Heddle preferably for handling strip-shaped material and method for the production thereof

A belt-shaped and heald technology is applied in the field of manufacturing said heald to achieve the effects of improving stability and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

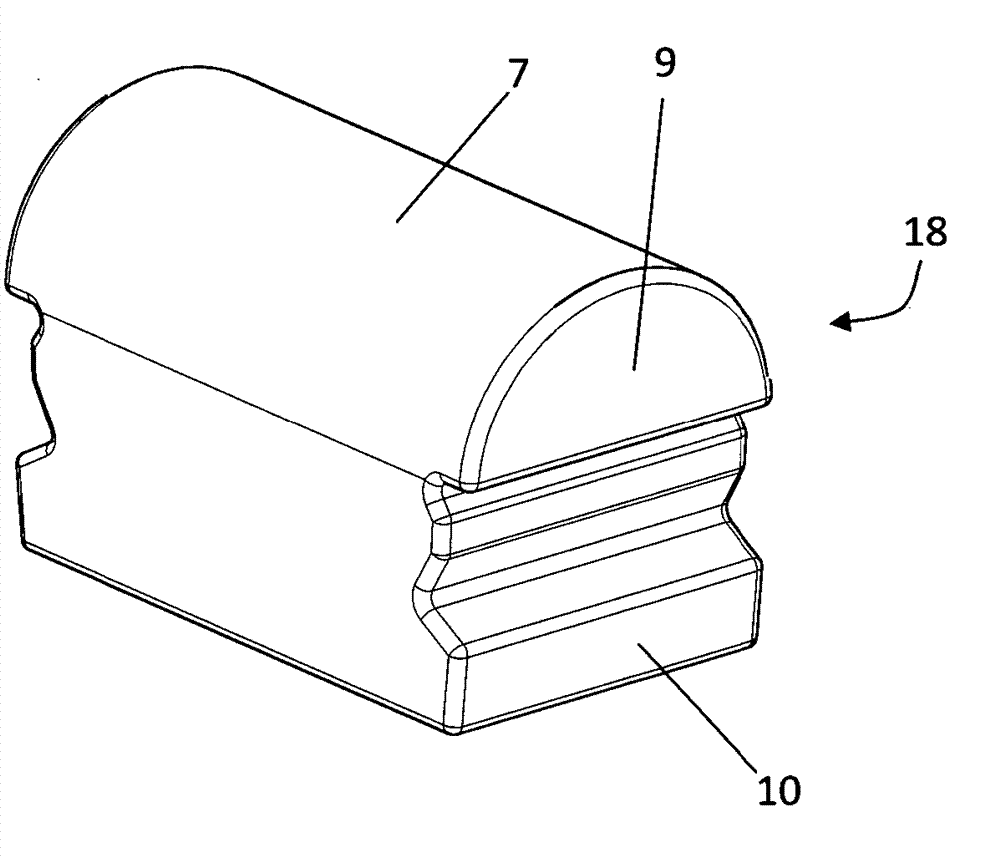

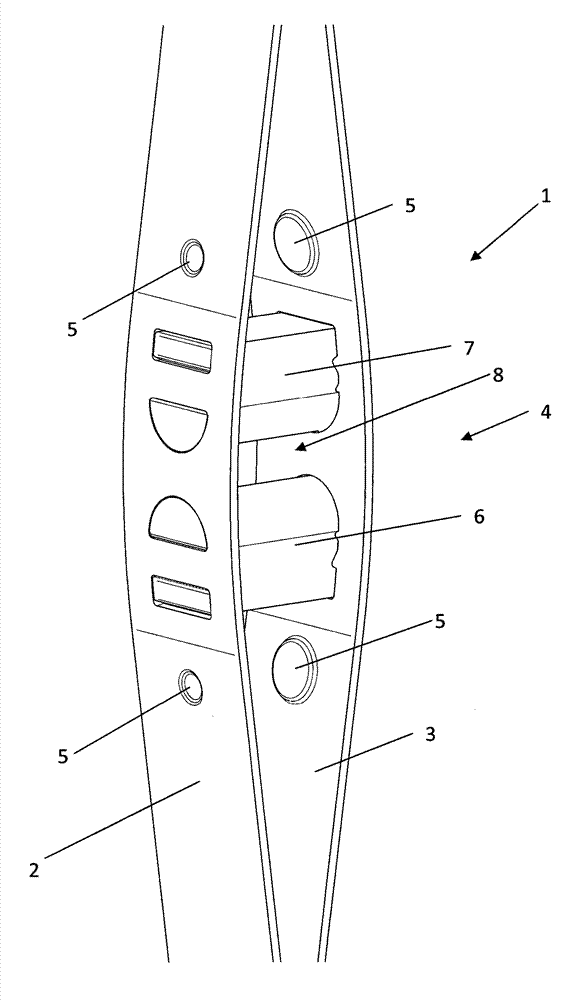

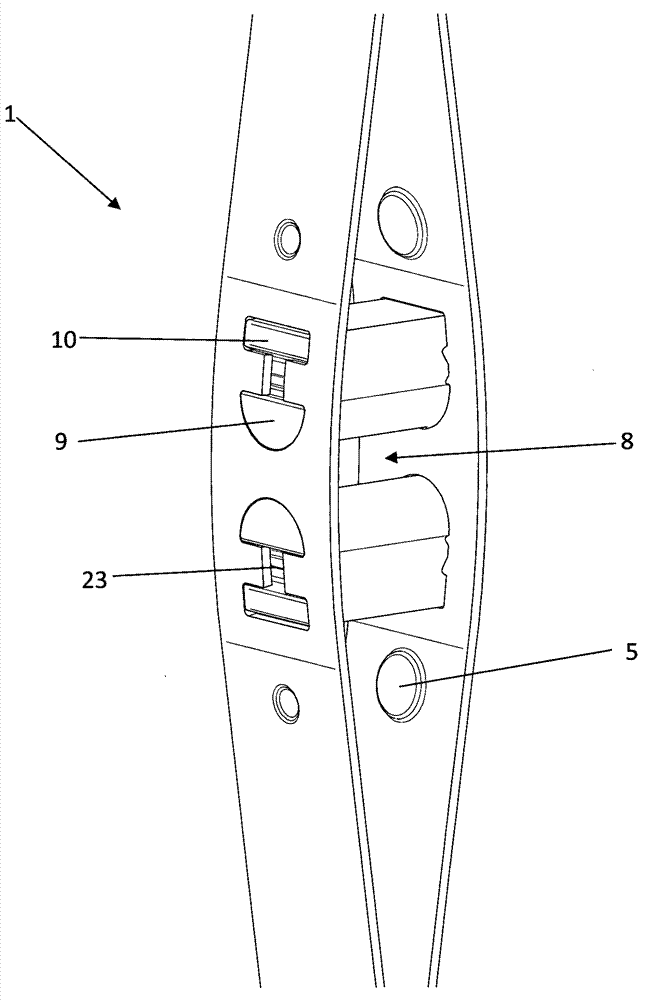

[0044] figure 1 and 2 A partitioned region 4 of an embodiment of a heald 1 according to the invention is shown, which consists of two strips 2 and 3 . In the present exemplary embodiment, the two strips 2 , 3 are already provided with embossing points 5 before they are put together, which already function as spacer elements during the manufacture of the heald 1 .

[0045] Between the two strips 2 and 3 are held two structural elements 6 , 7 delimiting said eyelet 8 . In the exemplary embodiment shown, the two structural elements 6 , 7 have fastening elements 9 , 10 which are inserted into recesses 11 , 12 in the two strips 2 , 3 . In the illustrated embodiment, the interstices 11 , 12 are holes which pass through the strip. However, blind holes are also conceivable, which can be realized, for example, as embossments or recesses. Figure 8 , 9 and 11, 12 and 13 also show the following figure 1 and 2 General view or components of the heddle 1. by means of Figure 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com