Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

550results about "Healds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

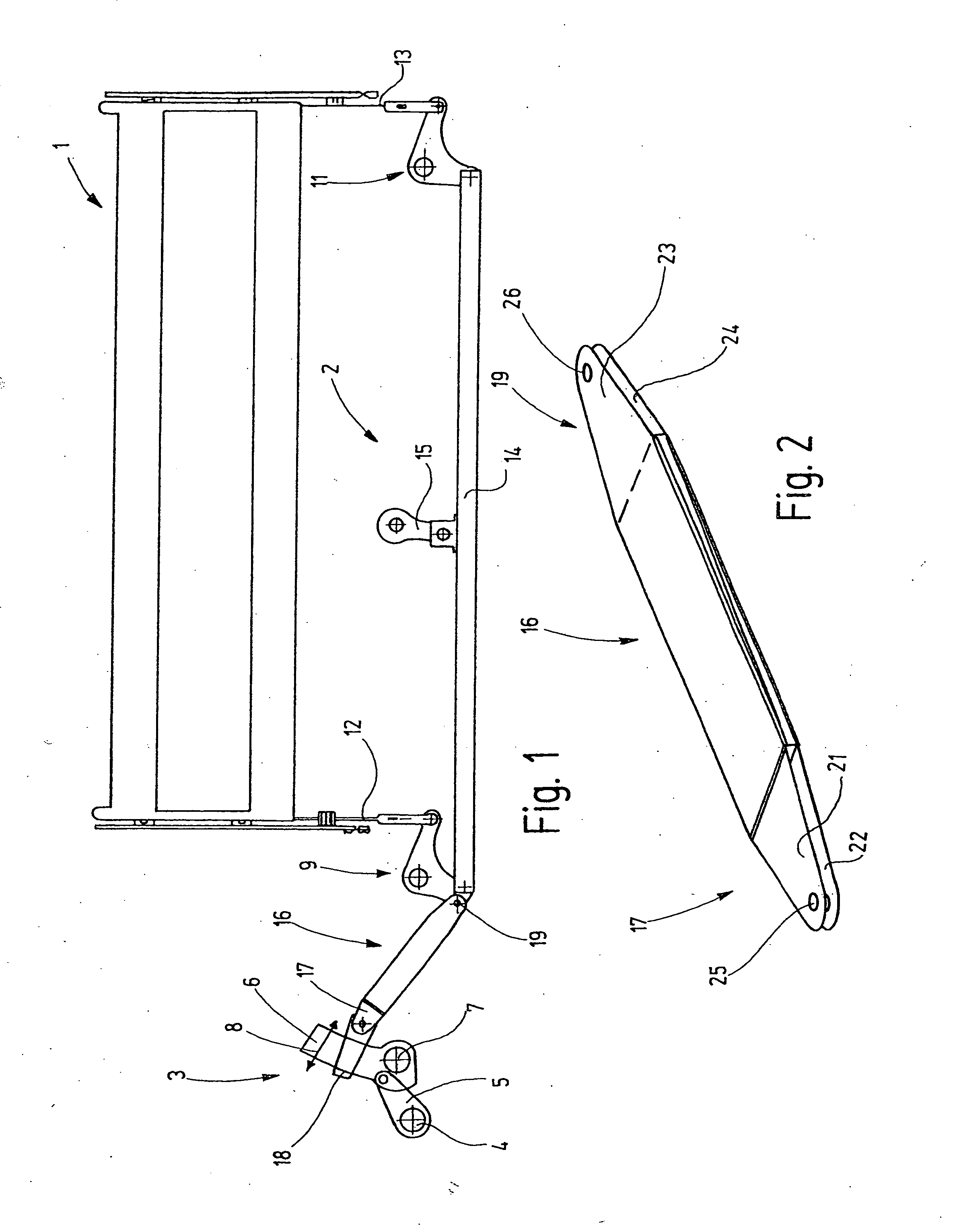

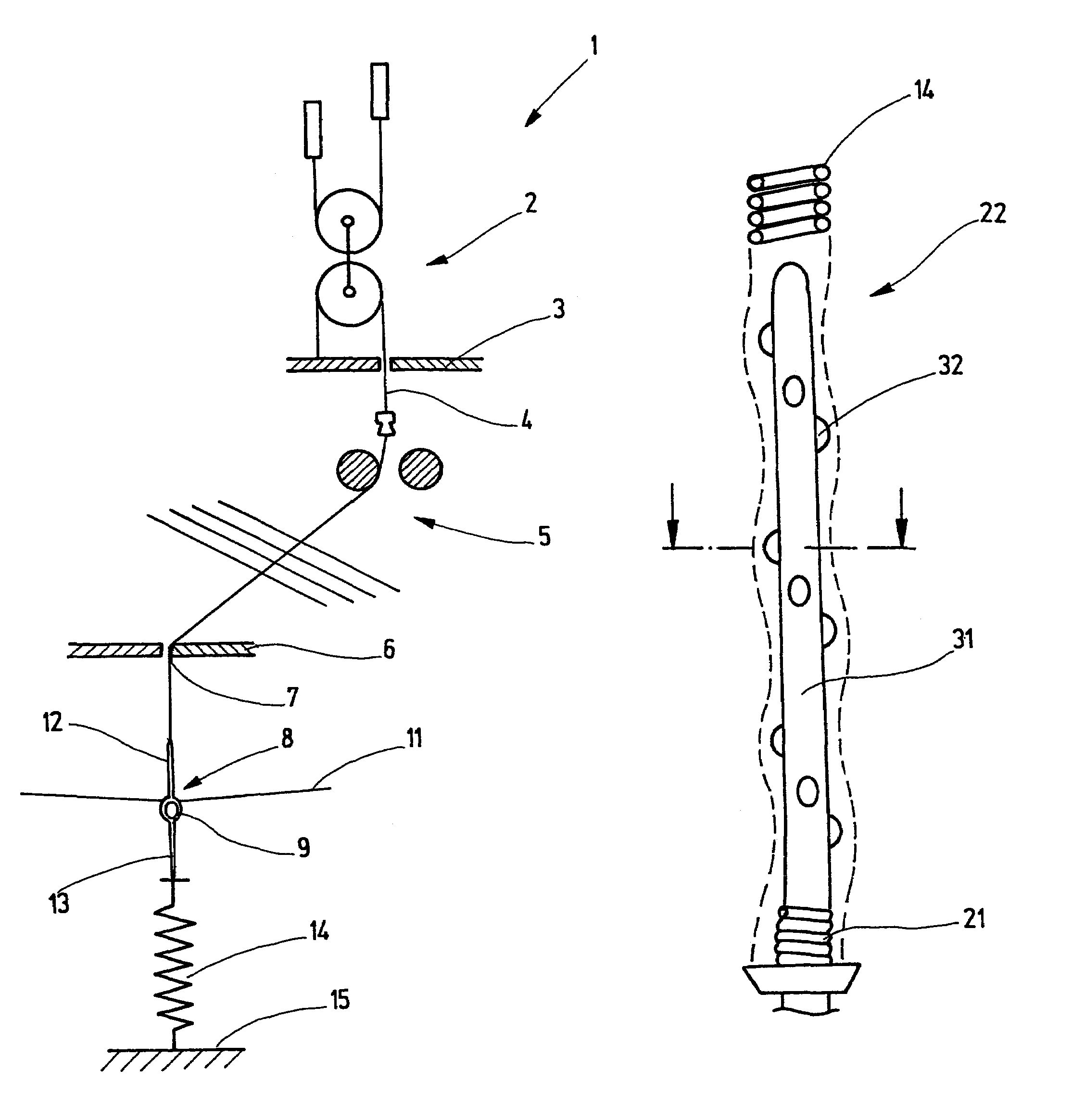

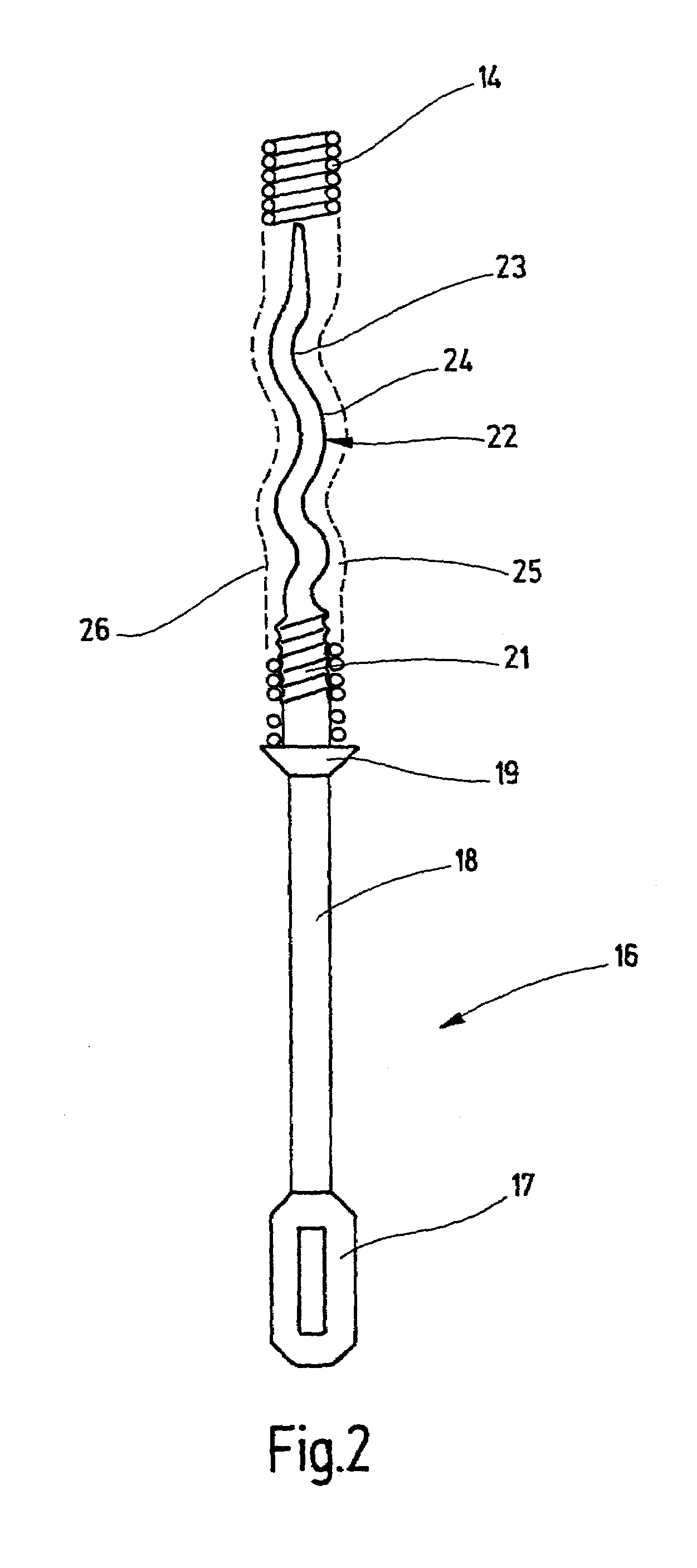

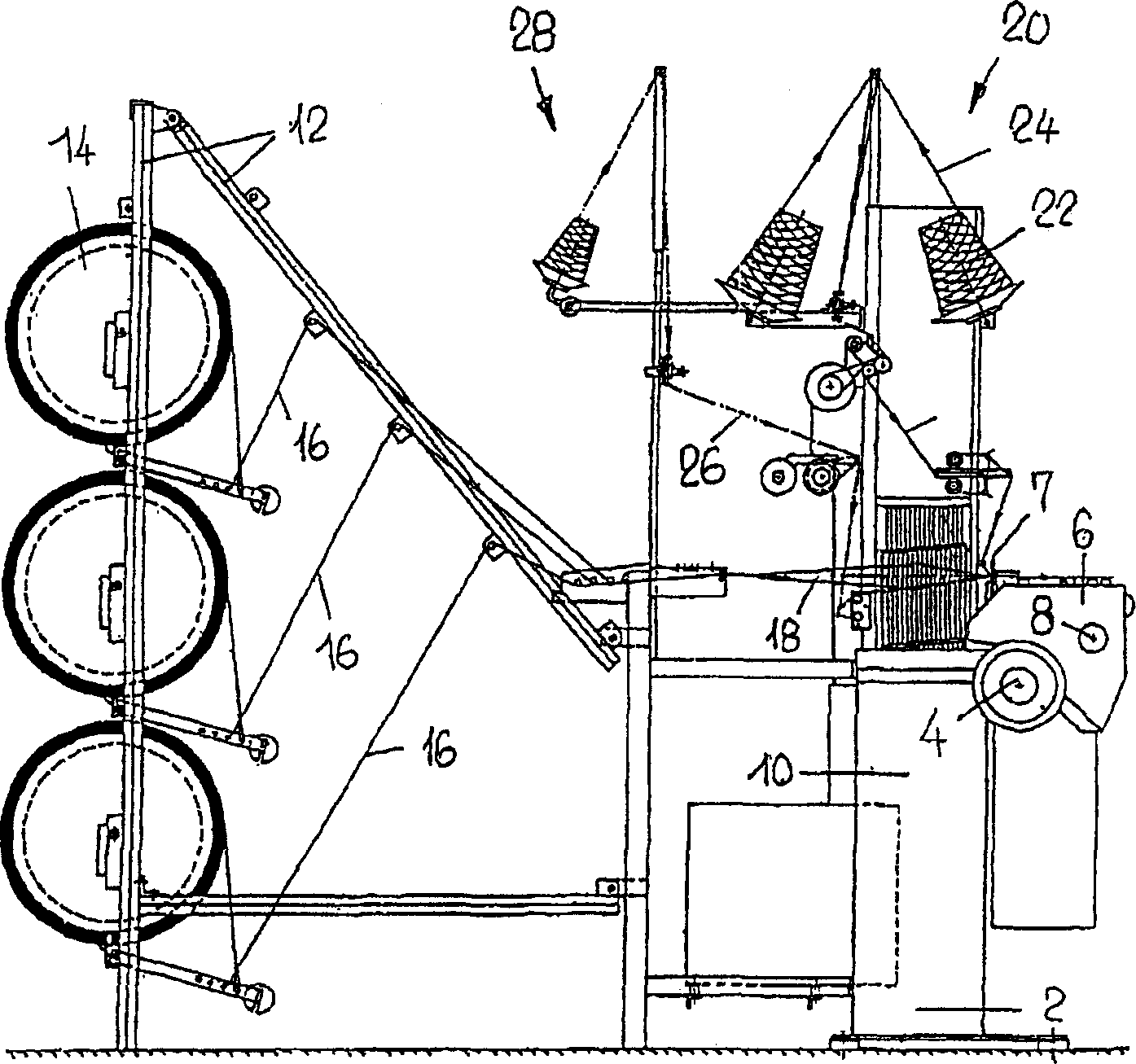

Low-vibration shedding system

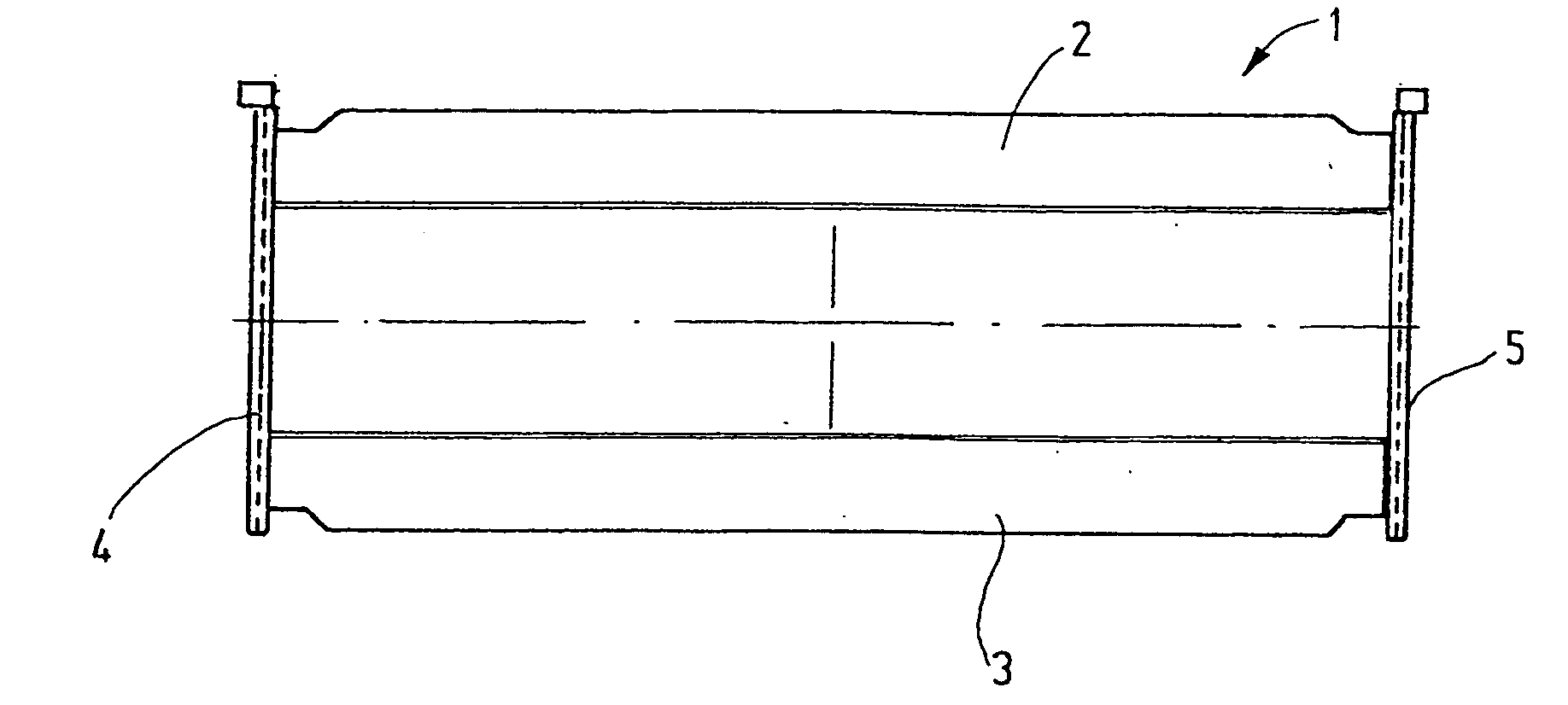

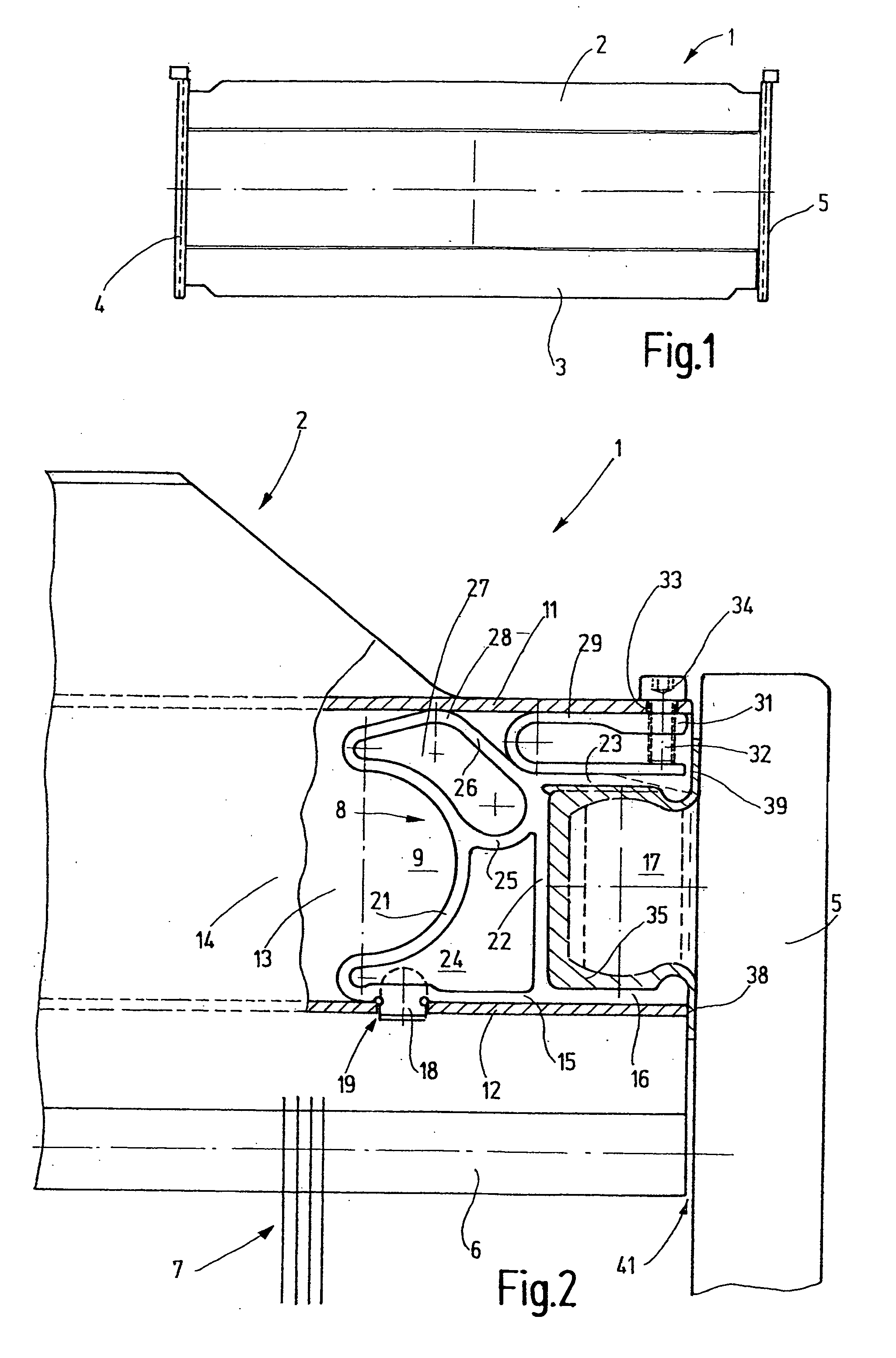

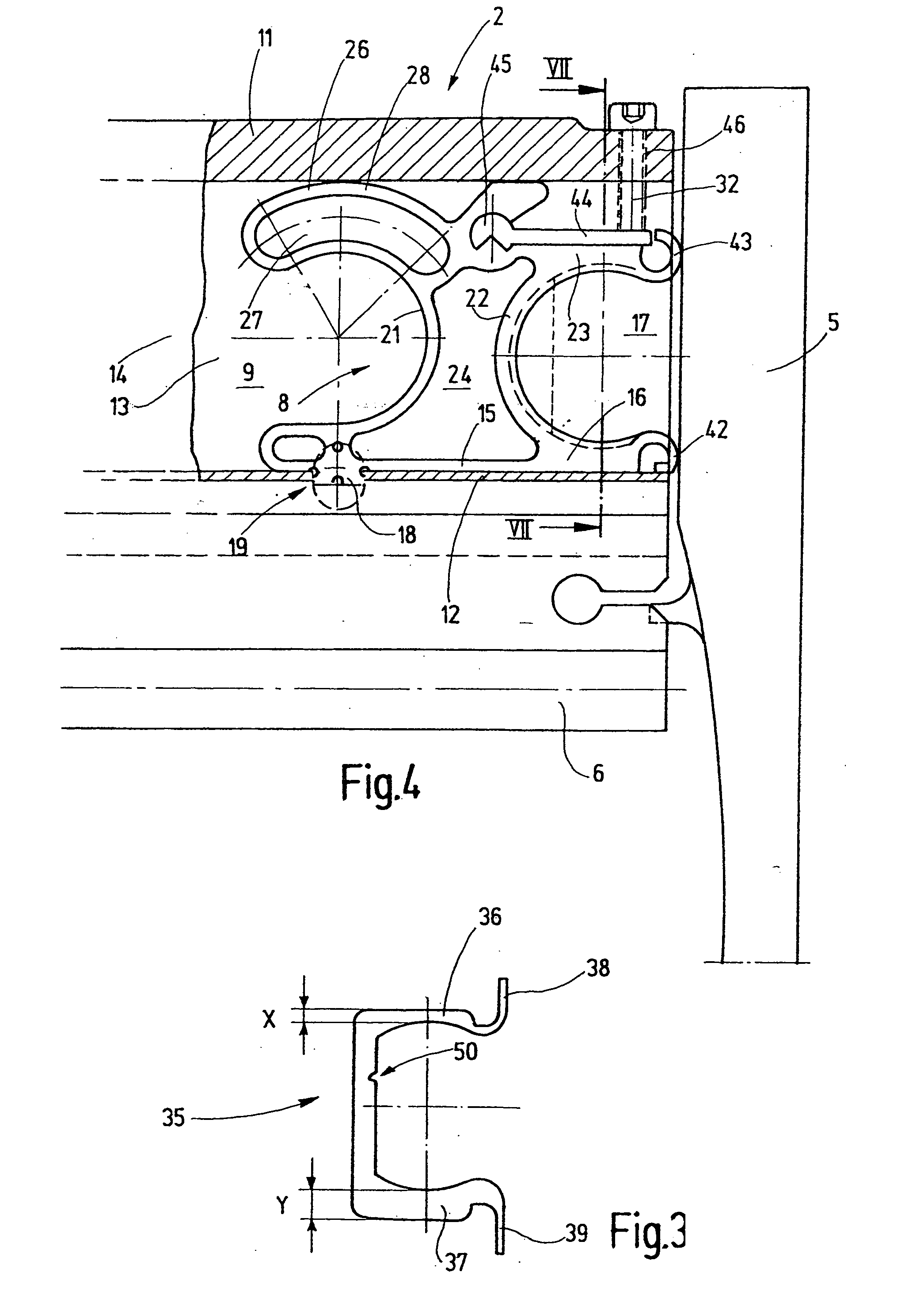

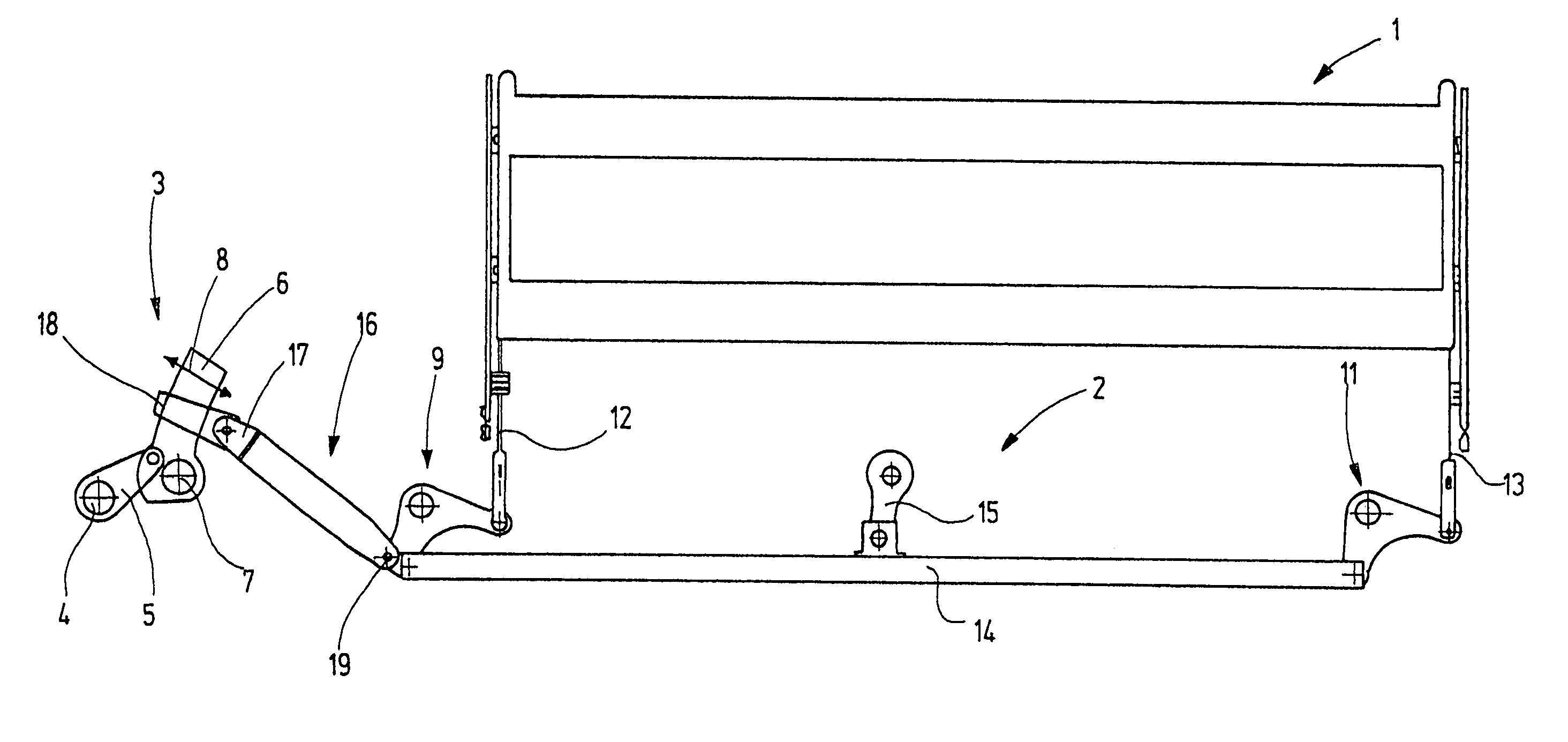

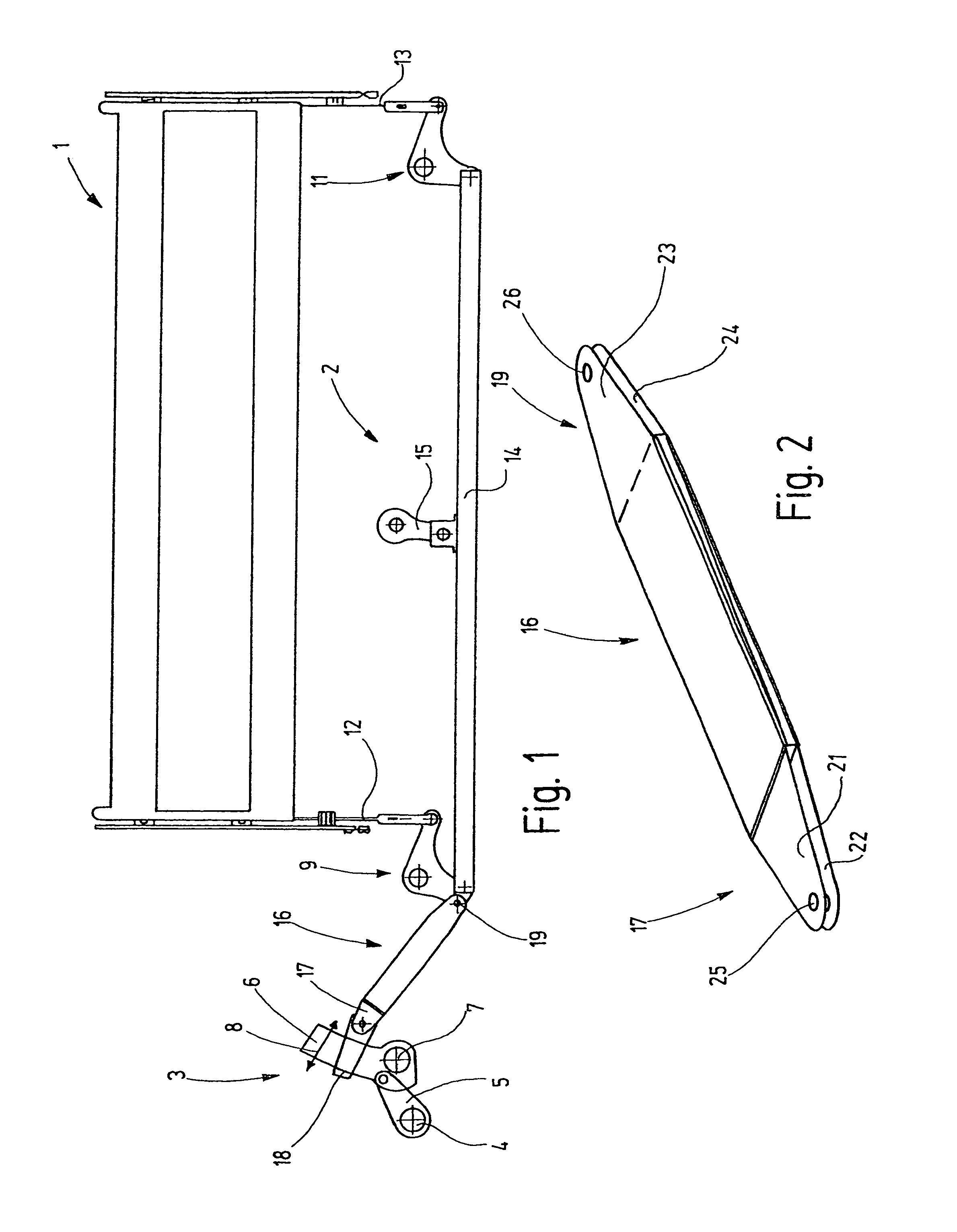

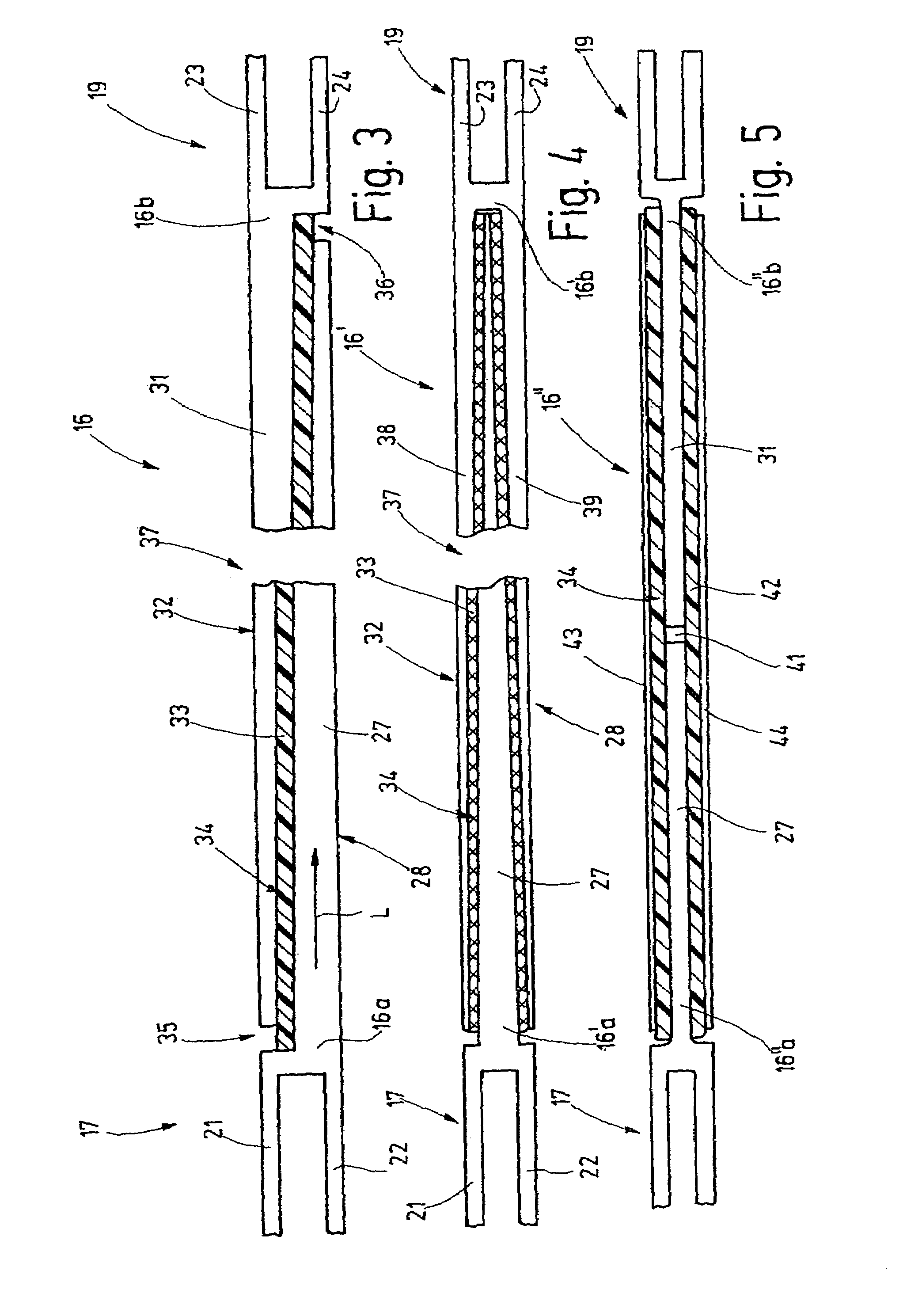

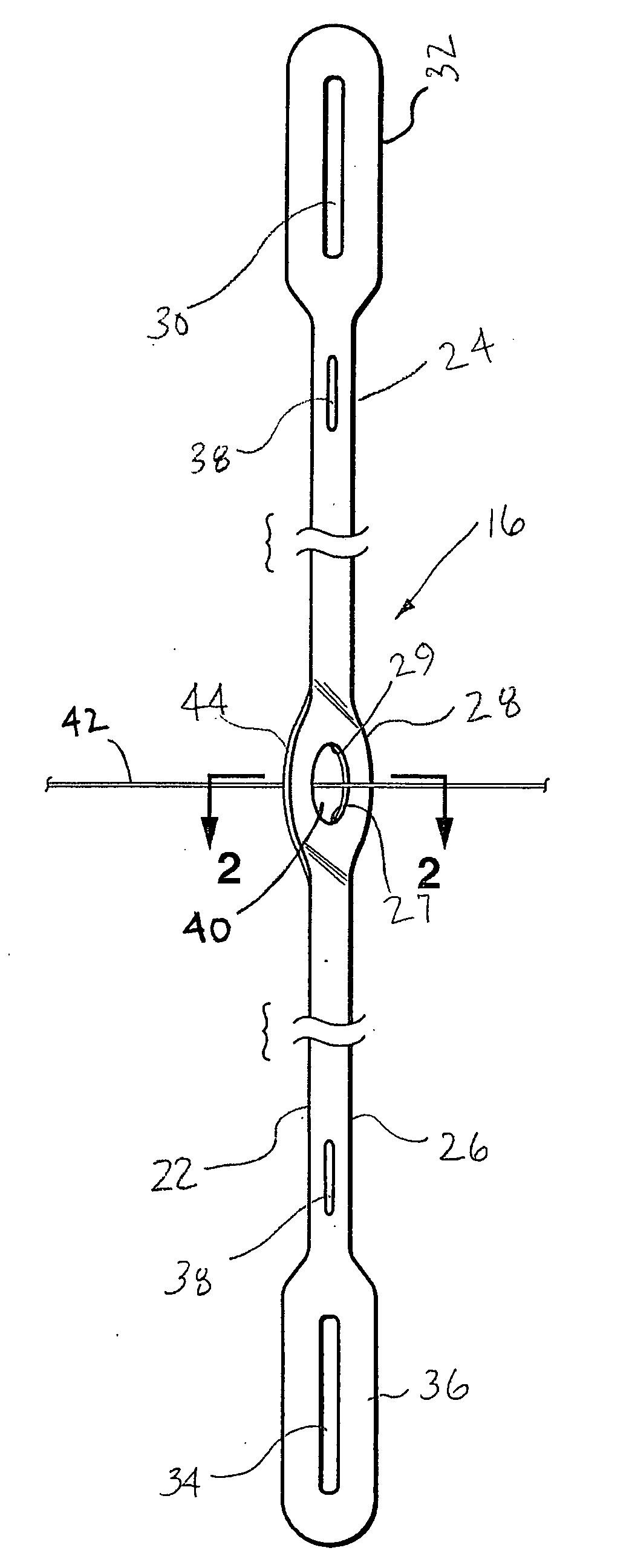

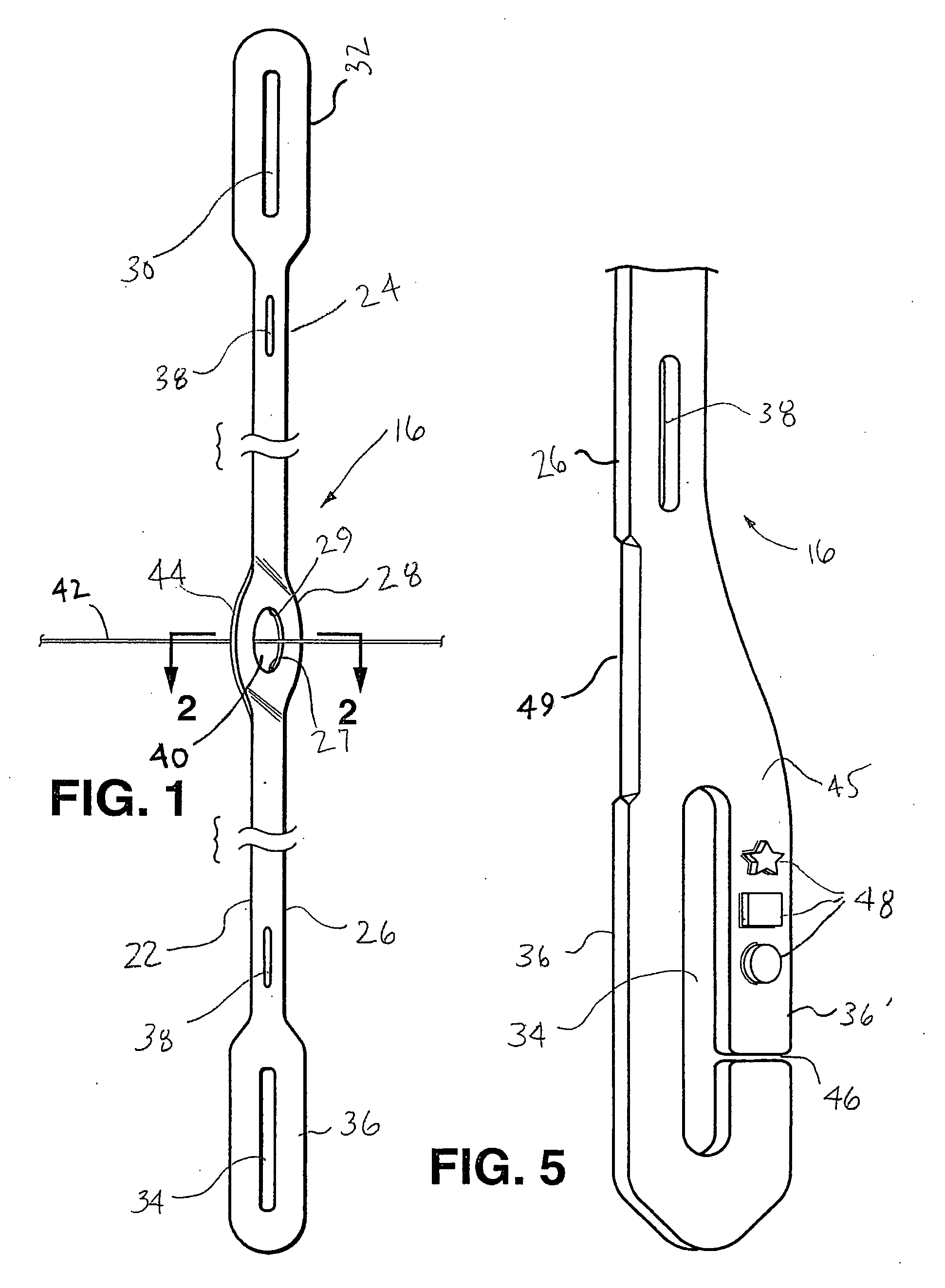

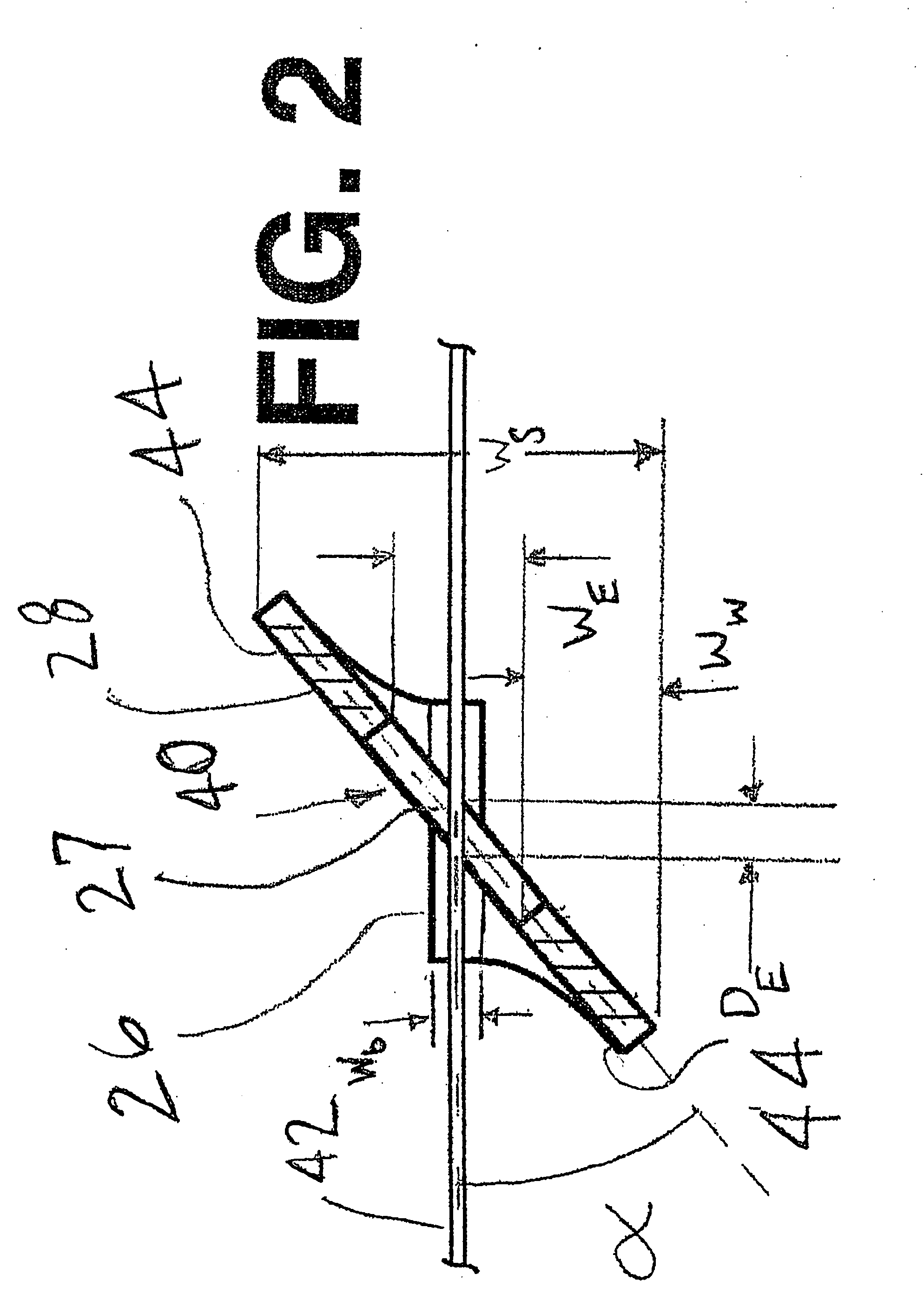

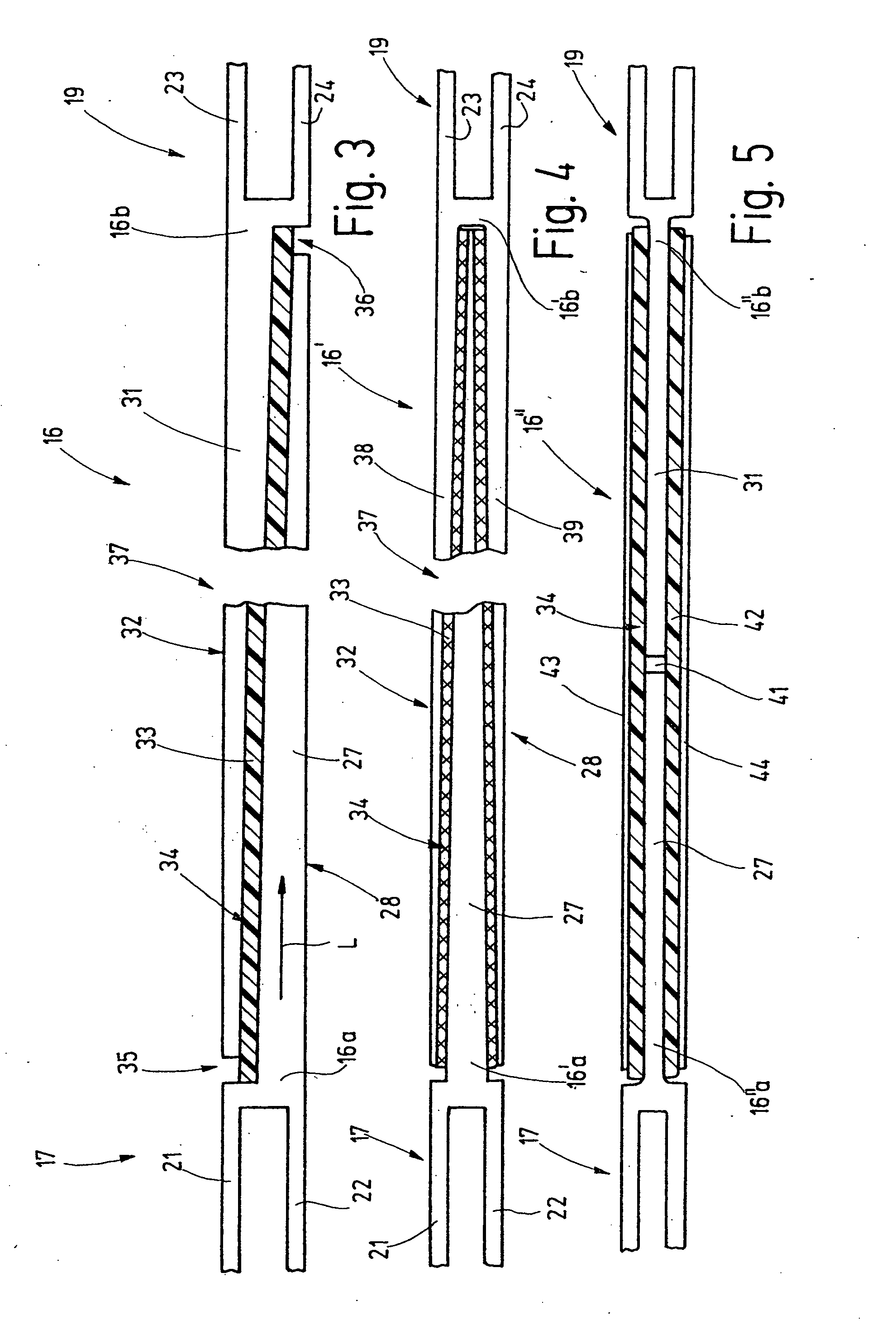

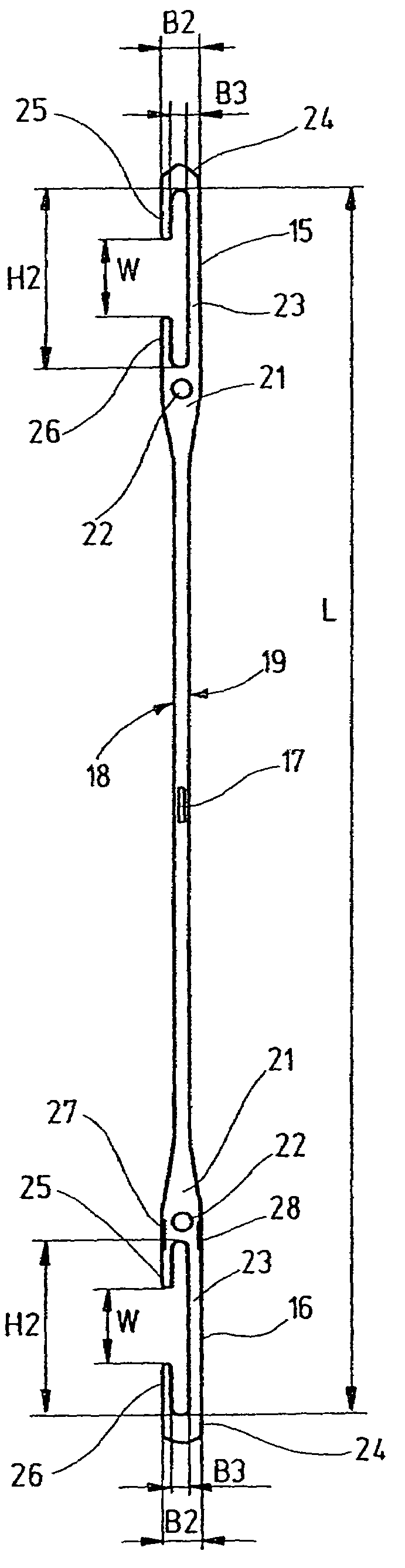

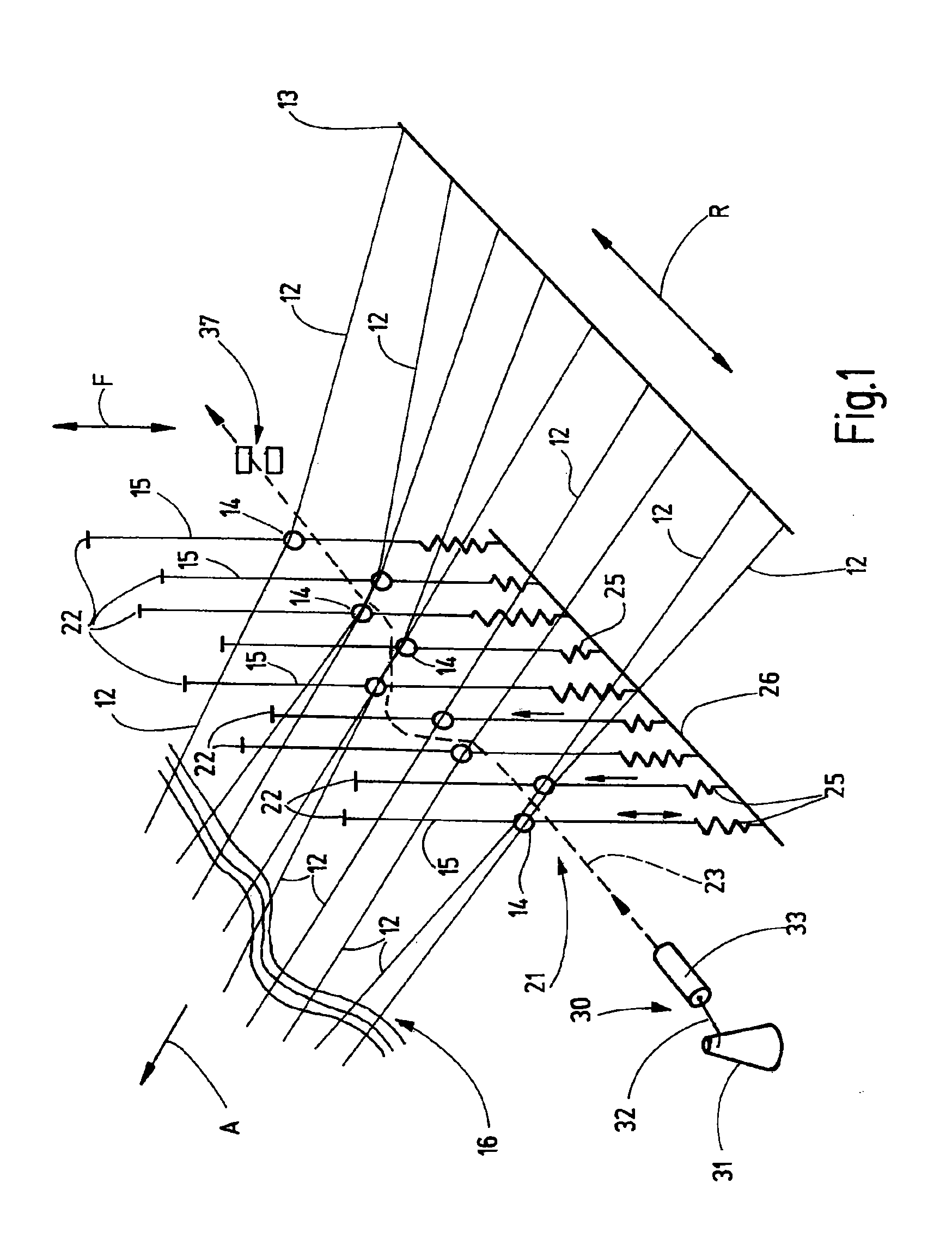

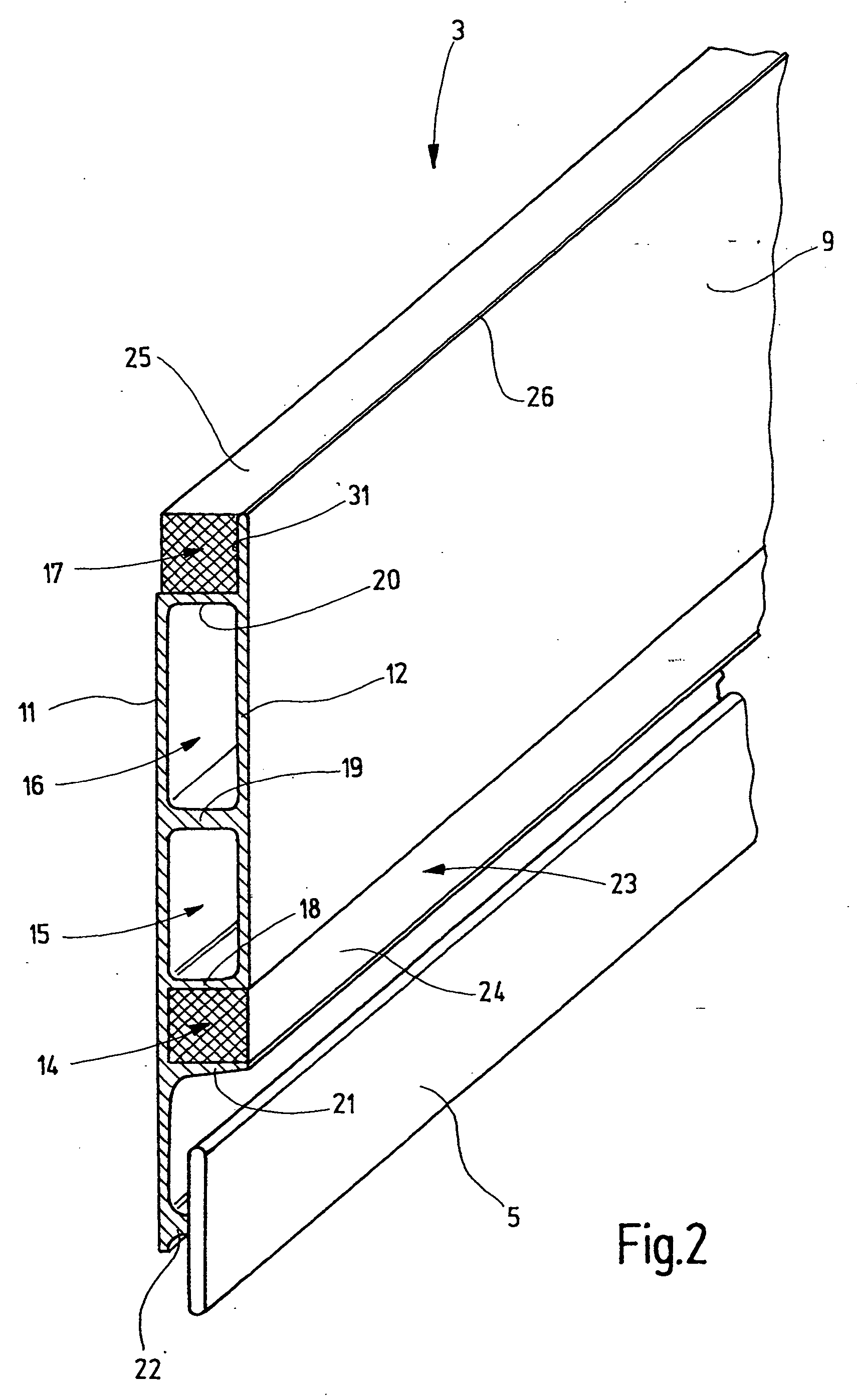

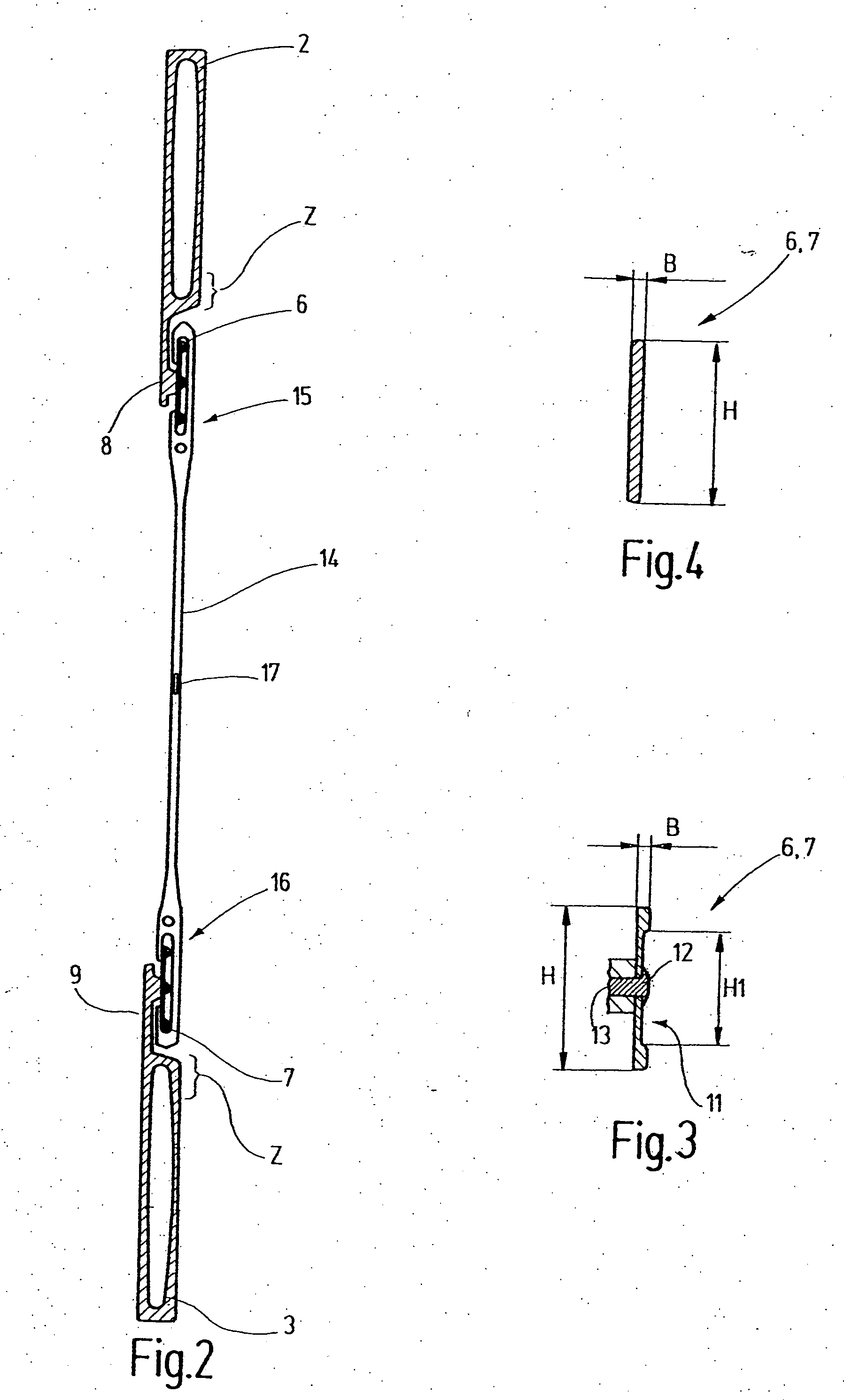

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

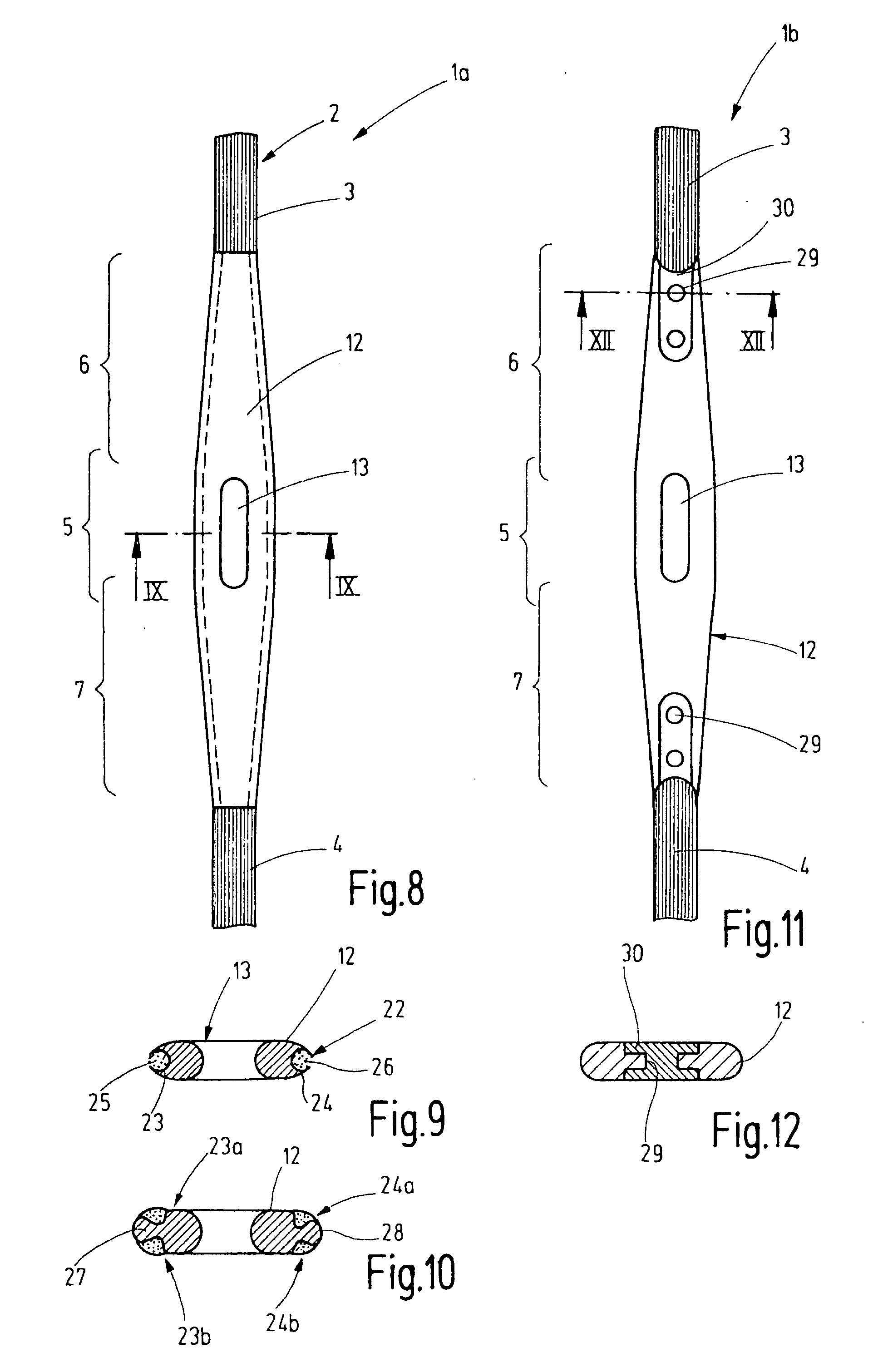

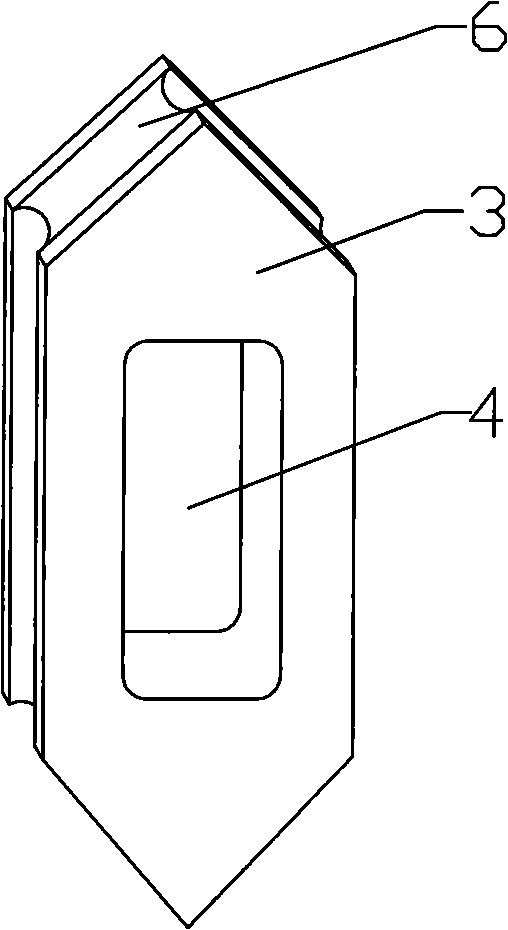

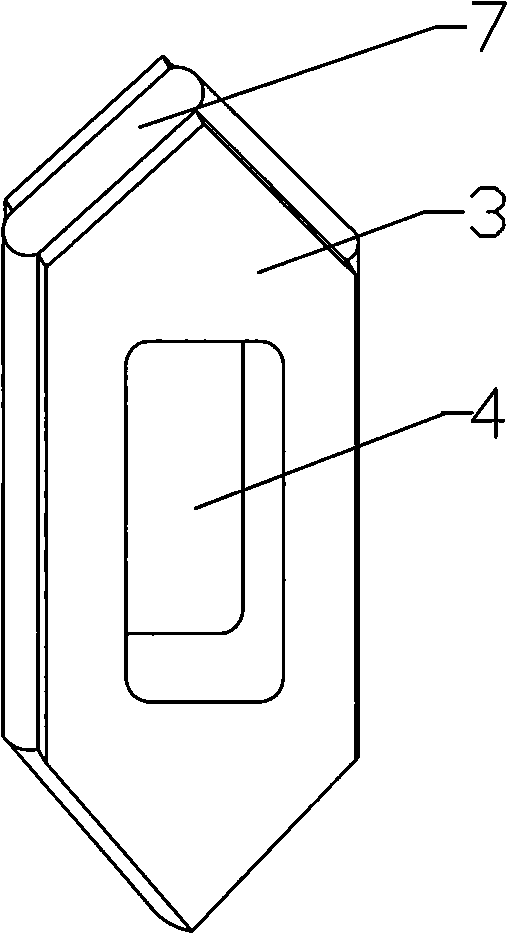

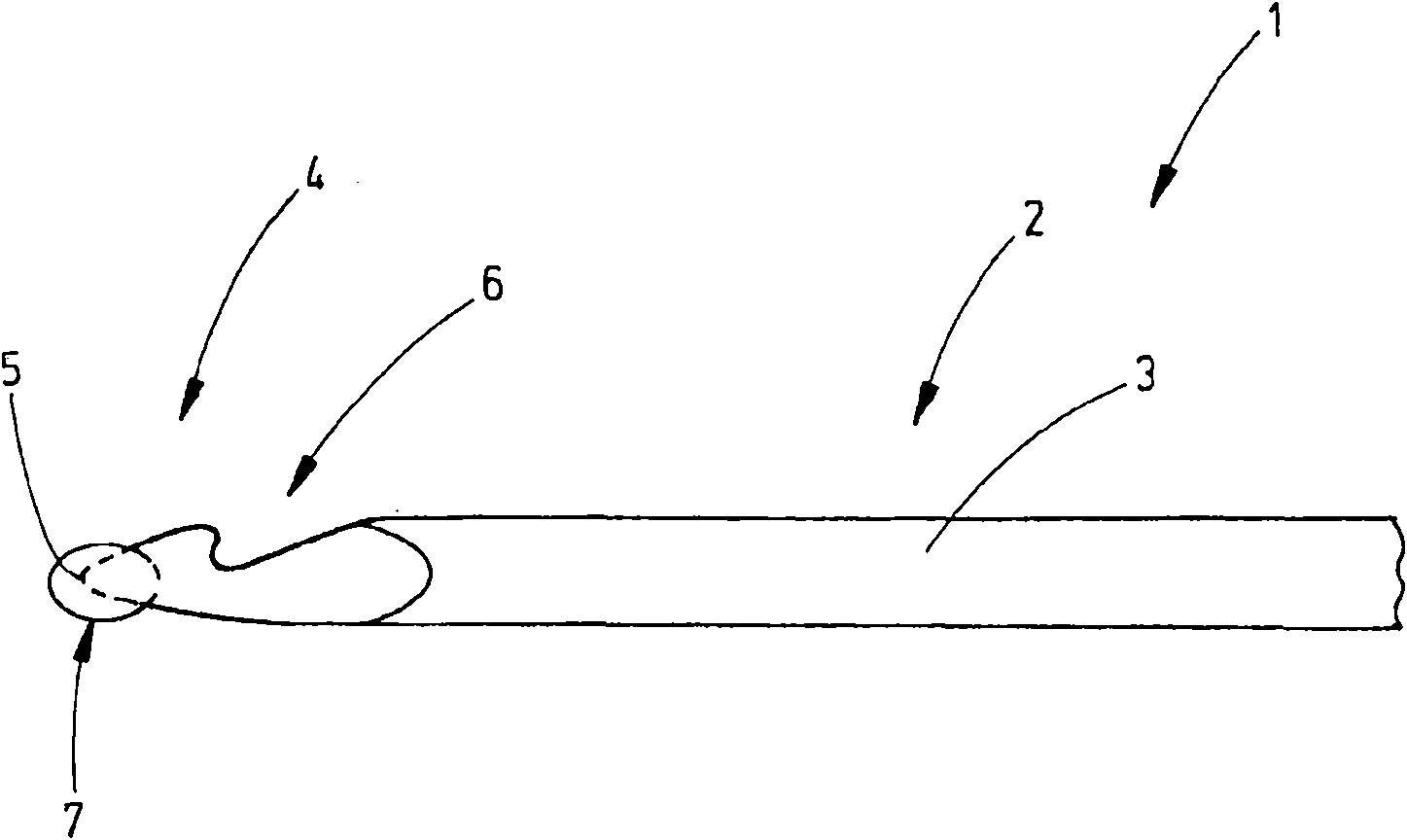

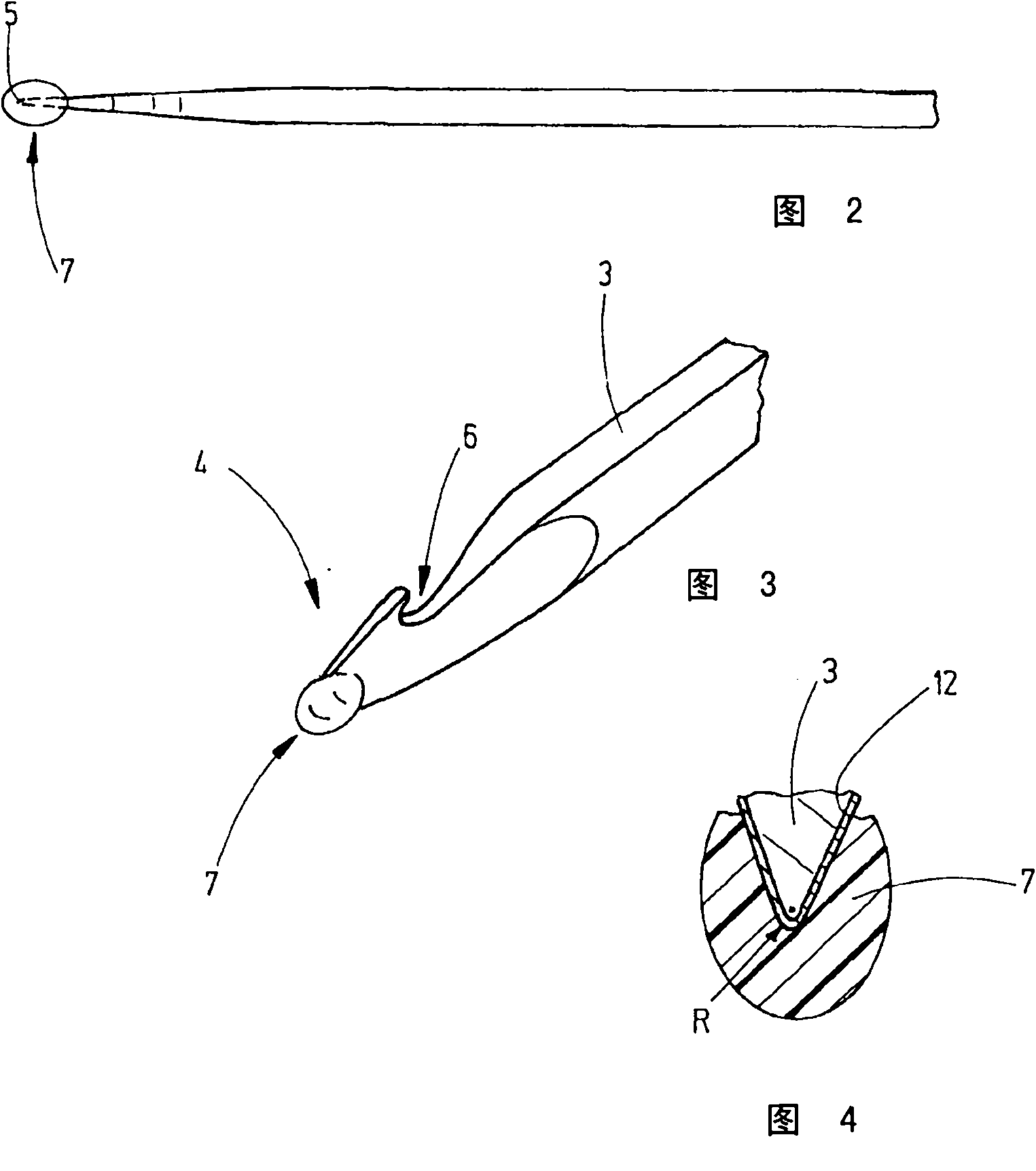

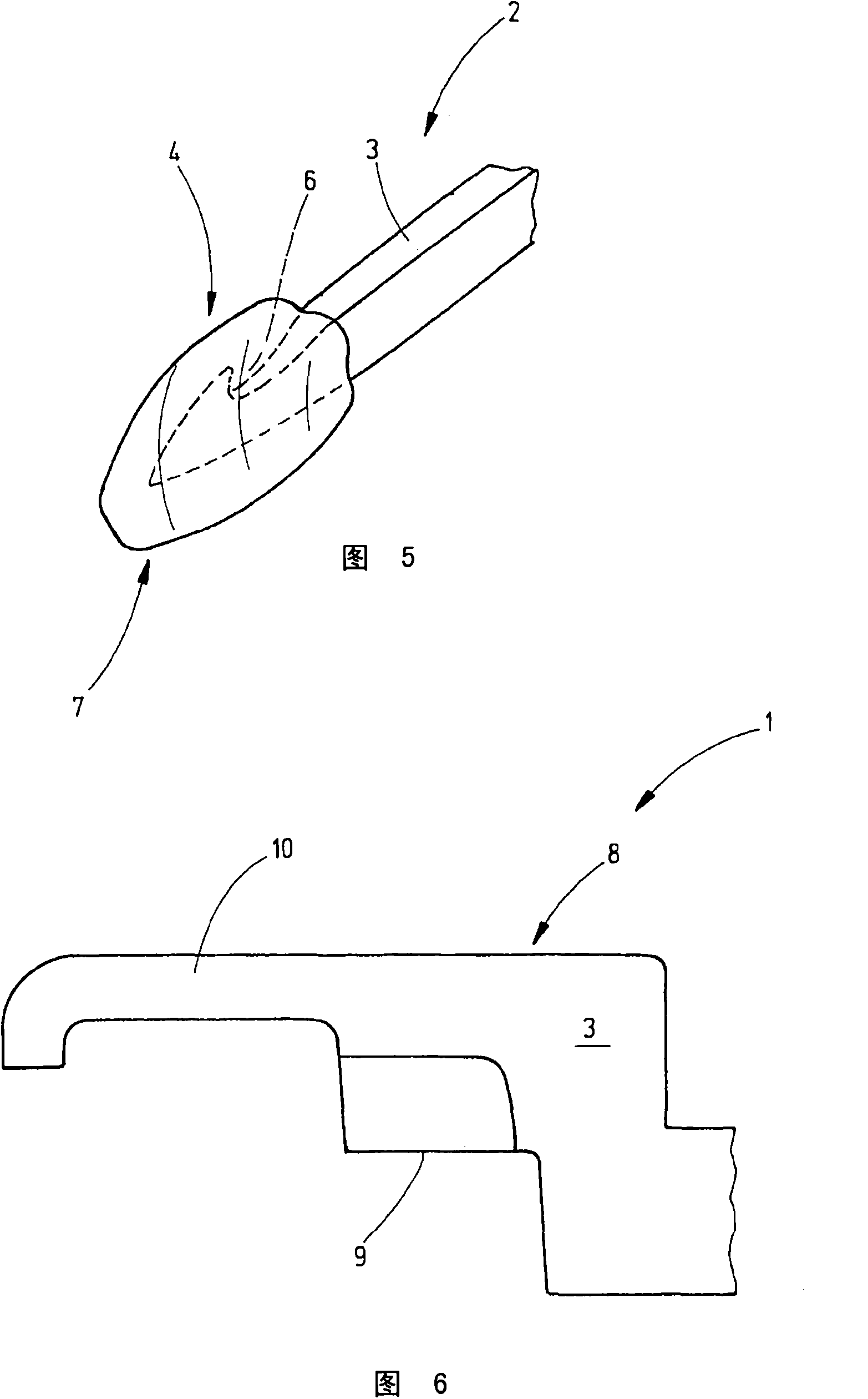

Weaving heddle for jacquard weaving machine

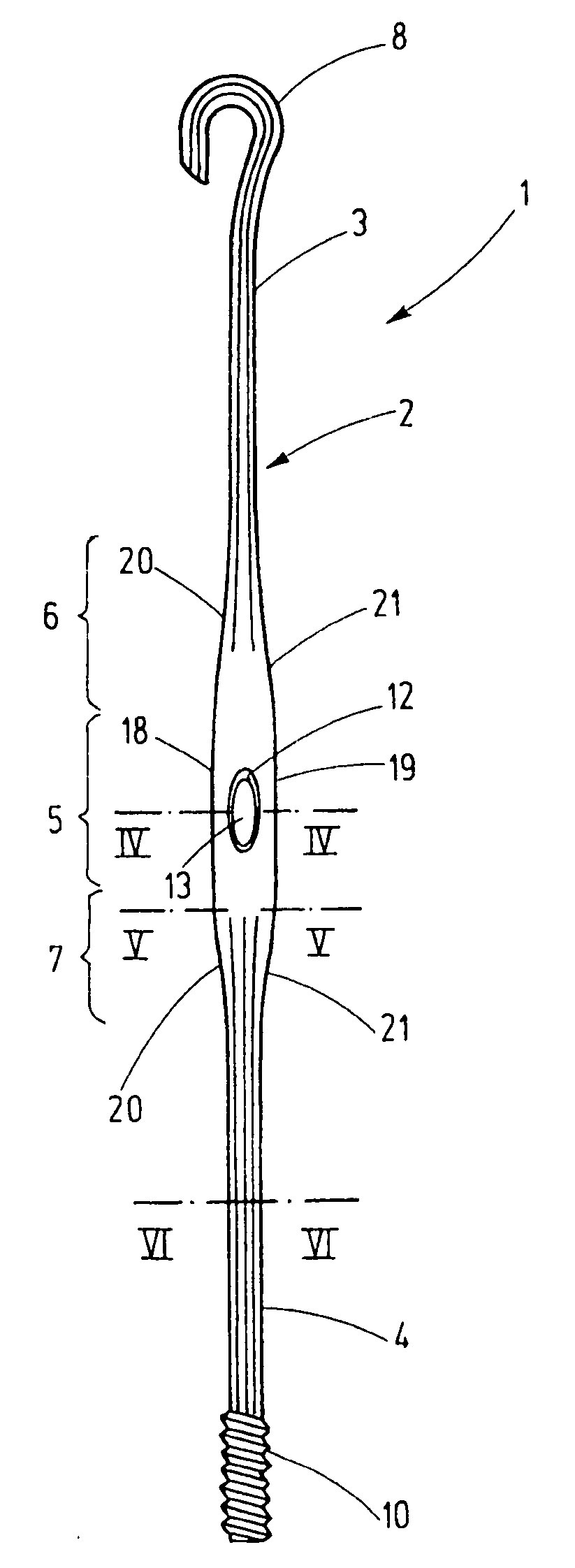

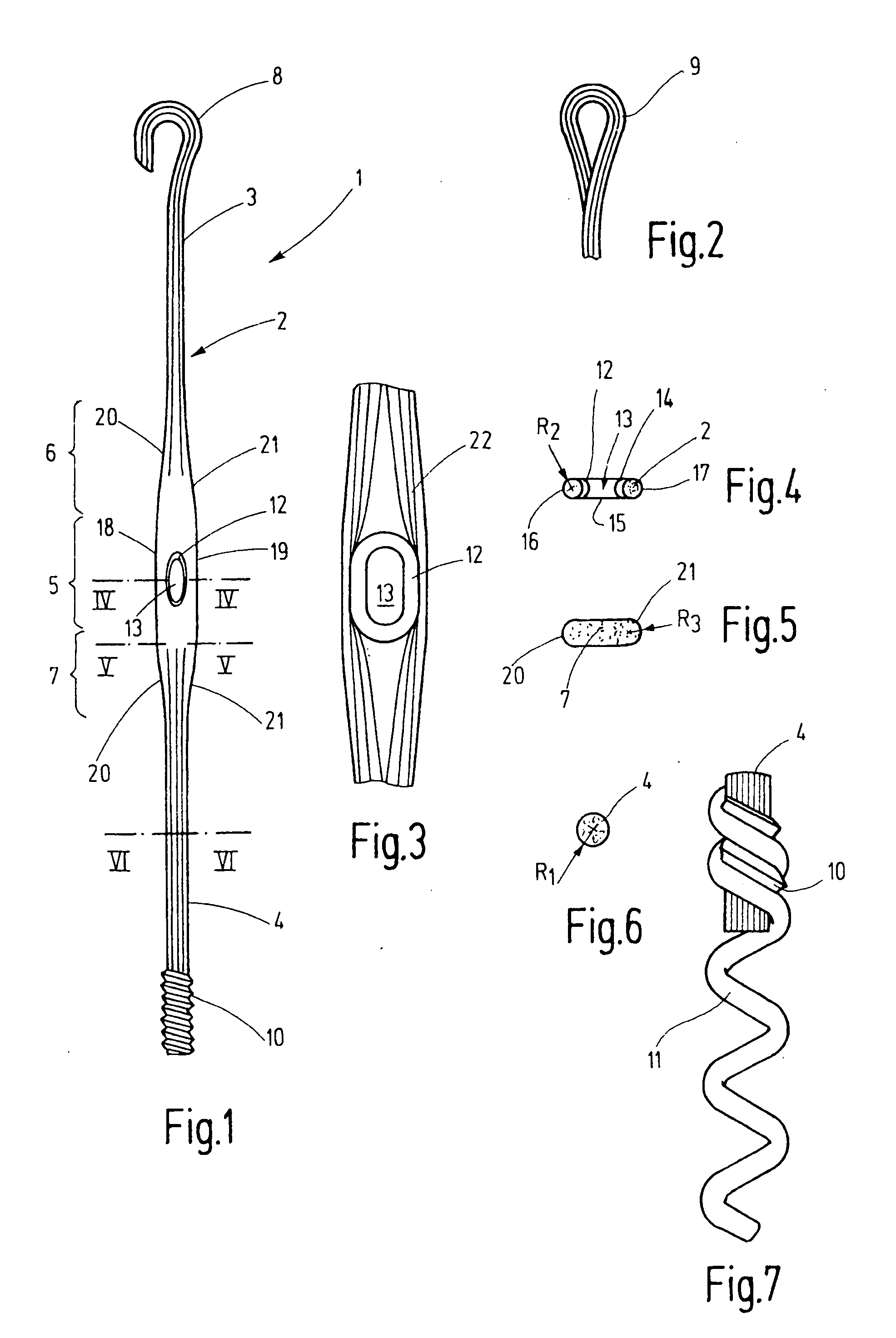

An inventive heddle for jacquard machines essentially consists of fiber-reinforced plastic material, whereby the thread eye is formed by a mail (12). The heddle body comprises two legs (3, 4). Between the relatively wide thread eye region (5) and the legs (3, 4), ramp sections (6, ) are provided, which sections have a length that is greater than the length of the thread eye (1). Preferably, the length is greater than twice the longitudinal extension of the thread eye. In most cases, said length is between 10 and 30 mm. As a result of this measure, the wear of the plastic material in the vicinity of the thread eye (13) is kept minimal enough that neither any damage to the stiffening fibers (22) in the body of plastic material nor any damage to the warp threads needs to be feared.

Owner:GROZ BECKERT KG

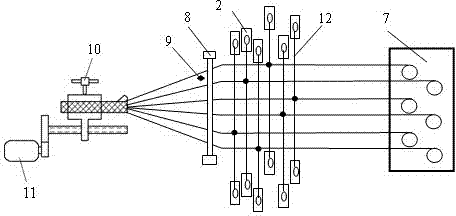

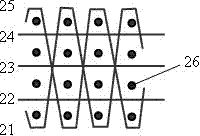

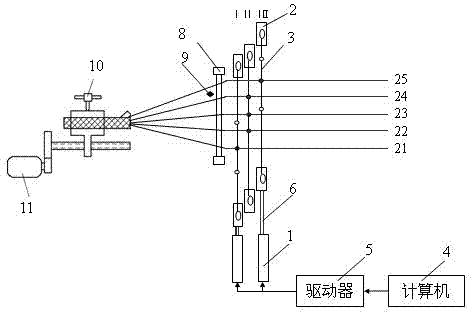

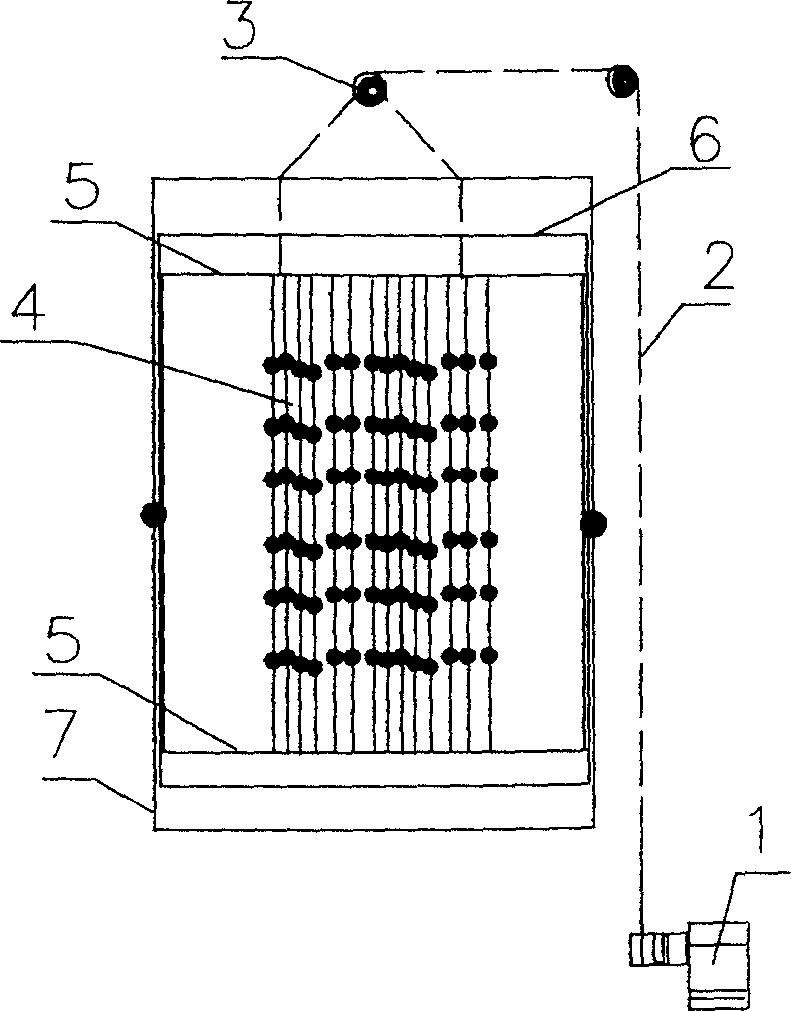

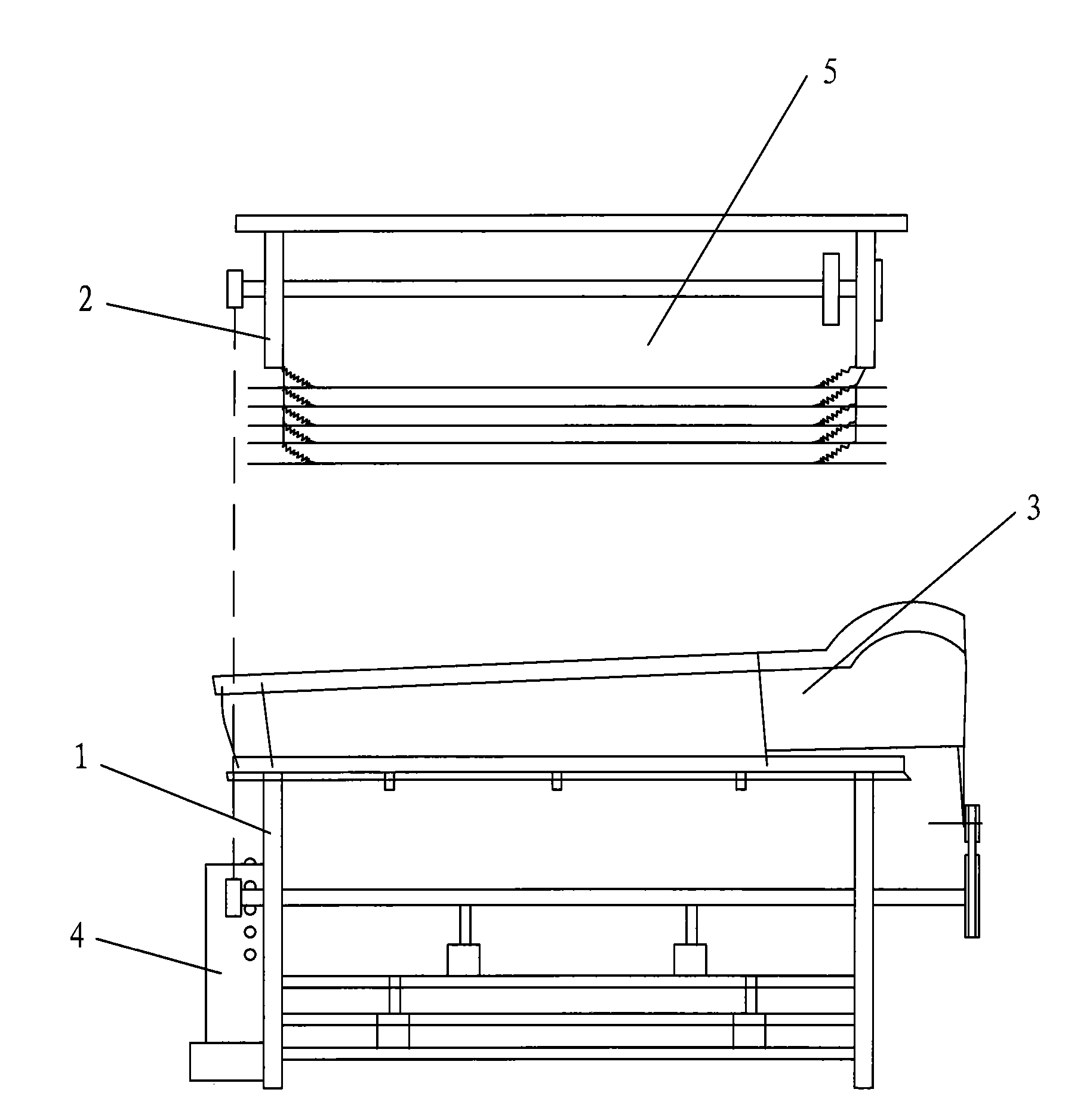

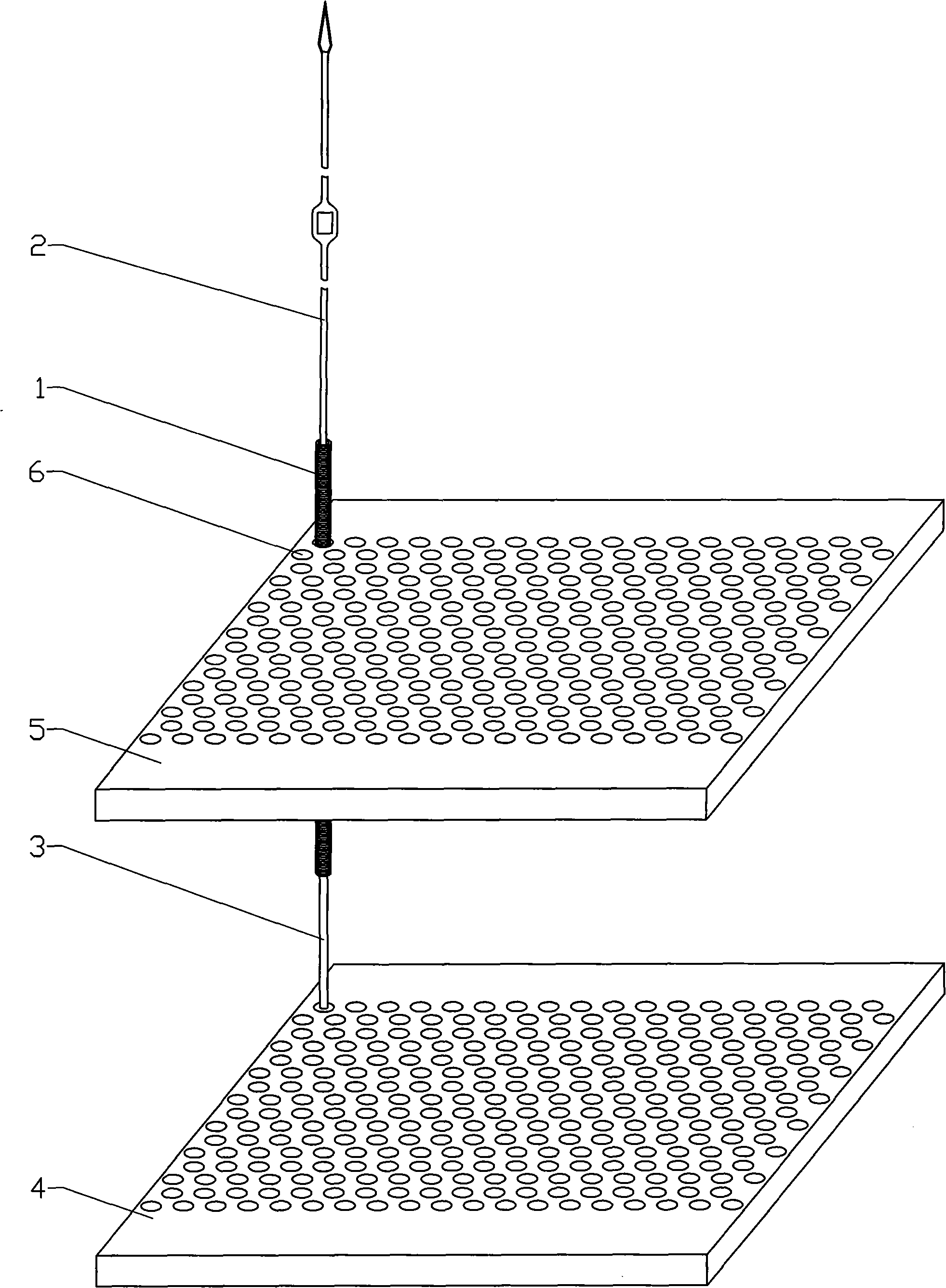

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

Plastic heddle

Heddles for use within a harness frame of a weaving machine are provided. Each of the heddles includes a body formed from a liquid crystal polymer resin. The body forms at least one rod slot enabling engagement with a harness frame. The body also has an eyelet section with the eyelet section forming a yarn eye through which a yarn is capable of passing.

Owner:GTP GREENVILLE INC

Novel shape memory type surfacing material of polyester PTT and process technique thereof

InactiveCN101109124ABacteriostaticIncrease elasticityOther manufacturing equipments/toolsDyeing processYarnPolyester

Owner:洪桂焕

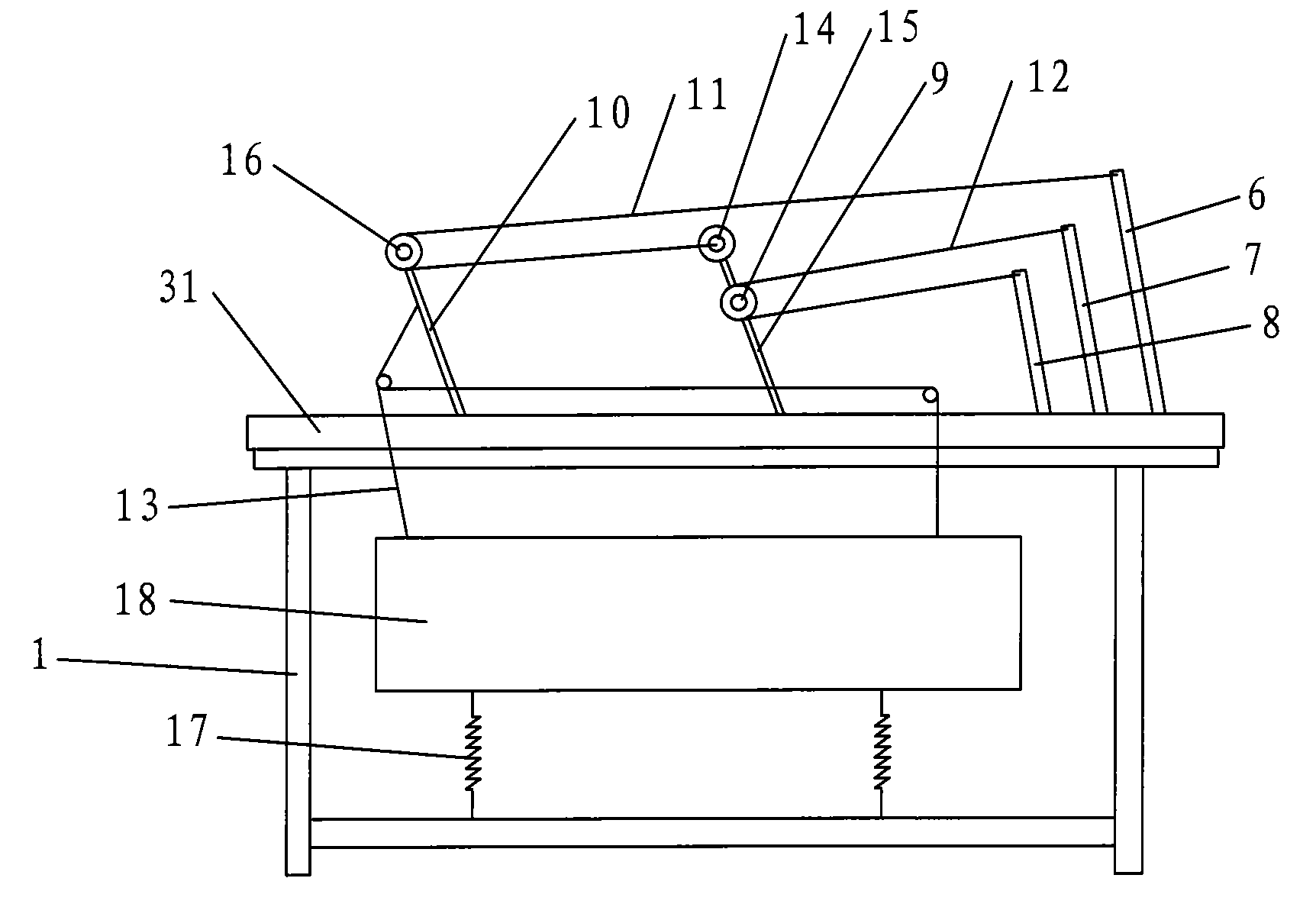

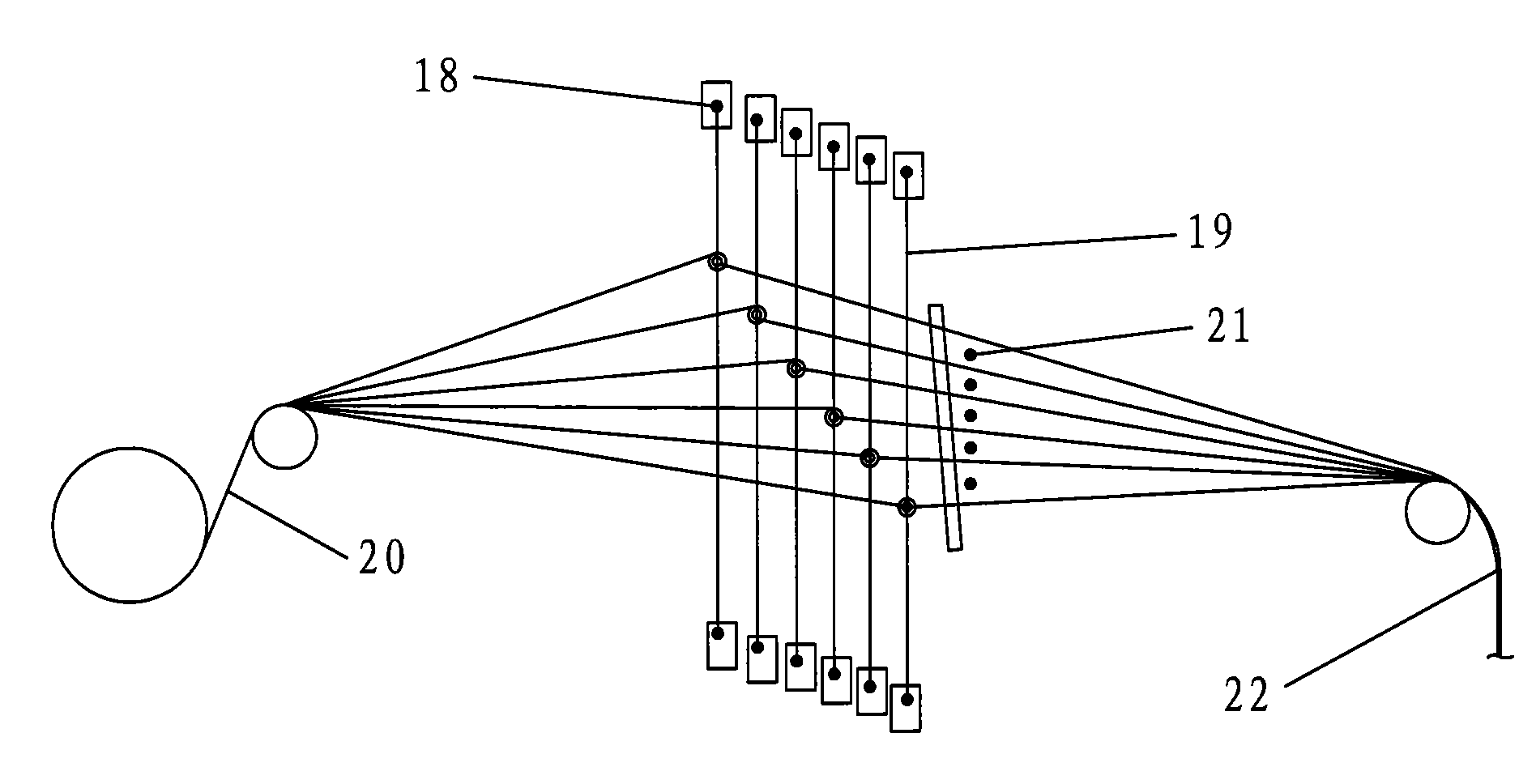

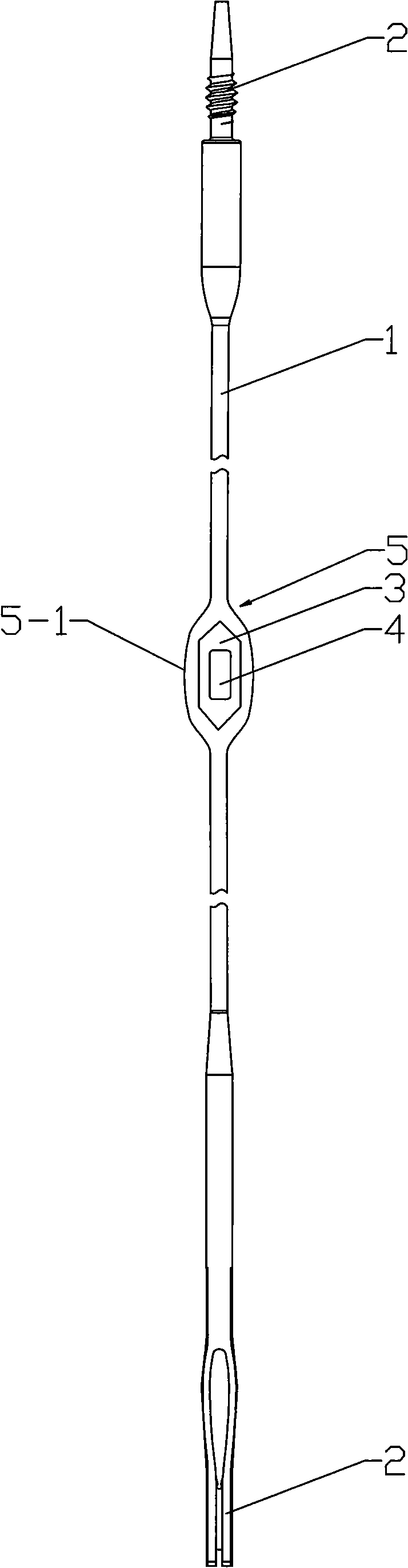

Process for weaving three-dimensional fabrics with special-shaped cross-section and special-purpose heald wire

ActiveCN1570234AImprove integrityHigh dimensional profiling accuracyLoomsWoven fabricsEngineeringAbnormal shaped

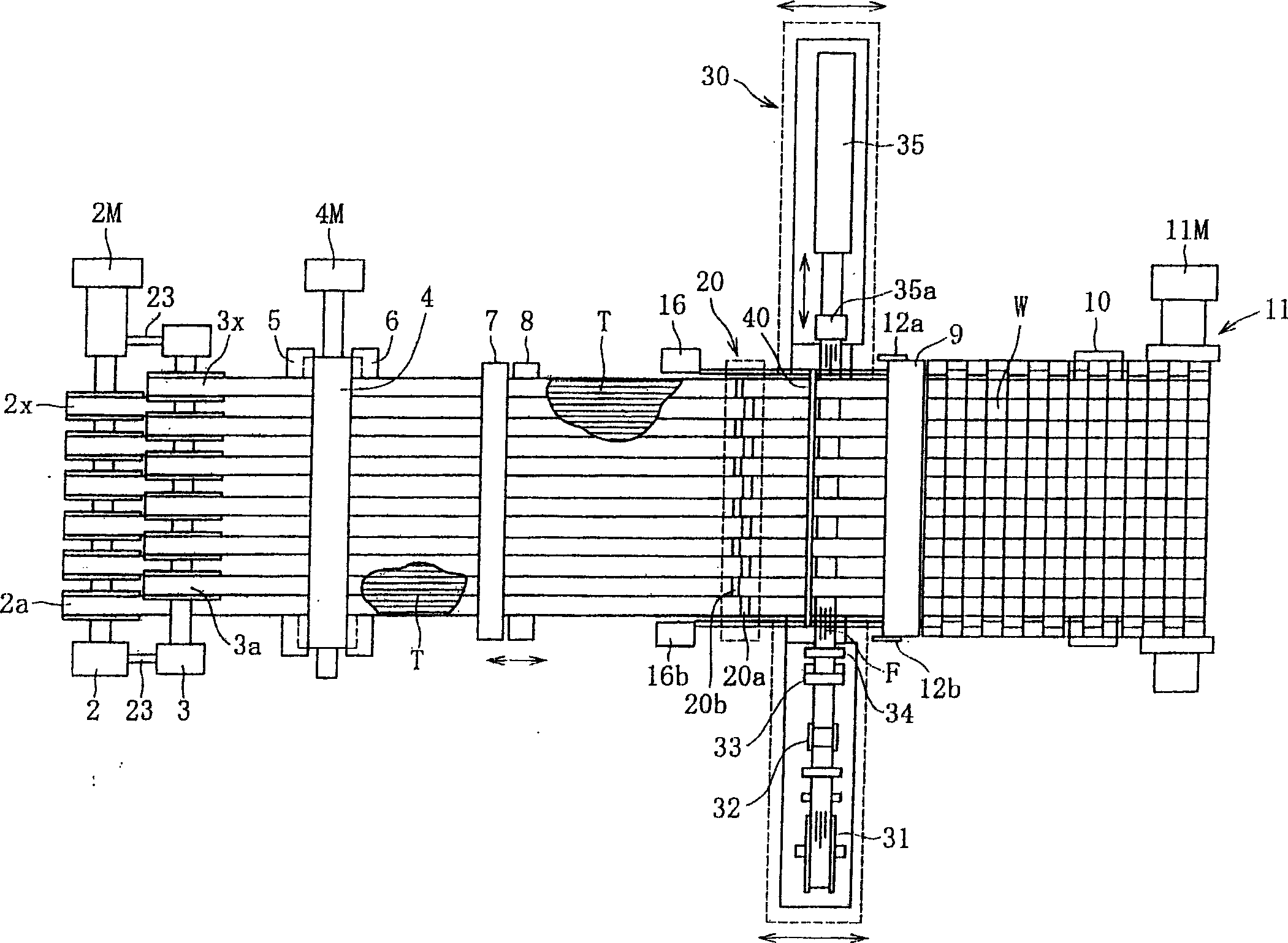

This invention involves manufacture craft of one kind of three dimensional fabric with heterogeneous type section and its special-purpose synthesis silk. This synthesis silk can be manufactured by three dimensional loom equipment. Harness wire in raise synthesis installment's harness frame to process the special multi- eyes synthesis silk. The warp thread arrangement on the multi- eyes synthesis silk is based on the heterogeneous type section implementation craft. According to the specific harness frame movement procedure, let the warp thread to form the multilayered aperture. According to the certain sequence introduction weft, realization fabric structure taking shape. This invention use the multi- eyes synthesis silk to realize the multilayered fabric structure to take shape, using the multilayer achieved the fabric thickness need, enable the fabric to have the certain thickness and the lateral section shape, the fabric overall performance strong, the fabric size profiling precision was high; In weaves process to progress the good warp thread arrangement according to the heterogeneous type section size need passable different harness frame fluctuation procedure in the multi- eyes synthesis silk, forms the multi-level clear aperture easy multilayer filling insertion to weave, fabric dimension control scope bigger, the fabric weaves the process to be possible operational to be strong, may process the many kinds of heterogeneous types section fabric.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

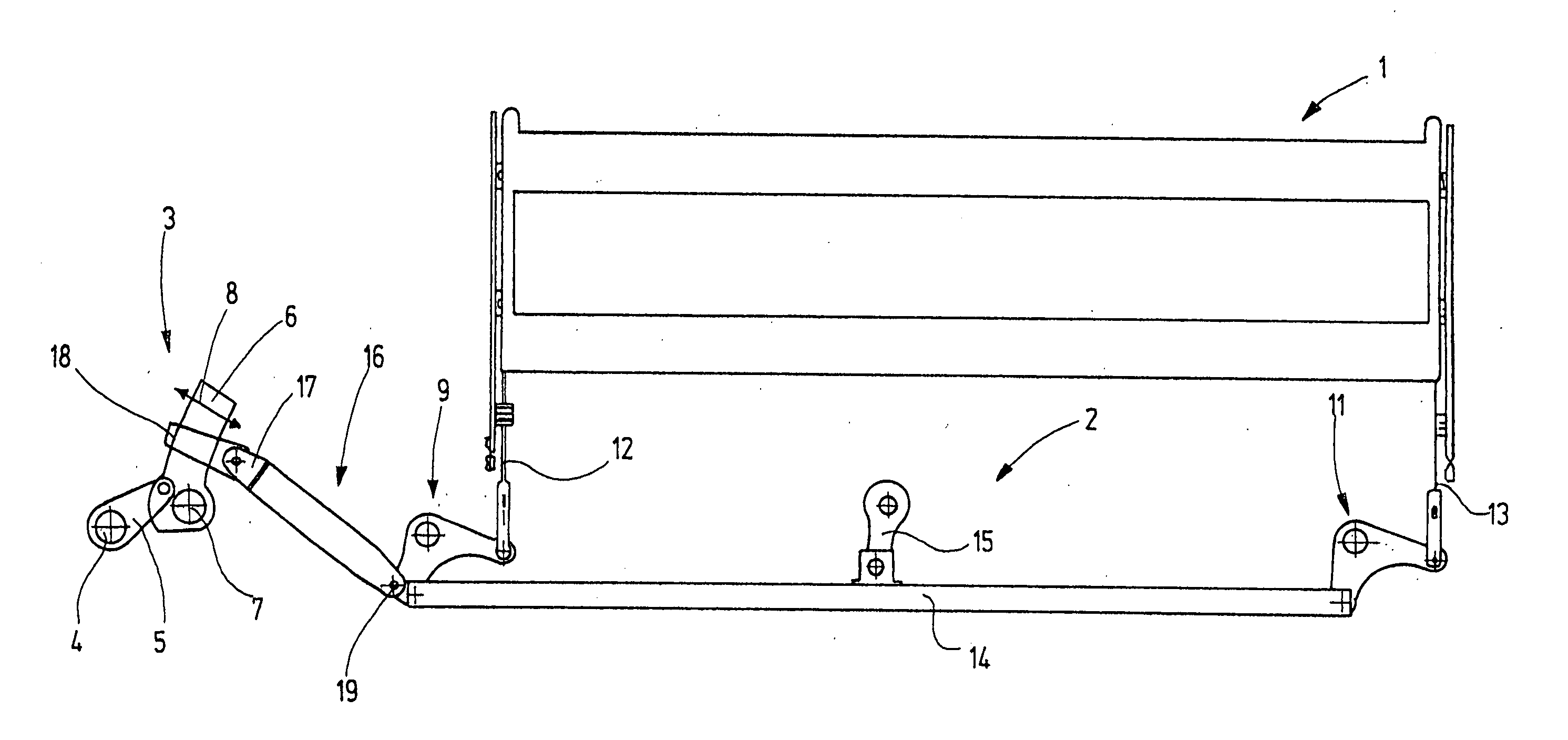

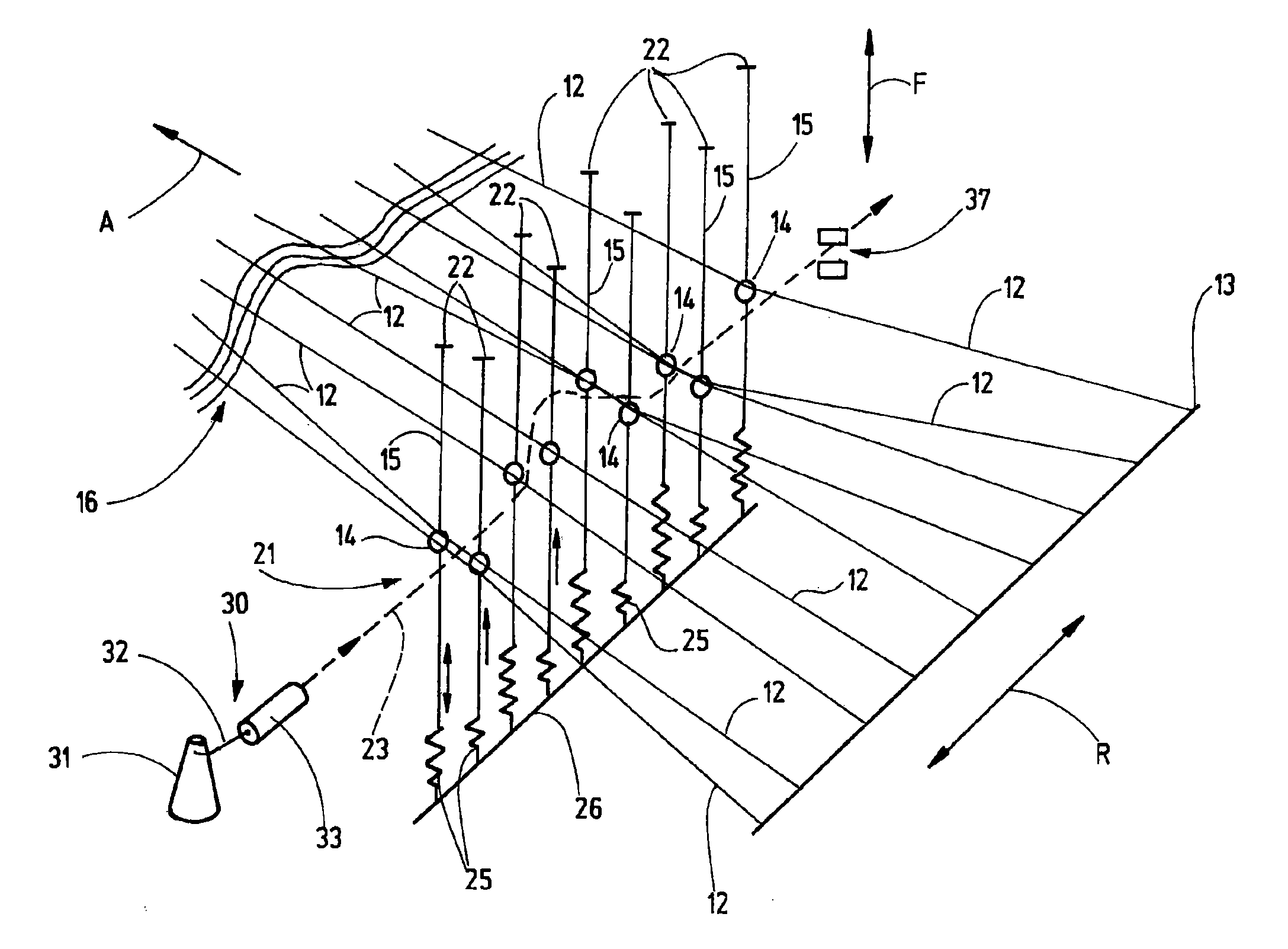

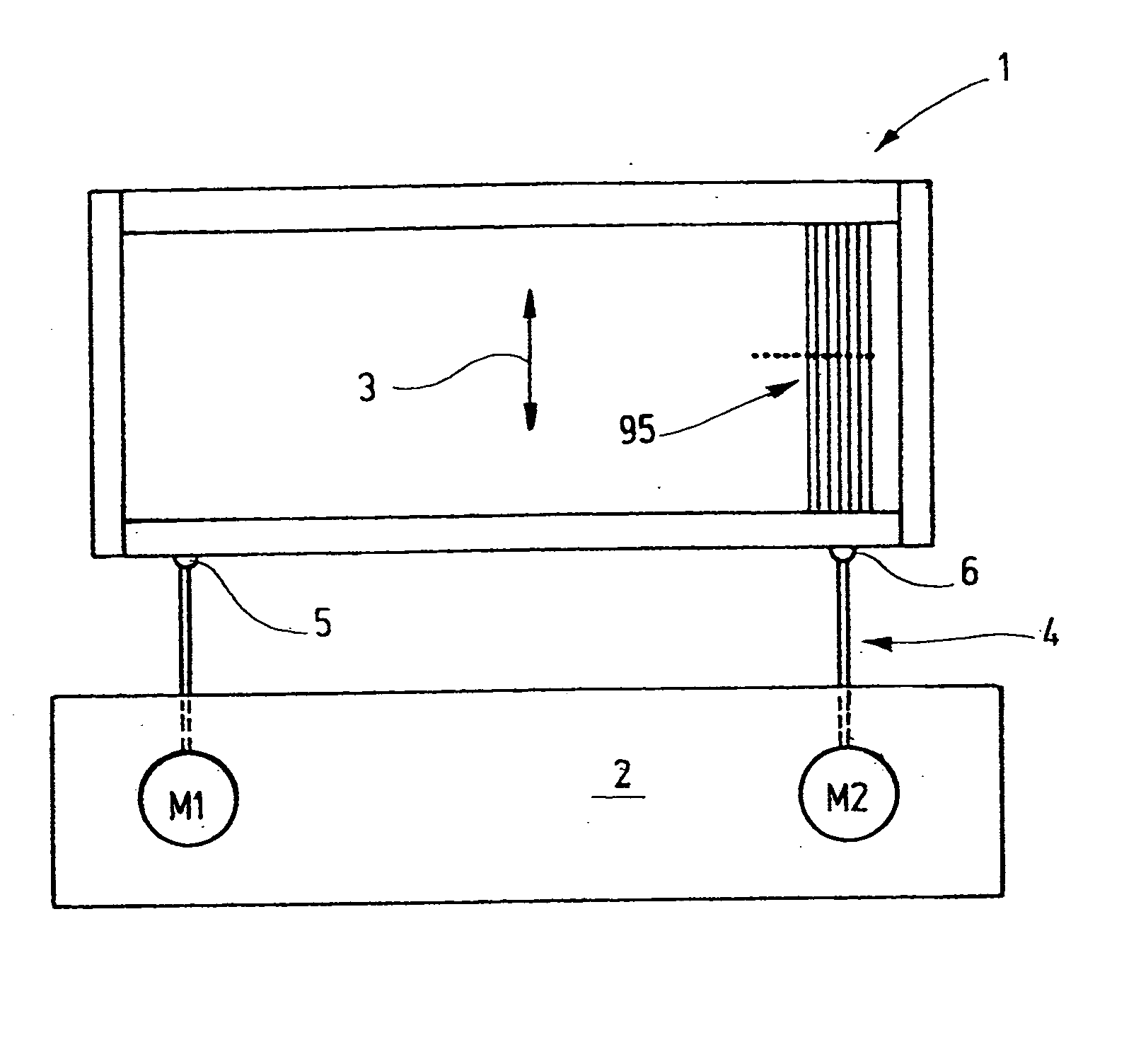

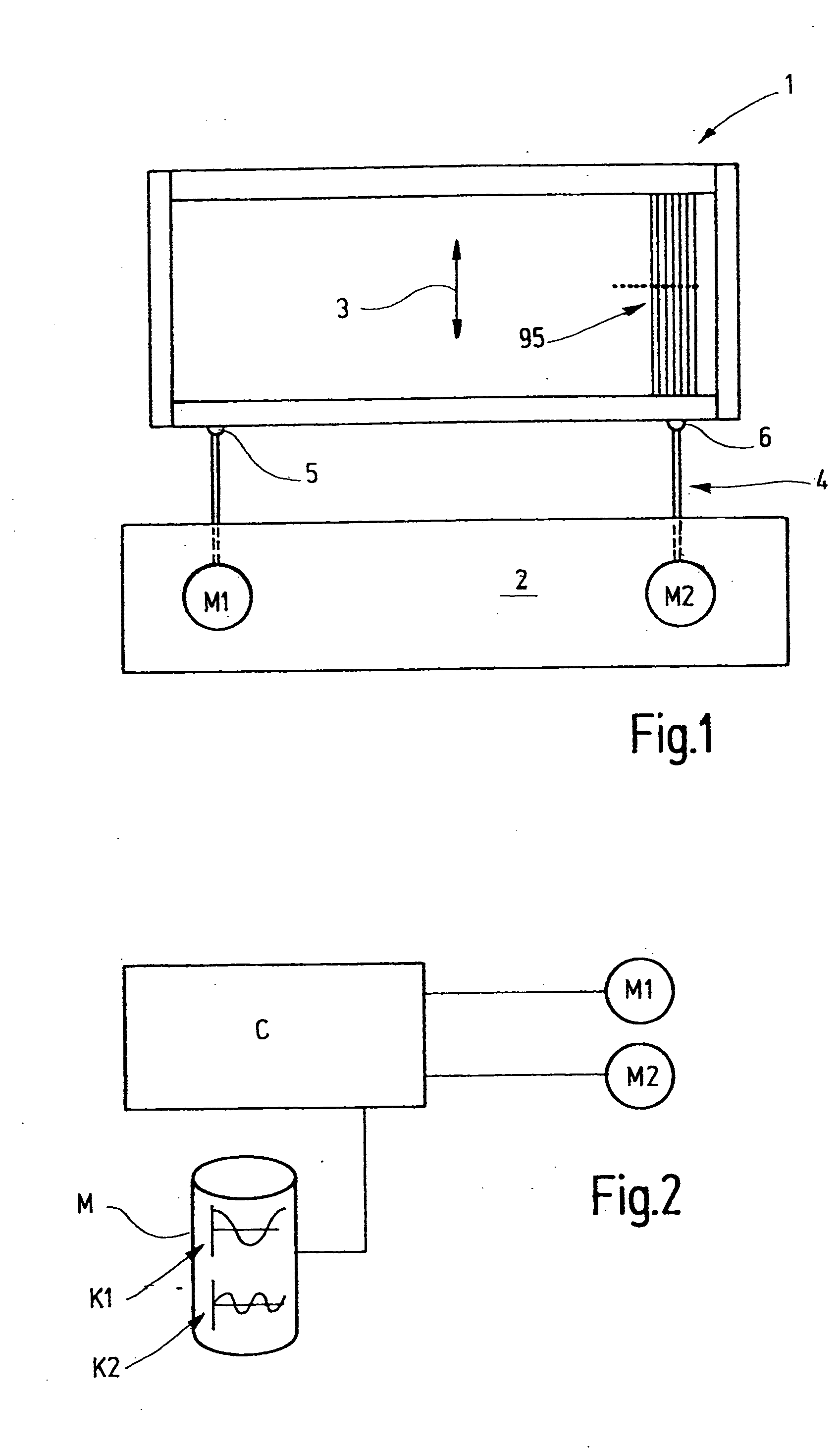

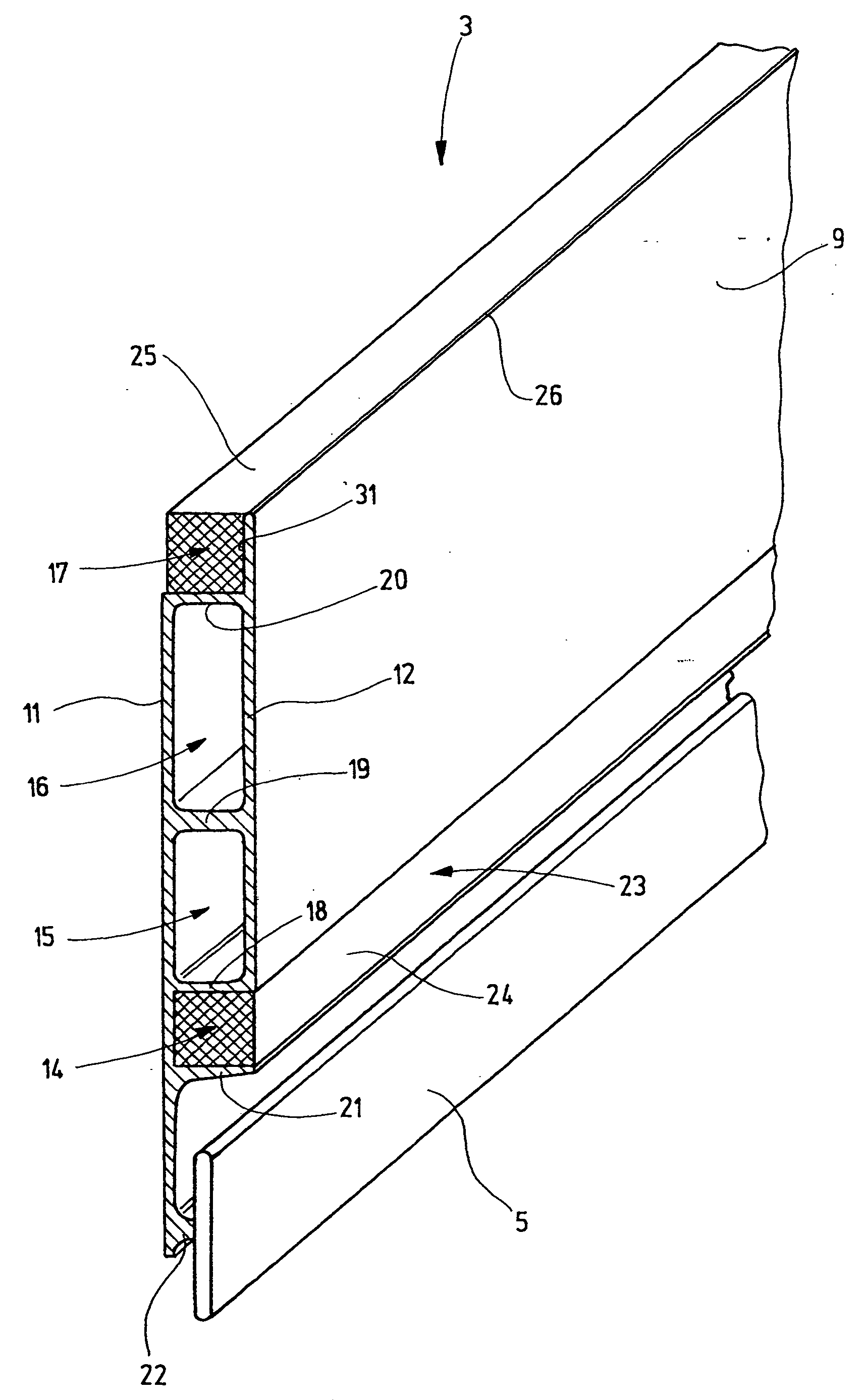

Low-vibration shedding system

InactiveUS20050051228A1Good oscillation absorptionImprove axial rigidityWeft knittingDobbiesCouplingEngineering

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

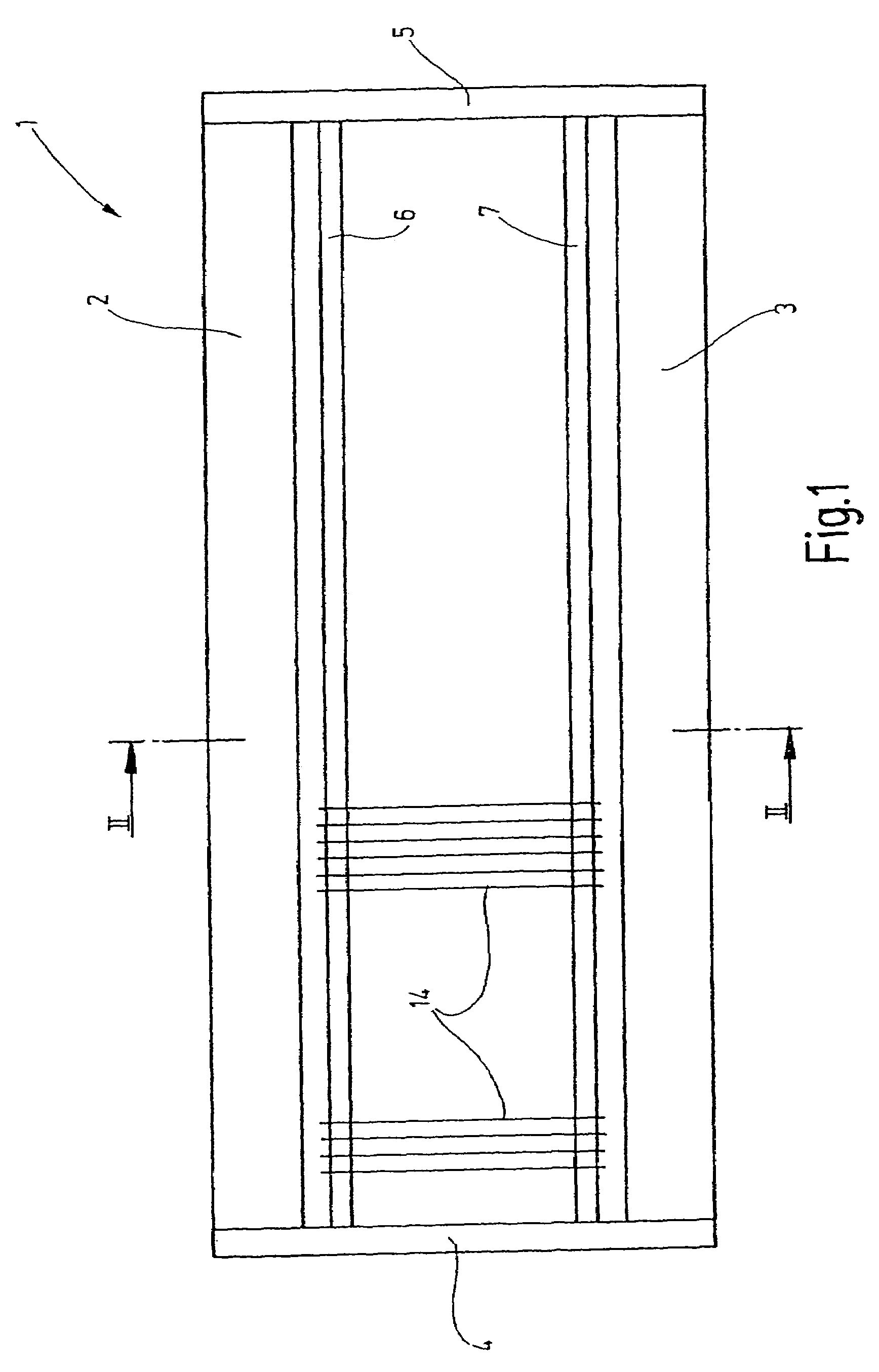

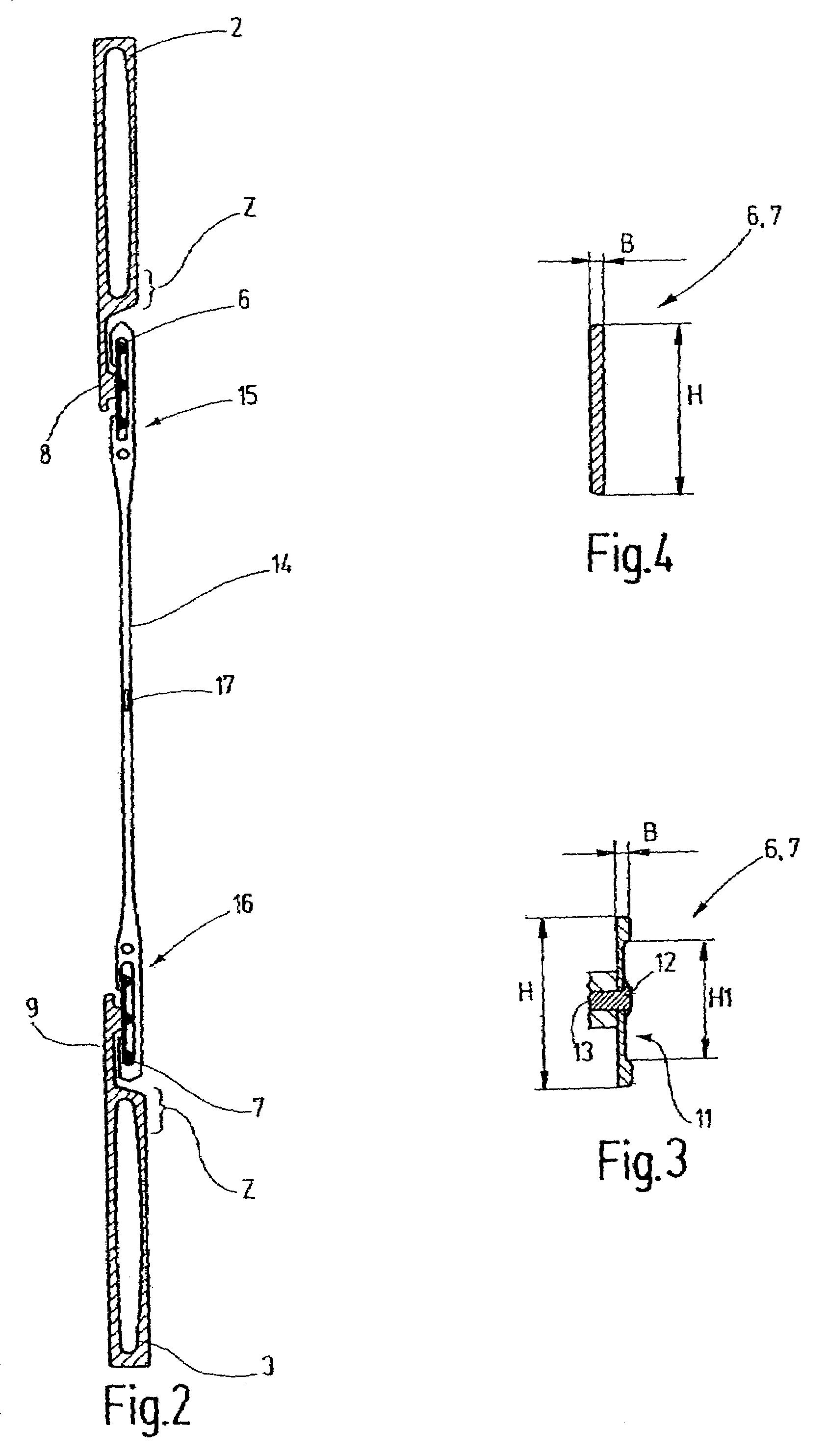

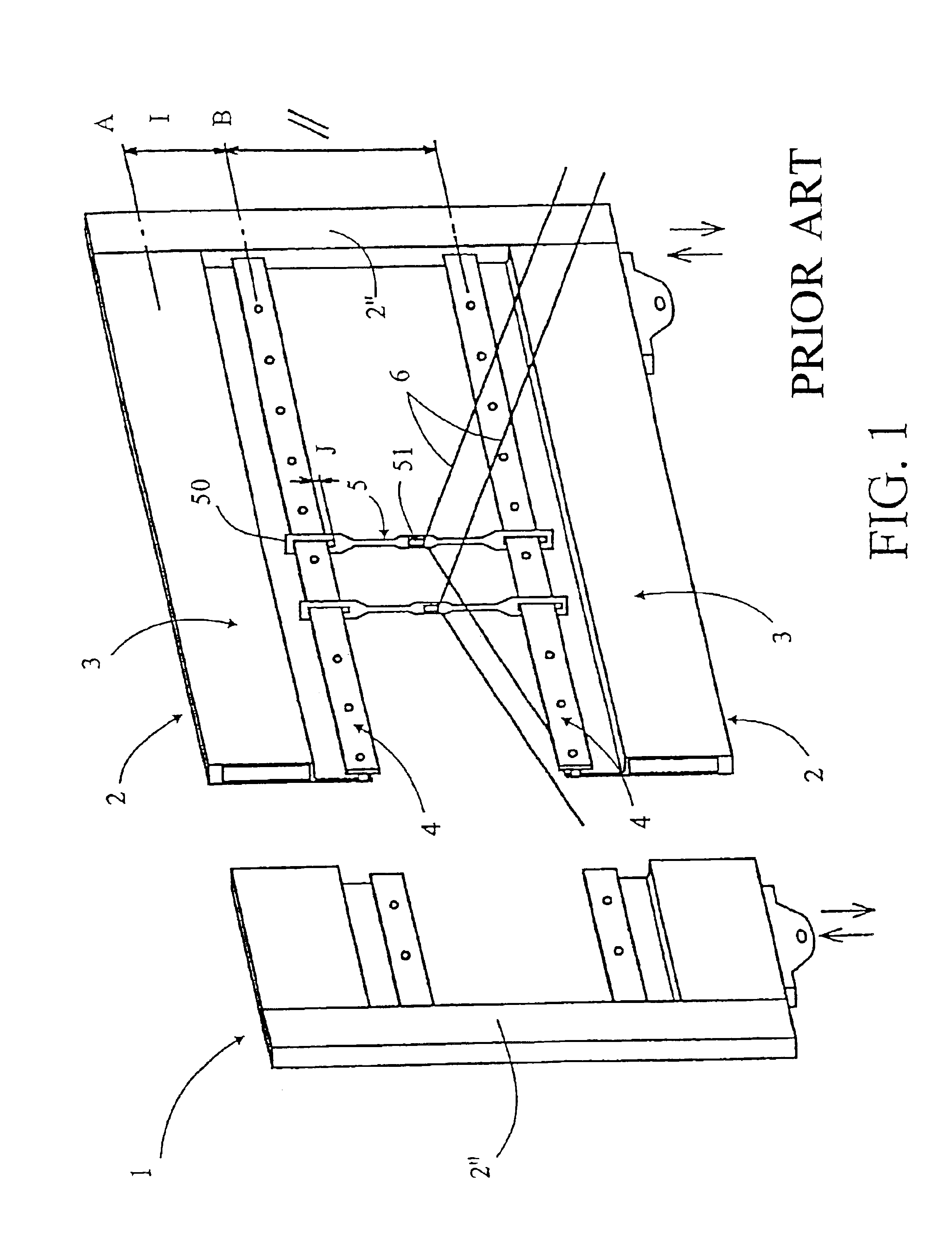

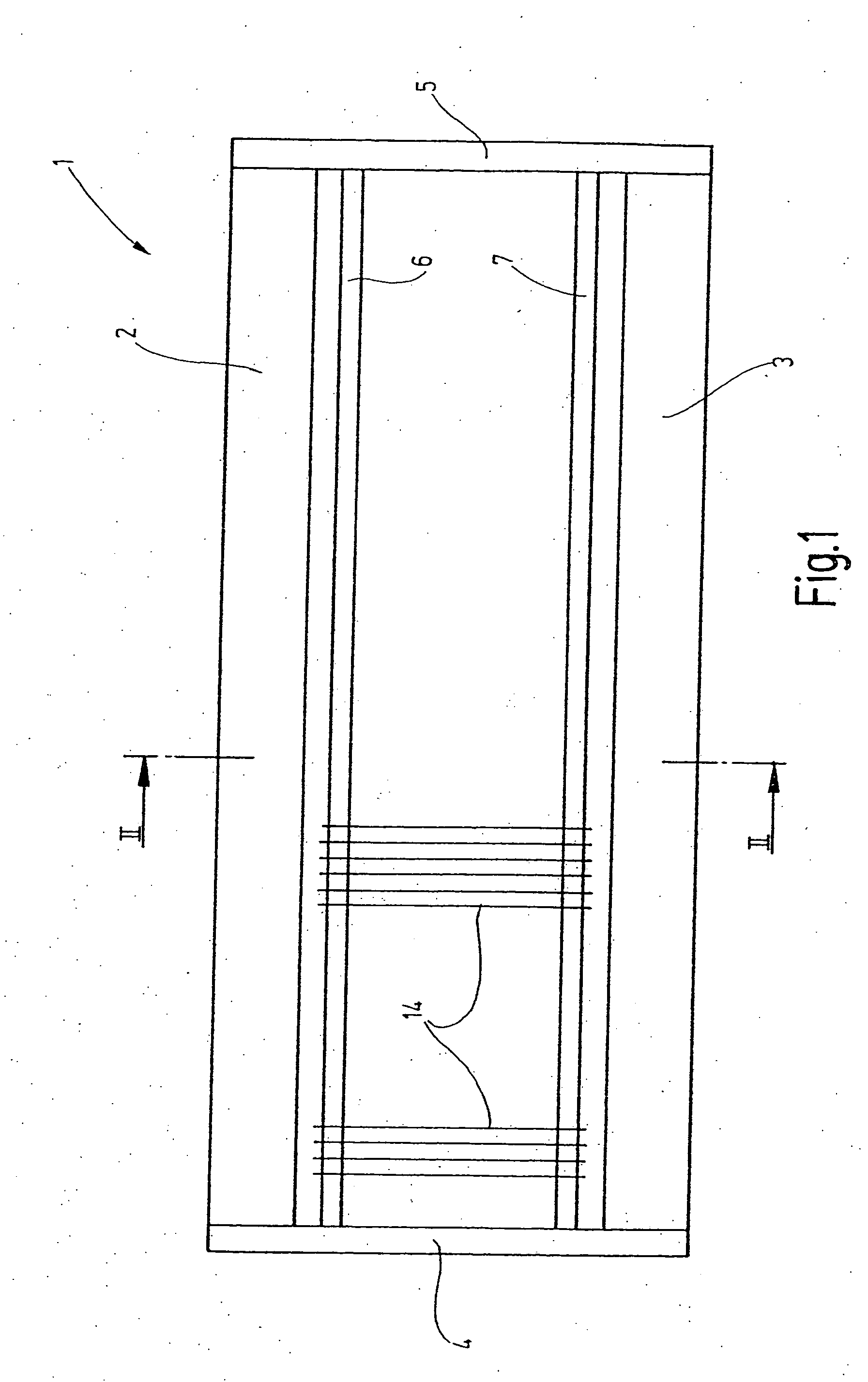

Heddle with reduced play

A heddle (14) of the invention is distinguished by end eyelets (15, 16) of reduced size, with which heddle support rails (6, 7) of reduced cross section are associated. The axial play of the heddles on the heddle support rails (6, 7) is limited to from 0.5 mm to 1.5 mm. The lateral play is in the range of 0.2 mm to 0.5 mm. This system formed of heddle support rails and heddles is especially suitable for particularly rigid heddle shafts for power looms with an extremely high operating speed.

Owner:GROZ BECKERT KG

Heddle damping system

A loom shaft for a heddle has two end eyes in which at least one eye is elongated in the longitudinal direction of the heddle such that even during operation and bending of the shaft in the region of the shaft center, the distance between an inner rail edge of the heddle support rail and the region of the cutout end of the eye and the outer rail edge of the opposite heddle support rail is greater than the distance between the inner stop of the cutout end eye and the outer stop of the opposite end eye. The inner edge facing the heddle support rail may be of elastic material on at least one support bar of the shaft to prevent impact of heddles against the support bar during high stress placed on the shafts.

Owner:GROZ BECKERT KG

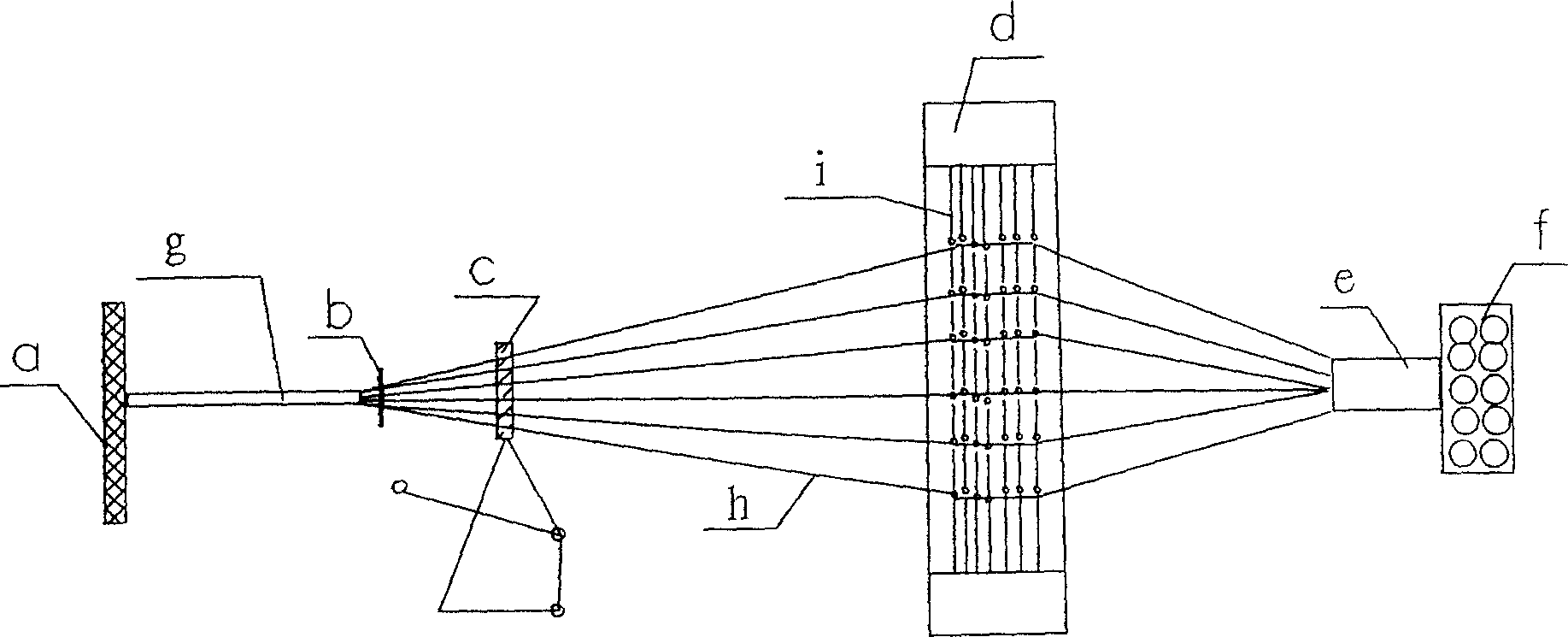

Weaving Machine and Method for Three-Dimensional Weaving

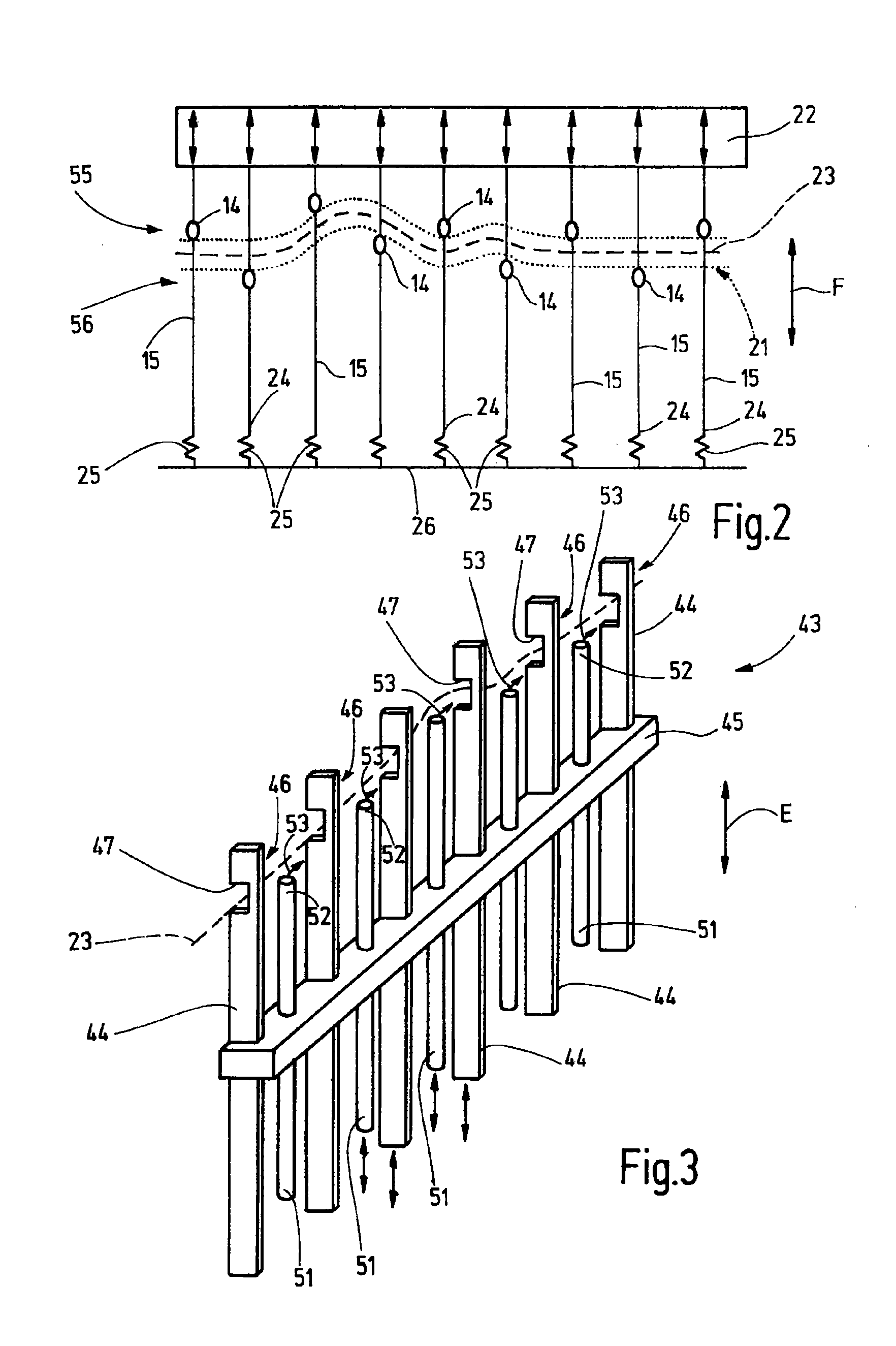

a weaving machine and a weaving method for direct three-dimensional weaving, wherein the weft thread (32) is imparted with its desired two-dimensional course already when the weft thread is being input. The position of the warp threads (12) is adapted to the weft thread path (23). The weft thread path (23) is defined by the lamellae (44) that extend into the shed (21) in between the warp threads (12). The lamellae (44) are arranged on a common bar (45) so that they can be individually adjusted, thus enabling the adjustment of the desired weft thread path (23) by positioning the lamellae (44). The lamellae (44) and the bar (45), at the same time, form the reed (43) that is used for casting on the weft thread (32) at the fabric edge (16).

Owner:GROZ BECKERT KG

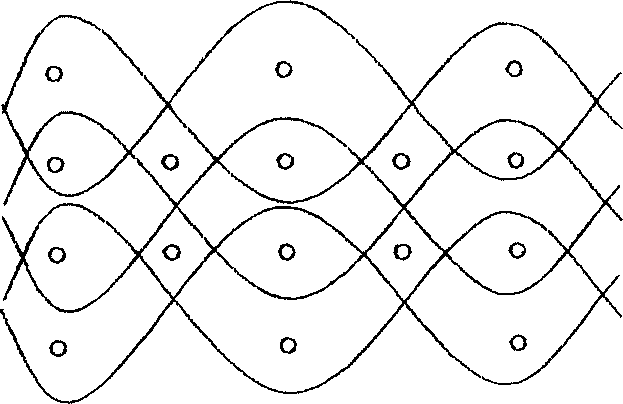

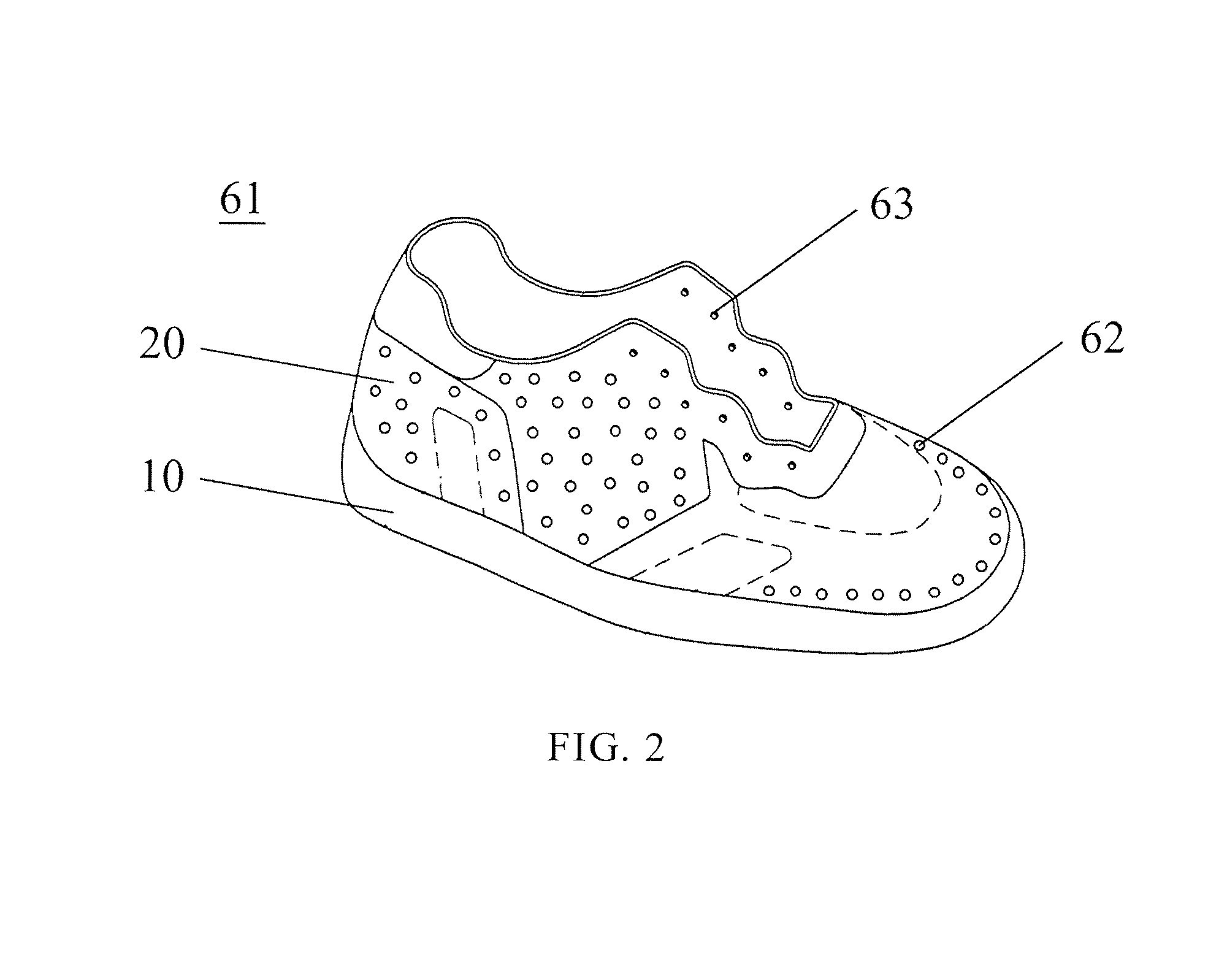

Footwear assembly with breathable and wear-resistant woven vamp

InactiveUS20160106182A1Improve wear resistanceWear resistance can be promotedUpperMulti-ply fabricsWear resistantBiomedical engineering

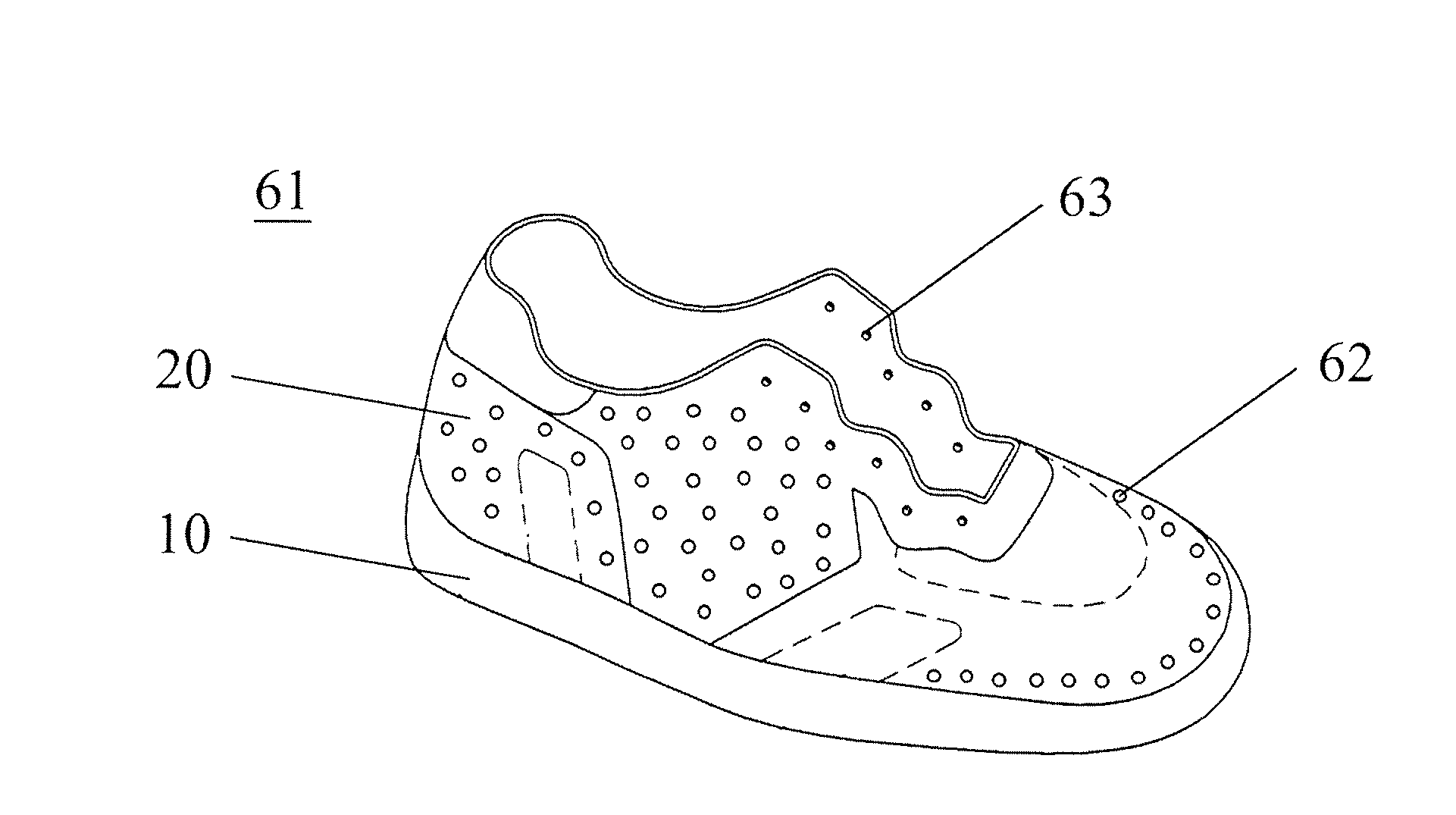

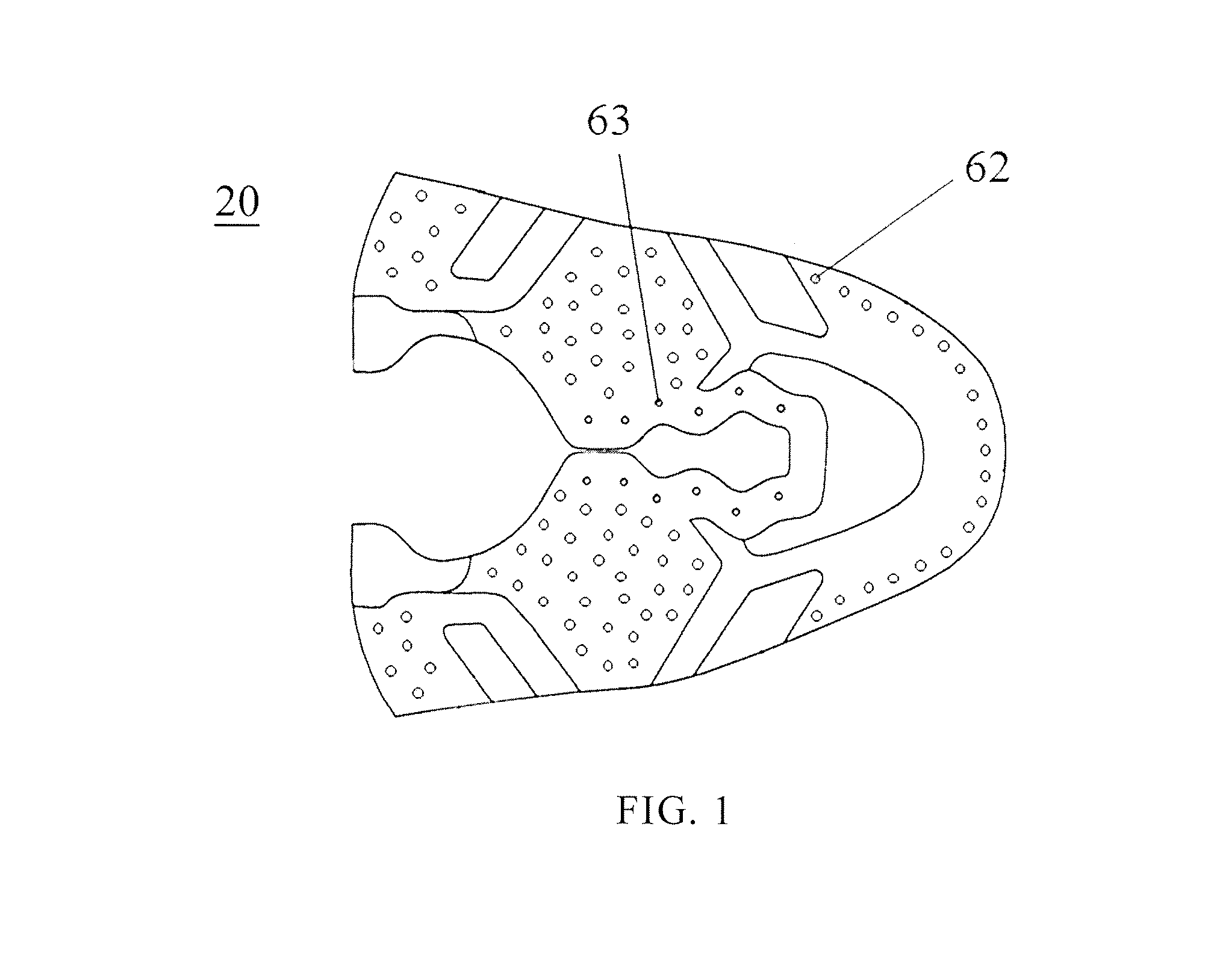

A footwear assembly with breathable and wear-resistant woven vamp is disclosed, which includes a sole structure and a breathable and wear-resistant woven vamp. The breathable and wear-resistant woven vamp has a woven fabric with a two-layered structure and is assembled on the sole structure to form the footwear assembly. The breathable and wear-resistant woven vamp is made by a double beam jacquard based on a texture composition and planned pores and a plurality of breathable pores are formed by obliquely interlacing a first warp yarn series, a second warp yarn series and a plurality of weft yarn series.

Owner:DEERTEX

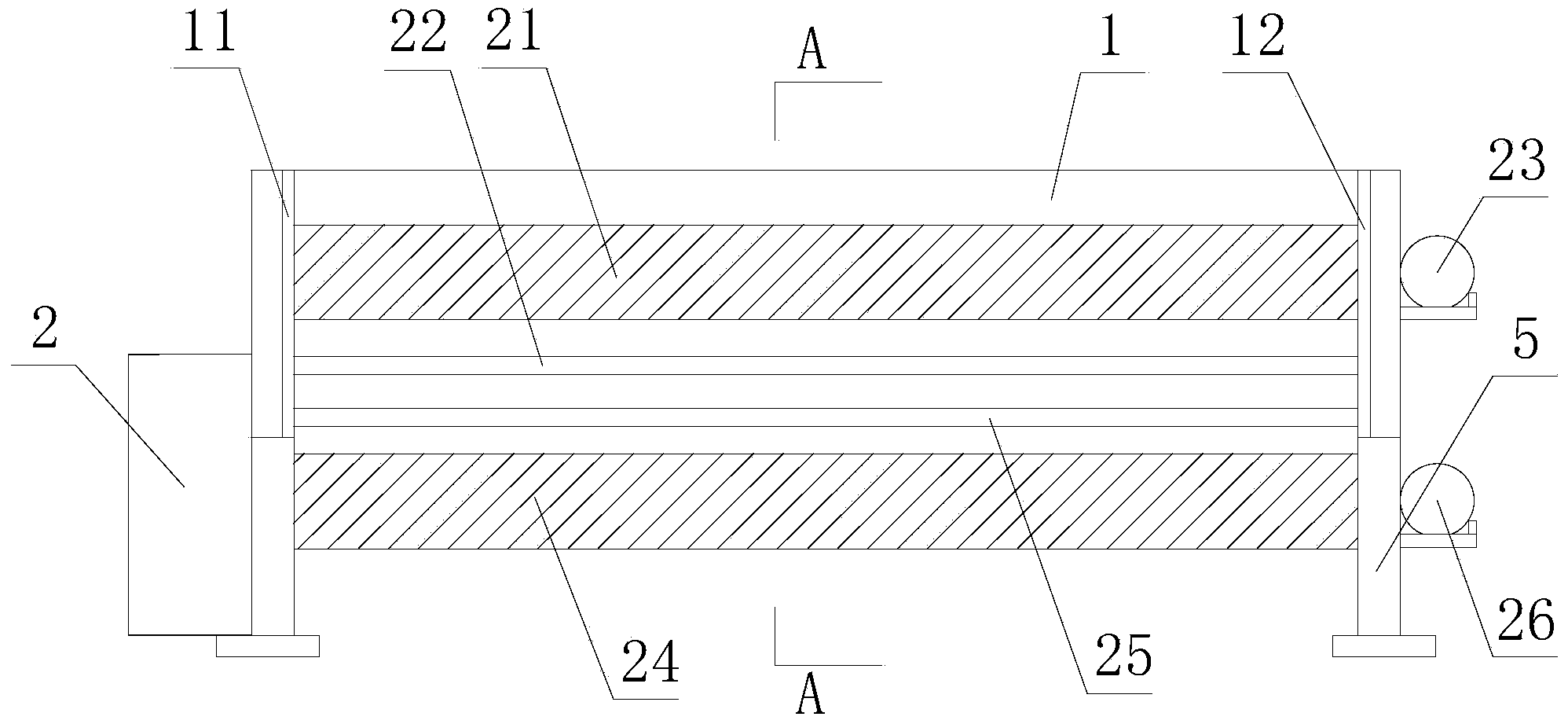

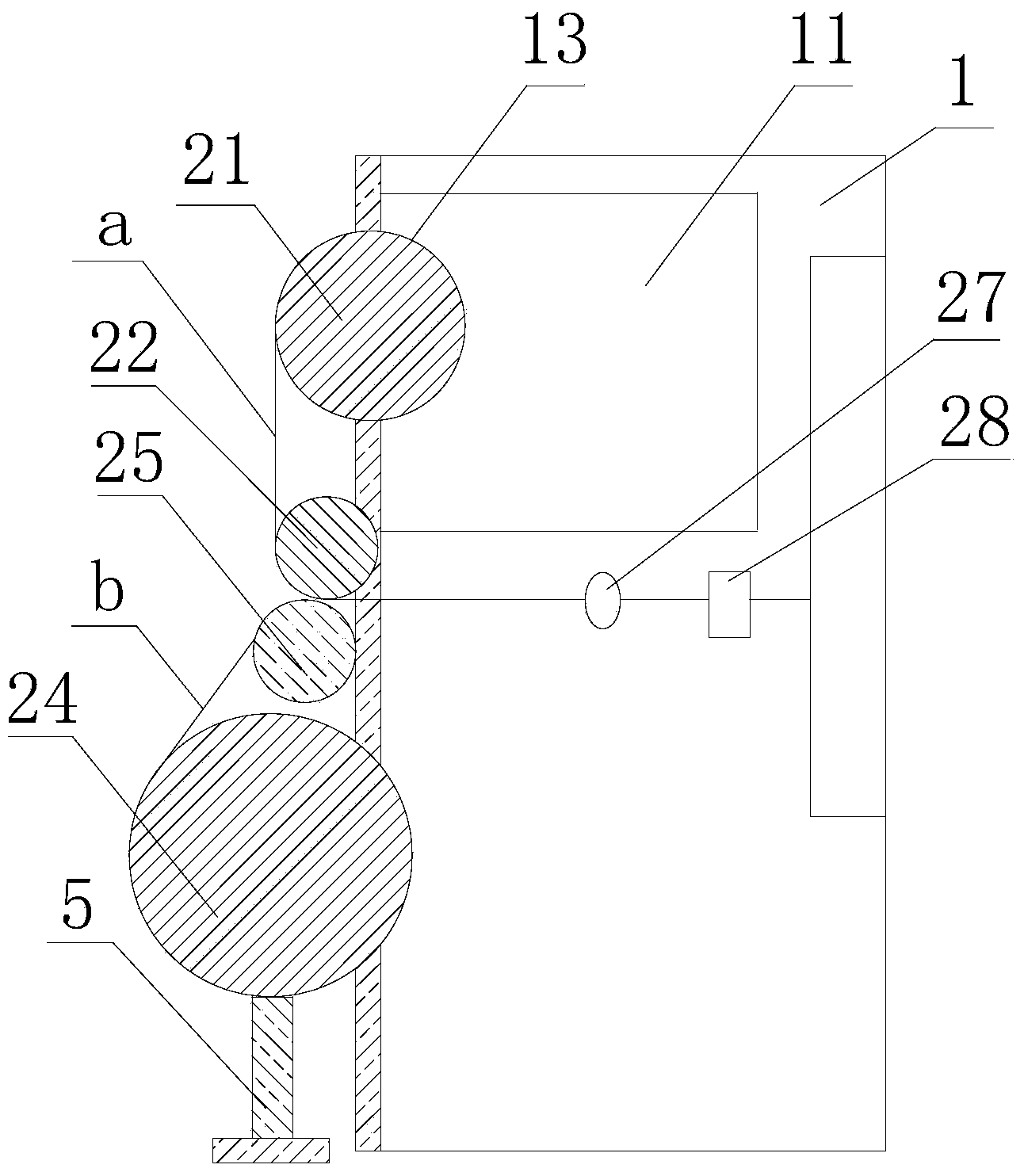

Novel double-beam rapier loom

The invention discloses a novel double-beam rapier loom. The novel double-beam rapier loom comprises a rack, a let-off mechanism, a beating-up mechanism, a driving system and a winding mechanism, wherein a left wallboard and a right wallboard are arranged on the rack, a heald frame mechanism is arranged behind the let-off mechanism, a first let-off beam is horizontally fixed on a beam seat, and two ends of a second let-off beam are fixed on a fixing device independent of the rack. According to the rapier loom, the second let-off beam is arranged below the first let-off beam in parallel through the fixing support independent of the rack, the first and second let-off beams are driven by an independent driving system, and a traditional press roll device is omitted, so that the operation and the inspection treatment by operators are more convenient, and in addition, the tension of the two let-off beams can be well controlled; and the thickness of the left wallboard is larger than that of the right wallboard, so that the instability of left and right gravity centers can be avoided. Compared with the prior art, the novel double-beam rapier loom also has the advantages of simple and reasonable structure, high production efficiency and good cloth cover quality.

Owner:浙江海茂纺织机械有限公司

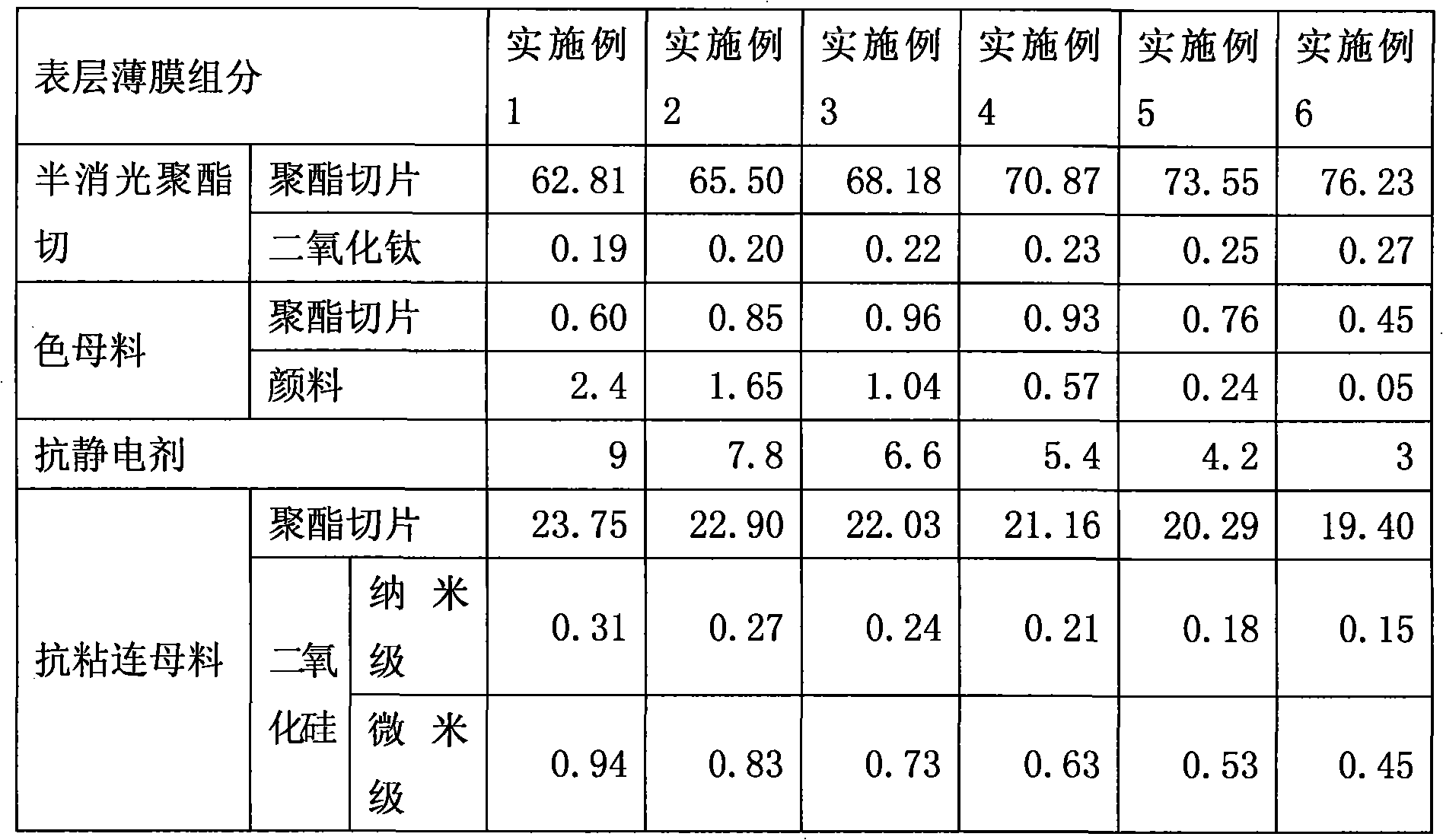

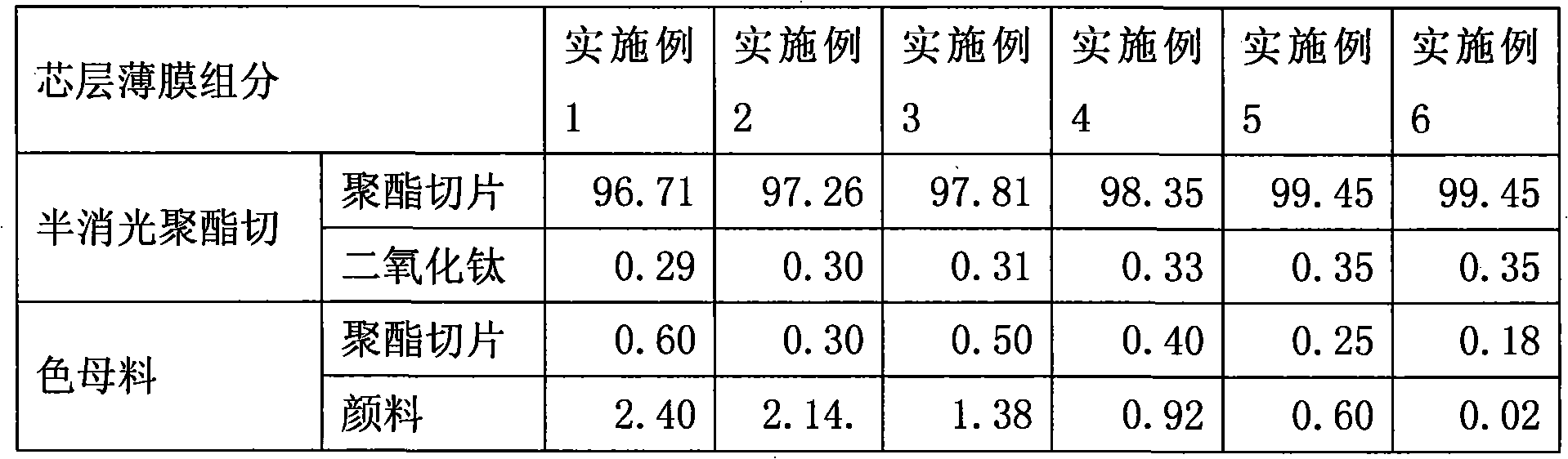

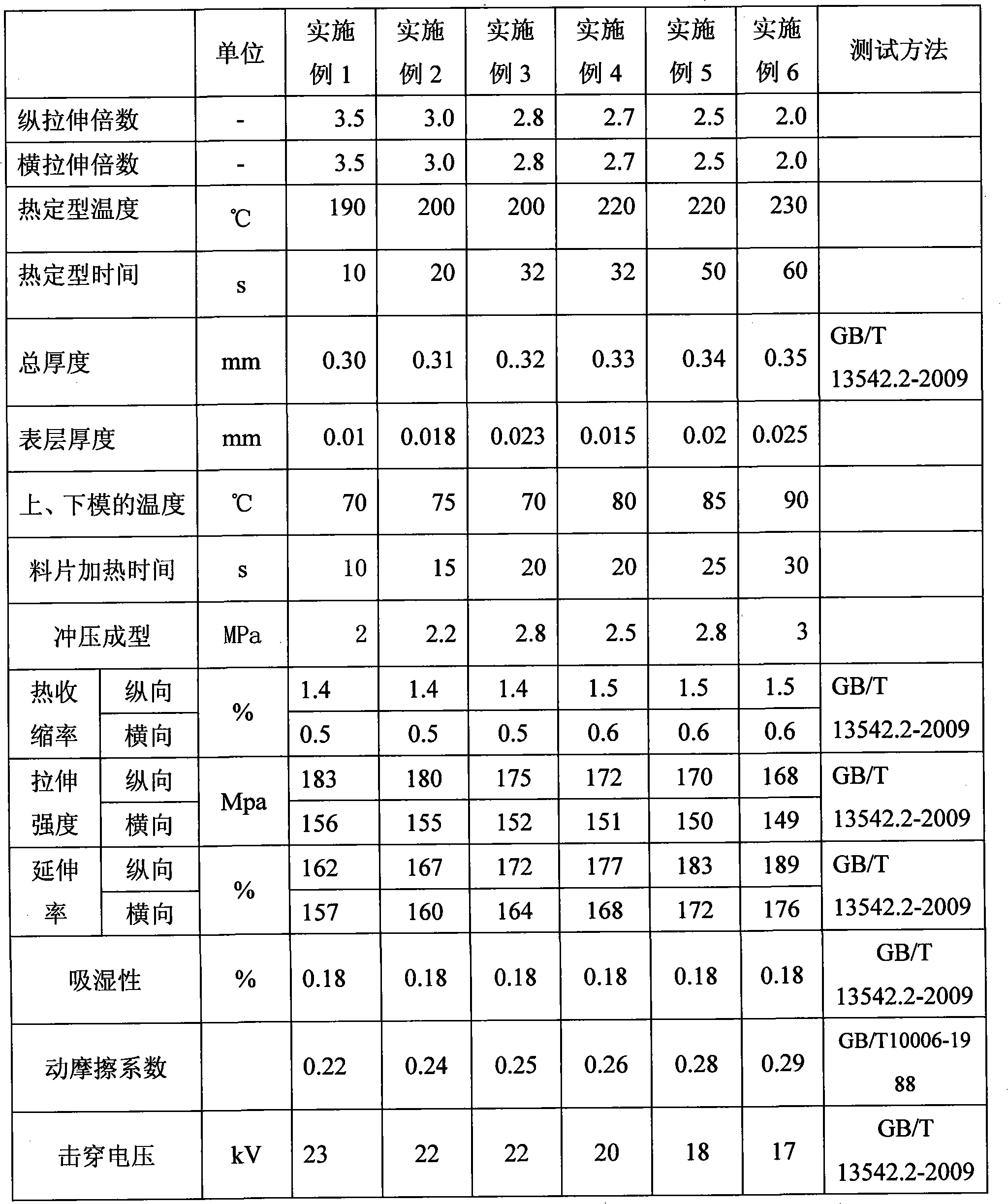

Polyester film harness wire and preparation method thereof

ActiveCN101942727ARigidHas acid and alkali resistanceSynthetic resin layered productsHealdsPolyesterMasterbatch

The invention relates to a polyester film harness wire which is prepared by the following steps: forming a three-layer film by two surface layers extruded mutually and a core layer arranged between the two surface layers; and drawing the three-layer film. The surface layer film comprises 63-76.5% of semi-dull polyester chip by weight percent, 3-9% of antistatic agent by weight percent, 0.5-3% of color masterbatch by weight percent and 20-25% of anti-adhesion master batch by weight percent; the core layer film comprises 97-99.8% of semi-dull polyester chip by weight percent and 0.2-3% of color masterbatch by weight percent; and the total thickness of the polyester film harness wire is 0.30-0.35mm, and the thickness of the isopachous surface layers is between 0.10-0.025mm. The invention has the characteristics of high comprehensive mechanical strength and good wear-resisting property.

Owner:JIANGSU YUXING FILM TECH

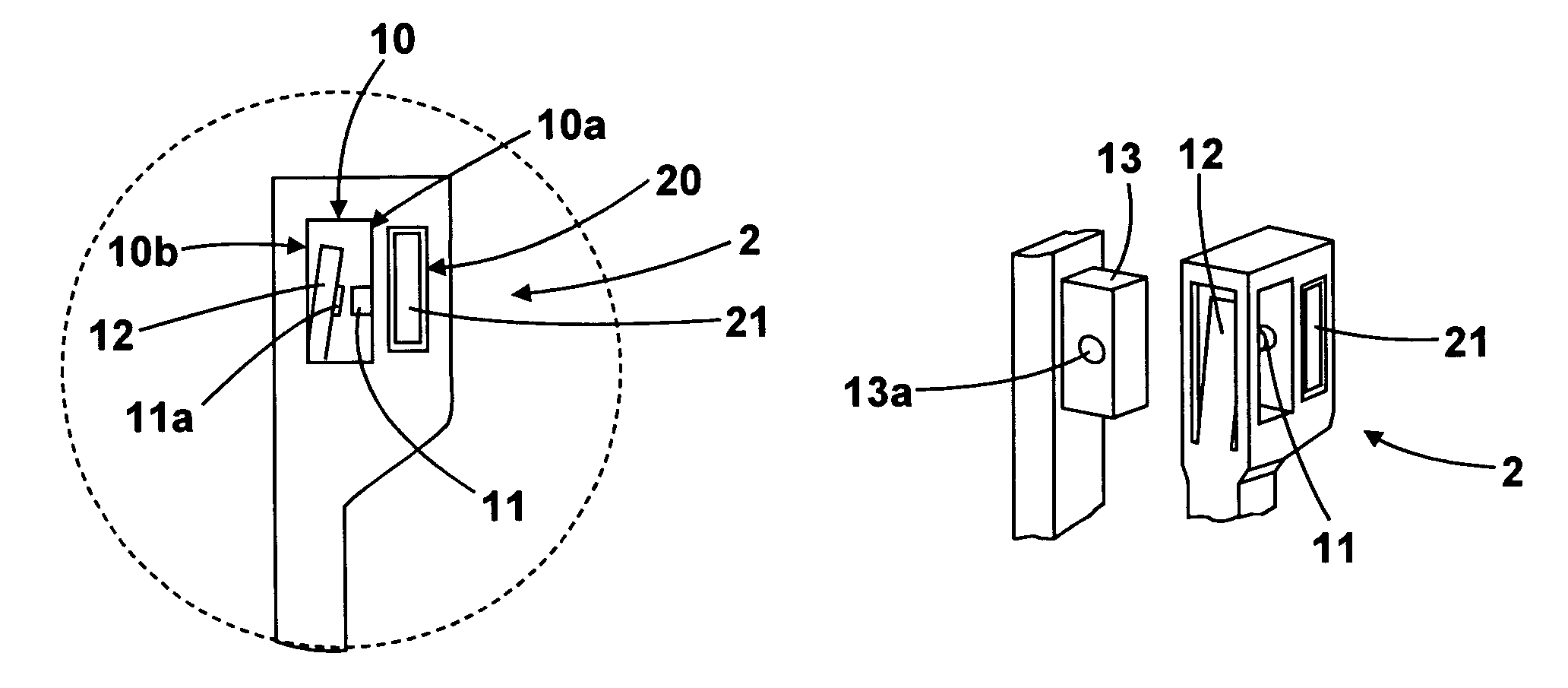

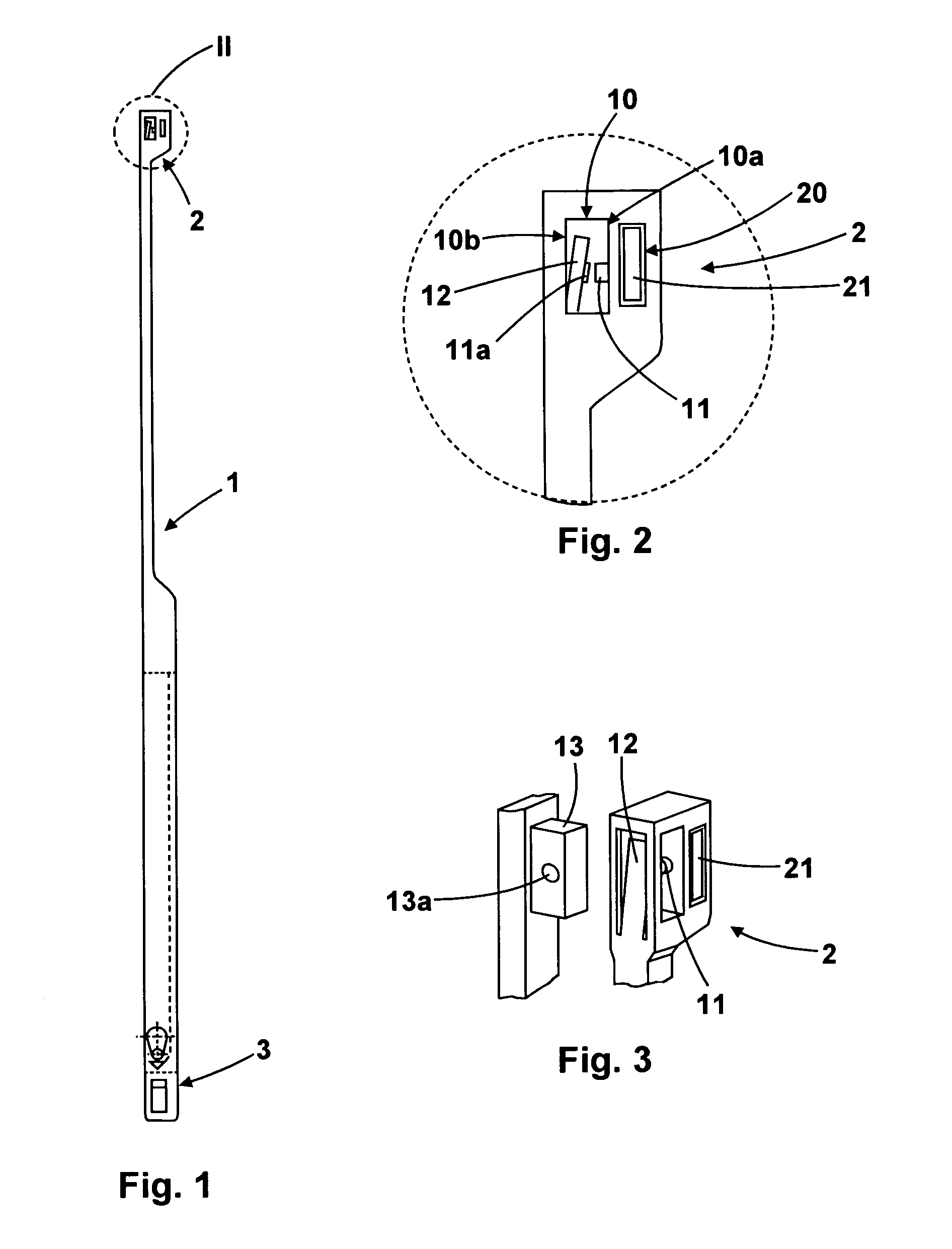

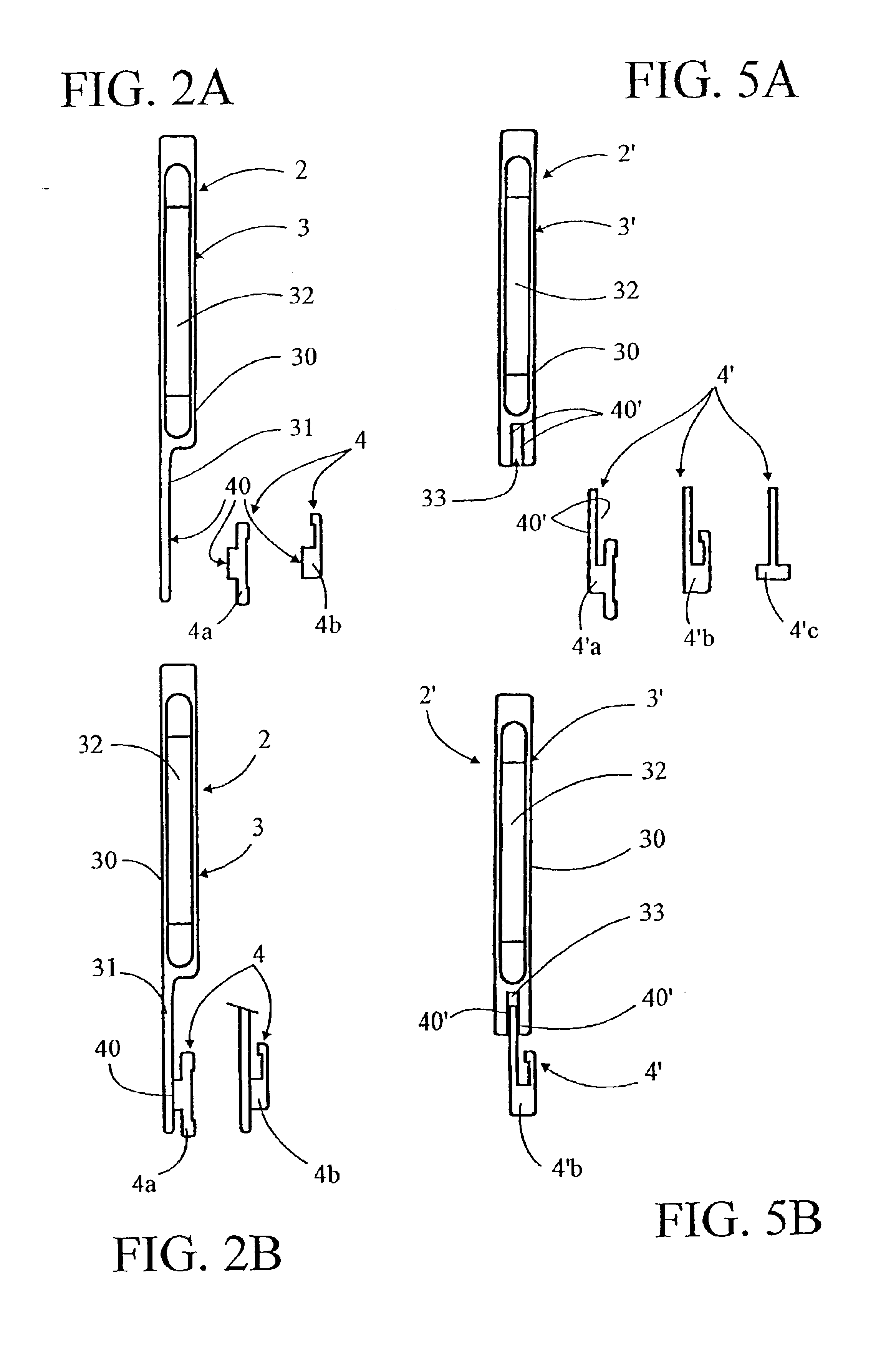

Heddle, especially lifting heddle

The subject matter of the invention is a heddle (1), more specifically a lifting heddle as part of a leno selvedge device, the heddle comprising a head portion and a base portion with a closed or an open eyelet for mounting to a heddle frame or to a heddle ridge bar (13), the head portion and / or base portion (2, 3) being adapted to be secured stationarily to the heddle frame or the heddle ridge bar (13), with the head portion (2) and / or the base portion (3) being adapted to be interlockingly and non-slidably fixed to the heddle frame or to the heddle ridge bar (13) by means of a detent system (11, 12, 13a).

Owner:GEBR KLOCKER

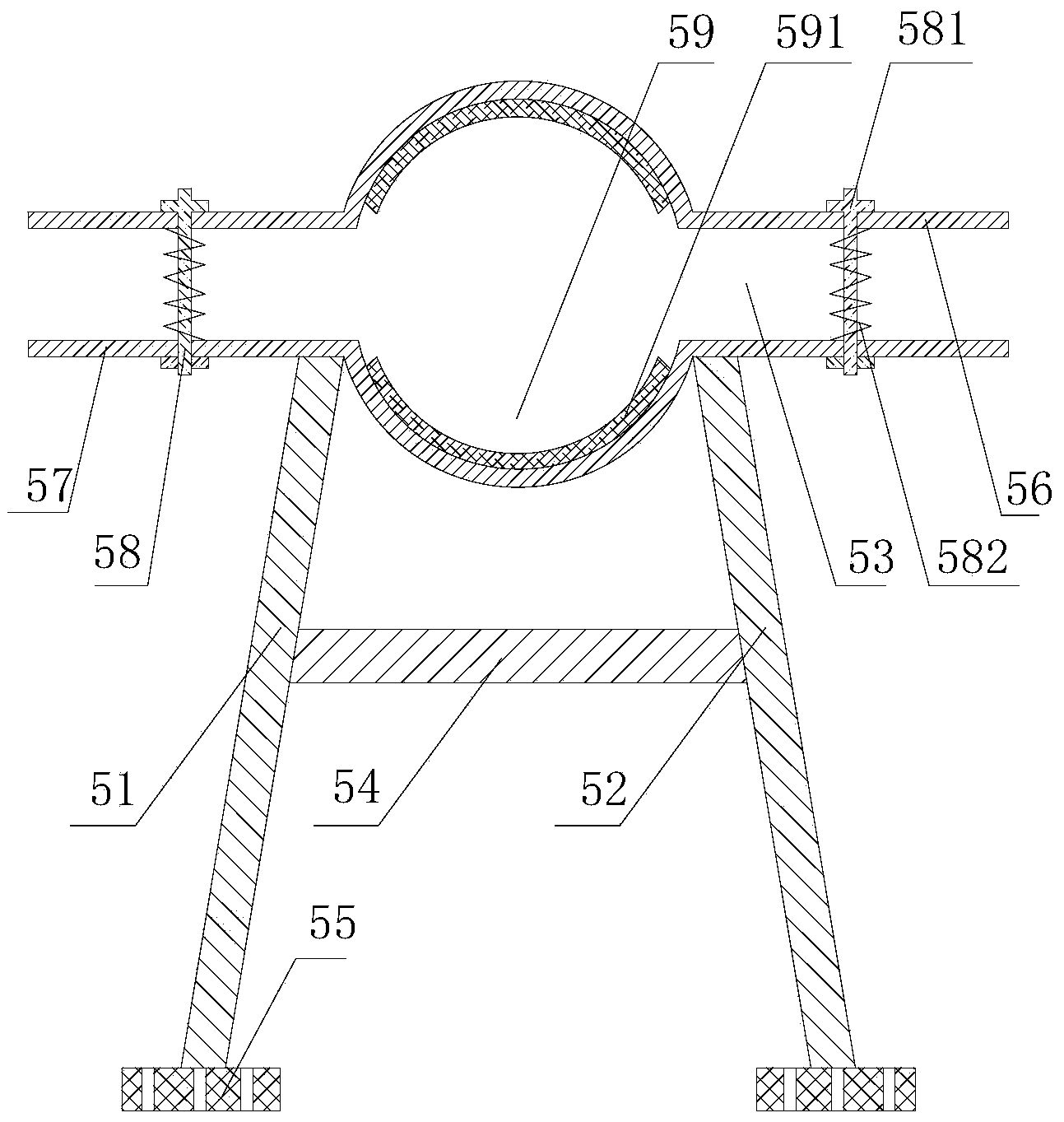

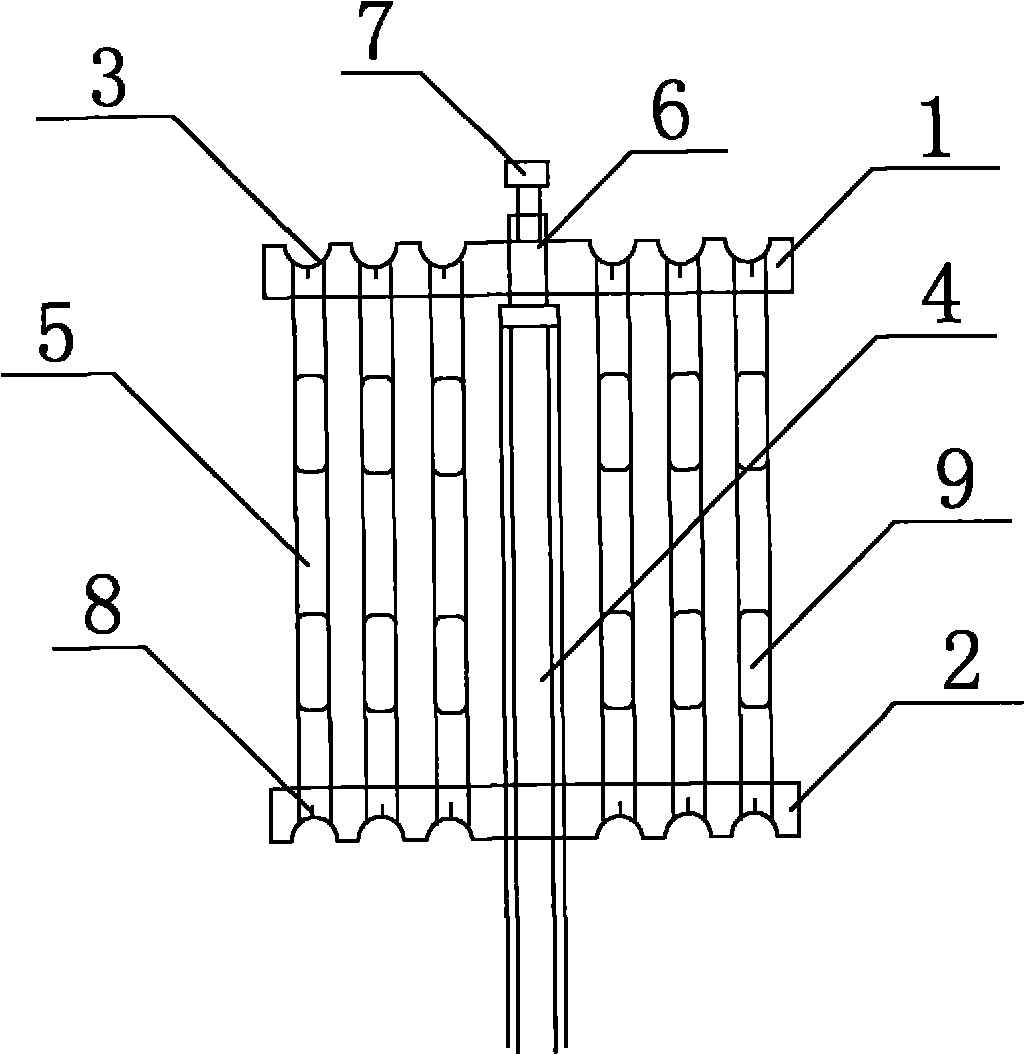

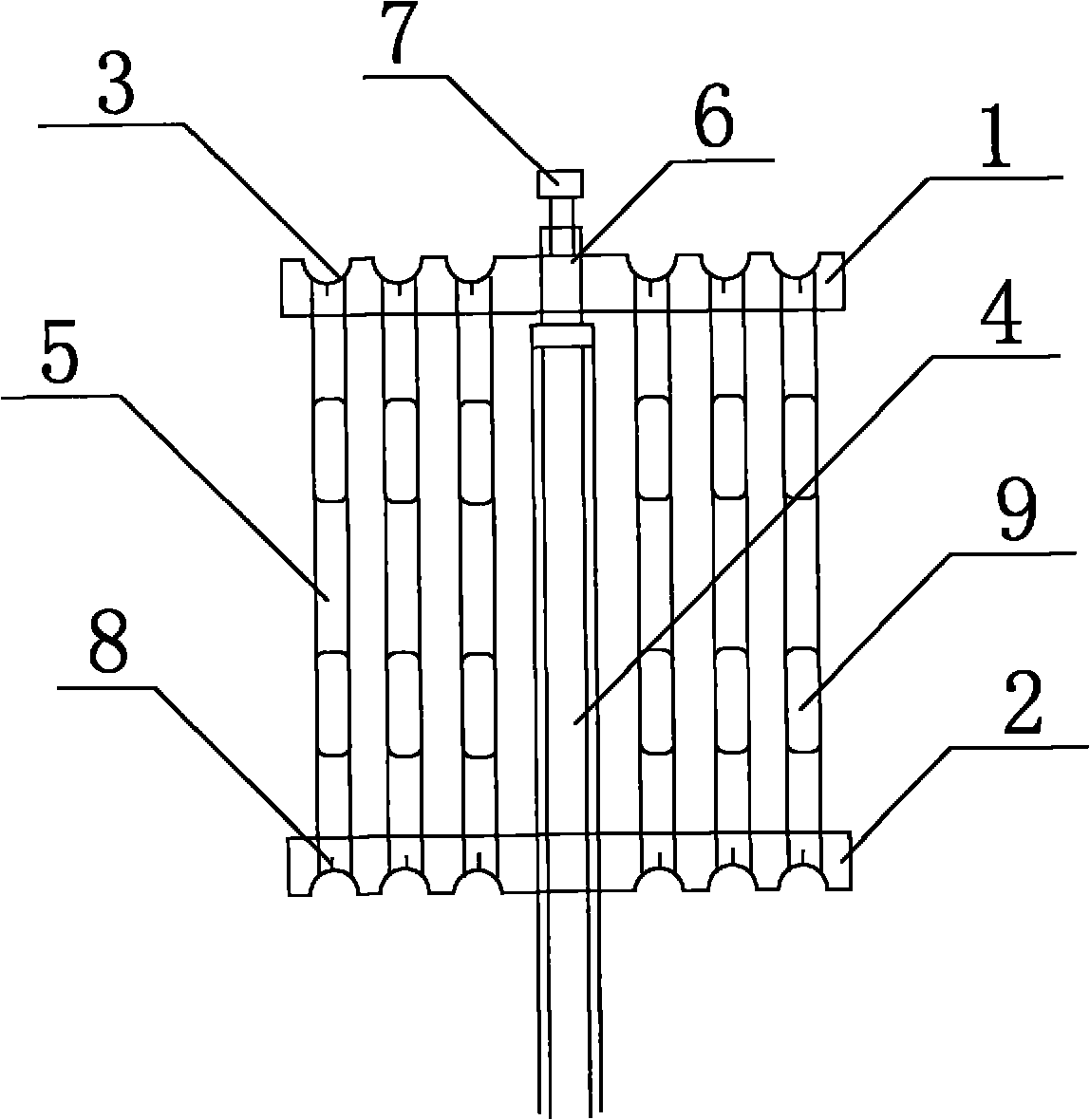

Heald frame of circular loom

The invention relates to the technical field of heald frames, in particular to a heald frame of a circuit loom, which comprises an upper beam, a lower beam, grooves, a heald bar and a heald wire, wherein the upper and lower beams have the grooves and are fixedly connected by the heald bar; the heald wire is fixedly connected with the upper and lower beams through the grooves; a threaded hole is formed in the middle of the upper beam; the upper beam is fixedly connected with the heald bar through the screw in the threaded hole; the grooves are semispherical; slots are formed at the bottom of the grooves; and the heald wire has two thread holes. In the circular loom, the grooves and slots are formed on the upper and lower beams, so that the heald wire is in a tightened state constantly in operation, the wear of machine parts is relieved, noises are reduced, the service life of the heald frame is prolonged, and working environment is improved; meanwhile, the heald wire has the two thread holes for two yarns to pass through, so the working efficiency is improved and working time is saved.

Owner:吴国平

Gauze weaving method and gauze waving equipment

The invention discloses a gauze weaving method and a gauze weaving device, and the gauze weaving method mainly leads each two corresponding warps to be twistedly woven in the interval between last shed and next shed, adopts water jet current as a carrier to carry wefts into the shed, and implements battening. The gauze weaving device comprises a shedding mechanism, a weft insertion mechanism, a let-off mechanism, a coiling mechanism and a driving mechanism, a fixed heddle clasp is arranged on a heald frame in the front row of the shedding mechanism, and a movable heddle clasp that can move left and right is arranged on a heald frame in the back row of the shedding mechanism; the shedding mechanism implements shedding once to drive the warps to form a shed once and then implements shedding again to drive each two corresponding warps to be twistedly woven once, the weft insertion mechanism impements water jet current in real time and carries the wefts into the shed when the shed is formed at every time, and the weft insertion is finished once. The gauze weaving method and the gauze weaving device of the invention are characterized by low production cost, high production efficiency and good gauze quality, etc.

Owner:QINGDAO JINSANYANG TEXTILE MACHINERY

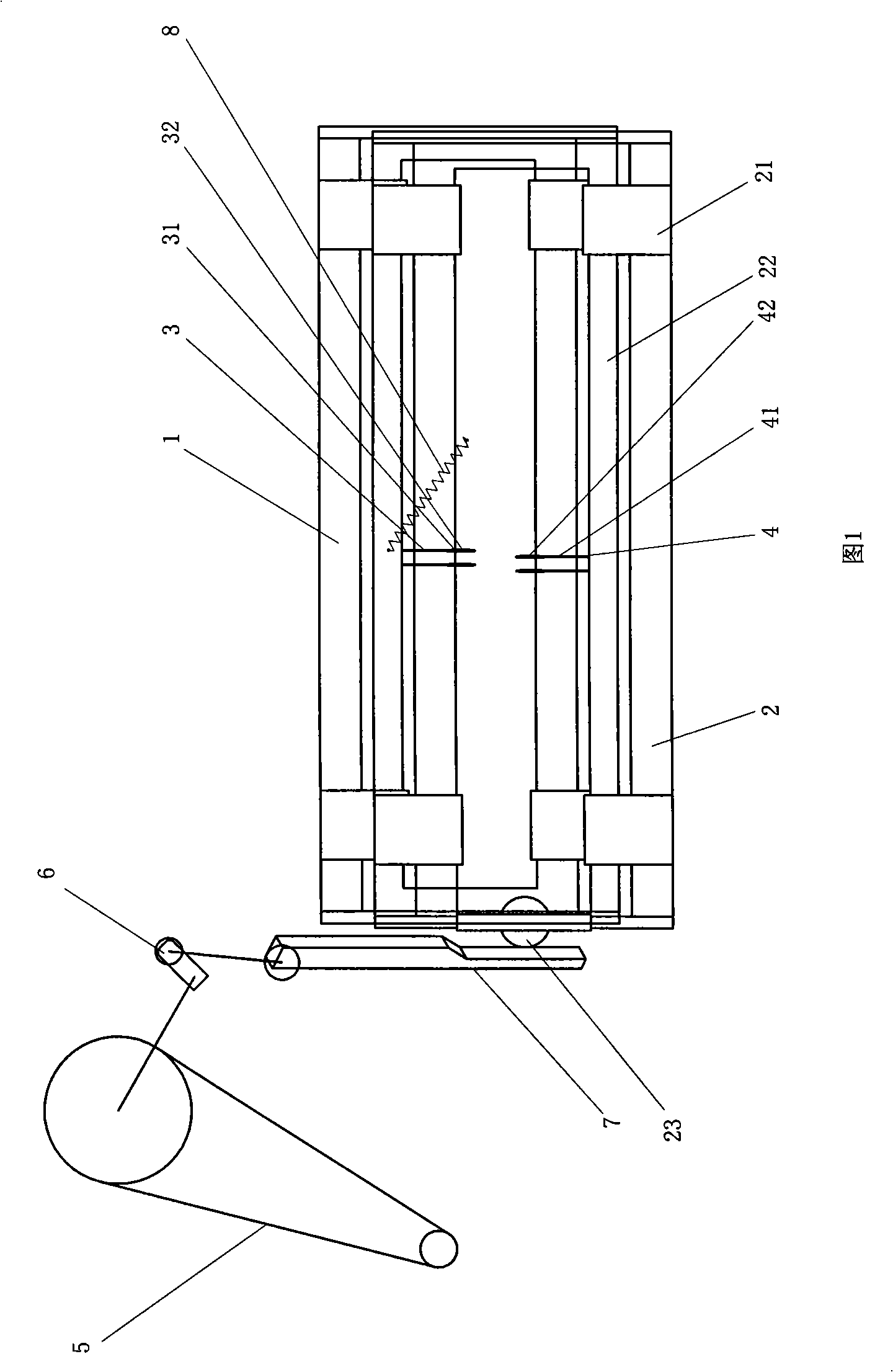

Device and method for harness wire transferring

ActiveCN103924365AImplement automatic transferHigh degree of automationAuxillary apparatusHealdsWire transferEngineering

The invention relates to textile devices, in particular to a device and method for harness wire transferring in the textile devices. The device for harness wire transferring comprises a machine base and a controller, a rotating driving device, an upper rotating disc and a lower rotating disc are arranged on the machine base, the upper rotating disc and the lower rotating disc are coaxially arranged, the rotating drive device is respectively connected with the upper rotating disc and the lower rotating disc through rotating shafts, upper supporting rods which are arranged in the radial direction of the upper rotating disc are arranged on the upper rotating disc, at least two upper supporting rods are arranged at intervals in the circumferential direction of the upper rotating disc, lower supporting rods which are arranged in the radial direction of the lower rotating disc are arranged on the lower rotating disc, at least two lower supporting rods are arranged in the circumferential direction of the lower rotating disc at intervals, the lower supporting rods are in rotation connection with the lower rotating disc, and the lower supporting rods are connected with elastic rotating tensioning mechanisms. A method for harness wire transferring is further provided. The method and device have the advantages of achieving automatic transferring of harness wire elements, being high in automation degree and improving efficiency.

Owner:SHENZHEN HAYHON EQUIP TECH

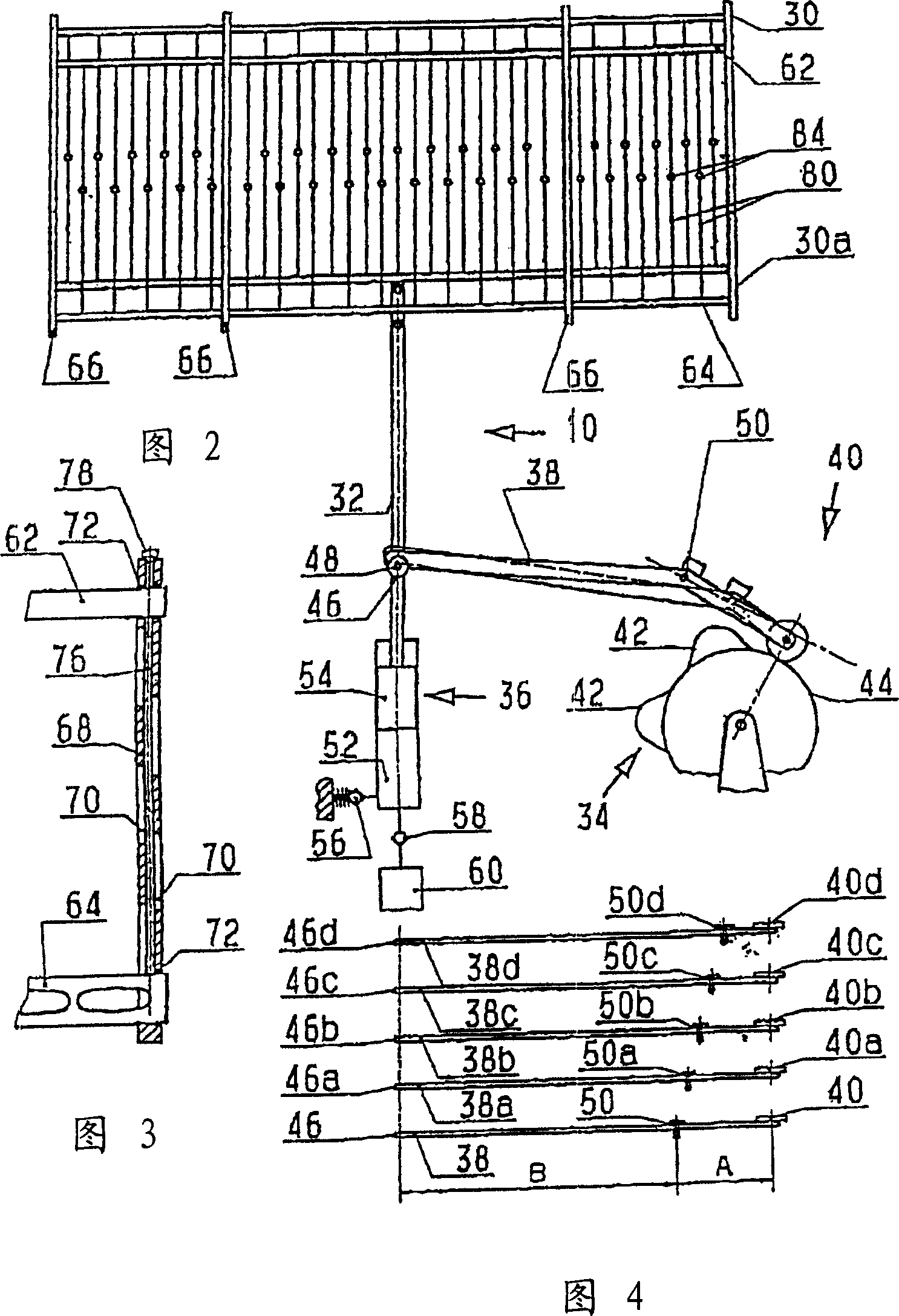

Shaft drive system for power loom shafts

A novel shaft gear for harmonious engagement and disengagement of individual heddle shafts and for deriving their motion from the rotary motion of a single input shaft has a coupling system with two input elements. While one of the input elements serves to drive the output element of the coupling system permanently, the other input element serves solely to synchronize the output element briefly with the first input element. The switchover takes place in the brief synchronous phases, in selected angular regions that correspond to the top or bottom reversal point of the heddle shaft. For the switchover, such novel shaft drive mechanisms do not require any stoppage of motion for the input shaft or the shaft drive mechanism.

Owner:GROZ BECKERT KG

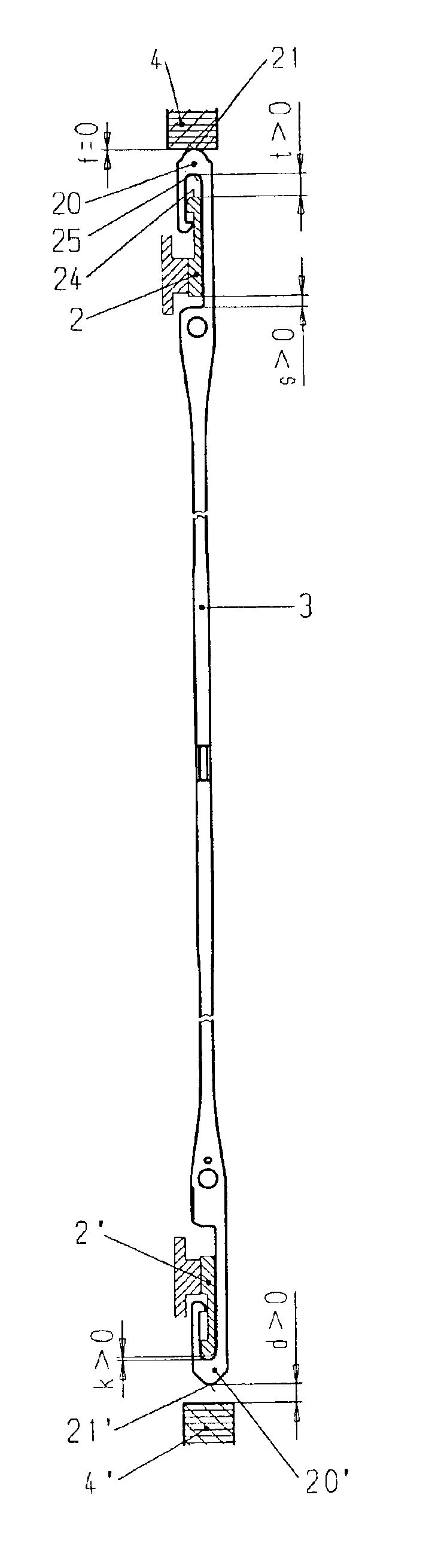

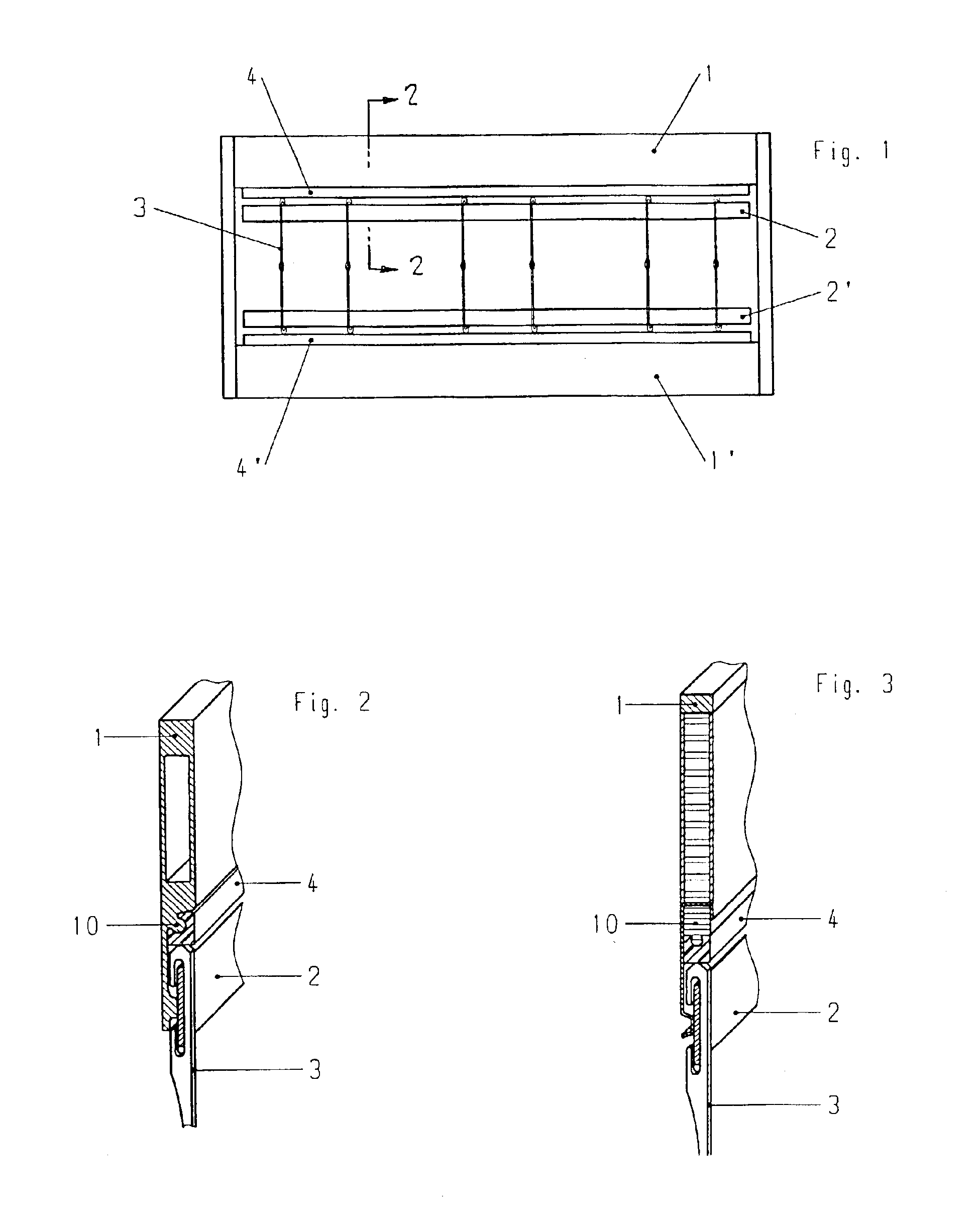

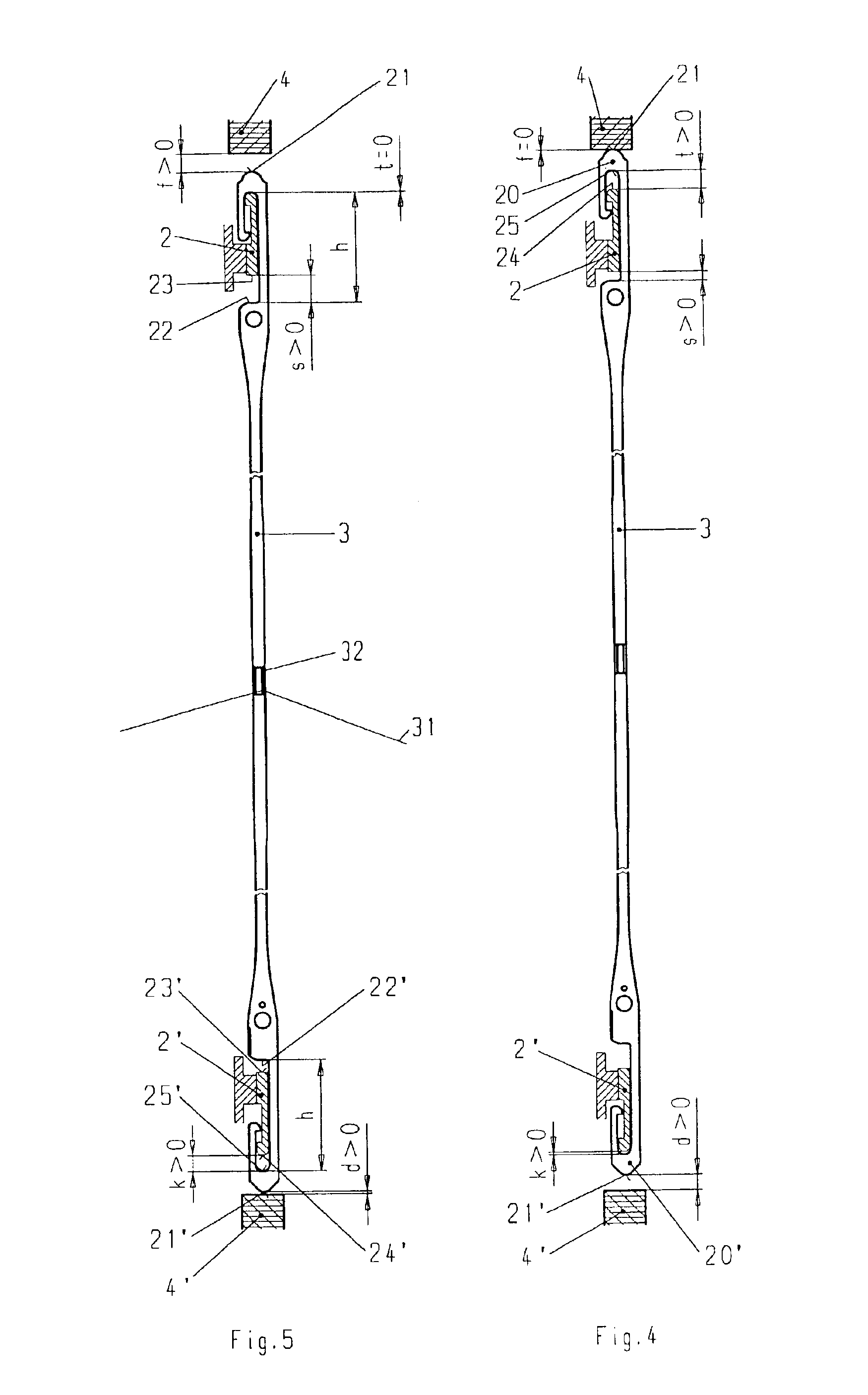

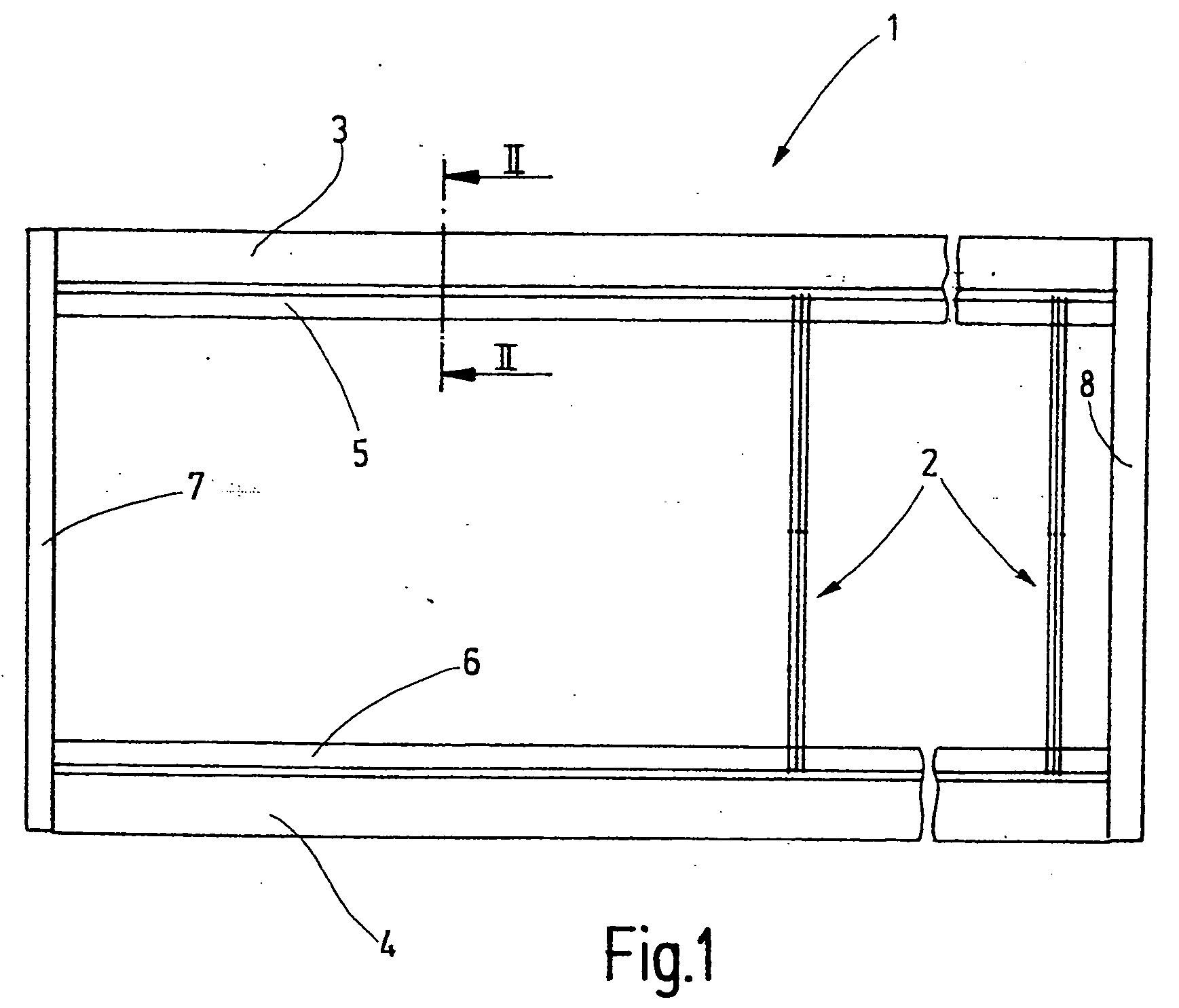

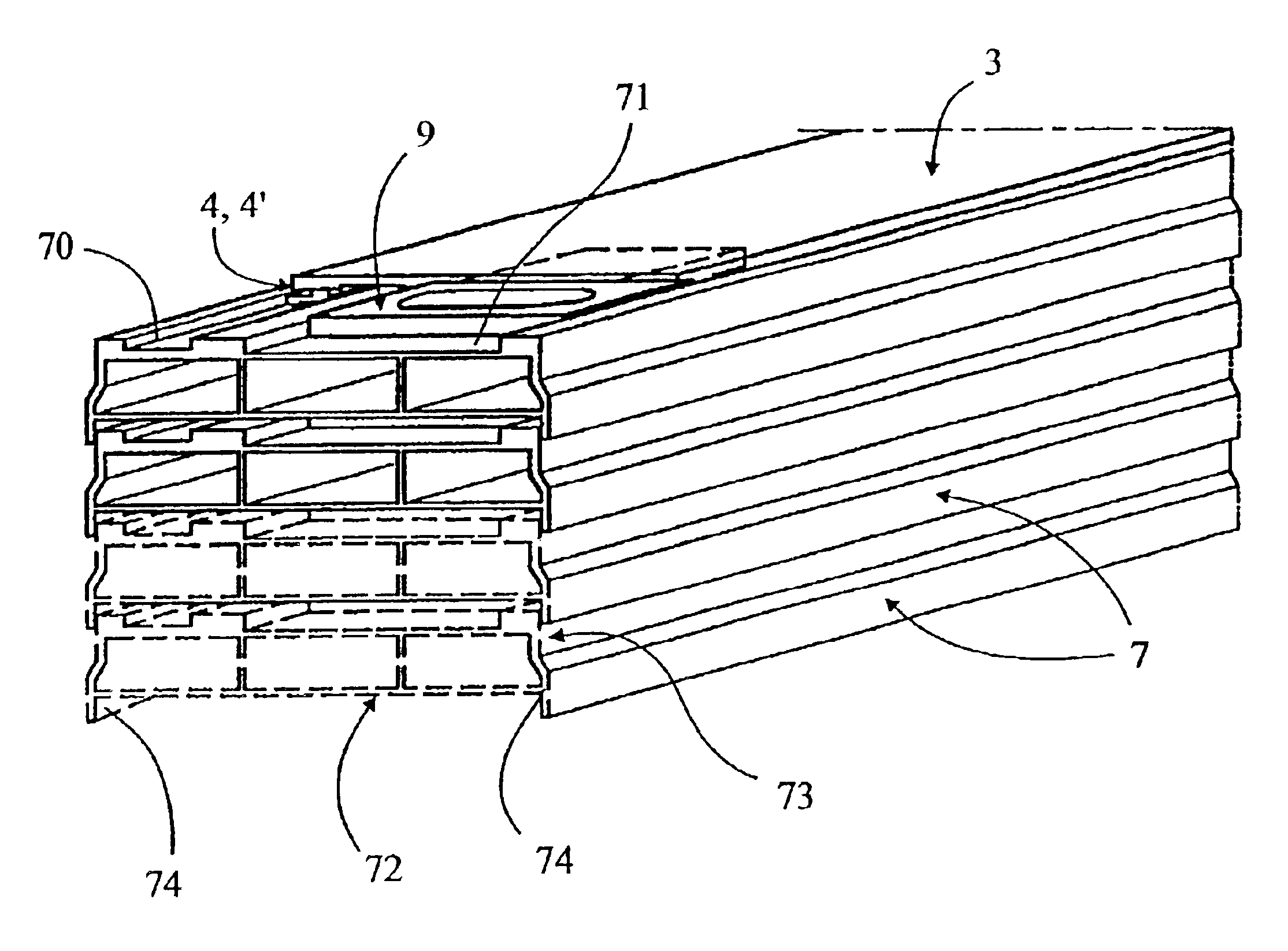

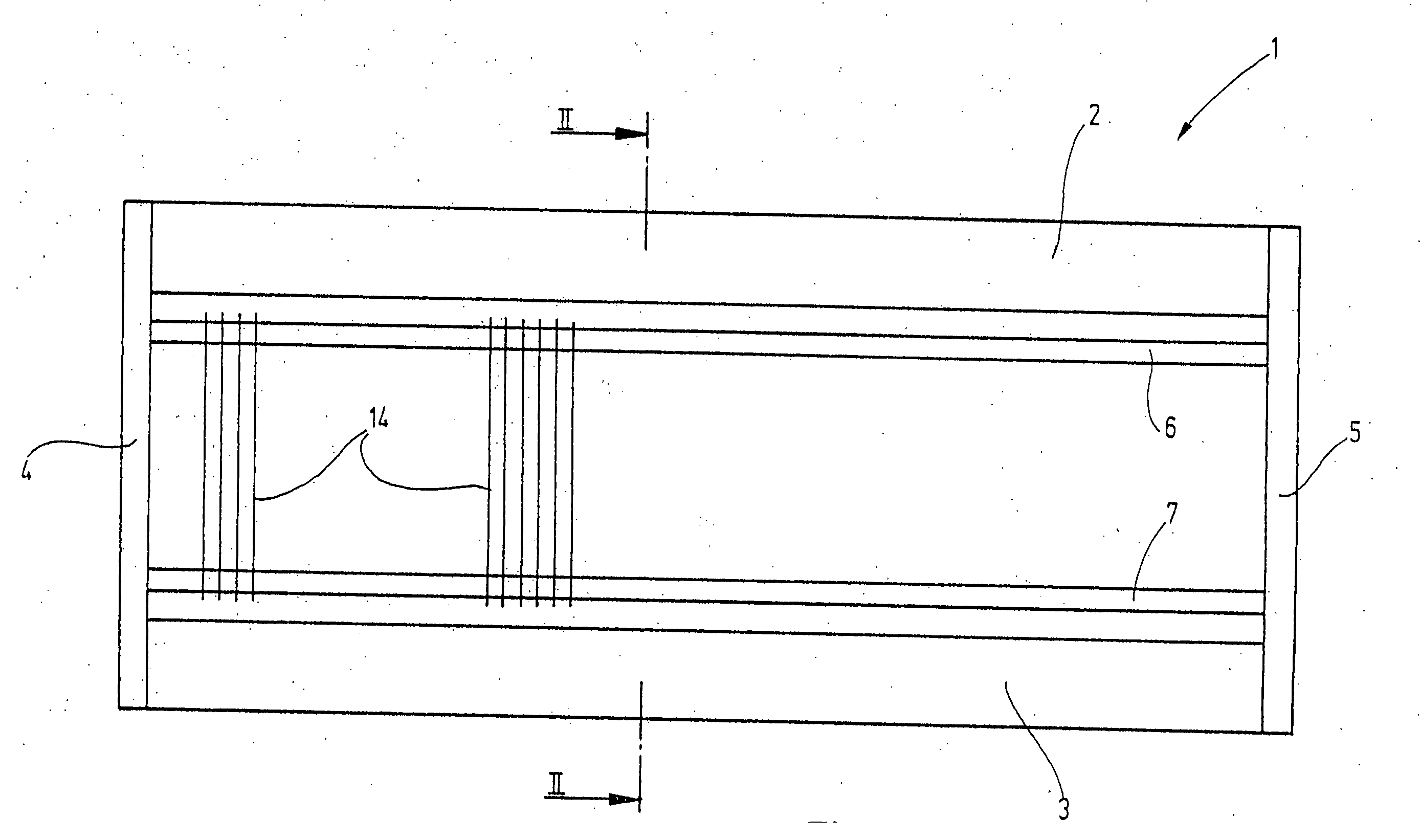

Heald shaft of composite construction

InactiveUS20050081941A1Easy to manufactureImproved force transmissionEngine sealsHealdsComposite constructionEngineering

A heald shaft for weaving machine has a shaft rod (3) which is formed of a one-piece light-metal profile and two stiffening bodies (24, 25) glued to the shaft rod (3). The stiffening bodies bridge the entire width of the shaft rod (3), wherein the width is measured between the side walls (11, 12). The chambers 14, 16 for receiving the stiffening bodies (24, 25) each have at least one open side through which the stiffening body is visible from the outside and through which it may be introduced into the respective chamber (14, 16). This construction facilitates manufacture. Further, a rigidity in the working direction, as well as a good rigidity transversely thereto is achieved.

Owner:GROZ BECKERT KG

Multilayer cloth multi-shed water jet loom

The invention relates to a multilayer cloth multi-shed water jet loom, which comprises a front rack and a rear rack, wherein a multi-arm mechanism is arranged above the front rack, a heald frame assembly controlled by the multi-arm mechanism is arranged below the front rack, the left side of the front rack is provided with a weft insertion mechanism, and the rear part of the front rack is provided with a ground warp weaving shaft; and a seam warp weaving shaft and a tension compensating device are arranged on the rear rack. The multi-arm mechanism enables warps passing through harness wires in a seam warp heald frame to form six warp positions and five sheds; the weft insertion mechanism can simultaneously jet five wefts in the five sheds up and down, and multilayer cloth of less than or equal to five layers can be woven by weft insertion and battening; and the seam warp weaving shaft and the tension compensating device enable seam warps to be conveyed at a constant speed and subjected to seam warp tension compensation in a single seam warp heald frame so as to meet weaving of the multilayer cloth of less than or equal to five layers with a comparatively complex tissue structure. The multilayer cloth multi-shed water jet loom has the advantages of doubled production efficiency, production variety increment, wide application and the like.

Owner:WUJIANG HENGSHENGLI SPRAY & KNITTING

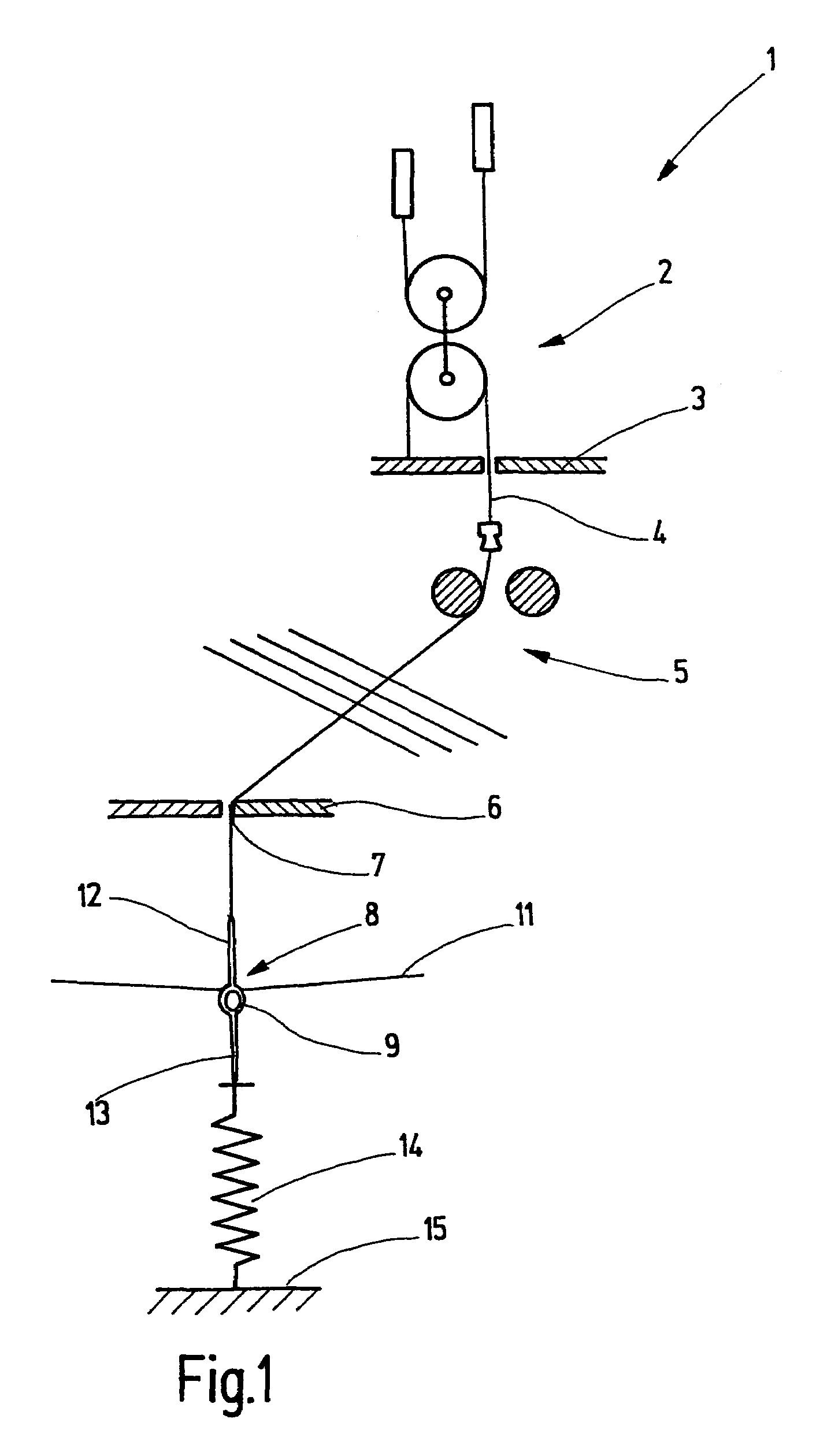

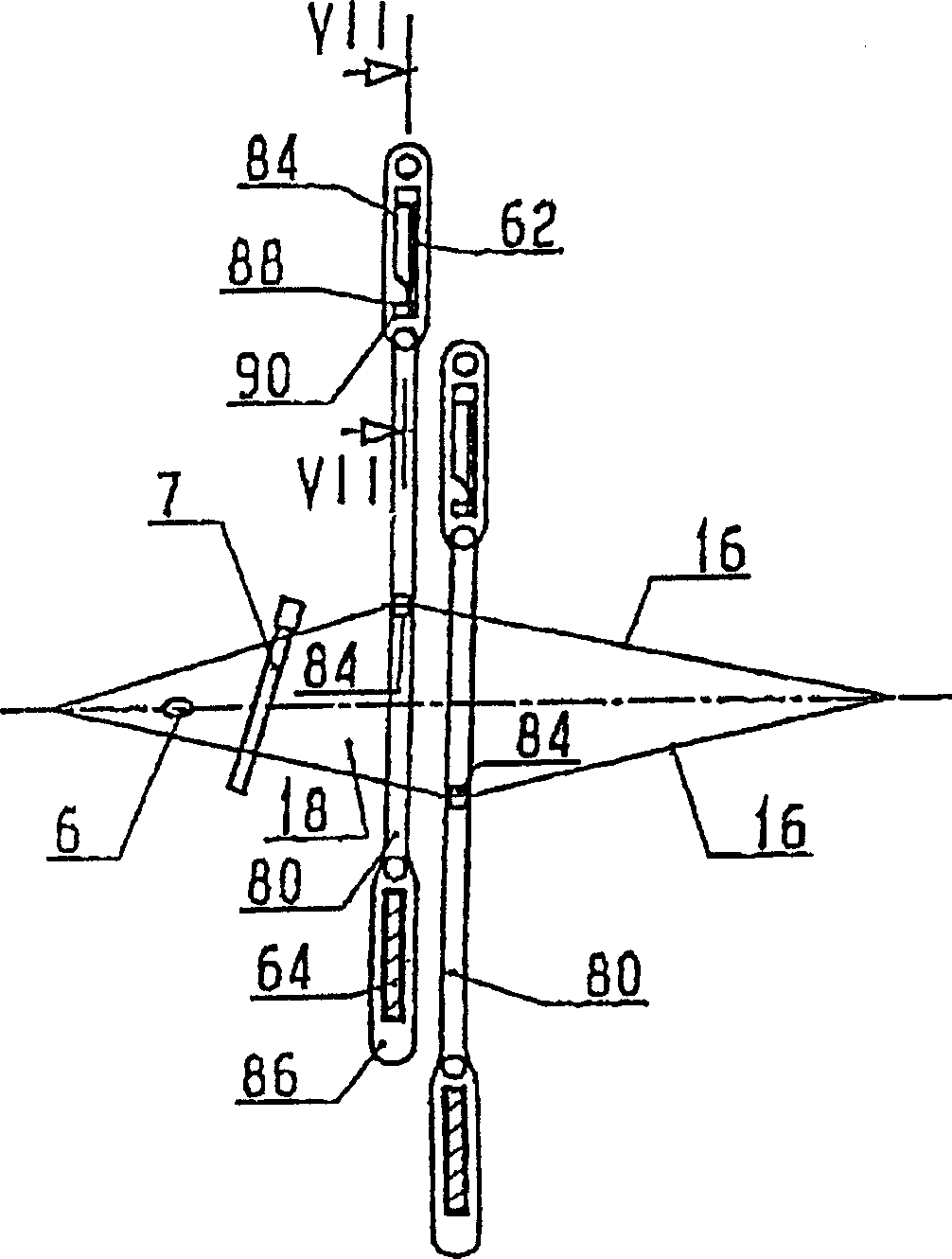

Spring dampened shedding device

InactiveUS7036532B2Effectively dampens undesirable resonating propagationAccurate pressureJacquardsLeno shedding mechanismJacquard loomResonance

A shedding device in a jacquard loom, having a heddle with a retracting spring rigidly anchored in the loom or to the floor for urging the heddle to a lower shed forming position. To suppress the development of resonance in the spring, a core element is provided, which contacts the inside of the spring at points spaced apart from one another and forces the spring to take a course which deviates from the rectilinear. As a result, friction forces that contribute to damping the spring motion are created between the spring and the core element.

Owner:DEUTE INST FUR TEXTIL & FASERFORSCHUNG STUTTGART

Method for manufacturing a crossbeam for a heddle frame of a loom and crossbeam obtained by said method

The present invention relates to a method for manufacturing a crossbeam for a heddle frame of a loom allowing to make, at low cost and without waste, a lightweight and very rigid crossbeam, whose heddle-support rod is positioned on the support section in an accurate position that is completely linear, controlled and capable of being reproduced. This manufacturing method is characterized in that one uses a rigid template that has at least one rectilinear groove having a width substantially equal to that of the heddle-support rod; one positions the non-rigid heddle-support rod in the groove to make it rectilinear; one lays a glue line on the junction zone; one positions a rigid support section that is not necessarily rectilinear in a predetermined manner on the template and on the heddle-support rod by flattening the glue line, and one maintains the support section and the heddle-support rod integral with the template, at lease while the glue is setting.

Owner:STAUBLI ALSACE

Ribbon needleloom

InactiveCN1856608ASupport (hold) improvementForced motion volume reductionSmallware loomsHealdsEngineeringMechanical engineering

Owner:TEXTILMA AG

Multi-color warp and weft dual-jacquard type high-speed flat ribbon loom

ActiveCN105063861ARich patternsColorfulSmallware loomsHealdsProtection mechanismPulp and paper industry

The invention discloses a multi-color warp and weft dual-jacquard type high-speed flat ribbon loom. The flat ribbon loom comprises a rack with a middle stand column and a weaving base, and a transmission mechanism, a warp yarn delivery mechanism, a weft yarn delivery mechanism, a catch end delivery mechanism and an electronic head needle selection mechanism are arranged on the rack. A connecting rod weaving mechanism, a heald frame opening mechanism, a warp yarn breaking power outage protection mechanism and a winding mechanism are arranged on the weaving base. By means of the loom, while warp yarn jacquard weaving is performed, multi-color jacquard weaving can also be performed on weft yarn, the weft yarn is changed into multiple colors from a single color, ribbons brighter in color can be obtained without increasing the thickness of the ribbons, and the usage amount of colorful warp yarn is greatly reduced.

Owner:泉州众锦源精密机械有限公司

Heddle with reduced play

InactiveUS20050087252A1Reduce end weightReduce the total massHealdsOther shedding mechanismReduced sizeEngineering

A heddle (14) of the invention is distinguished by end eyelets (15, 16) of reduced size, with which heddle support rails (6, 7) of reduced cross section are associated. The axial play of the heddles on the heddle support rails (6, 7) is limited to from 0.5 mm to 1.5 mm. The lateral play is in the range of 0.2 mm to 0.5 mm. This system formed of heddle support rails and heddles is especially suitable for particularly rigid heddle shafts for power looms with an extremely high operating speed.

Owner:GROZ BECKERT KG

High wear resistant heddles

The invention discloses a heddle with high wear resistance, a connecting joint is arranged at two ends of a heddle rod, and a heddle eye which is a porcelain eye with smooth threading eyelets inside is arranged on the heddle rod. The heddle rod is a plastic heddle rod, the porcelain eye is fixedly connected with the plastic heddle rod through insert molding, and peripheral surfaces of the threading eyelets are smooth surfaces. As the heddle rod is the plastic heddle rod, the heddle of the invention does not rust. As the heddle eye is the porcelain eye, the wear resistance and the service life of the heddle can be improved. As the porcelain eye is fixed with the plastic heddle rod through insert molding, the plastic heddle rod and the porcelain eye do not swing relatively in working and have reliable fixing, and yarn break caused by the swinging of the porcelain eye is avoided. As the peripheral surfaces of the threading eyelets are smooth surfaces, yarn break caused by the heddle in working can be prevented.

Owner:胡金永

Textile tool with temporary protection

ActiveCN101988235APrevent wear attacksAvoid harmWeft knittingTufting apparatusEngineeringMechanical engineering

The present invention relates to a textile tool with temporary protection. An anti-abrasion layer (12) is provided on the textile tool (1). The anti-abrasion layer extends and covers a cutting edge (9) or a top end (5). A cap (7) or a cap (11) which is made of protection material is provided for the top end (5) or the cutting edge (9). The protection material is preferably constructed to have viscoplasticity or damping characteristic. Preferably, the cap (7,11) can be easily removed. For instance, in a first using process of the textile tool, the cap is integrally or partially separated from the textile tool (1). Preferably, the protection material is molten impregnated material, such as molten impregnated material based on thermoplasticity.

Owner:GROZ BECKERT KG

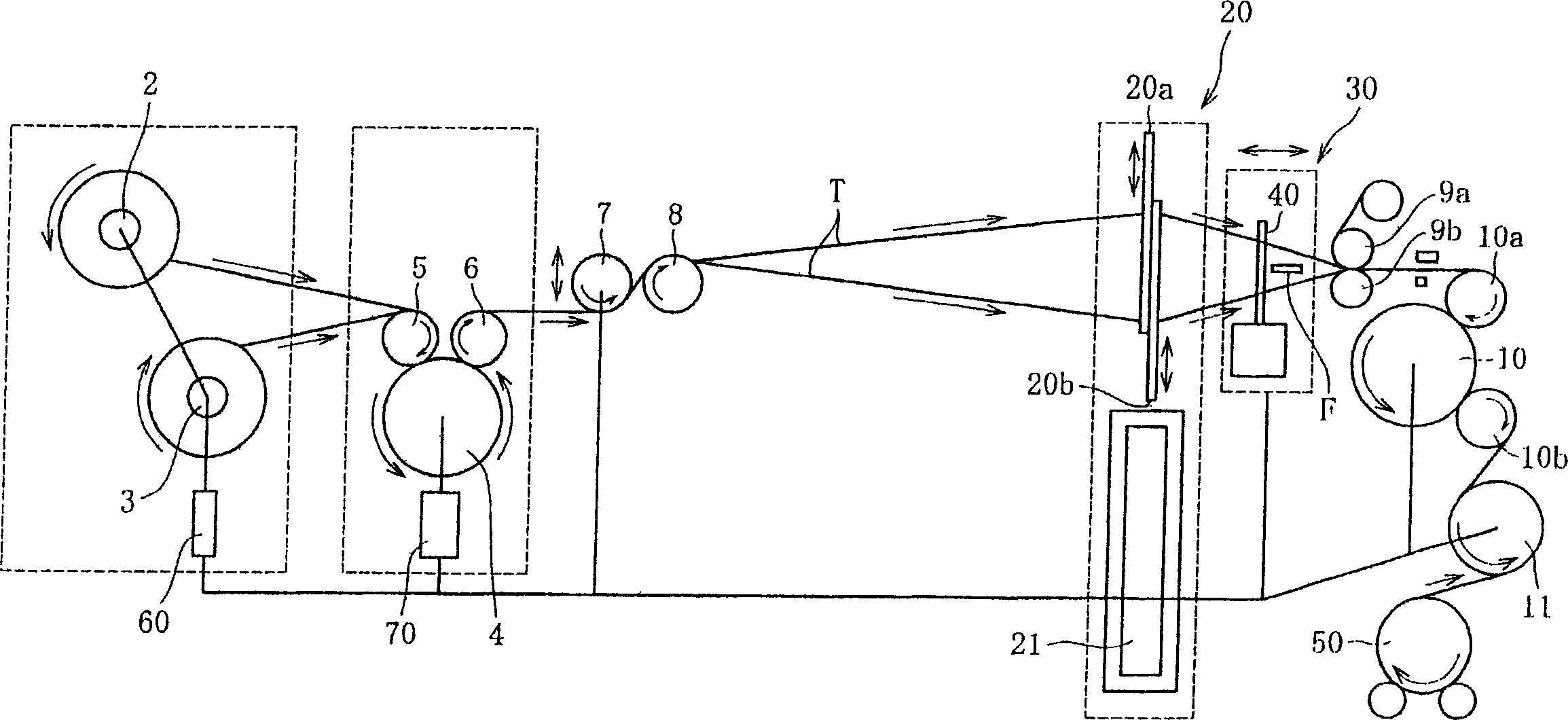

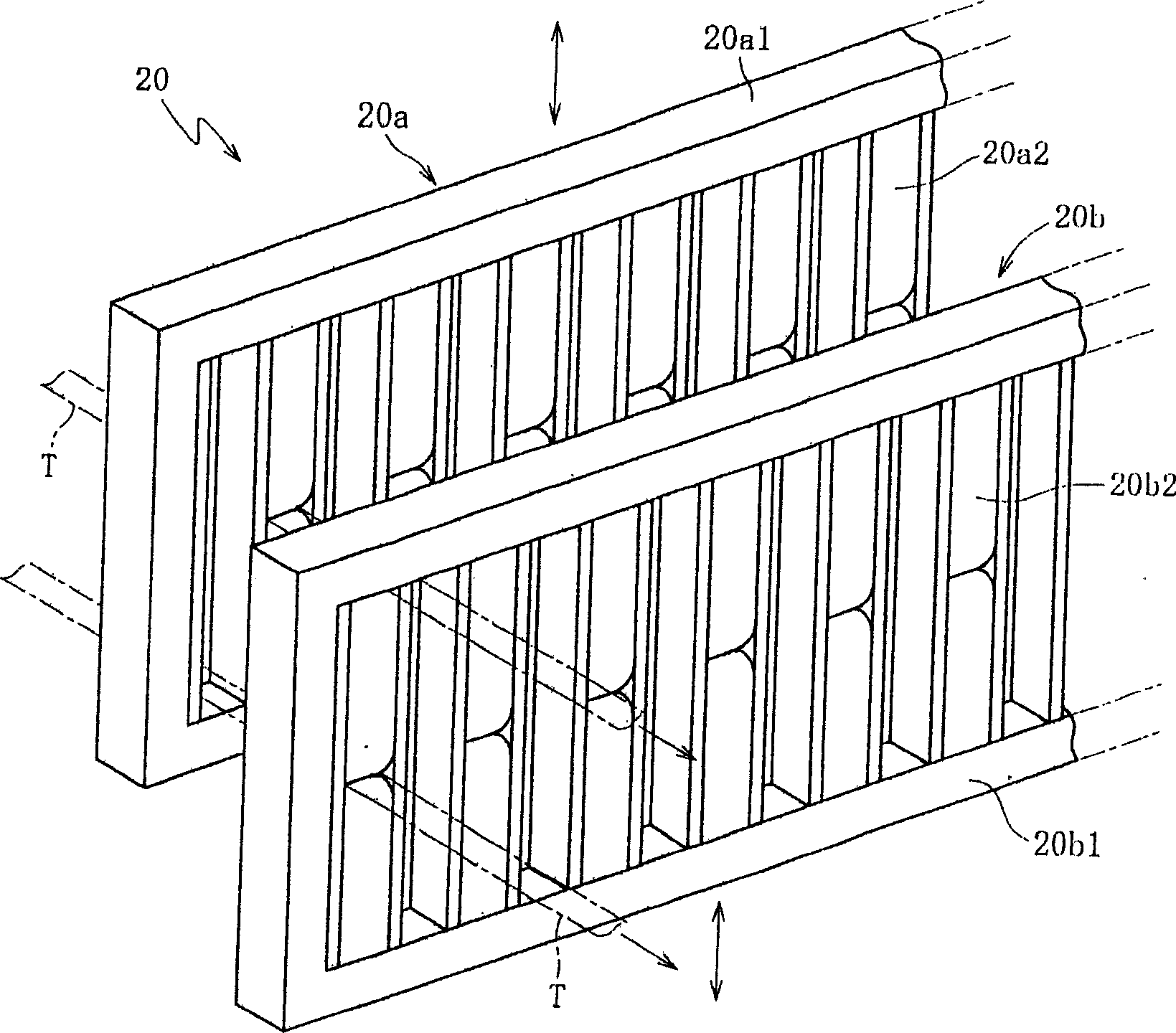

Device and method for weaving band shaped fibre beam fabrics

The present invention provides a weaving device for a ribbon-shaped fiber bundle fabric capable of maintaining a good state of the ribbon-shaped fiber bundle. The weaving device consists of a weft insertion device that inserts the weft yarn (F) into the warp opening area formed by the heddle in a tensioned state, and a moving device that maintains the weft yarn (F) in a tensioned state and moves parallel to the front of the fabric. constitute. The weft inserting device has a rapier mechanism of a rapier loom (or a gripper mechanism of a projectile loom). The rapier mechanism (or projectile mechanism) utilizes the moving device to move parallel to the front of the fabric. On the position close to the rear of the weft yarn (F) picked by the rapier mechanism (or the gripper mechanism of the projectile loom), the yarn guide bar (40) of the warp knitting machine is configured, and the yarn guide bar (40) of the warp knitting machine ( 40) and the rapier mechanism (projectile mechanism) are moved in parallel by the moving device.

Owner:北京亚太高科投资顾问有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com