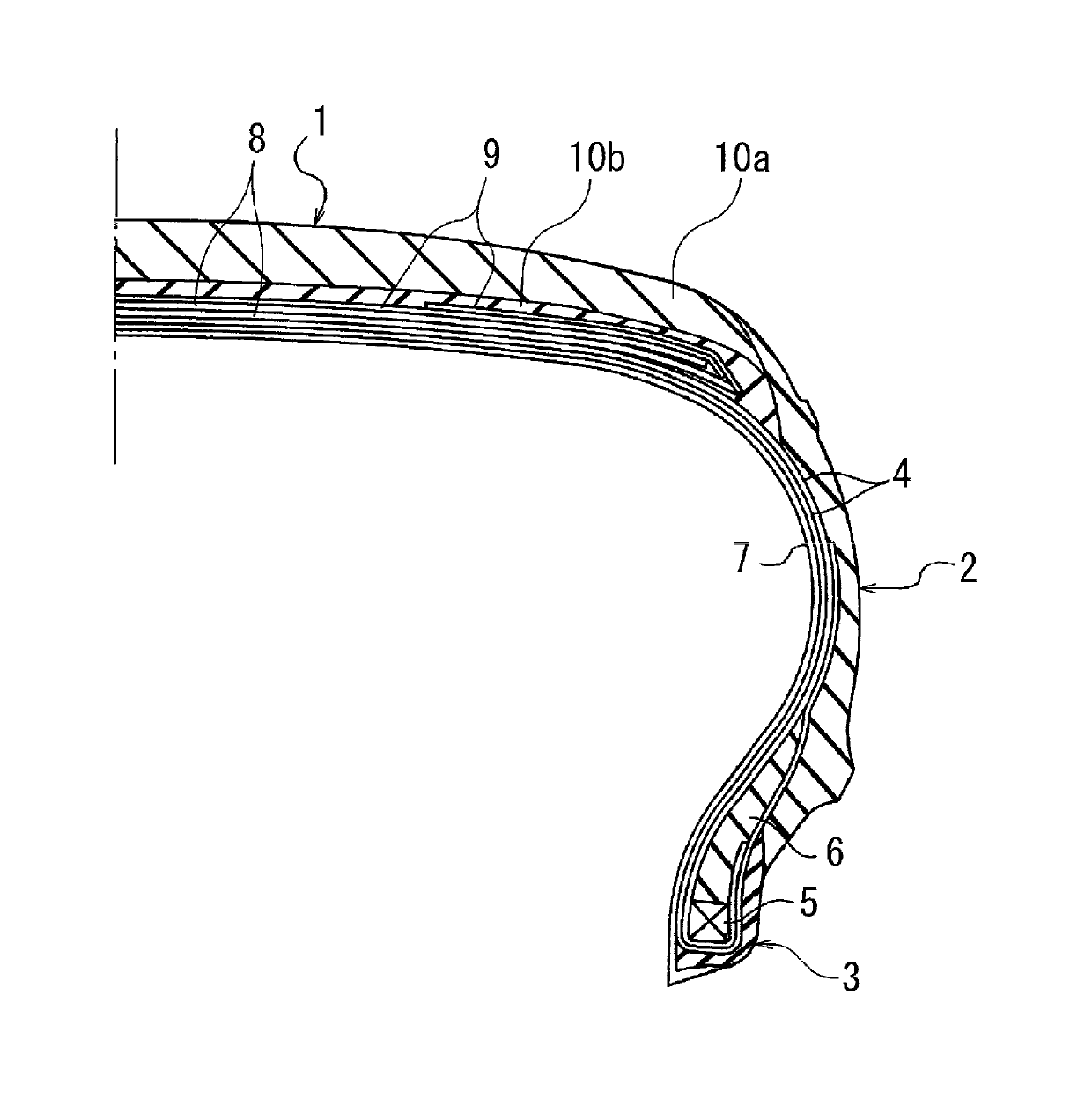

Radial tire for aircraft

InactiveUS20100276053A1Reduce stiffnessElongation at breakPneumatic tyre reinforcementsWheelsFiberHigh pressure

The present invention relates to a radial tire for an aircraft having a belt structure capable of sufficiently satisfying a demand for recent high pressure resistance without increase in tire weight and more particularly to a radial tire for an aircraft having a carcass serving as a framework and toroidally extending between a pair of bead portions, and a belt disposed on a radially outer side of the carcass and consisting of at least two belt layers consisting of plies having a plurality of organic fiber cords coated with rubber, wherein the belt is configured in such a manner that elongation at break Lout of a radially outermost belt layer is smaller than elongation at break Lin of a radially innermost belt layer, a ratio Lout / Lin satisfies the relationship 0.8<Lout / Lin<0.95, and elongation at break of a radially outer belt layer is not more than elongation at break of a radially inner belt layer between respective radially adjacent belt layers.

Owner:BRIDGESTONE CORP

Extrusion coated textile laminate with improved peel strength

InactiveUS20150308039A1High tensile strengthFewer line breaksSynthetic fibresSynthetic resin layered productsElastomerFiber

The present invention relates to nonbreathable extrusion coated nonwoven structures. The structures comprise a nonwoven web comprised of monocomponent or bicomponent fibers having a coating comprising LDPE optionally blended with LLDPE and / or an elastomer. The monocomponent or bicomponent fibers comprise an ethylene based polymer, preferably at the surface of the fiber.

Owner:DOW GLOBAL TECH LLC +1

Graphene electrothermal film as well as preparation method and application thereof

The invention discloses a graphene electrothermal film as well as a preparation method and application thereof. The graphene electrothermal film is prepared from the following raw materials in parts by weight: 68-90 parts of graphene oxide, 30-40 parts of water-based fluorocarbon resin, 11-15 parts of calcium dinonylnaphthalene sulfonate, 10-15 parts of zinc lactate and 6-18 parts of 2,5-furan dioctyl phthalate. The graphene electrothermal film disclosed by the invention is prepared from the graphene oxide, the water-based fluorocarbon resin, calcium dinonylnaphthalenesulfonate, zinc lactate and the 2,5-furan dioctyl phthalate, and has excellent repeated bending resistance, electrical conductivity and heat conductivity; the graphene electrothermal film disclosed by the invention also has the advantages of high elongation at break, high strength, strong adhesive force, small leakage current, low resistance change rate and the like; and the preparation process is simple and can realize industrial production.

Owner:内蒙古石墨烯材料研究院

Thermoplastic elastomer composition and method for producing same

ActiveUS20180086904A1High low temperature impact resistanceImprove mechanical propertiesElastomerPolymer science

Provided is a thermoplastic elastomer composition with which it is possible to obtain a molded article having exceptional low-temperature impact resistance. A thermoplastic elastomer composition is produced that contains a crystalline olefin polymer (A) and an ethylene-α-olefin (C4-20)—unconjugated polyene copolymer (B) that satisfies requirements (1) and (2). (1) The B value represented by the equation: ([EX]+2[Y]) / (2×[E]×([X]+[Y])) is 1.20 or higher. [E], [X] and [Y] respectively indicate the molar fraction of structural units derived from ethylene, the molar fraction of structural units derived from C4-20 α-olefin and the molar fraction of structural units derived from unconjugated polyene, and [EX] indicates the diad chain fraction of structural units derived from ethylene-structural units derived from C4-20 α-olefin. (2) The molar ratio of structural units derived from ethylene with respect to structural units derived from α-olefin (C4-20) of copolymer (B) is 40 / 60-90 / 10.

Owner:MITSUI CHEM INC

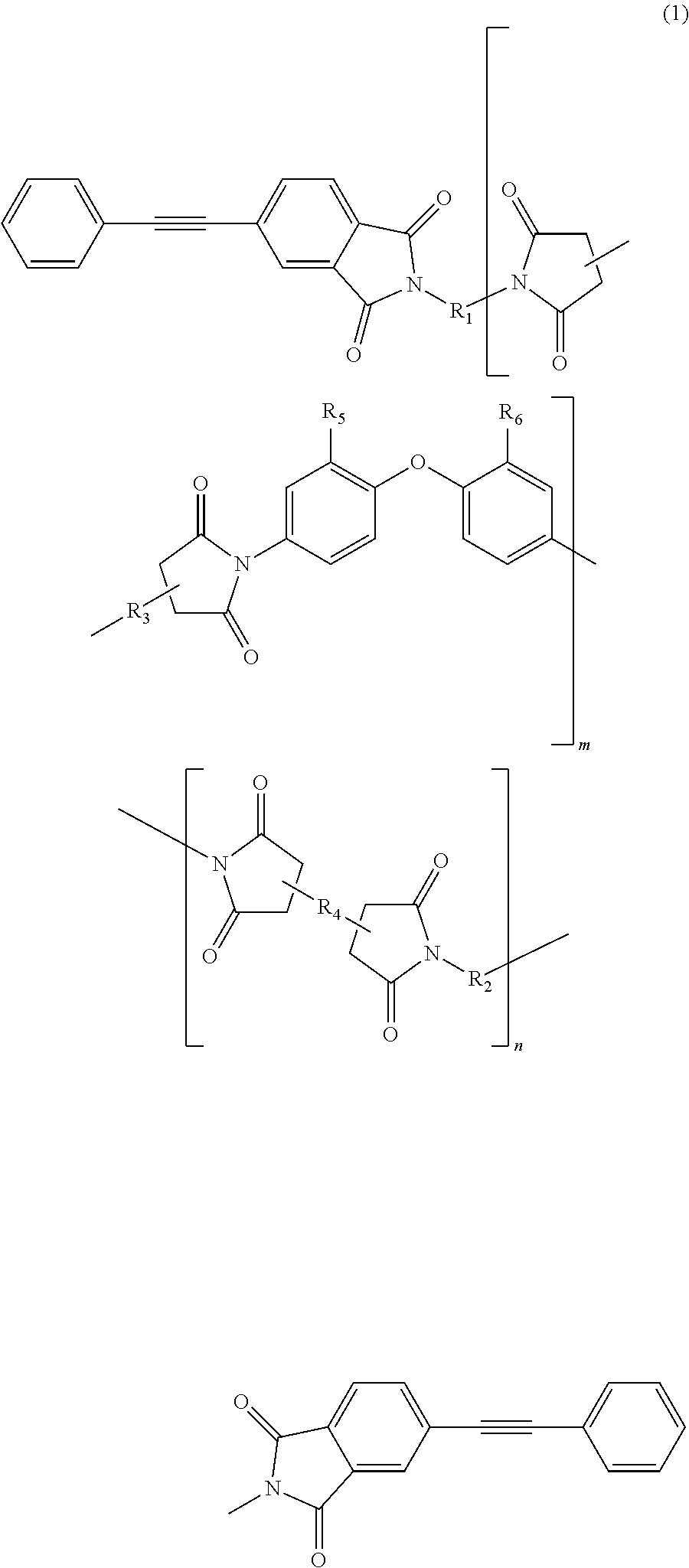

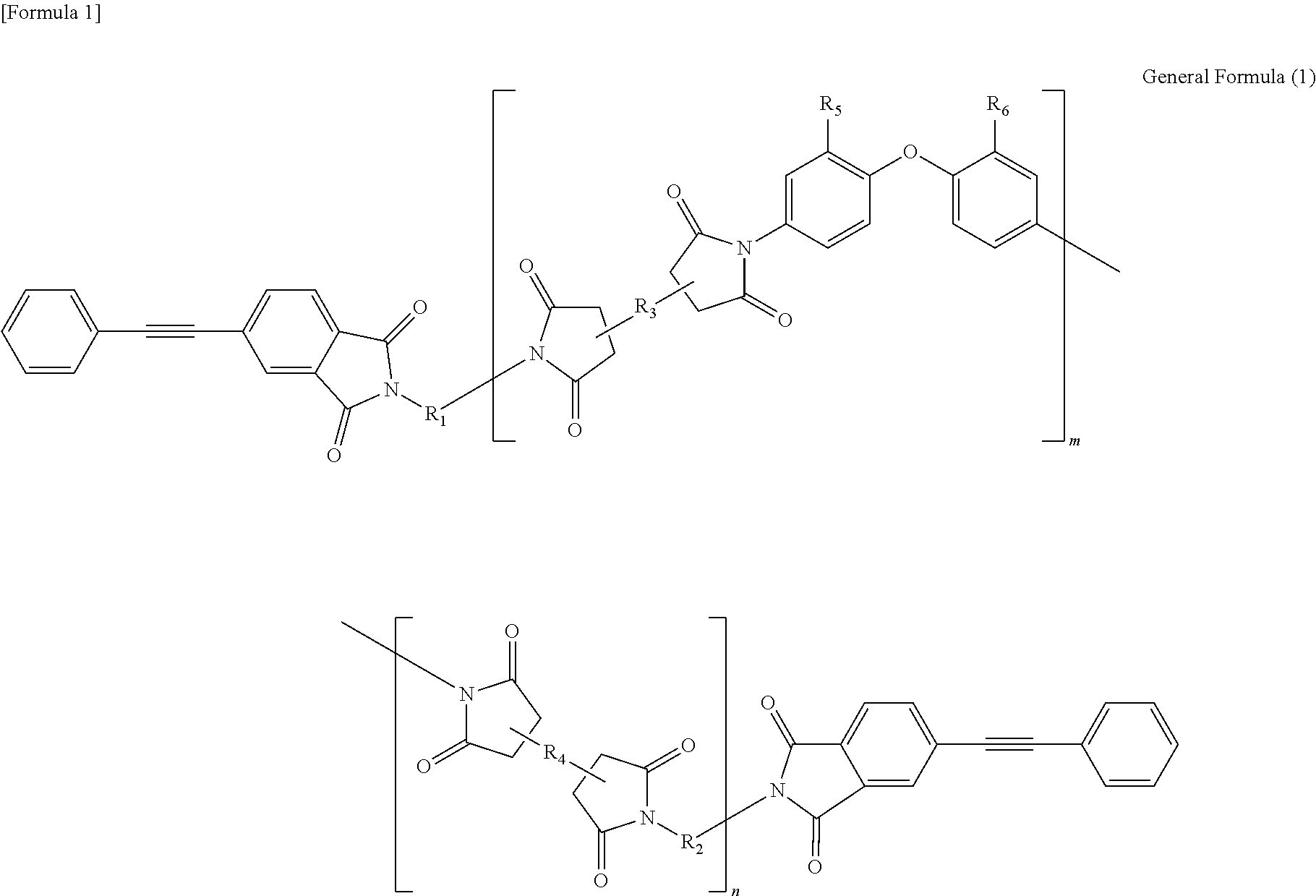

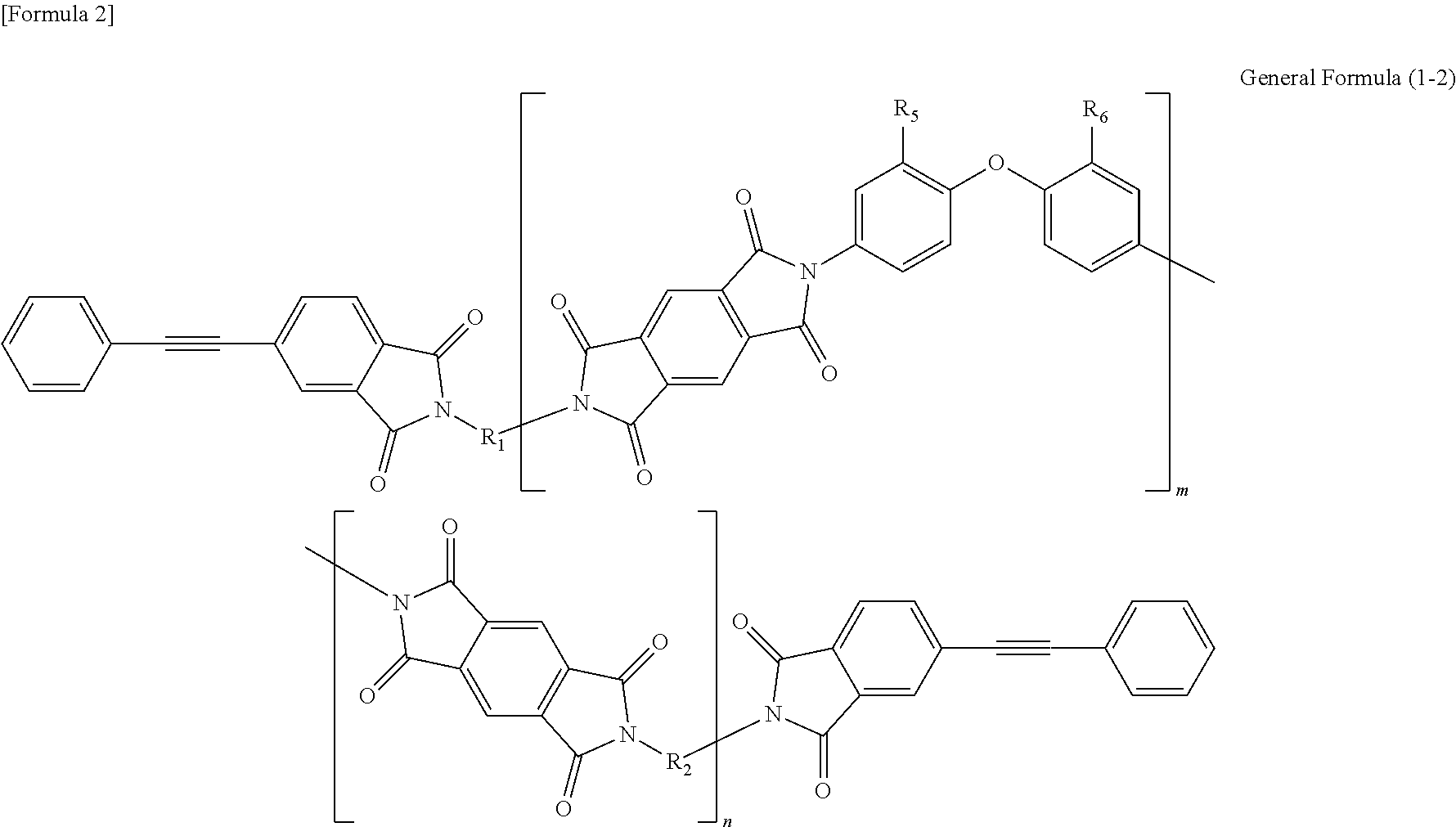

Soluble terminally modified imide oligomer using 2-phenyl-4, 4′-diaminodiphenyl ether, varnish, cured product thereof, imide prepreg thereof, and fiber-reinforced laminate having excellent heat resistance

ActiveUS8846552B2Poor processabilityImprove balanceOrganic chemistryAdhesive processes with surface pretreatmentFiberSolubility

A novel terminally modified imide oligomer having excellent solubility in organic solvents, excellent solution storage stability, and excellent molding properties such as low melt viscosity. Also, a varnish obtained by dissolving the terminally modified imide oligomer in an organic solvent; a cure product obtained by using the terminally modified imide oligomer and having excellent thermal and mechanical characteristics such as heat resistance, elastic modulus, tensile strength at break and tensile elongation at break; a prepreg; and a fiber-reinforced laminate. The soluble terminally modified imide oligomer is represented by general formula (1). In the formula, R1 and R2 each represents a divalent aromatic diamine residue; R3 and R4 each represents a tetravalent aromatic tetracarboxylic acid residue; R5 and R6 each represents a hydrogen atom or a phenyl group, with R5 or R6 being a phenyl group; m and n satisfy the following relations: m≧1, n≧0, 1≦m+n≦20 and 0.05≦m / (m+n)≦1; and the repeating units may be arranged in blocks or randomly.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

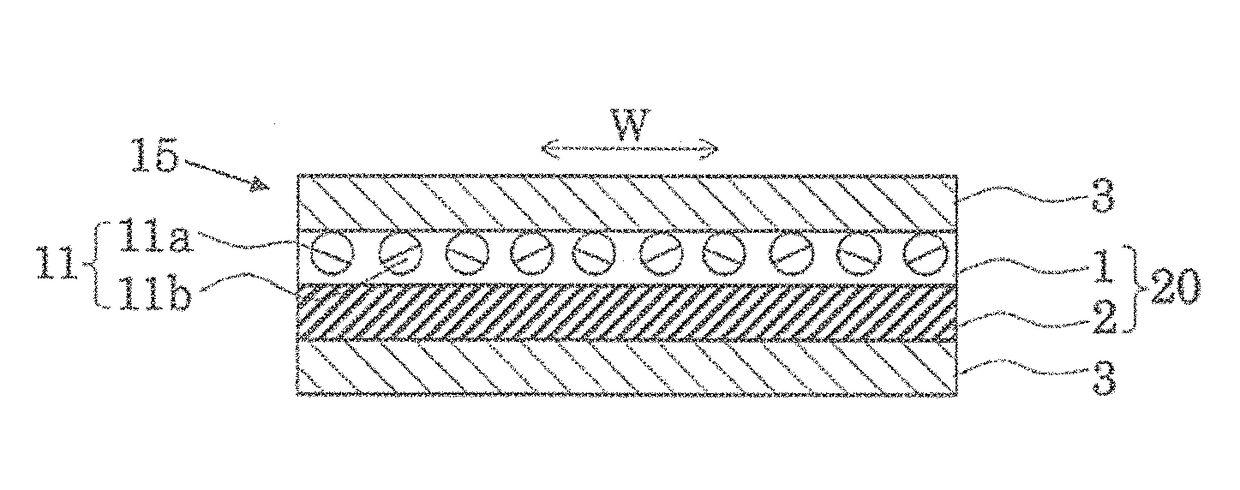

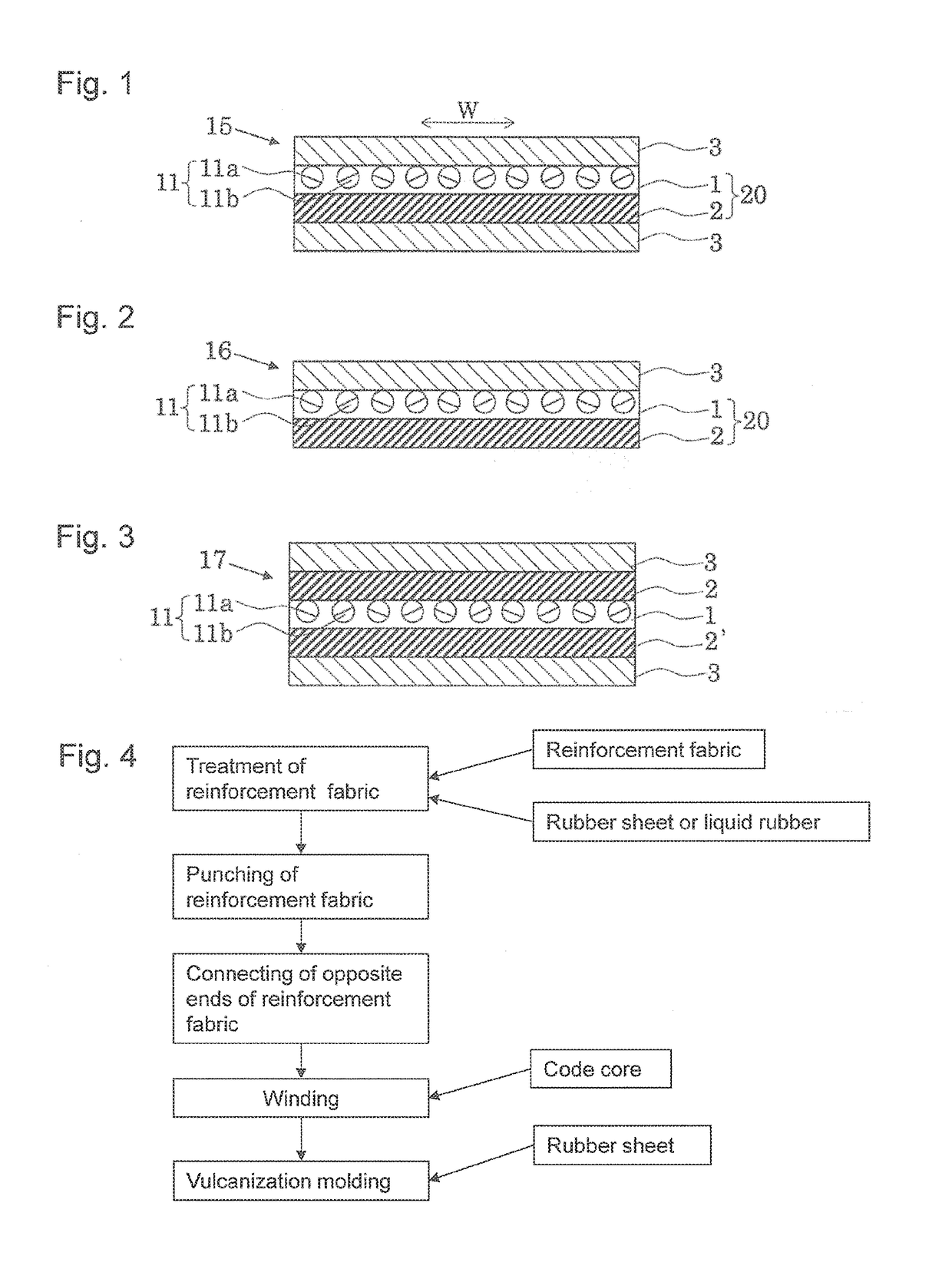

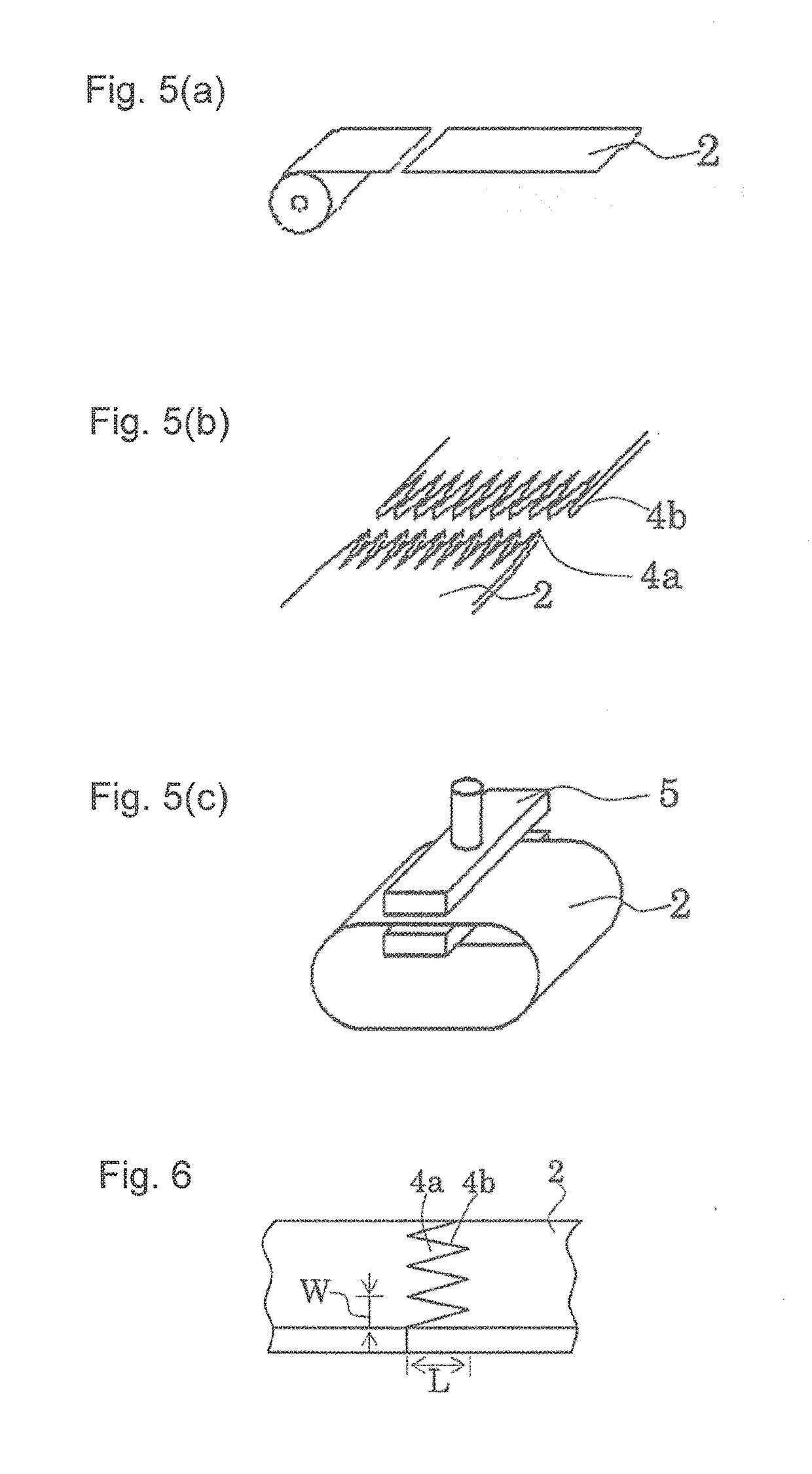

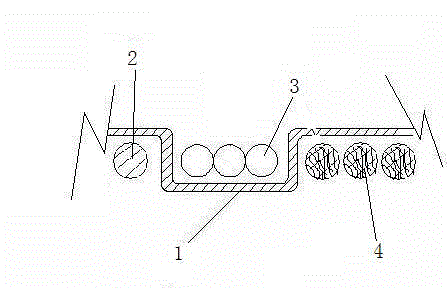

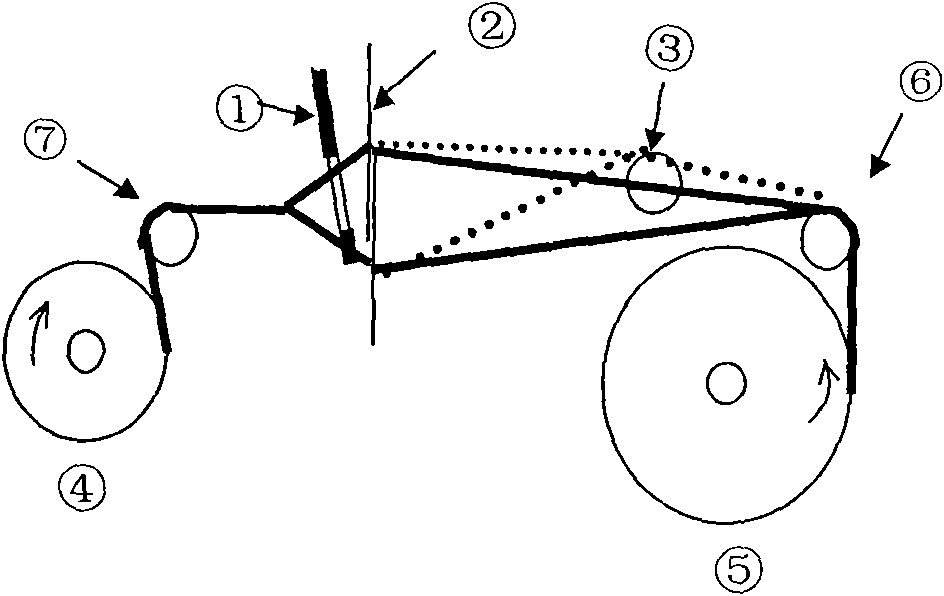

Endless flat belt and method for manufacturing the same

ActiveUS20170074350A1Stable tensionStabilize travel performanceDriving beltsBeltsEngineeringMechanical engineering

An endless flat belt includes an inner rubber layer 1, a cord core 11 buried in the inner rubber layer 1 and spirally wound at a predetermined pitch in a width direction of the belt, and a reinforcement fabric 2 stuck to the inner rubber layer 1. The cord core comprises polyamide fiber. Opposite ends of the reinforcement fabric 2 are connected with each other into an endless form by adhesion or sewing. A surface rubber layer 3 is stuck to a surface of the reinforcement fabric 2 which is opposite a surface thereof stuck to the inner rubber layer 1.

Owner:NITTA CORP

Antibacterial cool fabric

InactiveCN102912514ARefreshingGood moisture absorption and permeabilityWoven fabricsFiberBreaking strength

The invention discloses an antibacterial cool fabric which is woven by warp yarns and weft yarns, wherein the warp yarn is obtained by arranging the blended multifilament, flax multifilament and cotton multifilament at a circular proportion of 1:3:3; the blended multifilament is the long stapled cotton and superfine silver fiber blended multifilament; the specification of the multifilament is (200S / 3)-(300S / 3); the weft yarn is polypropylene monofilament with a diameter of 0.2mm; and the warp yarns and the weft yarns are woven into a composite-tissue structure. By interweaving monofilaments and multifilaments, the multifilaments all float on the whole cloth surface to realize good hand feeling; and the antibacterial cool fabric has the characteristics of low monofilament fineness, light specific gravity, high breaking strength, relatively high breaking elongation, good gloss, high humidity absorbability and permeability and the like as well as excellent wearability such as the gentle gloss of silk, the humidity absorbability and permeability of cotton fiber, the coolness of flax and the like. The mixed silver fiber is partially exposed on the fabric surface, can realize an antibacterial effect, and has good wear resistance and washing resistance.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Strong yarn with forming filaments

InactiveCN100336948CFavorable roundingReduce the risk of disengagementPedestrian/occupant safety arrangementFilament/thread formingHigh intensityEngineering

A yarn containing filaments made from synthetic polymers has a cross-section having at least 5 vertices, a titer of 1 to 7 dtex and a tenacity of at least 60 cN / tex. The filaments of the yarn preferably have a cross-section having 5 to 8 vertices, possibly with indentations between the vertices. The cross-section of the filaments is preferably star-shaped. The yarn preferably has a tenacity of 60 to 85 cN / tex, an elongation at break of 15% to 35%, a hot-air shrinkage of 4% to 10% and a stretch recovery of 250 to 400 cN / tex. The yarn is excellently suited for use in the manufacture of industrial fabrics, particularly airbag fabrics.

Owner:POLYAMIDE HIGH PERFORMANCE

Production method of fabric for gas bag

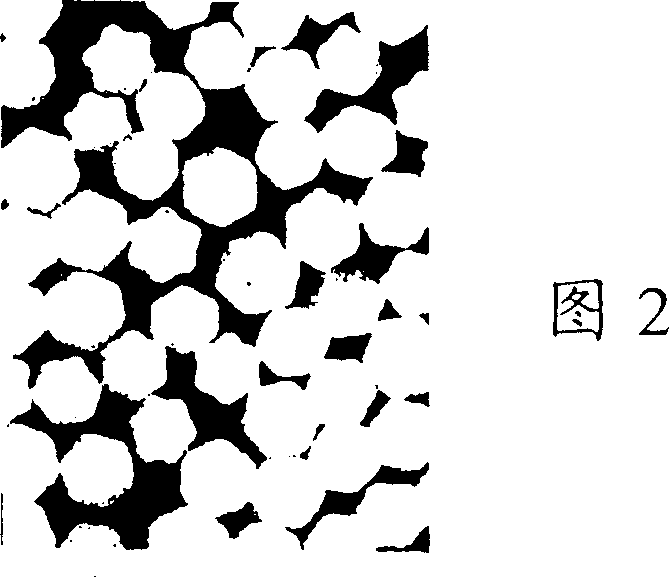

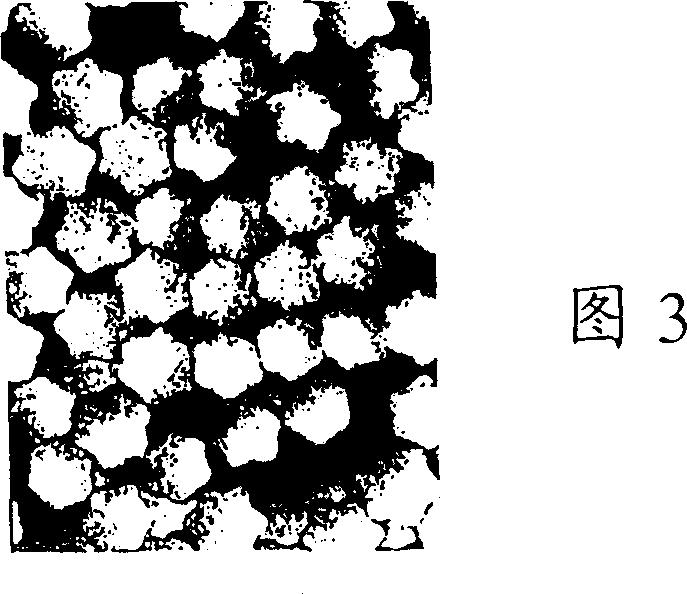

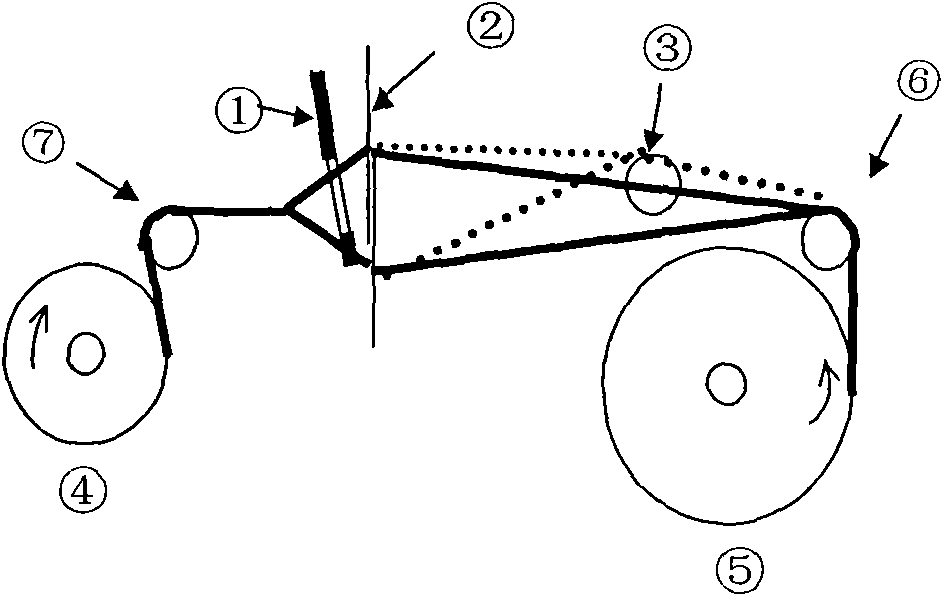

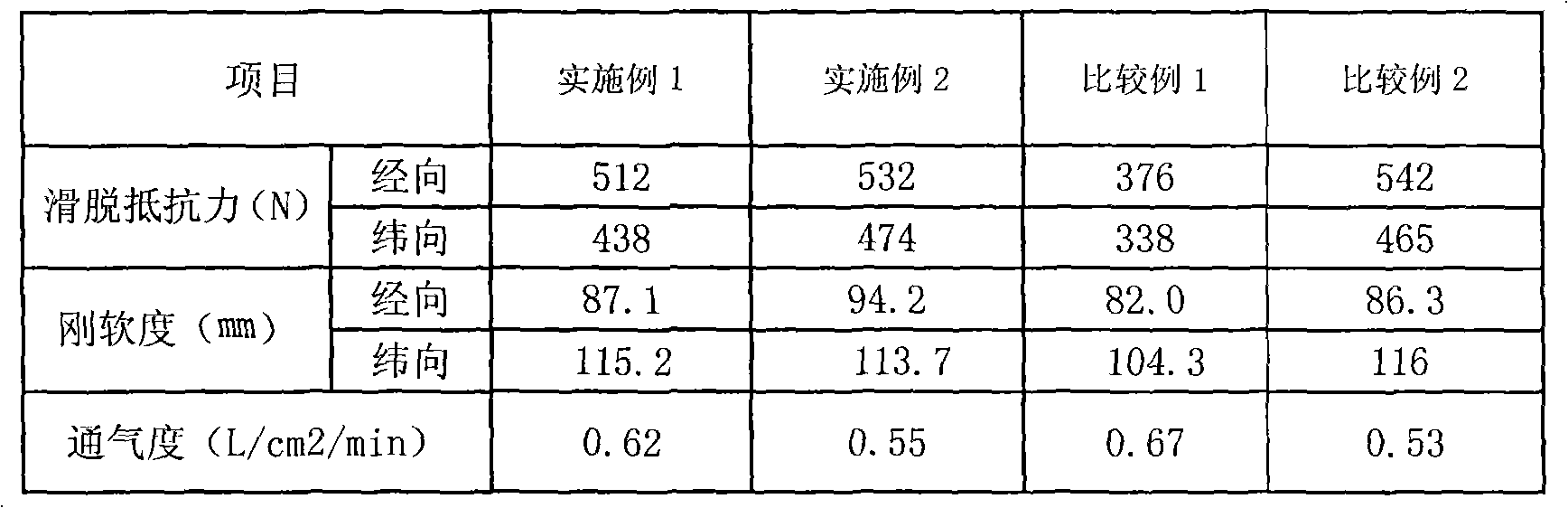

InactiveCN101886307AReduce air permeabilityHigh slip resistanceLoomsWoven fabricsAfter treatmentEngineering

The invention discloses a production method of fabric for a gas bag, which comprises the step of weaving. In the fabric weaving process, a presser bar is additionally arranged below lamella warp between the heald frame of a weaving machine and the back beam of the weaving machine. The fabric obtained by the invention has no need of after-treatment and has good flexibility, low gas permeability and high slip resistance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

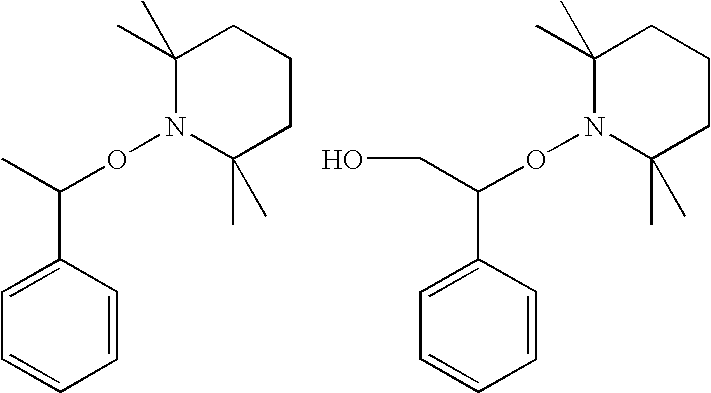

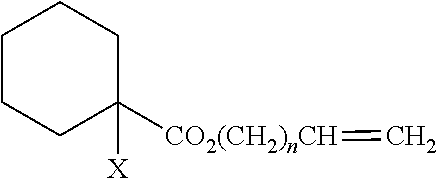

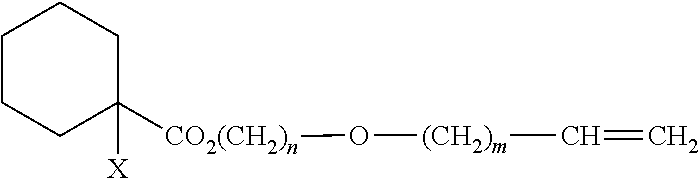

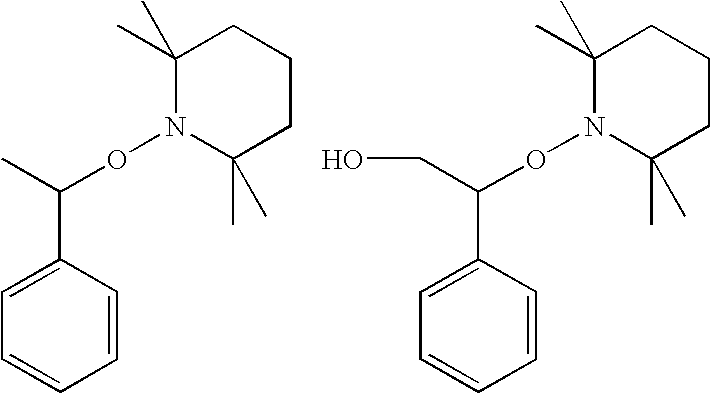

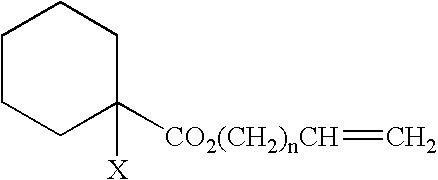

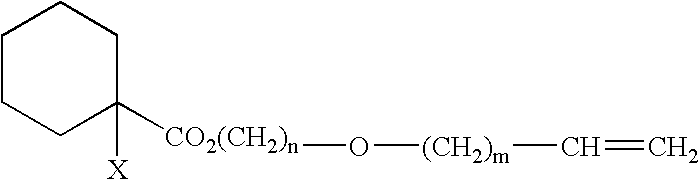

Curable composition

ActiveUS8067498B2Good adhesivenessIncrease resistanceOther chemical processesVehicle sealing arrangementsSilylenePolymer science

The present invention has its object to provide a transparent curable composition which may be prepared as a one package formulation, and which is excellent in strength, elongation at break, weather resistance, and adhesiveness of the resultant cured product.In addition, the present invention provides a curable composition which comprises 100 parts by weight of a vinyl polymer (I) the main chain of which is the product of living radical polymerization and which contains a crosslinkable silyl group, and 1 to 200 parts by weight of a micronized hydrophobic silica (II). Furthermore, the present invention also provides a curable composition which comprises 100 parts by weight of a vinyl polymer (I) the main chain of which is the product of living radical polymerization and which contains at least one crosslinkable silyl group, and 1 to 200 parts by weight of a graft copolymer (III) obtained by graft polymerization of a crosslinkable rubber-like acrylic ester polymer and a vinyl monomer.

Owner:KANEKA CORP

Curable Composition

ActiveUS20080200613A1Suitable materialGood adhesivenessOther chemical processesVehicle sealing arrangementsSilylenePolymer science

The present invention has its object to provide a transparent curable composition which may be prepared as a one package formulation, and which is excellent in strength, elongation at break, weather resistance, and adhesiveness of the resultant cured product.In addition, the present invention provides a curable composition which comprises 100 parts by weight of a vinyl polymer (I) the main chain of which is the product of living radical polymerization and which contains a crosslinkable silyl group, and 1 to 200 parts by weight of a micronized hydrophobic silica (II). Furthermore, the present invention also provides a curable composition which comprises 100 parts by weight of a vinyl polymer (I) the main chain of which is the product of living radical polymerization and which contains at least one crosslinkable silyl group, and 1 to 200 parts by weight of a graft copolymer (III) obtained by graft polymerization of a crosslinkable rubber-like acrylic ester polymer and a vinyl monomer.

Owner:KANEKA CORP

Viscoelastic Foams Having High Dissipation Energy

A viscoelastic polyurethane foam formed from a polyisocyanate and a polyol composition comprising palm olein-based polyol in an amount of 10% to 35% by weight of the total polyol composition and petroleum-based polyol in an amount of 65% to 90% by weight of the total polyol composition. The dissipation energy of the viscoelastic polyurethane foam is between 0.01 J to 0.30 J as calculated based on a hysteresis loop normalized a density of 40.80 kg / m3. This shows that the viscoelastic foam produced has an improved dampening property. The introduction of palm olein-based polyol into the production of viscoelastic foam does not affect the support factors and mechanical properties of the foam produced. The viscoelastic foams can be produced using an amount of up to 35% of palm olein-based polyol derived from palm olein or up to 25% of palm olein-based polyol derived from a mixture of palm olein and soybean oil by weight of total composition without any adjustment in the catalyst package.

Owner:MALASIAN PALM OIL BOARD

Hollow fiber pore-forming agent and application thereof in fuel cells

ActiveCN112853530AReduce activation polarizationLower internal resistanceHollow filament manufactureCell electrodesElectrochemical responseFiber

The invention relates to a hollow fiber pore-forming agent and application thereof in fuel cells. The pore-forming agent is PAN-PVP coaxial hollow fiber prepared from peroxyacetyl nitrate and polyvinylpyrrolidone as raw materials, and a preparation method of the pore-forming agent comprises the following steps of preparing a PAN-PVP mixed solution from peroxyacetyl nitrate and polyvinylpyrrolidone; and then operating on a coaxial high-voltage electrostatic spinning machine, placing methyl silicone oil in an inner needle hole, placing the PAN-PVP mixed solution in an outer needle hole, and rotating a roller collector to collect the PAN-PVP coaxial hollow fiber. The PAN-PVP hollow fiber can form a three-dimensional network cross-linked cavity after a fuel cell anode is fired to remove the fiber, so that the connection of the anode in the hole is improved, the internal specific surface area of an electrolyte is increased, the activation polarization of the cell is integrally reduced, the electrochemical reaction area is increased, the internal resistance of the cell is reduced, and the substance diffusion is accelerated, and therefore, the output performance of the cell is finally improved, and attenuation of specific capacity is slowed down.

Owner:XIAMEN UNIV

Super linen-like knitted fabric

The invention relates to the technical field of spinning, in particular to a super linen-like knitted fabric. The super linen-like knitted fabric is weaved from, by weight, 30% to 60% of purified cotton bunchy yarn and 40% to 70% of cotton and linen composite yarn. The cotton and linen composite yarn is spun from, by weight, 50% to 60% of purified cotton fibers and 40% to 50% of linen fibers. Dueto the fact that the cotton and linen composite yarn is adopted, and the cotton and linen composite yarn is spun from the purified cotton fibers and the linen fibers, the cotton and linen composite yarn has the advantages of being good in strength, large in breaking elongation, good in elasticity and capable of forming yarn easily, and the super linen-like knitted fabric has a linen-like effect and the functions of absorbing moisture and dispelling sweat and has the advantages of being good in strength, large in breaking elongation and good in elasticity.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

Hard capsule

InactiveUS20160208125A1Excellent gel performanceLow hazePharmaceutical non-active ingredientsCapsule deliveryWater solubleEther

Owner:LOTTE FINE CHEM CO LTD

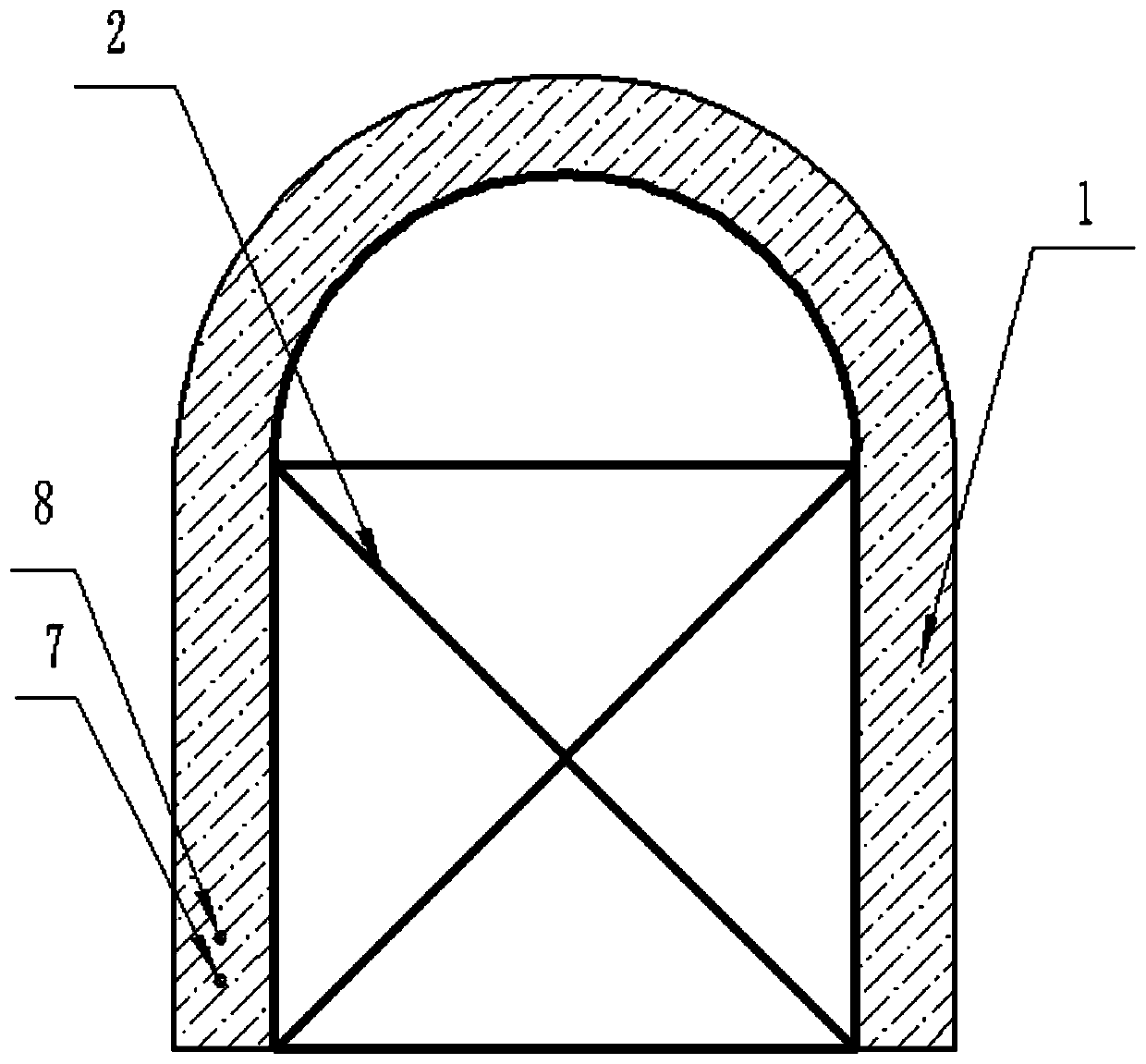

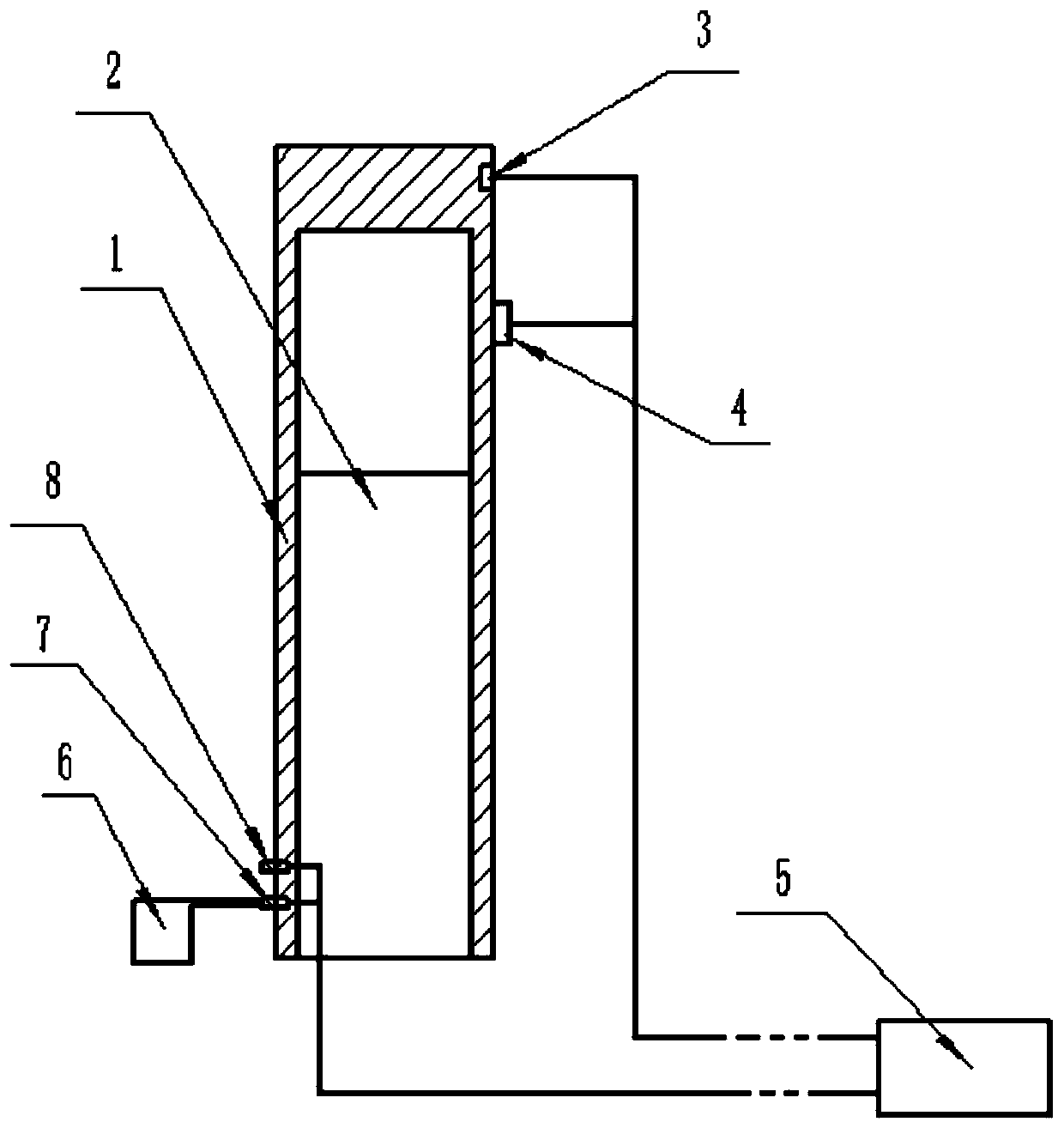

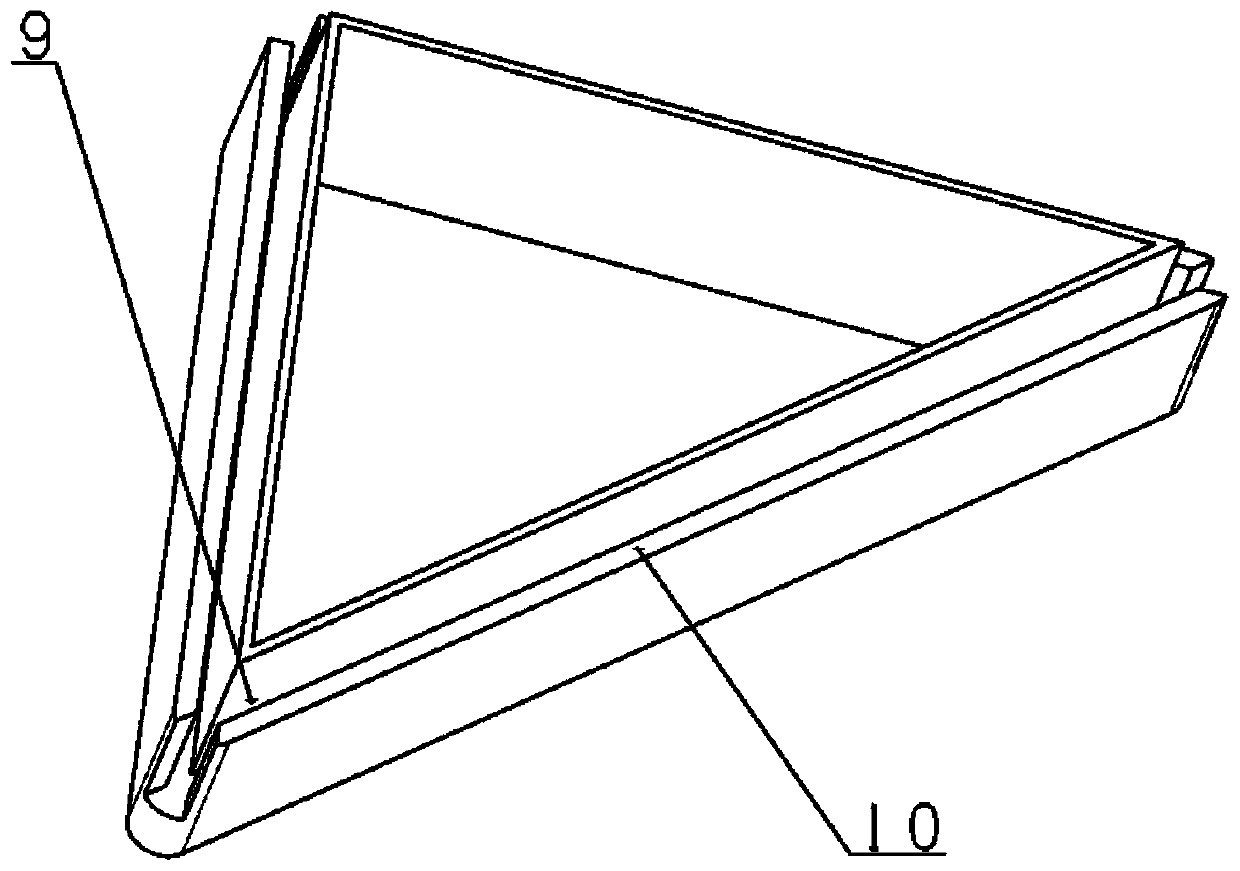

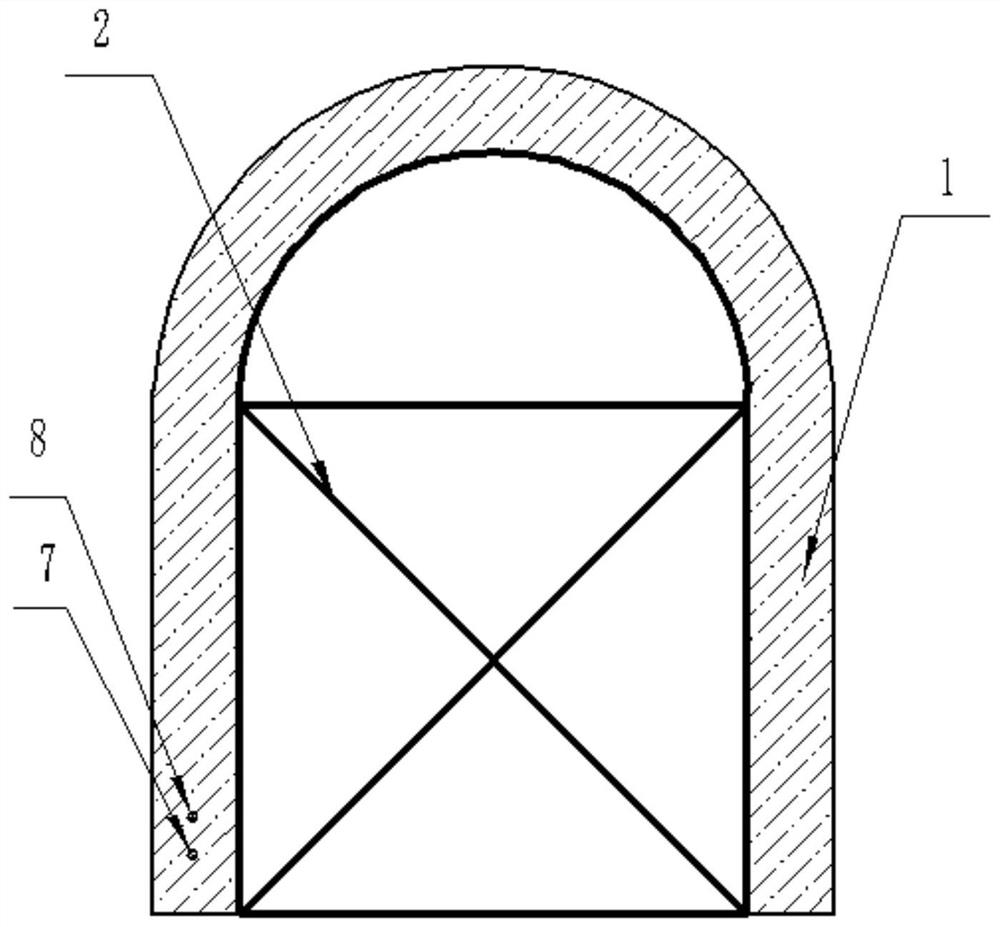

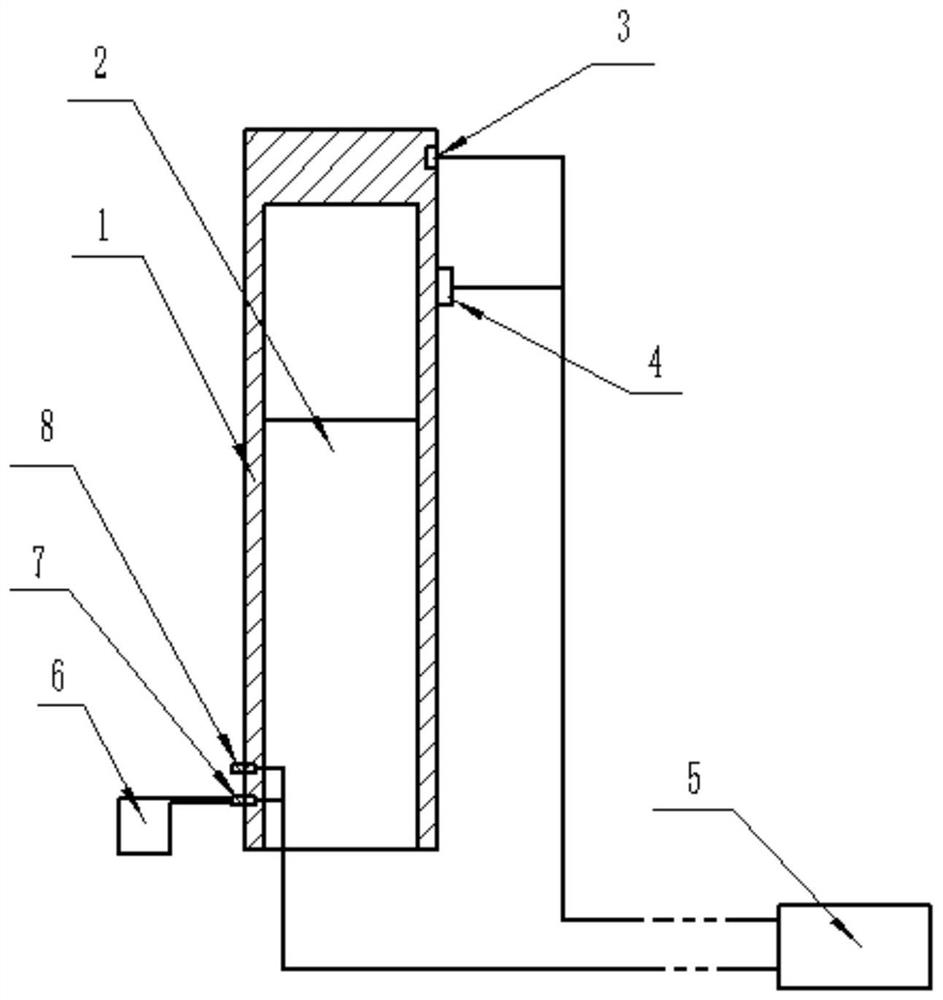

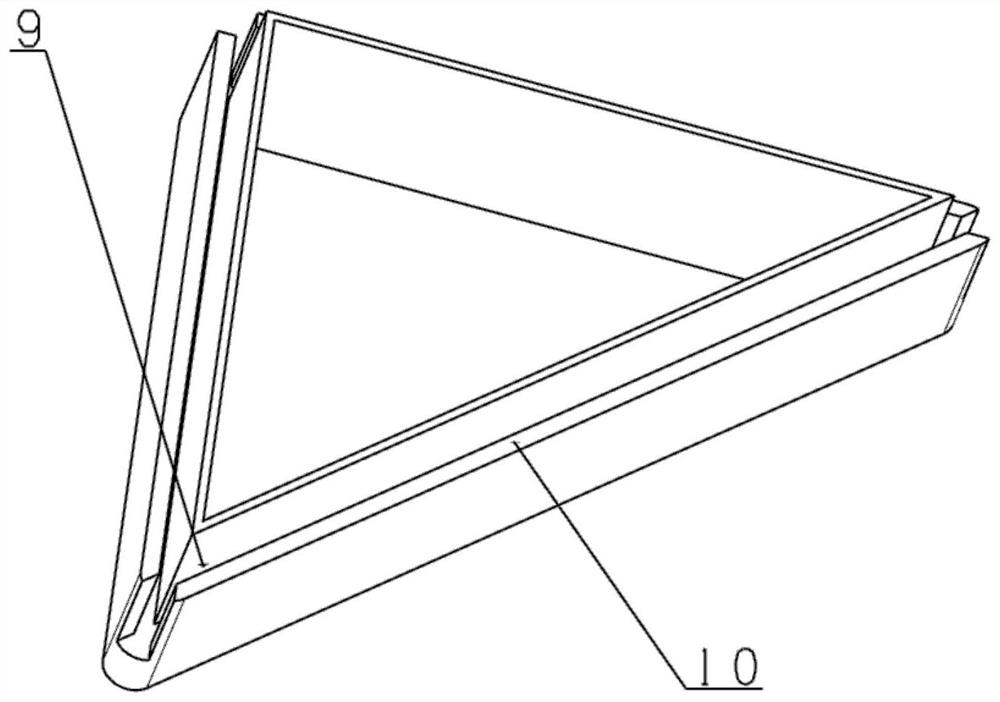

Combined rapid plugging device based on arched roadway

The invention relates to a combined rapid plugging device based on an arched roadway. The combined rapid plugging device comprises a temperature sensing air bag, a combined support and an automatic inflation system, the combined support is arranged in the temperature sensing air bag to support and fix the temperature sensing air bag, and the temperature sensing air bag is connected with the automatic inflation system; the temperature sensing air bag is an air bag with the arch-shaped top and can sense the surrounding temperature, different colors are shown according to different surrounding environment temperatures, and multi-section color changing is achieved; the automatic inflation system comprises a temperature sensor, a pressure sensor, a computer, an inflation device, an inflation solenoid valve and an exhaust solenoid valve. The device is simple in structure, rapid assembly and disassembly can be achieved, and automatic inflation and deflation can be achieved according to the set temperature and pressure.

Owner:SHANDONG UNIV OF SCI & TECH

Rubber composition and pneumatic tire using same

ActiveUS10472503B2Elongation at breakStrength break breakSpecial tyresPolymer scienceButadiene-styrene rubber

The present technology provides a rubber composition containing a diene rubber including a styrene-butadiene copolymer component including at least one type of styrene-butadiene copolymer and a reinforcing filler. The bonded styrene content is from 5 to 50 wt. %. The total amount of styrene of an ozone decomposed component S1 including one styrene-derived unit and an ozone decomposed component S1V1 including one styrene-derived unit and one 1,2-bonded butadiene-derived unit is less than 80 wt. % of the amount of bonded styrene. The total amount of styrene of the decomposed component S1V1 is less than 10 wt. % of the amount of bonded styrene. The integrated intensity of an ozone decomposed component S1V2 including one styrene-derived unit and two 1,2-bonded butadiene-derived units is less than 15% of the integrated intensity of all decomposed components including styrene-derived units. The vinyl content of a butadiene portion is not less than 50%.

Owner:THE YOKOHAMA RUBBER CO LTD

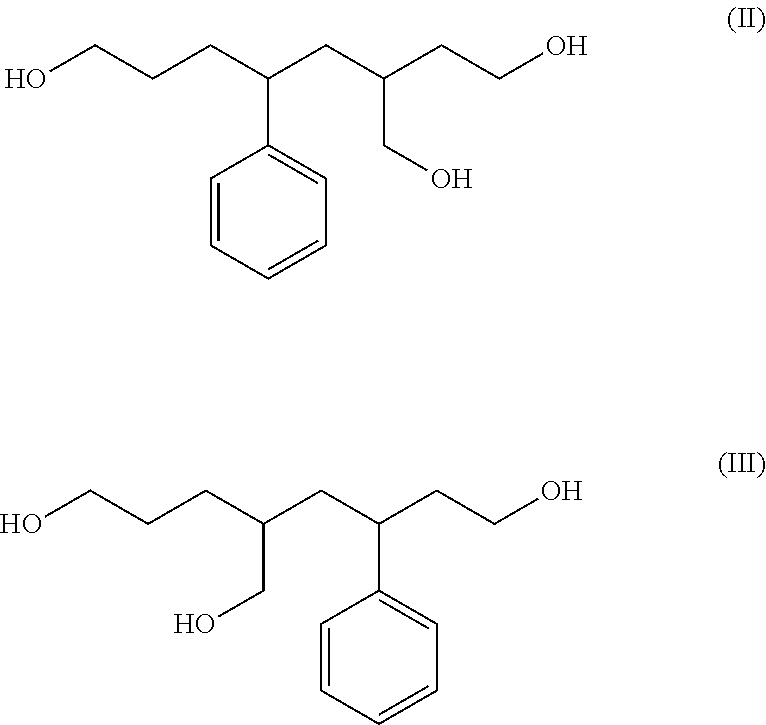

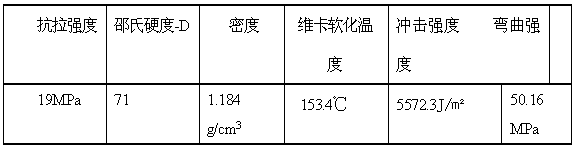

A kind of preparation method of natural Eucommia wood-plastic composite material

The invention relates to a preparation method of a natural eucommia wood-plastic composite material, which relates to a preparation method of the composite material. The protein contained in the eucommia wood of the present invention is similar to most foods, and various amino acids and mineral elements necessary for the human body have been detected. At the same time, eucommia wood itself contains a lot of lignin, and the composite material made by filling pure polypropylene and other thermoplastic resins with natural eucommia wood powder and adding additives has certain hardness, tensile strength, Vicat softening temperature and density, and Has a certain elongation at break. Compared with traditional materials, wood-plastic materials have unique advantages: they can release some beneficial elements to the human body, have no defects of wood products (knots, oblique grains, decay, etc.), have a wood-like appearance, and are harder than plastics. Molding and weather resistance, etc. This wood-plastic product has a wide range of applications, such as wall panel decoration, floor, fence, indoor tables and chairs, automotive interior parts, etc.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

A Combined Rapid Blocking Device for Arched Roadway

The invention relates to a combined fast blocking device based on an arched roadway, which includes a temperature-sensitive airbag, a combined bracket and an automatic inflation system, the combined bracket is arranged inside the temperature-sensitive airbag to support and fix the temperature-sensitive airbag, the temperature-sensitive airbag and the automatic inflation system connection. The temperature-sensing airbag is an airbag with an arched top, and its material can sense the surrounding temperature, and present different colors according to different surrounding ambient temperatures to achieve multi-stage color change. The automatic inflation system includes a temperature sensor, a pressure sensor, a computer, an inflation device, an inflation solenoid valve, and an exhaust solenoid valve. The invention has a simple structure, can realize fast assembly and disassembly, and can realize automatic inflation and deflation according to the set temperature and pressure.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com