Spring mechanism harness structure for water jet loom

A technology of water jet loom and spring mechanism, which is applied in looms, textiles, papermaking, textiles, etc. It can solve problems such as malfunction, breakage, and spring wear, and achieve the effect of avoiding mutual friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

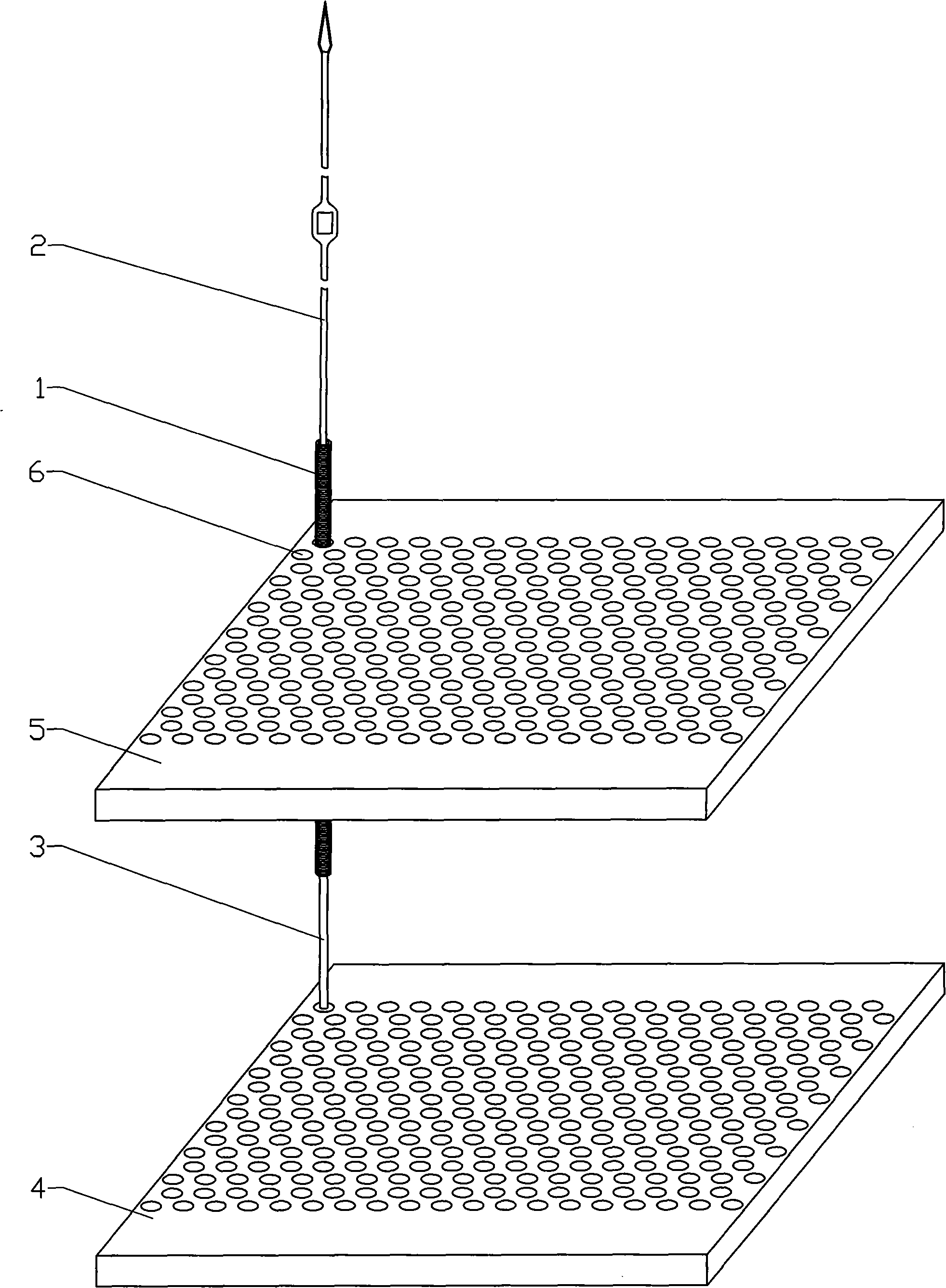

[0010] Such as figure 1 Shown: the spring mechanism that the water-jet loom of the present embodiment is adorned with harness, the spring 1 upper end links to each other with the heddle 2, the spring 1 lower end links to each other with the connecting rod 3, and the connecting rod 3 is fixed on the return heald frame 4. The return heald frame of the present embodiment is plate-shaped, and of course, the return heald frame can also be combined by inserting pieces. The spring mechanism of the water jet loom is equipped with a limit plate 5, and the spring 1 passes through the spring limit hole 6 in the limit plate. The limiting plate in this embodiment is made of plastic, and the hardness of the limiting plate material is less than that of the spring material. In this embodiment, the spring limiting holes, springs, healds, and connecting rods in the limiting plate are arranged in sheets. For the convenience of a clear description, only one spring, heddle and connecting rod are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com