Strong yarn with forming filaments

A yarn and filament technology, applied in the direction of filament/thread forming, single-component polyamide rayon, yarn, etc., can solve the problems that the coating is not easy to adhere, and the coating is not easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will now be described in more detail through the following examples.

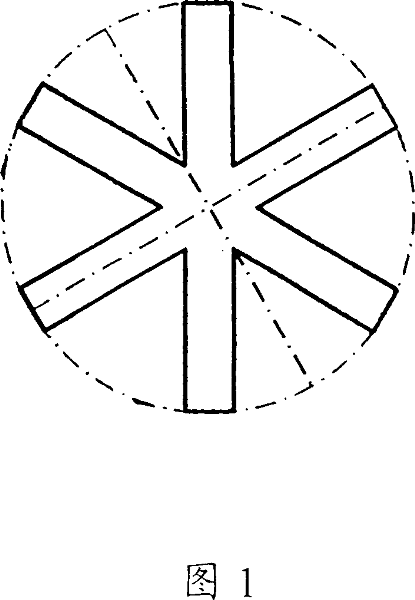

[0020] The polymer used to make the yarn is nylon 6,6 with a particle viscosity of 2.56 (255G). The pellets were melted at a temperature of 290°C and extruded through a spinneret with a diameter of 60 mm at a temperature of 280.5°C. Each of the 72 holes of the spinneret had three holes each having a length of 600 microns and a length of 70 microns. A rectangle with a width of micrometers (see Figure 1). The three rectangles are arranged in a star shape and connected to each other at the center of the hole. The extruded filaments were quenched in a quenching tunnel with cross-flow air of various speeds at a temperature of 22°C, and then wound at a speed of 450 m / min. The pressure set at the spinneret, the air velocity used and the properties of the yarn obtained are shown in Table 1.

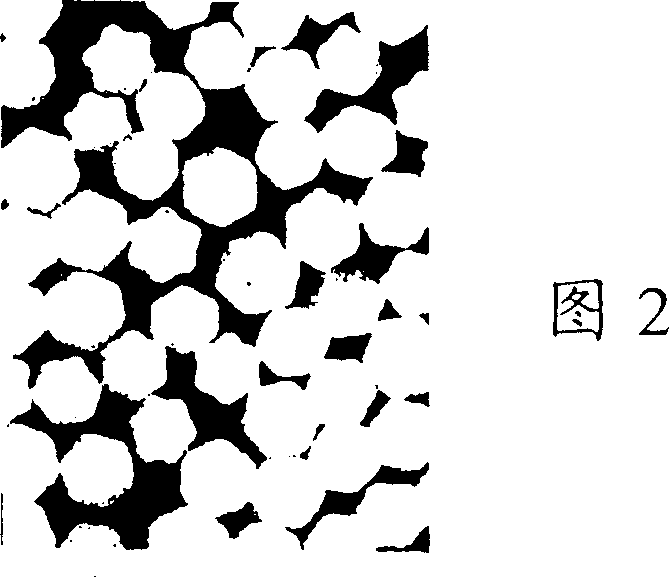

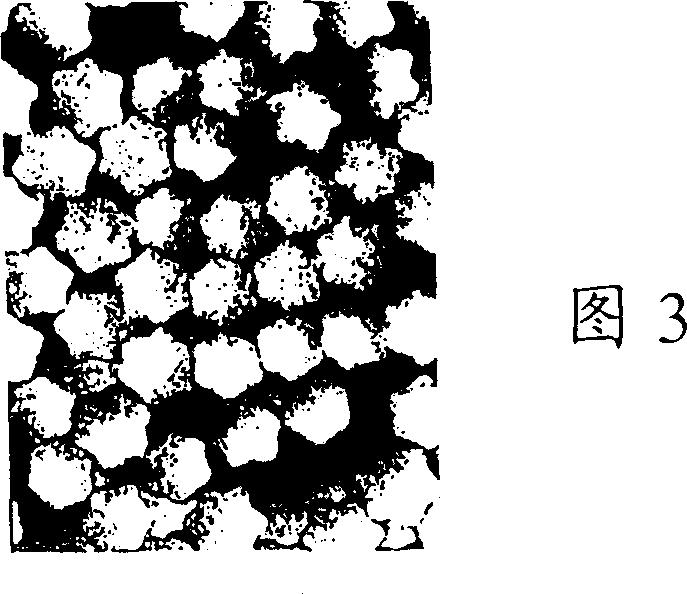

[0021] Take 50 meters 3 The filament obtained by the air flow at speed per hour has a hexagonal cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com