Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about "Selvedge shedding mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

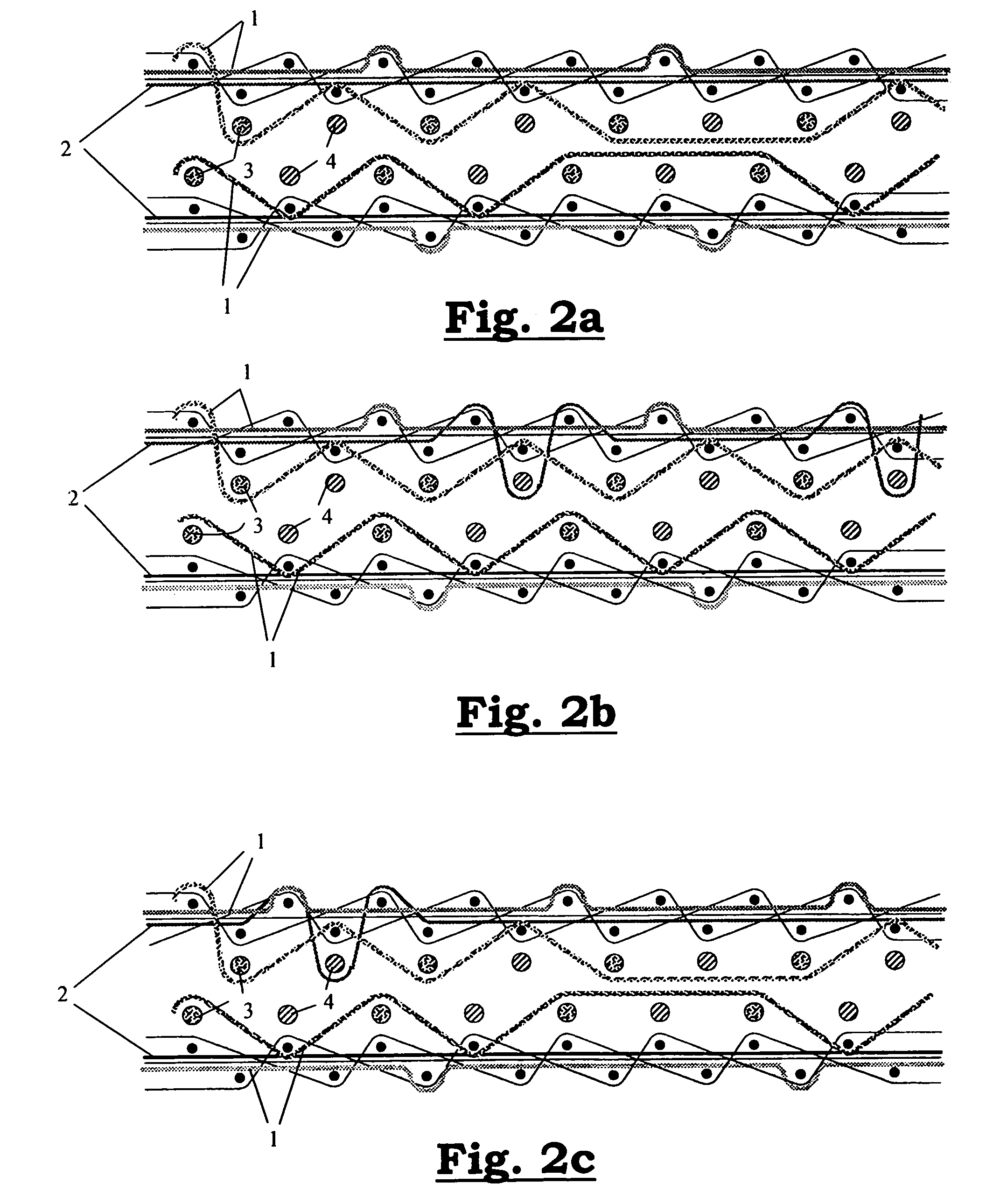

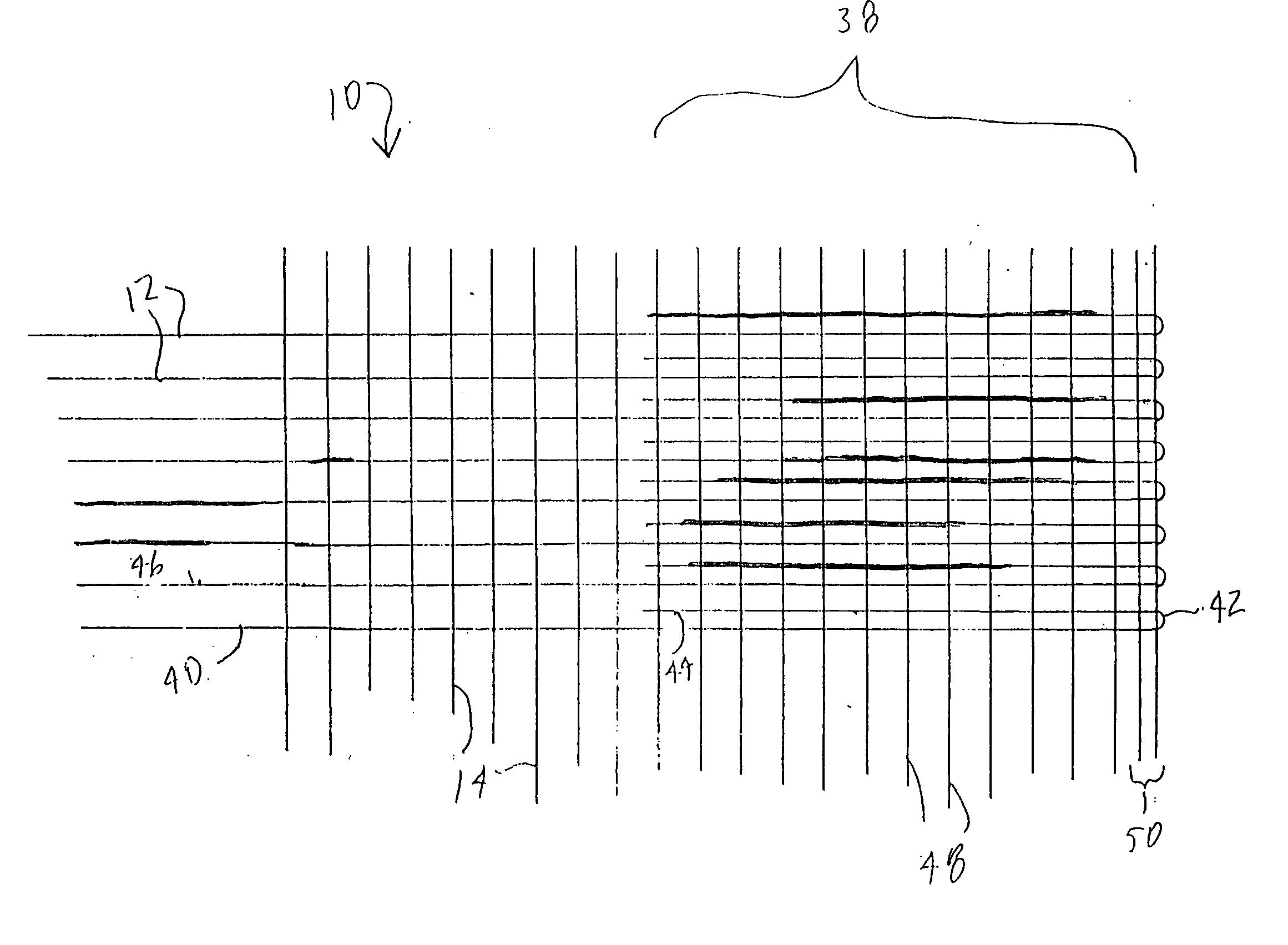

Leno cloth as well as method and weaving machine for production thereof

InactiveUS7287553B2Reduce tensionStronger working-in insertion or take-upOrnamental textile articlesLeno shedding mechanismYarnEngineering

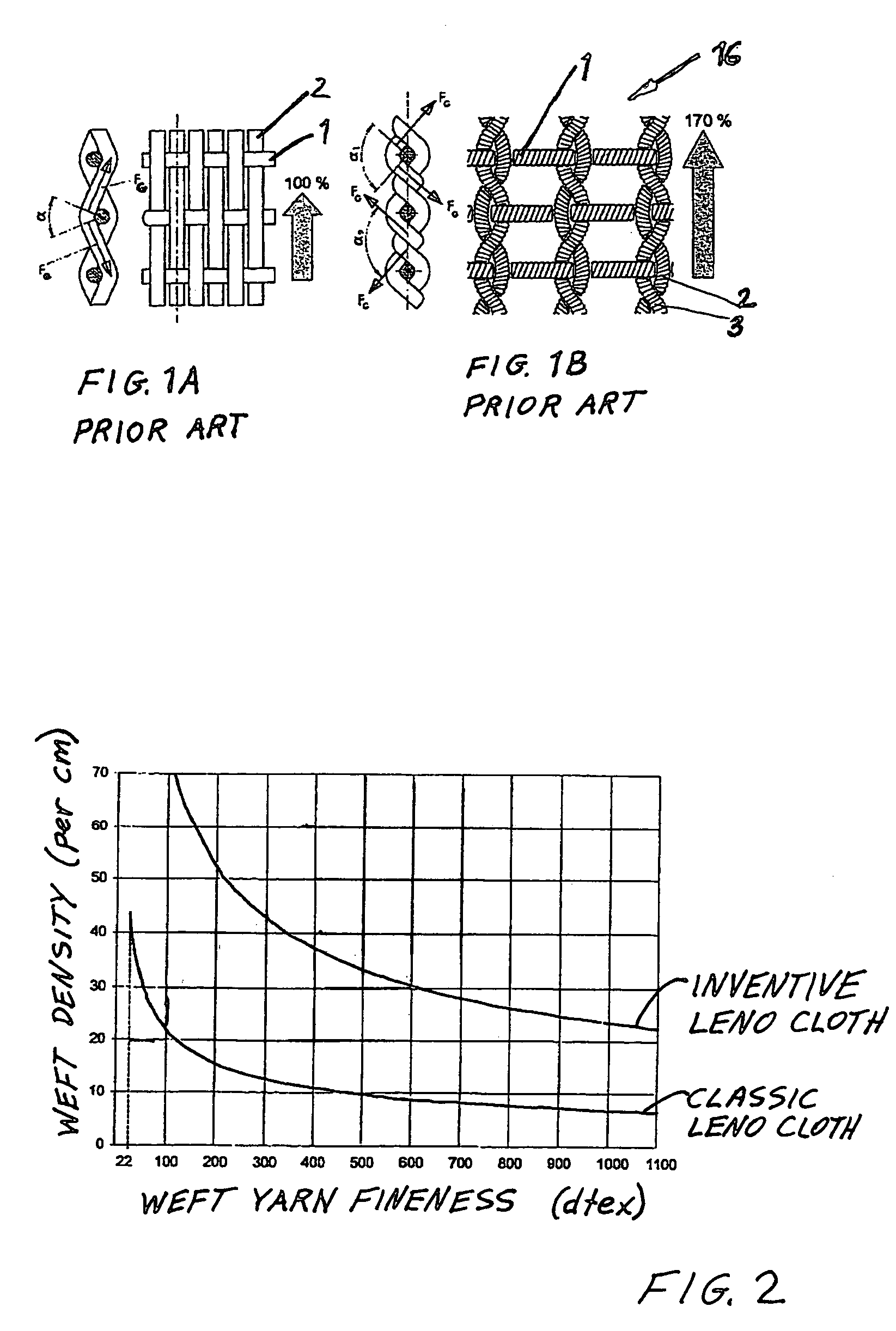

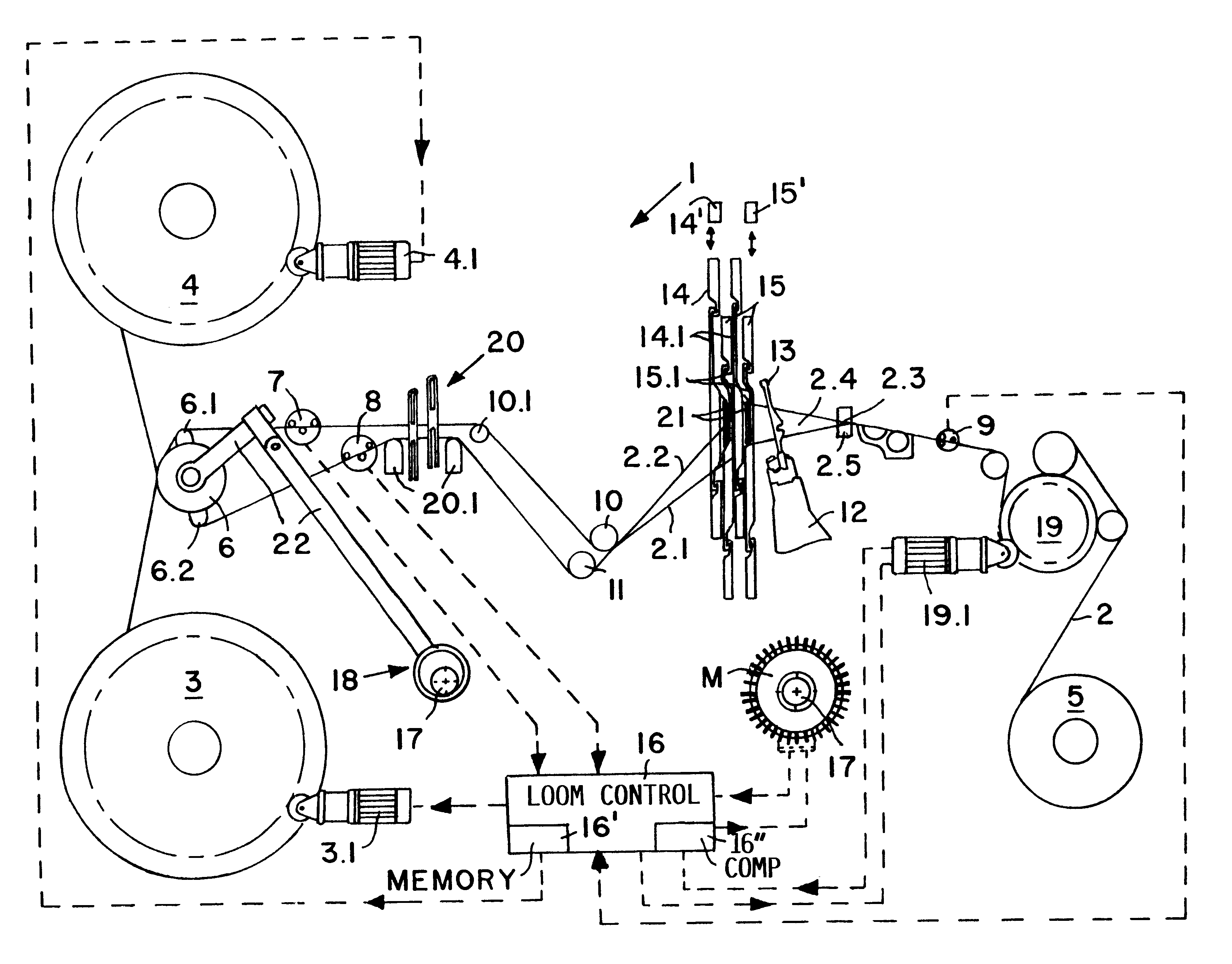

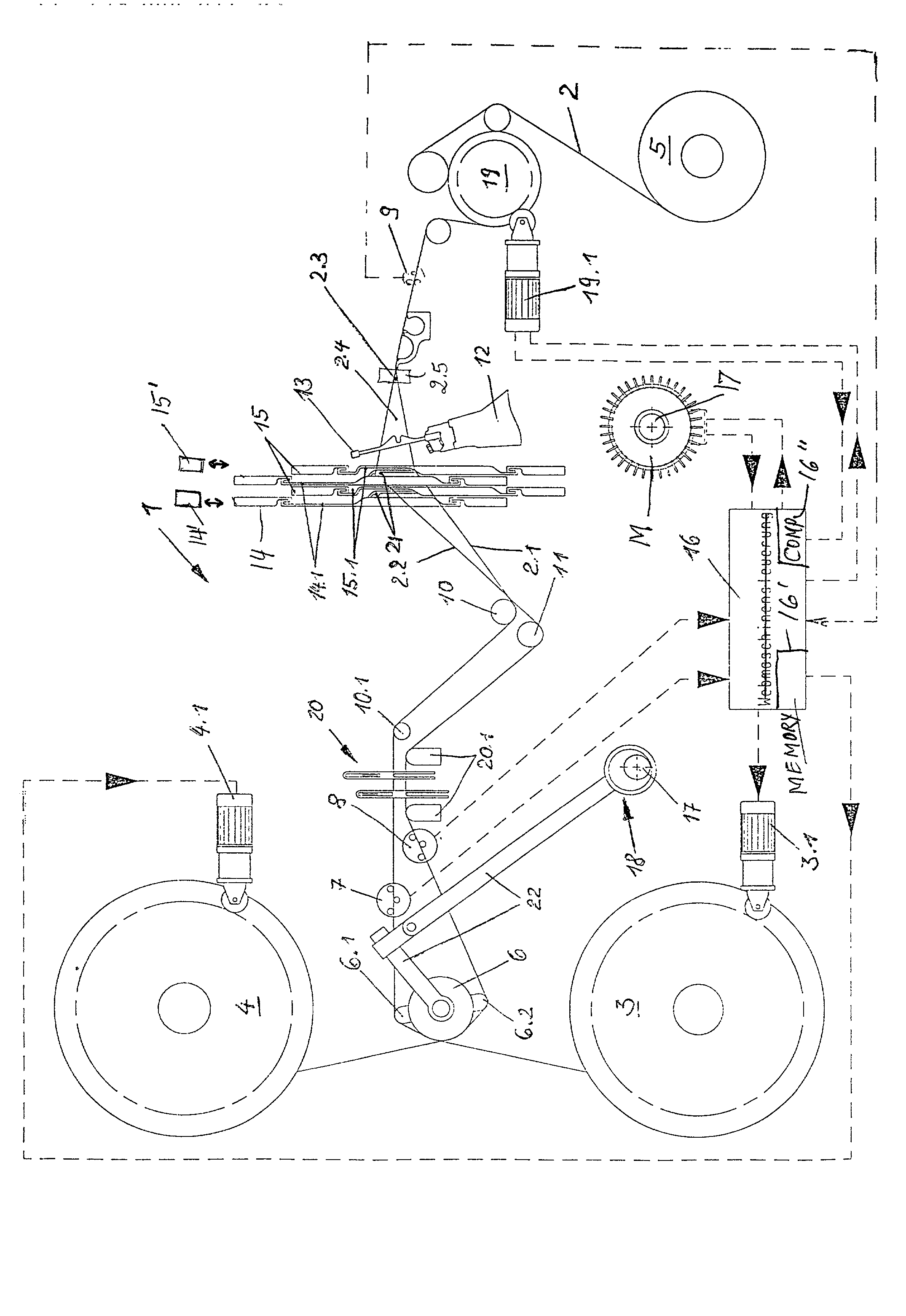

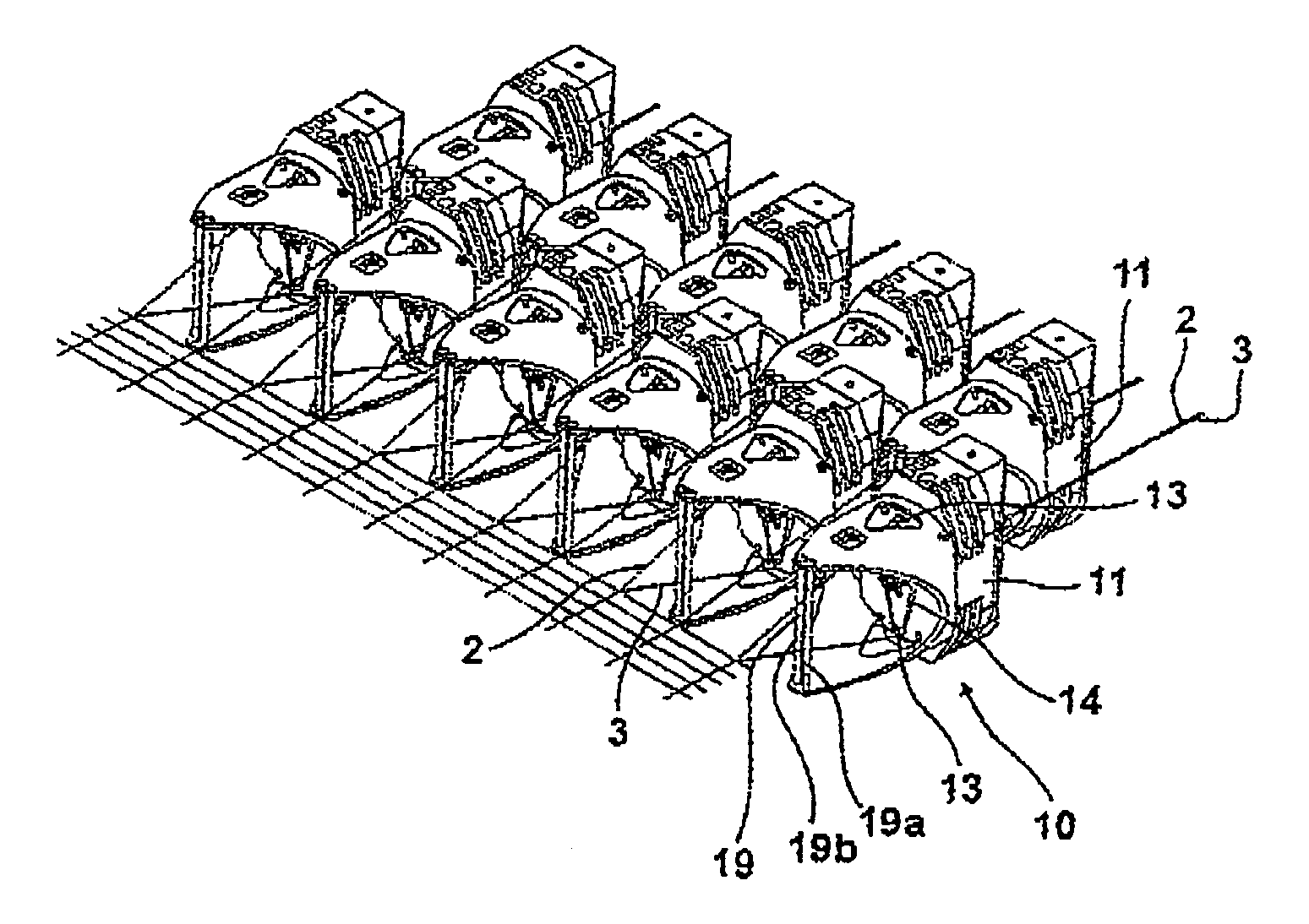

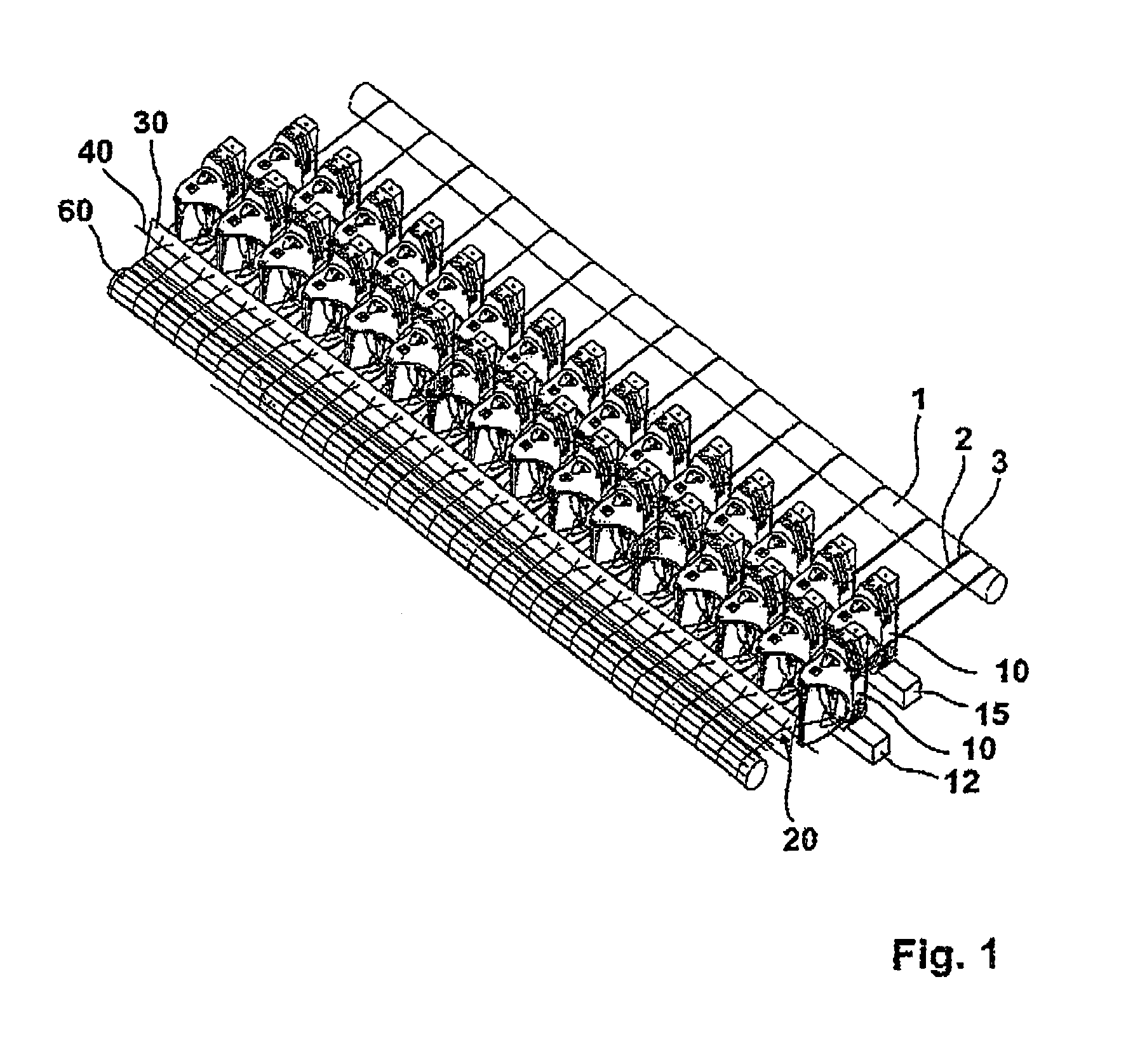

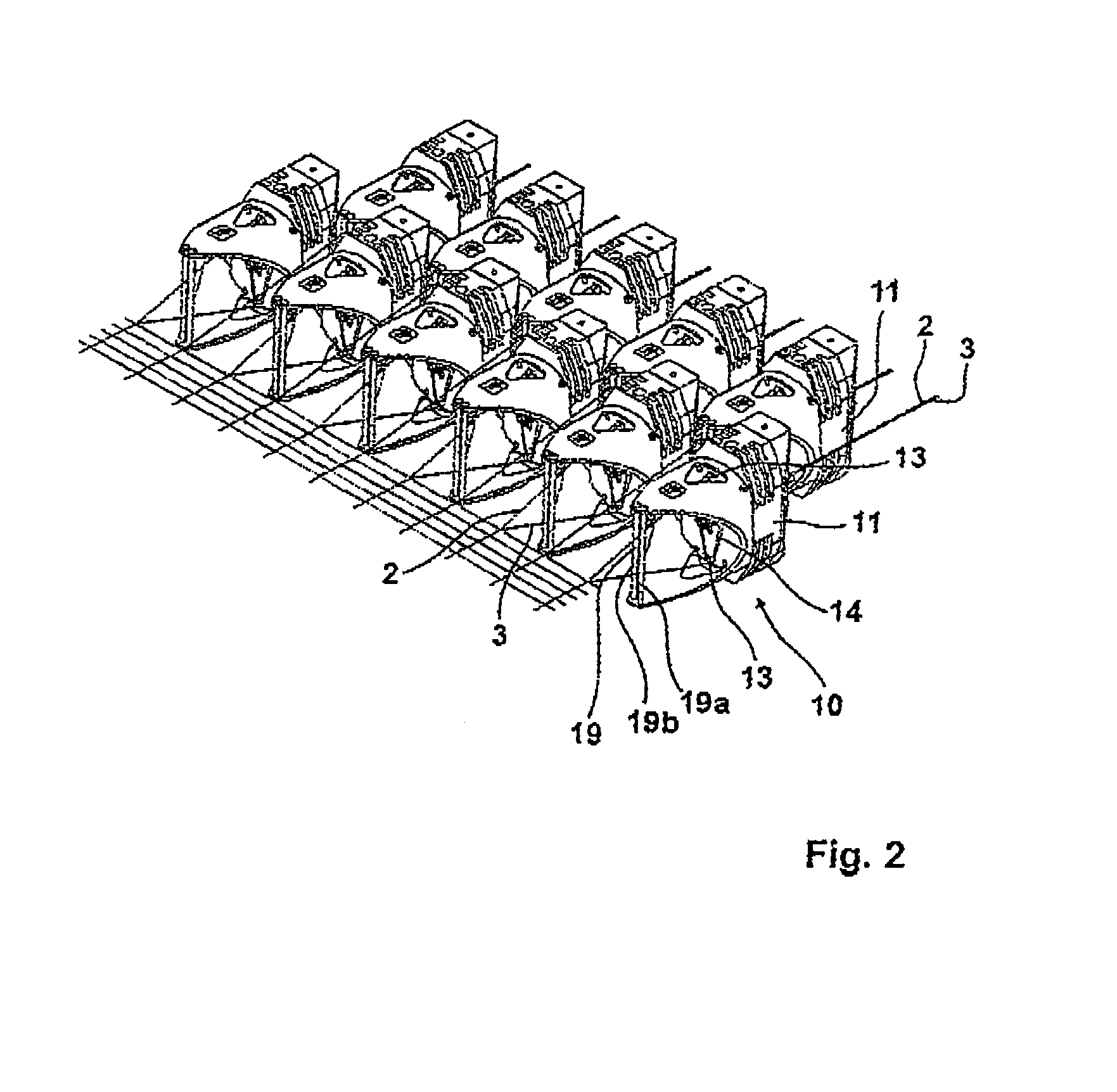

A leno cloth is prepared, which comprises at least ground warp threads 1, leno warp threads 3 and weft threads 2, and in which the weft threads 2 and the ground warp threads 1 are arranged essentially interspace free. The weft threads are bound-off by means of the leno warp threads 3, which comprise a clearly lower titer relative to the ground warp threads 1, with such a lower tension relative to the ground warp threads, so that the crossings of the leno warp threads 3 with the ground warp threads 1 that are present due to the binding are arranged in a plane parallel to the plane of the maximum thickness of the weft threads. The leno warp threads 3 comprise a higher working-in or take-up into the woven cloth than the ground warp threads 1. According to a further aspect of the invention, a method for the production of a leno cloth as well as a loom for the carrying out of the method for the production of a leno cloth are described.

Owner:LINDAUER DORNIER GMBH

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

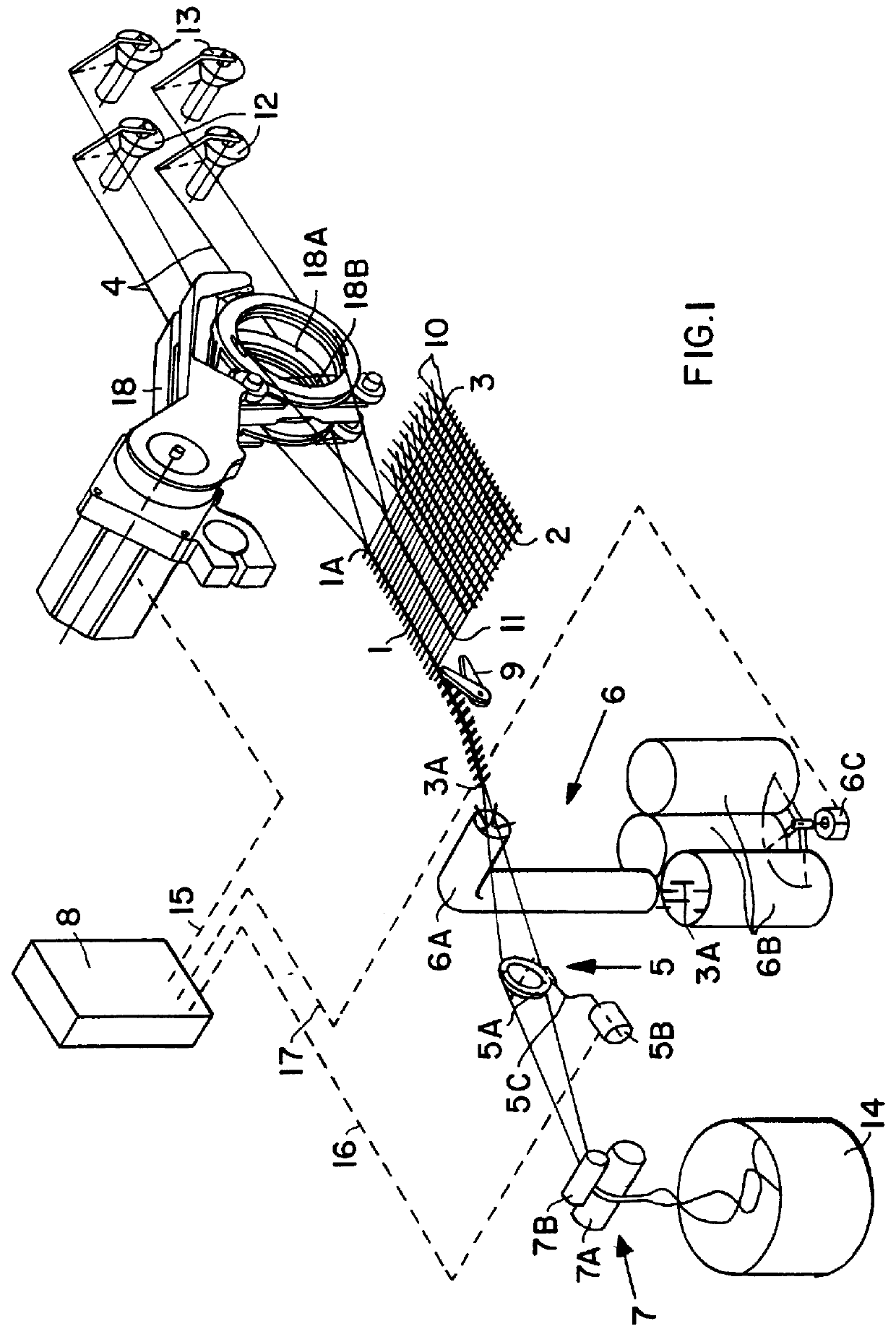

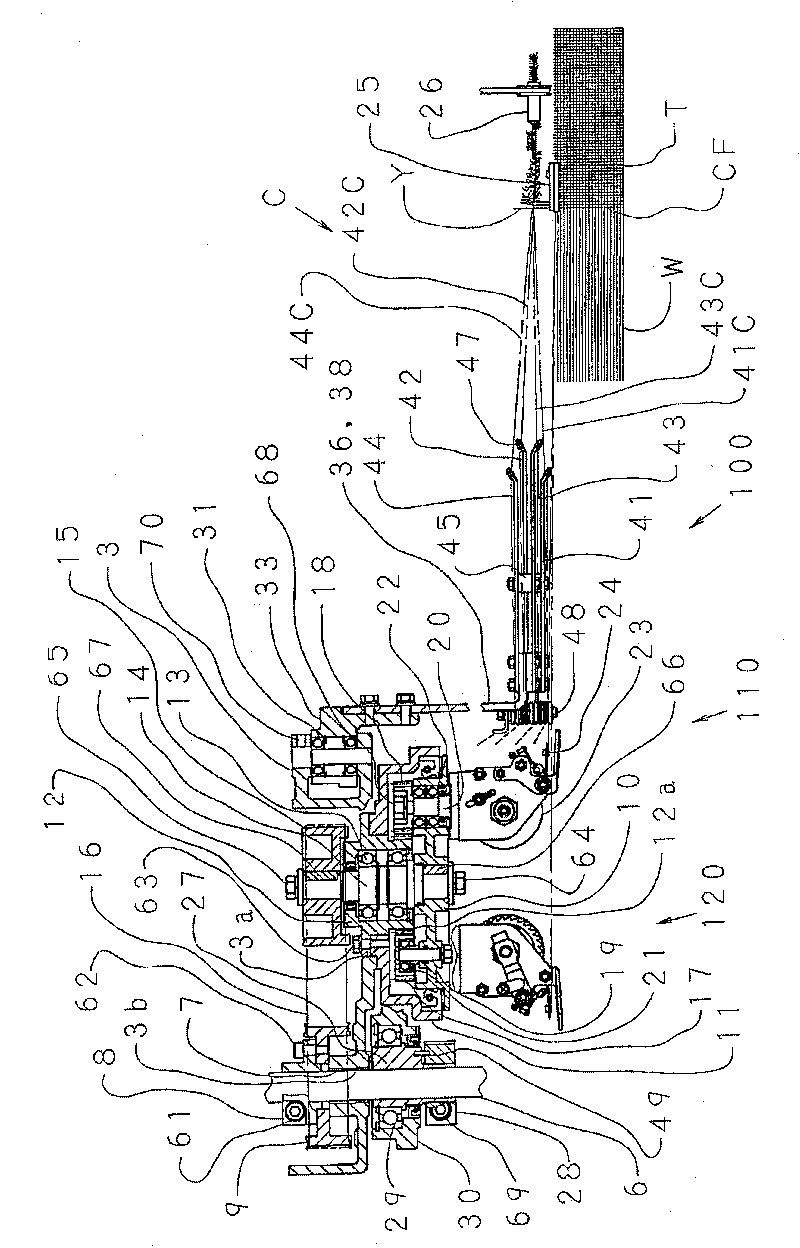

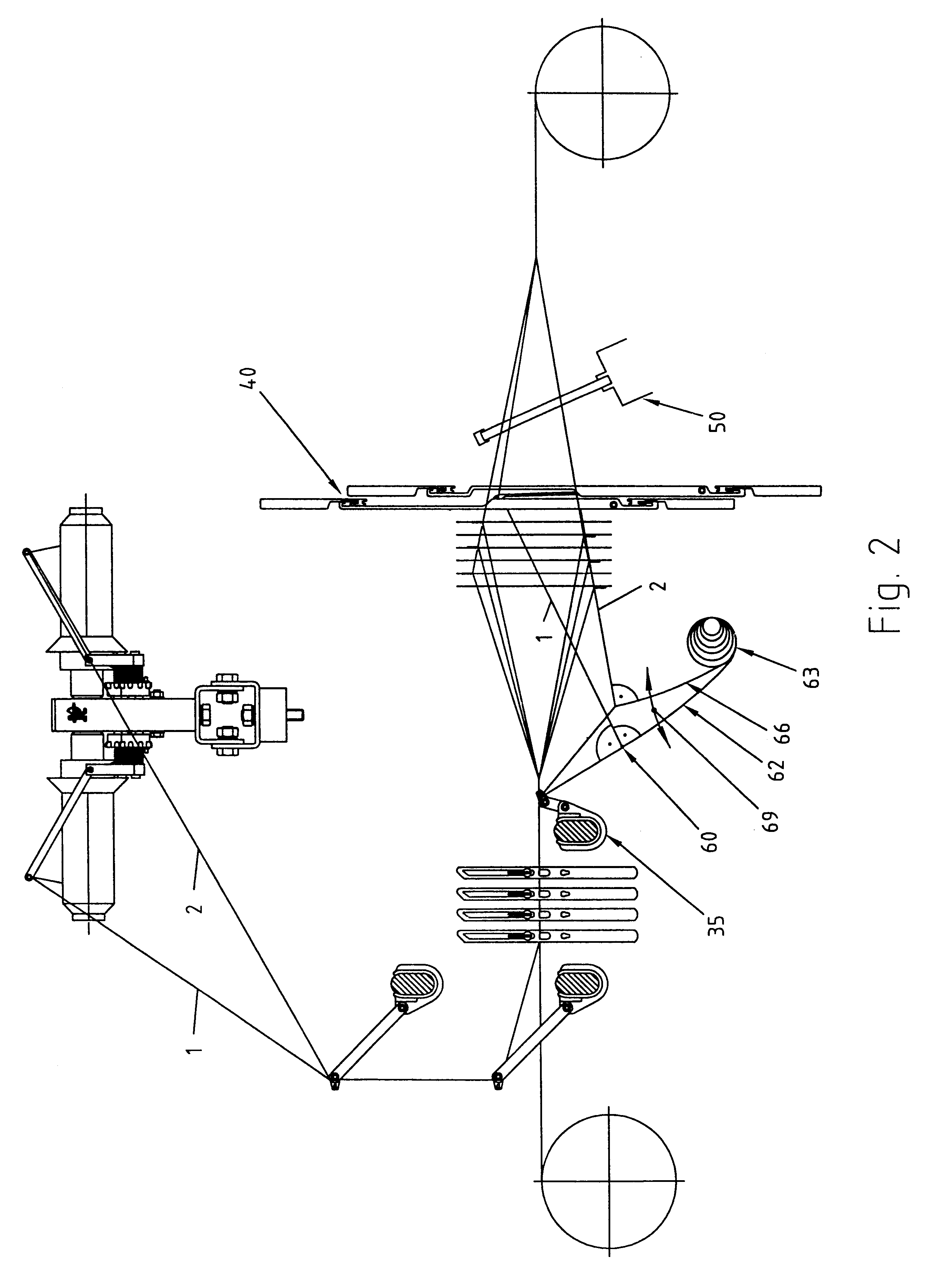

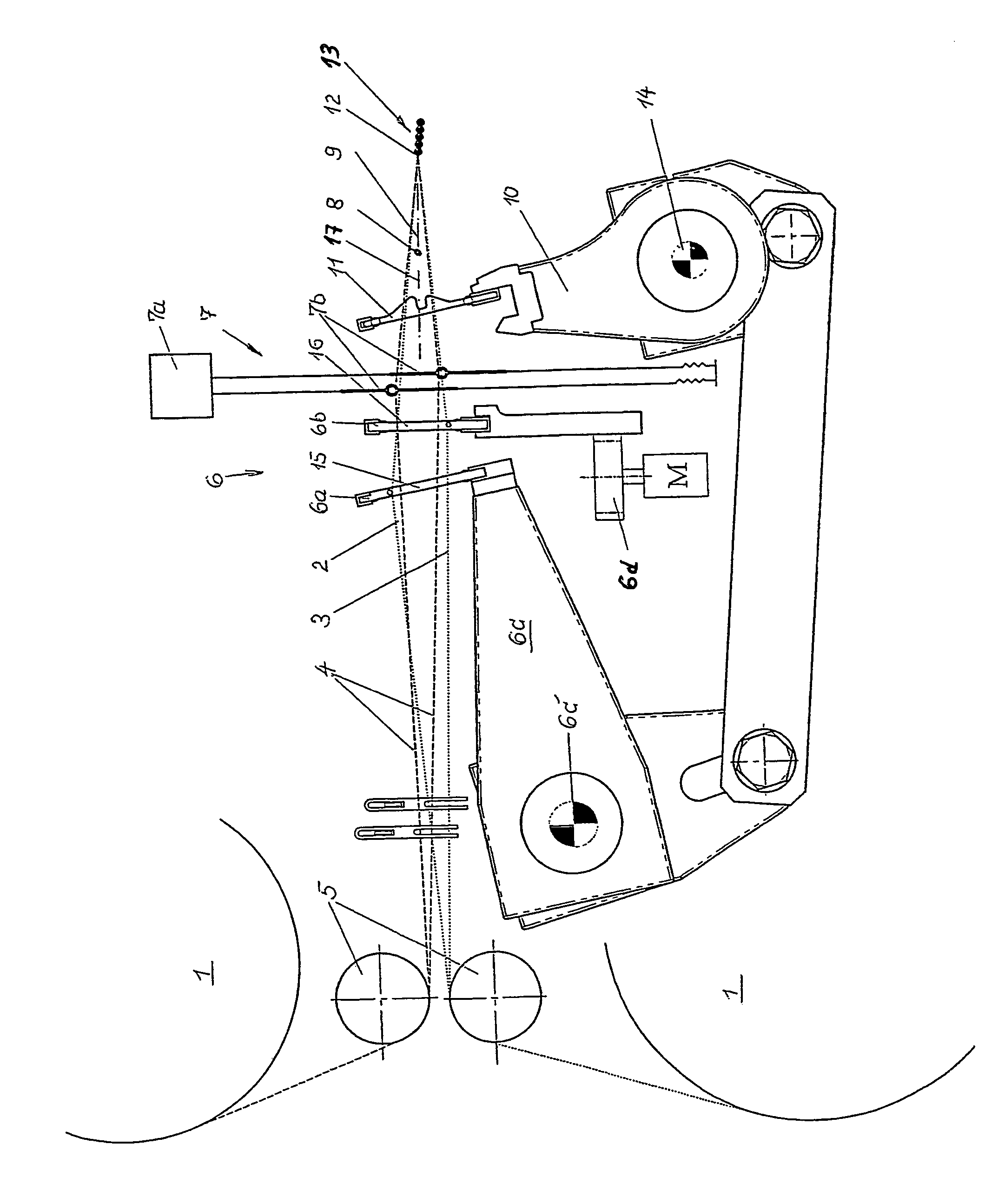

Separating weft thread waste of a single uncontaminated material from untwisted leno binding threads in trimmed catch selvages

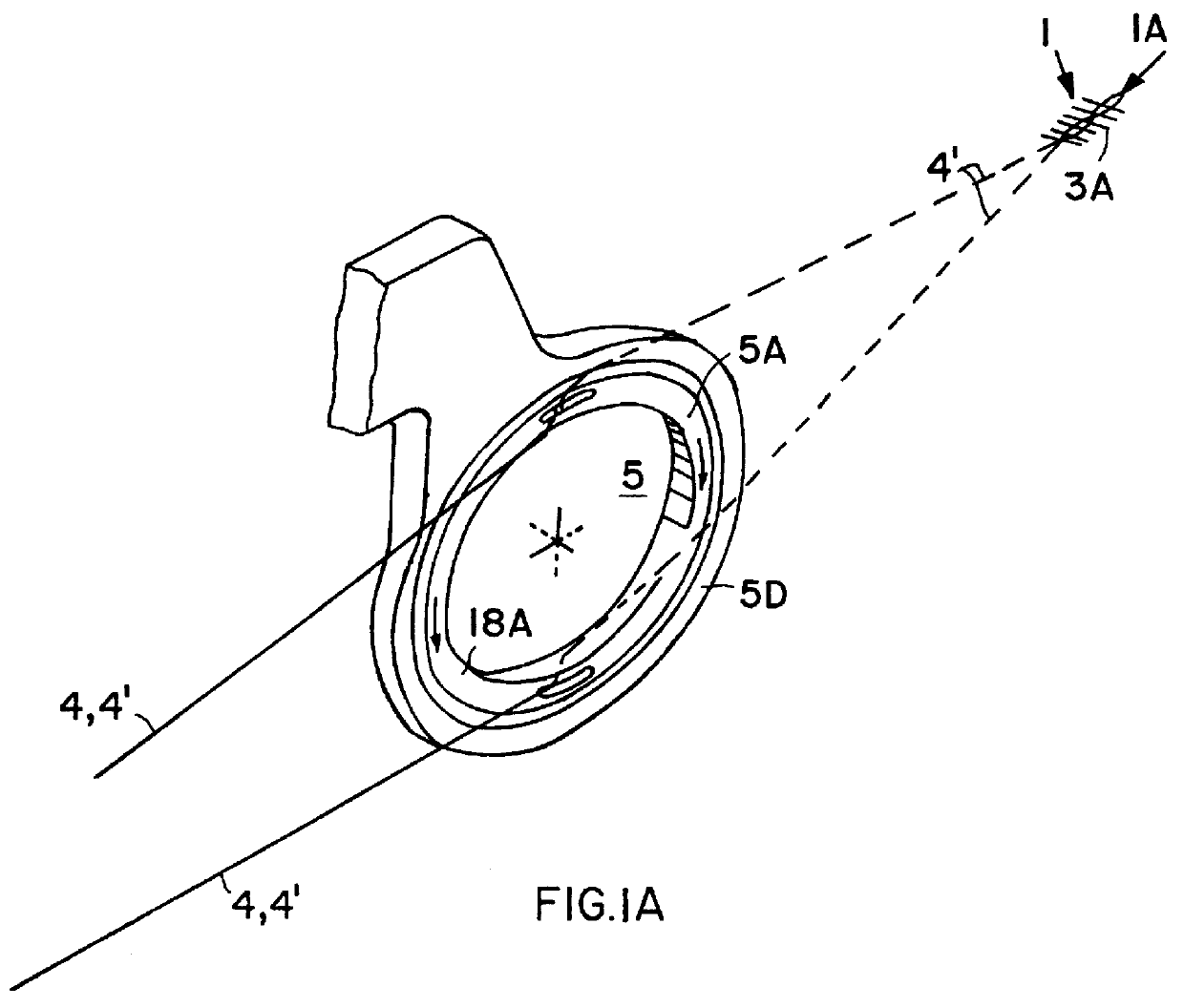

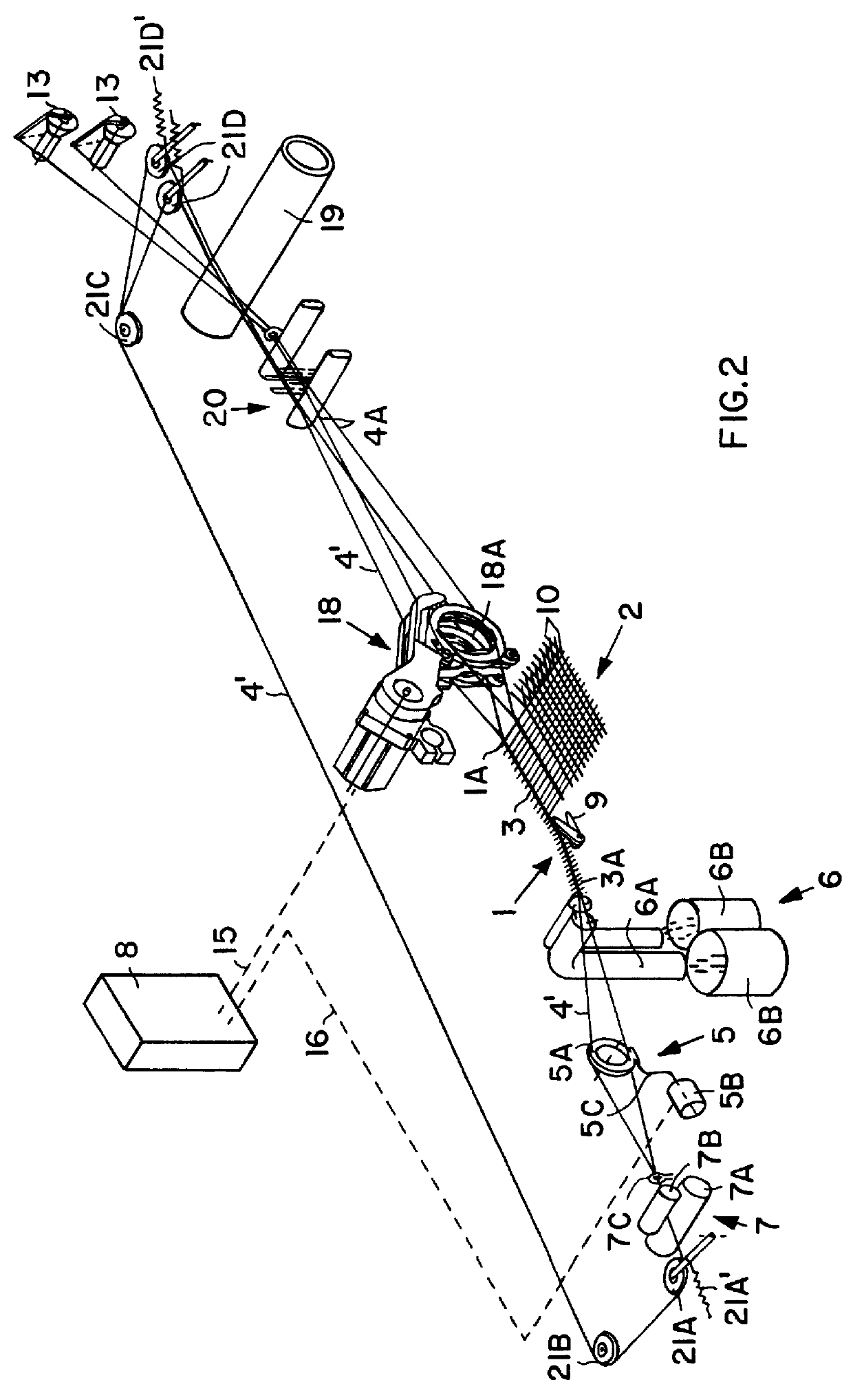

A method and an apparatus serve to process a catch selvage that has been trimmed from a web being woven on a loom, so as to separate weft thread ends and leno threads from the catch selvage to produce a type-pure weft thread waste and a type-pure leno thread waste or reusable leno threads. The term "type-pure" refers to a waste material containing a single uncontaminated type or color of thread material, e.g. wool vs. synthetic or blue vs. red. After the catch selvage (1) has been trimmed from the edge (11) of the woven web (2), the leno threads (4, 4') are untwisted from each other by being rotated by an untwisting apparatus (5) in a direction opposite the binding twist applied by the leno device (18). Thereby, the full leno binding (1A) is completely unbound and opened, so as to release the weft thread ends (3A), which are then sucked into a proper one of weft waste collection containers (6B) by a suction pipe (6A), so that only a single type-pure and / or color of weft thread end is collected in each container (6B). The unbound leno threads (4) are collected as a type-pure waste or are rewound on spools to be reused. Alternatively, by using endless closed-loop leno threads (4'), the leno threads (4') are continuously recirculated back to the leno device (18), without intermediately being wound onto spools.

Owner:LINDAUER DORNIER GMBH

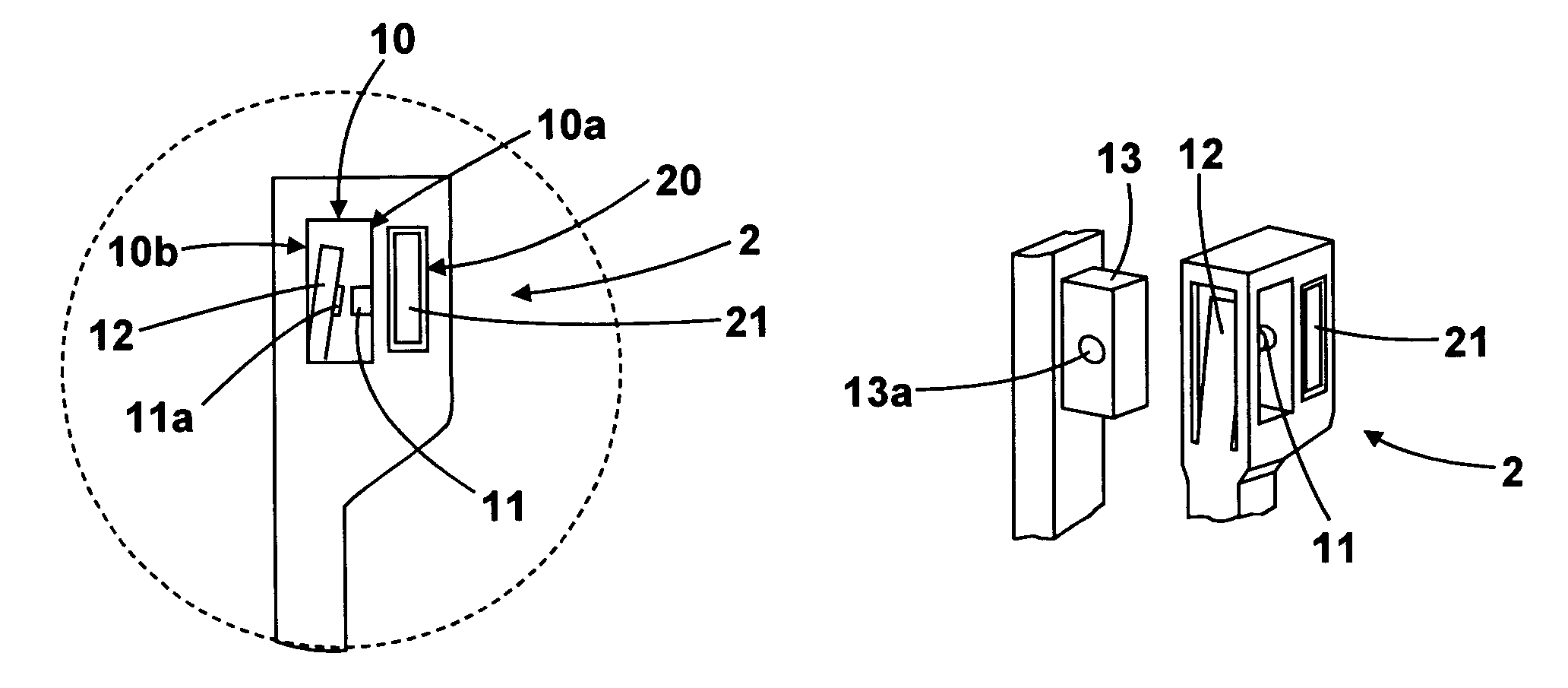

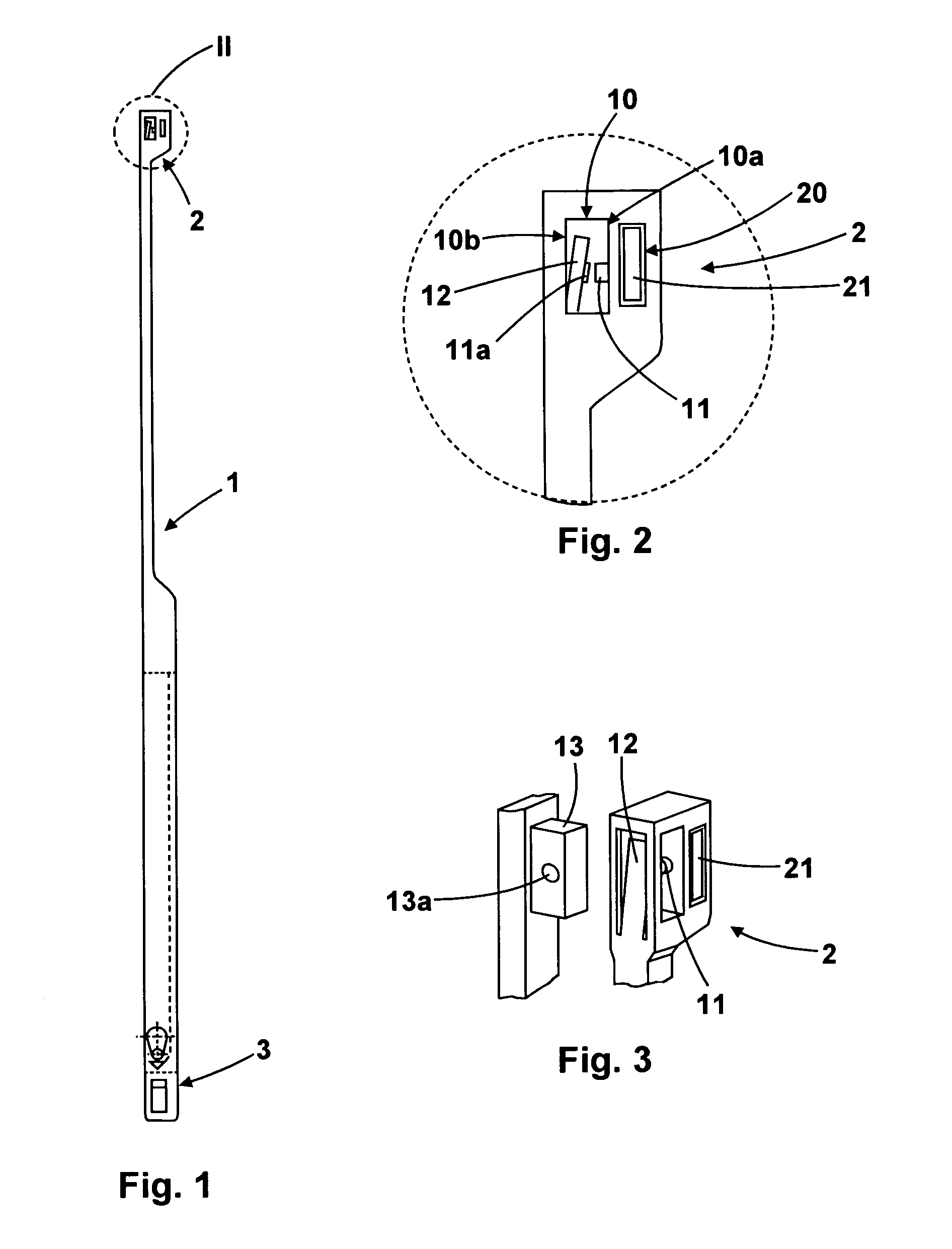

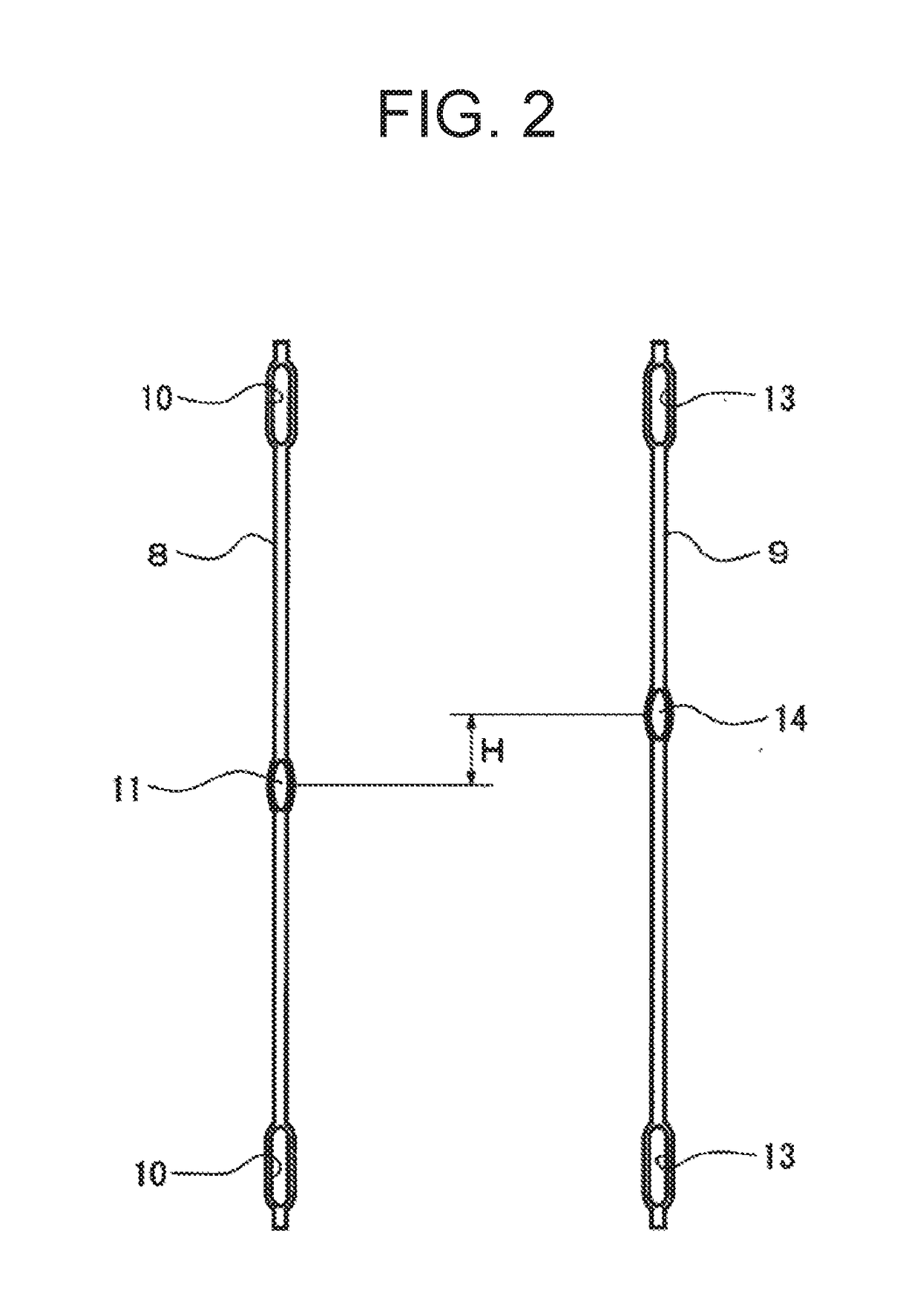

Heddle, especially lifting heddle

The subject matter of the invention is a heddle (1), more specifically a lifting heddle as part of a leno selvedge device, the heddle comprising a head portion and a base portion with a closed or an open eyelet for mounting to a heddle frame or to a heddle ridge bar (13), the head portion and / or base portion (2, 3) being adapted to be secured stationarily to the heddle frame or the heddle ridge bar (13), with the head portion (2) and / or the base portion (3) being adapted to be interlockingly and non-slidably fixed to the heddle frame or to the heddle ridge bar (13) by means of a detent system (11, 12, 13a).

Owner:GEBR KLOCKER

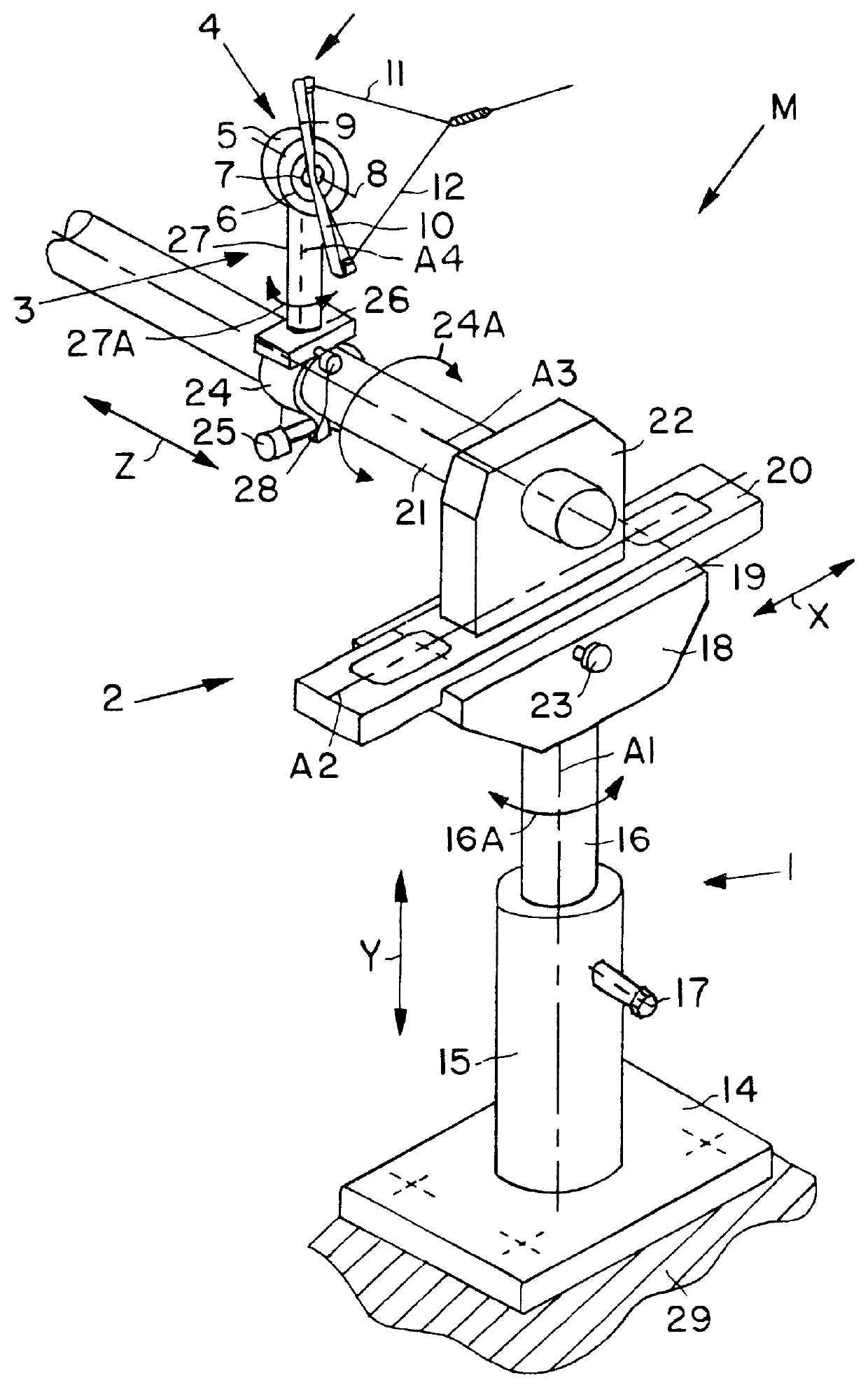

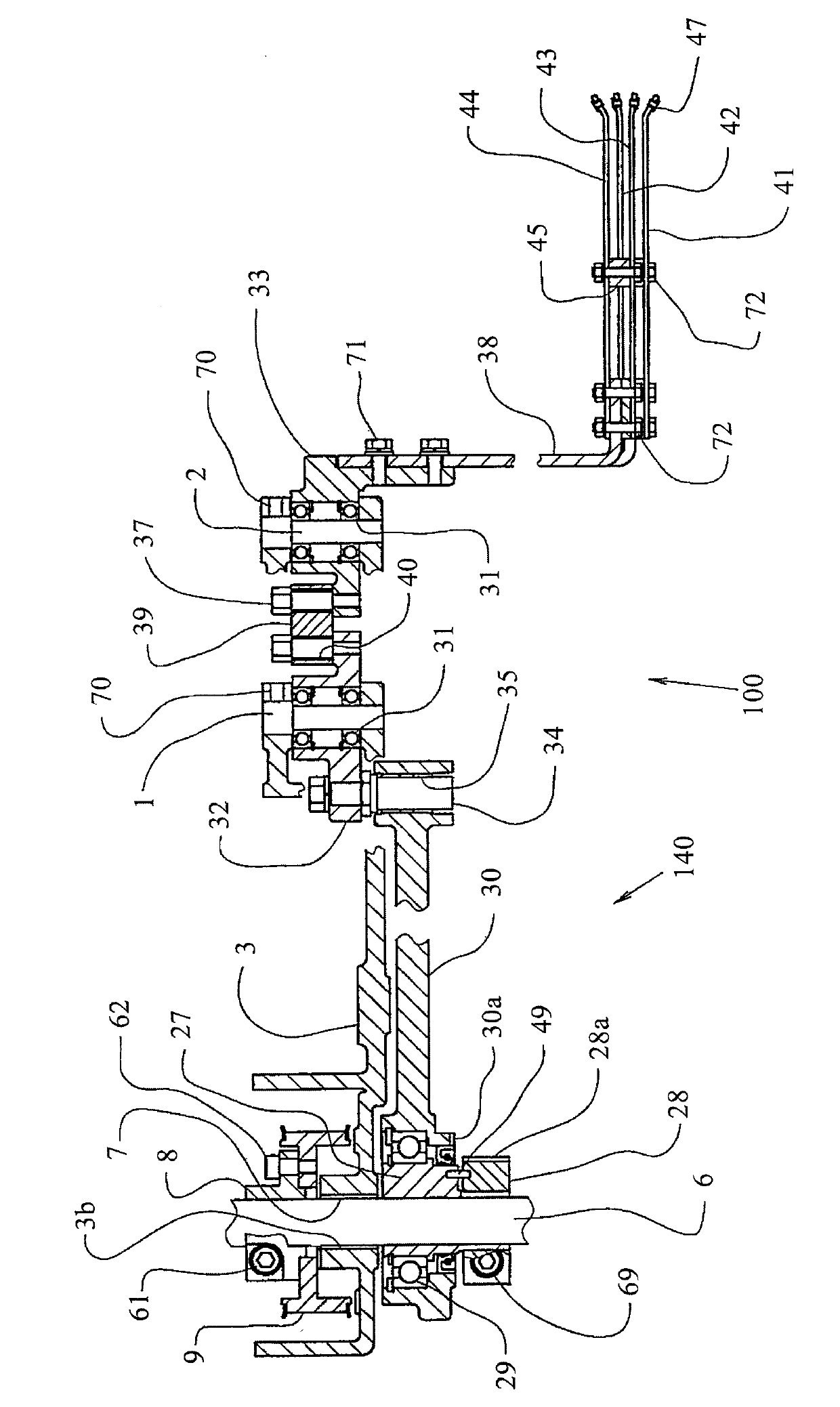

Mounting and positioning apparatus for a leno selvage former

A leno selvage former is supported by a mounting for position adjustments in the three directions of a three-dimensional rectangular coordinate system and preferably also for an angular position adjustment about at least one rotational axis. For this purpose the mounting has three sections. A first section carries a second section which carries a third section. The first section is, for example adjustable in the Y-direction, while the second section is adjustable in the X-direction and the third section is adjustable in the Z-direction of the rectangular coordinate system. At least one of the three sections is preferably also angularly adjustable. At least one lock such as a screw is provided for locking-in an adjusted position.

Owner:LINDAUER DORNIER GMBH

Device using for opening selvedge line of loom

Owner:TOYOTA IND CORP

Catchcord opening apparatus of loom

ActiveCN101724954AAvoid damageLossless tracking performanceLoomsSelvedge shedding mechanismEngineeringWeft yarn

The invention relates to a catchcord opening apparatus of loom, aims to provide a catchcord opening apparatus which doses not applies tension to the weft yarn end sharply, and reduces the possibility of texture disadvantage such as weft yarn retraction generated in fabric. The apparatus has: a first shaft and a second shaft disposed opposite wefting side; a plurality of first swing rods supported on the first shaft; and a plurality of second swing rods supported on the second shaft. each swing rod has a inserting hole for inserting warp yarn with actchselvedge, and the swing rods swing to opposite directions; the front ends of the second swing rods are arranged to move into and out from the spaces between the front ends of the first swing rods; the catchcords are arranged to perform an opening movement and intercrossed while clamping the weft yarn ends along with the swing of the first and second swing rods; thereby, in the catchcord opening apparatus of the fluid jet type loom on the catchcord holding weft yarn end, at least two of the first swing rods is inserted into the hole and reached to the cord position line at different times.

Owner:TSUDAKOMA KOGYO KK

Doup end tension regulating device for a selvedge former

Owner:GEBR KLOCKER

Method for weaving fabrics with areas having a corded structure with a large variety of colour effects

A method for weaving a pile fabric with areas having a corded structure, a backing fabric being woven on a weaving machine by inserting backing weft yarns during successive weft insertion cycles between binding and tension warp yarns, while pattern-weft yarns are inserted outside the backing fabric, and are covered by pile warp yarns forming cords. Successive series of different pattern-weft yarns are inserted into the pile fabric in areas having a corded structure and at least one pattern-weft yarn of each series is running essentially above the warp yarns in a first part of its trajectory and is forming the pattern, and is covered by pile warp yarns essentially forming cords in a second part of its trajectory, so that a predetermined pattern or design is formed. This enables the color palette and / or the effect palette to be modified across the width of the weaving machine with weft effects.

Owner:N V MICHEL VAN DE WIELE

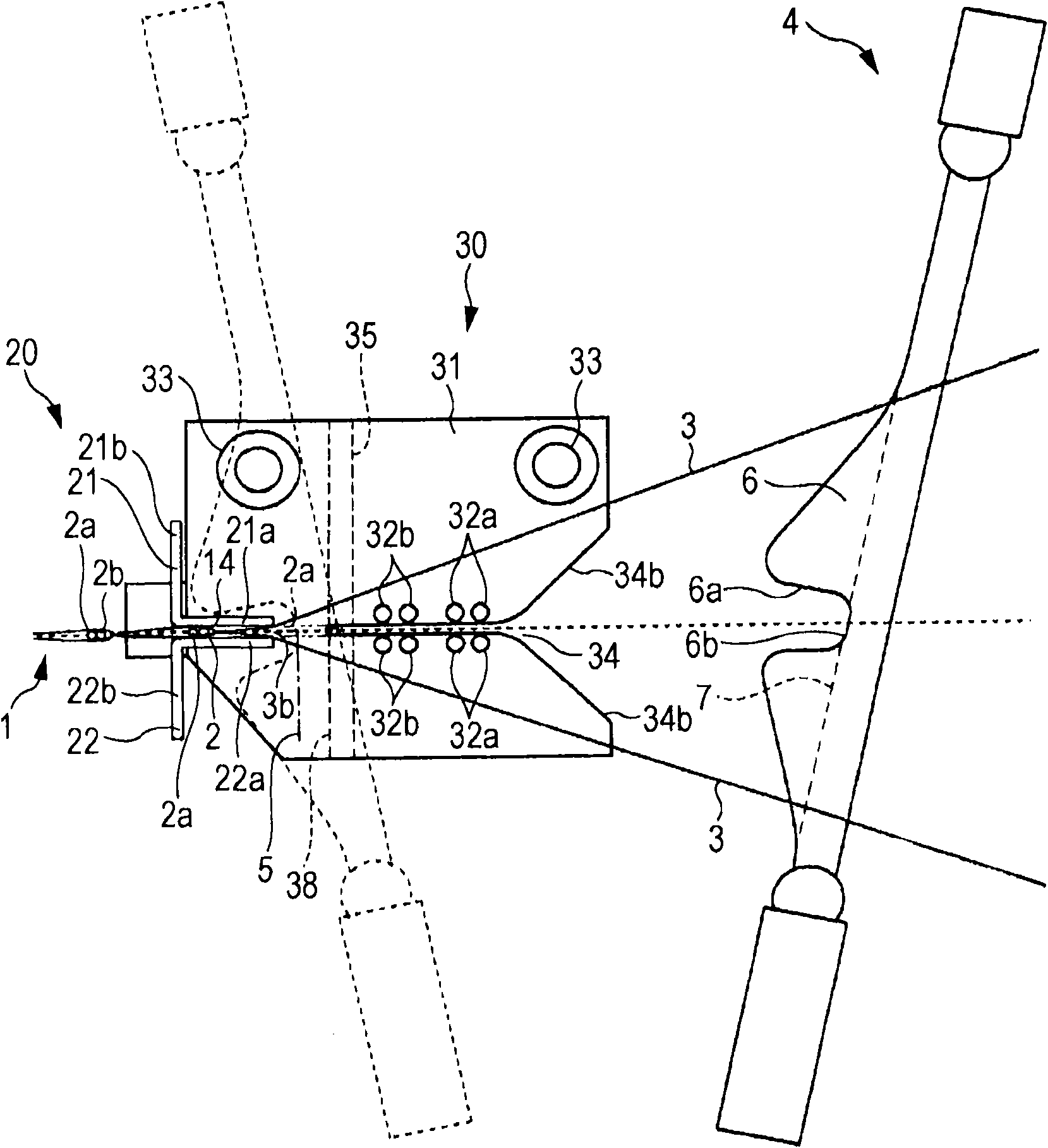

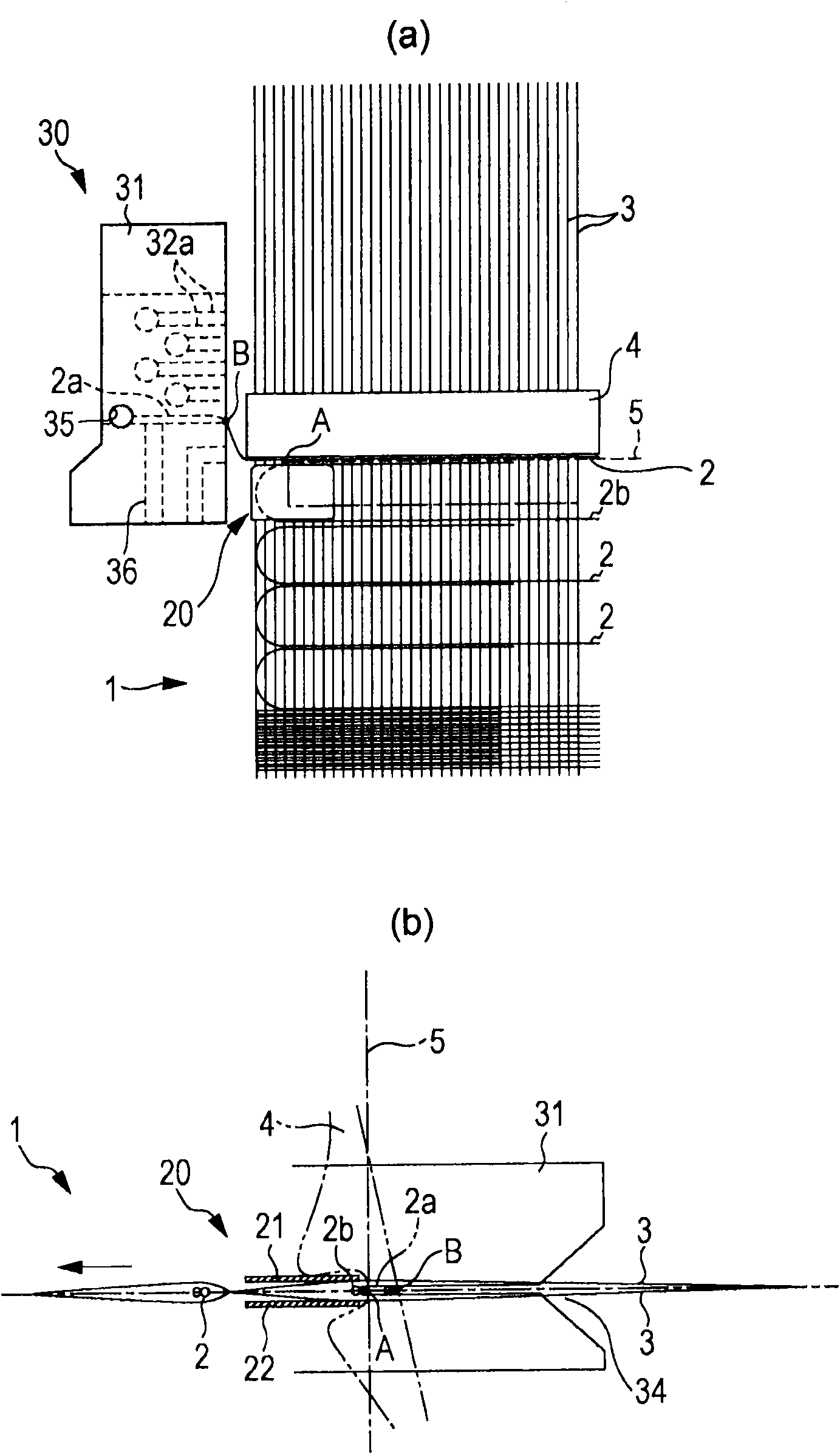

Weaving edge forming device of a rubber strengthening textile weaving loom

The invention provides a simple and cheap weaving edge forming device. In terms of the weaving part with carded weft density, the weaving edge forming device can stably form an arc weaving edge through the end of the weft cooperating with the density of the weft, and a rubber strengthening textile weaving loom of a rubber strengthening textile (1) having the weaving part with carded weft density (1a) is generated. The air spray type weaving edge forming device comprises over one weaving nozzles (32) which are disposed at the side of warp for weaving the end part (2a) of the lead-in weft. In the rubber strengthening textile weaving loom, the weaving edge forming device comprises a limiting device (20) which is disposed near the most front position (5) of a reed along the warp direction, and limits the opening of the warp (3) in a part of the warp array having warps at the most external side in the direction of weaving width.

Owner:TSUDAKOMA KOGYO KK

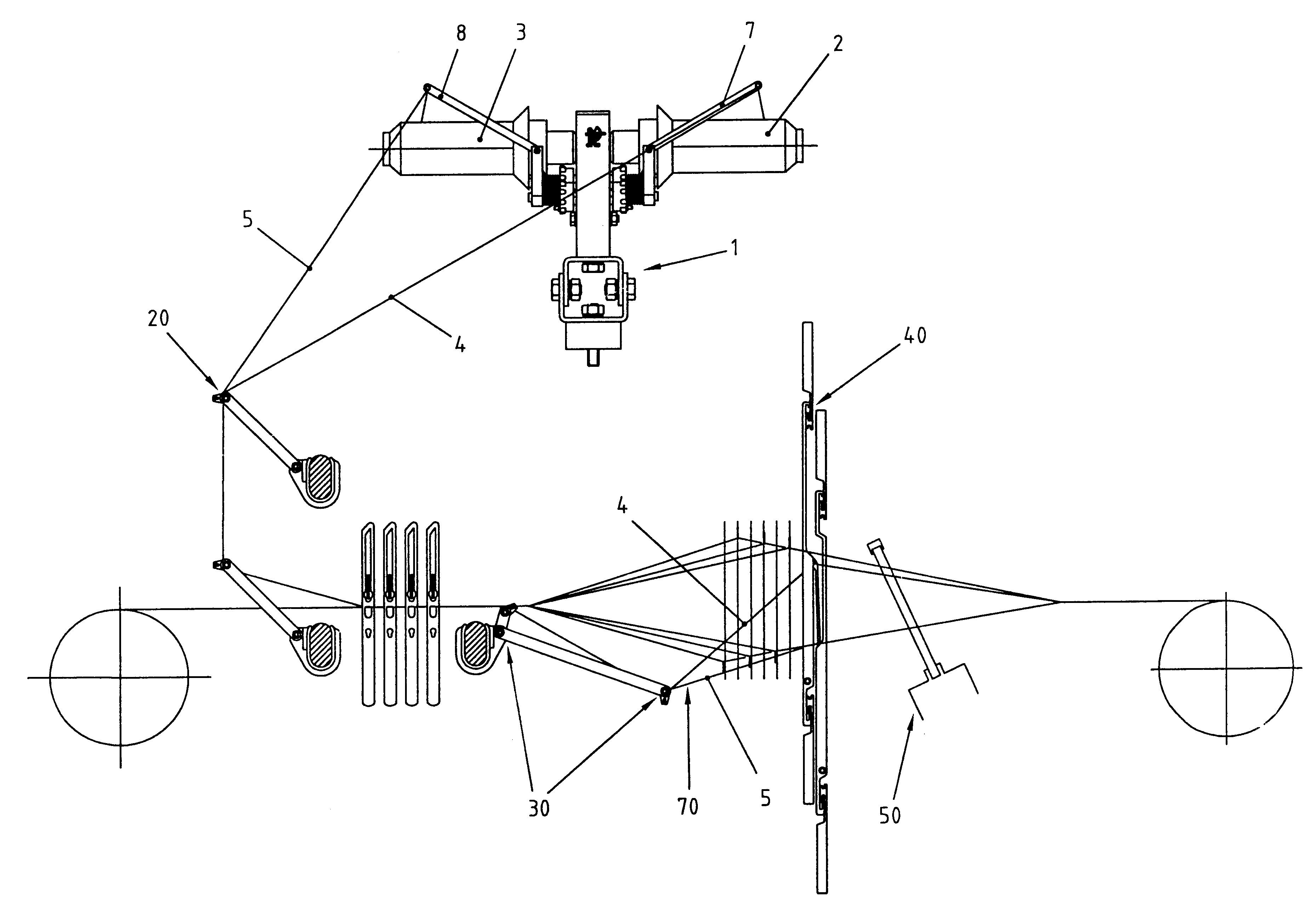

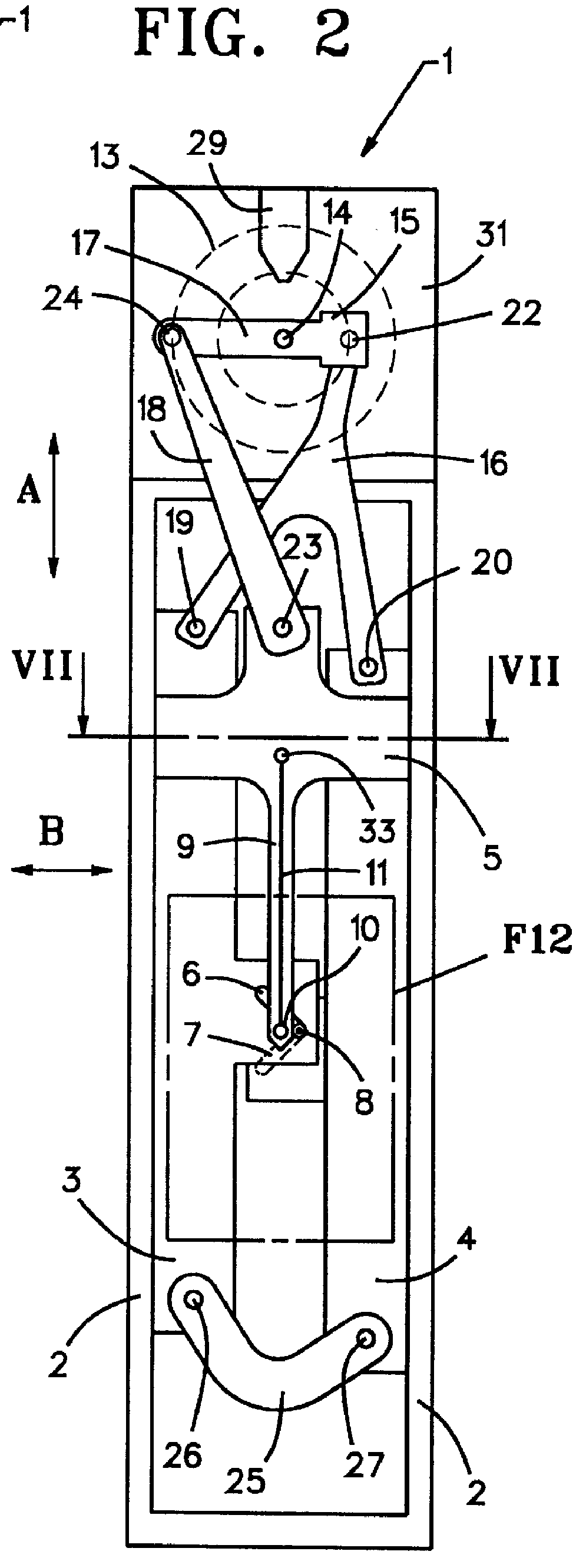

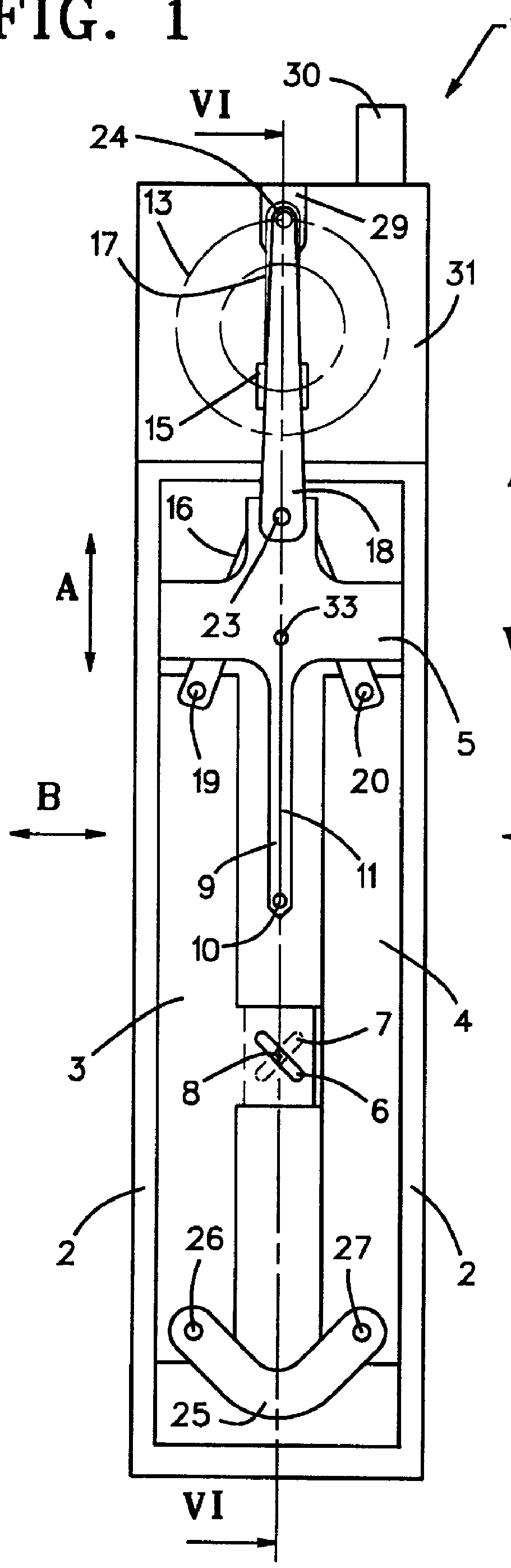

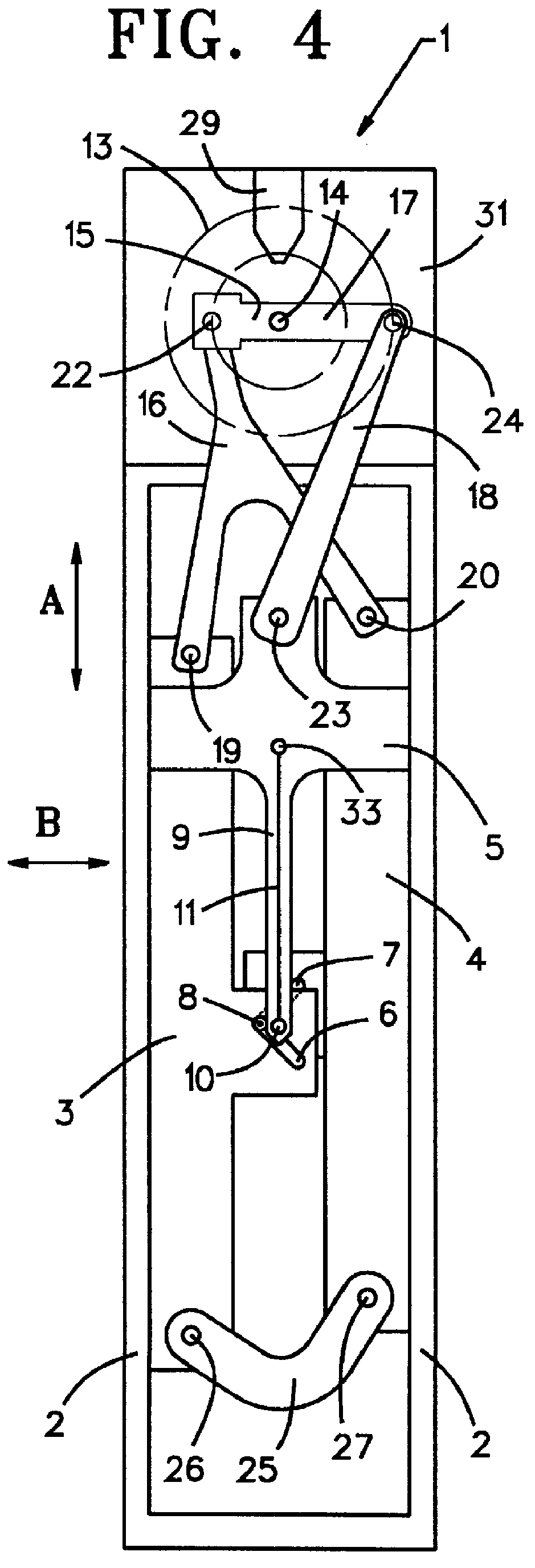

Selvedge-forming device with independent control and eccentric drive system

PCT No. PCT / EP97 / 00495 Sec. 371 Date Nov. 20, 1998 Sec. 102(e) Date Nov. 20, 1998 PCT Filed Feb. 4, 1997 PCT Pub. No. WO97 / 29232 PCT Pub. Date Aug. 14, 1997A selvage-forming device (1) for a loom includes yarn guide structures (2, 3, 5) to guide at least two selvage yarns (8, 11) that are alternating raised and lowered to form a selvage shed (12). These yarn guide structures are powered through the intermediary of eccentrics driven by their own independently controlled drive (13) and an eccentric drive coupling-bracket (16) that creates a motion by which one selvage yarn (8) is additionally shifted transversely to form mutually crossing interlacings.

Owner:PICANOL NV

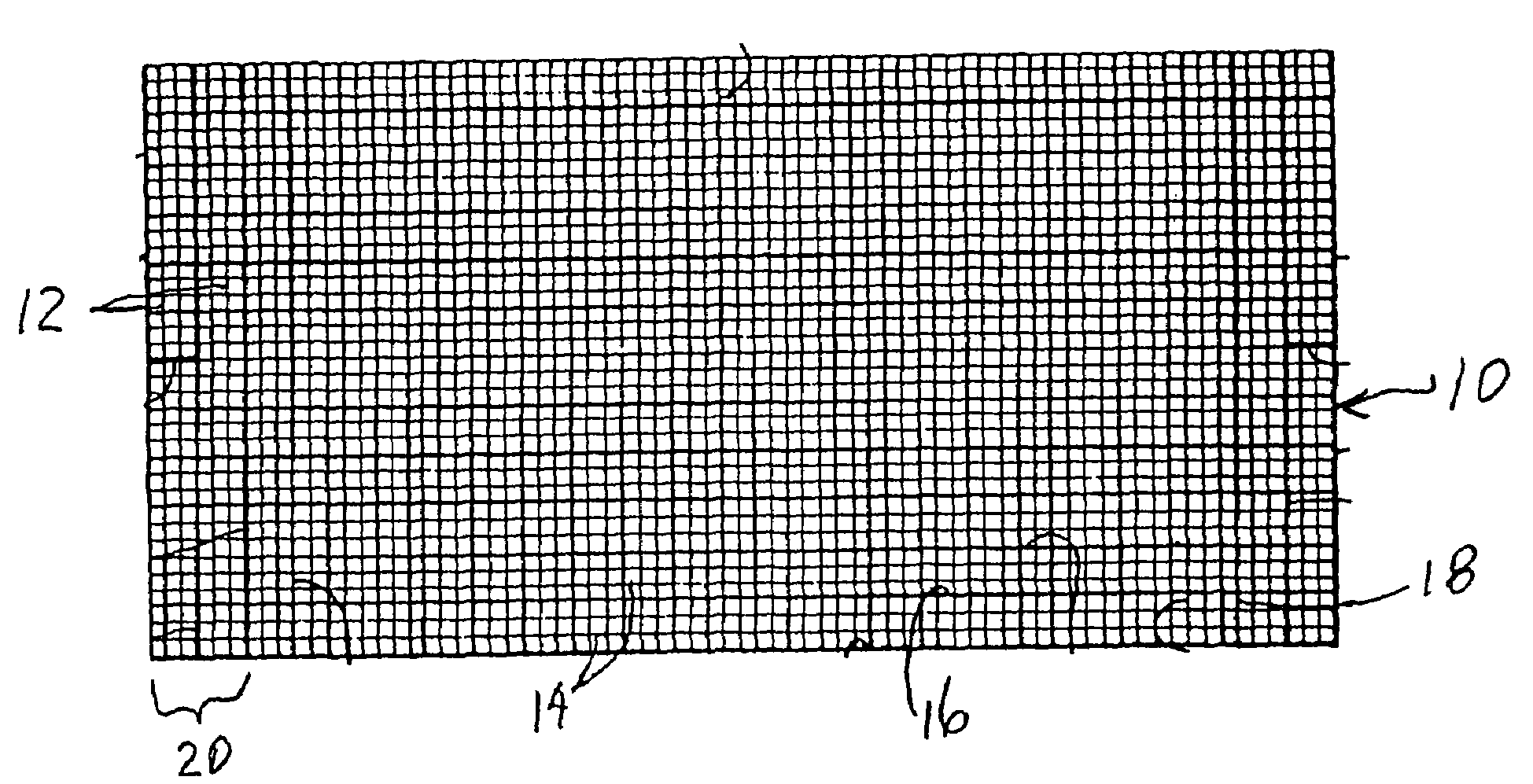

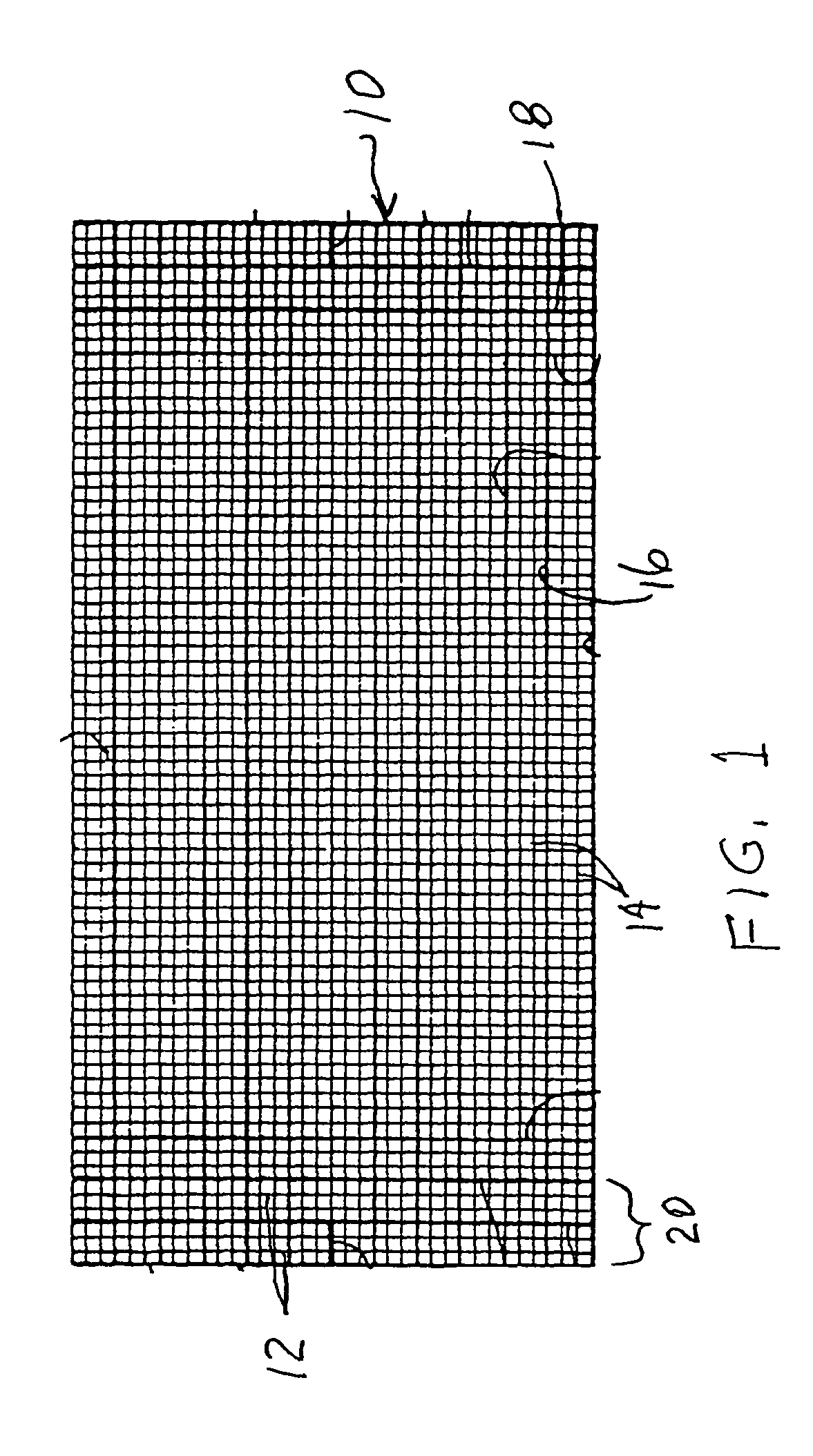

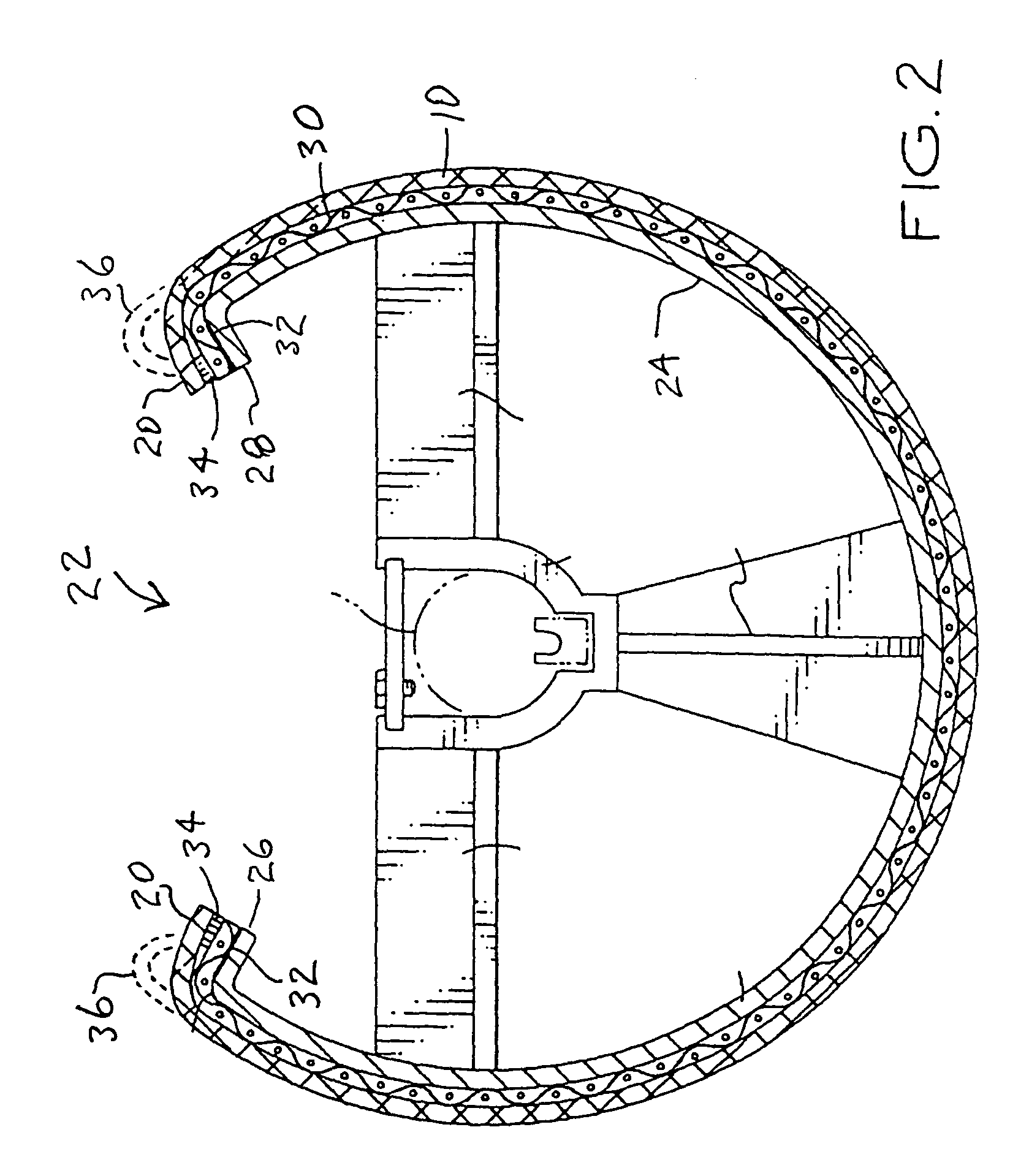

Printing press cylinder flexible jacket covering

A flexible jacket covering for a printing press transfer cylinder having a low density selvage for attaching one edge of the jacket to a hook and loop attachment strip on the transfer cylinder. The covering is cut from fabric woven on a shuttleless loom. The fabric has a reduced density selvage formed by reducing the density of warp threads in the selvage is no more than the warp thread density in the body of the covering fabric and preferably to about half the warp thread density in the body of the fabric.

Owner:PRINTING RES

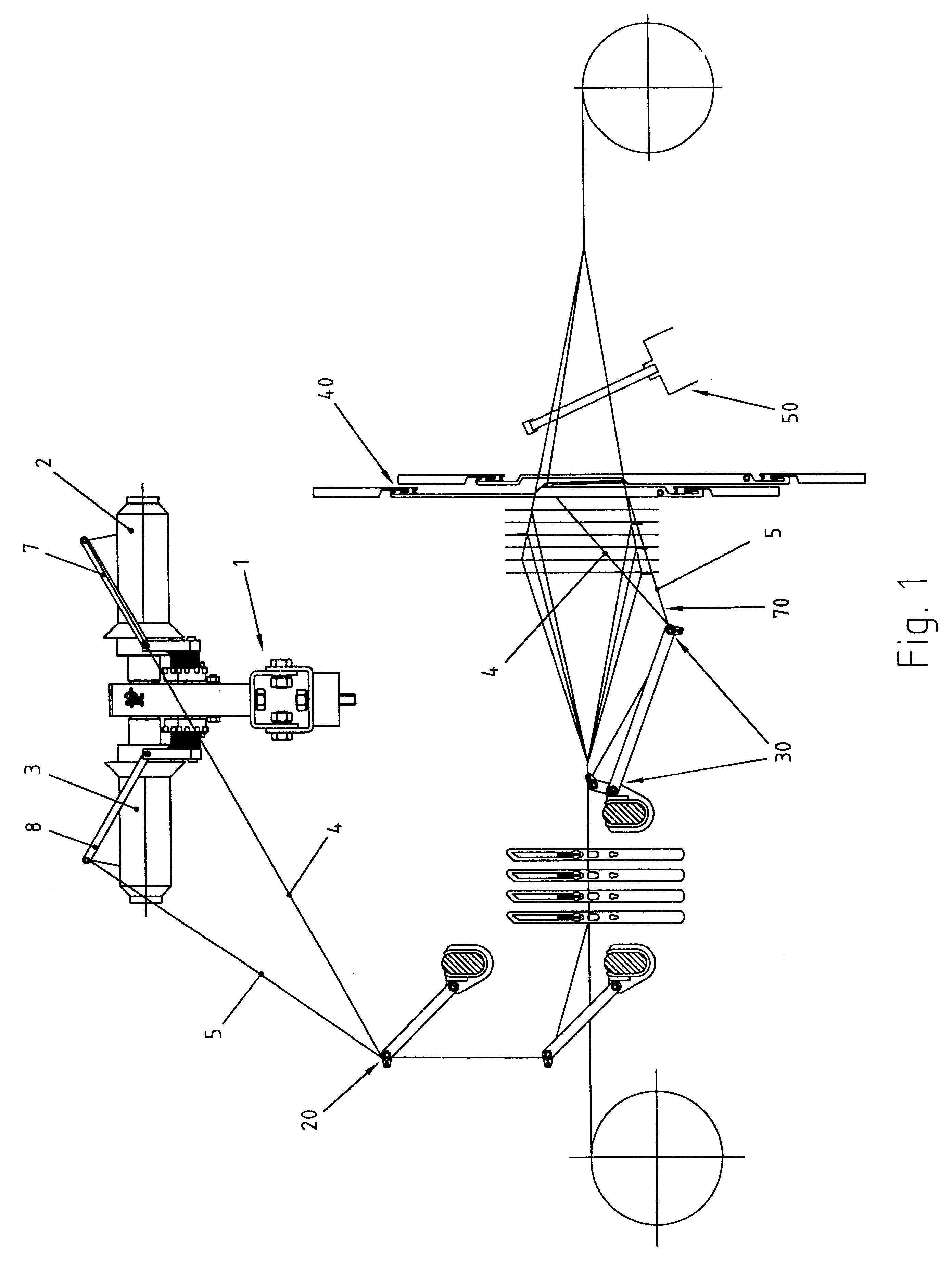

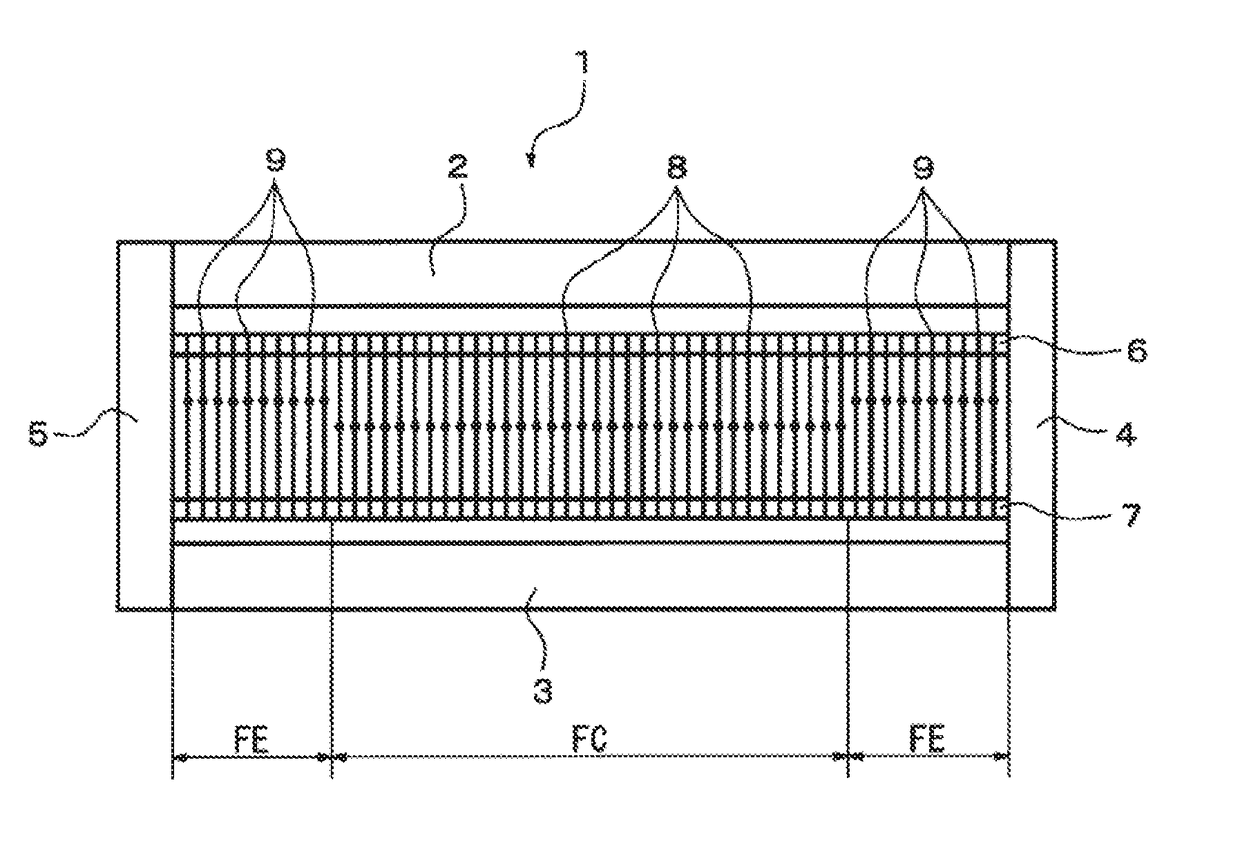

Power loom, particularly an air jet power loom, for the production of a leno fabric with integral patterning

A loom, especially an air jet loom for producing a leno cloth with integrated patterning includes a weaving reed and first and second shed forming devices. The first shed forming device includes a pivotable reed as a first guide arrangement for guiding and shedding leno warp threads, and an upright reed as a second guide arrangement for guiding and shedding ground warp threads, to form leno bindings. The second shed forming device includes a third guide arrangement for guiding and shedding patterning warp threads, to form pattern bindings. The third guide arrangement is arranged between the first shed forming device and the weaving reed.

Owner:LINDAUER DORNIER GMBH

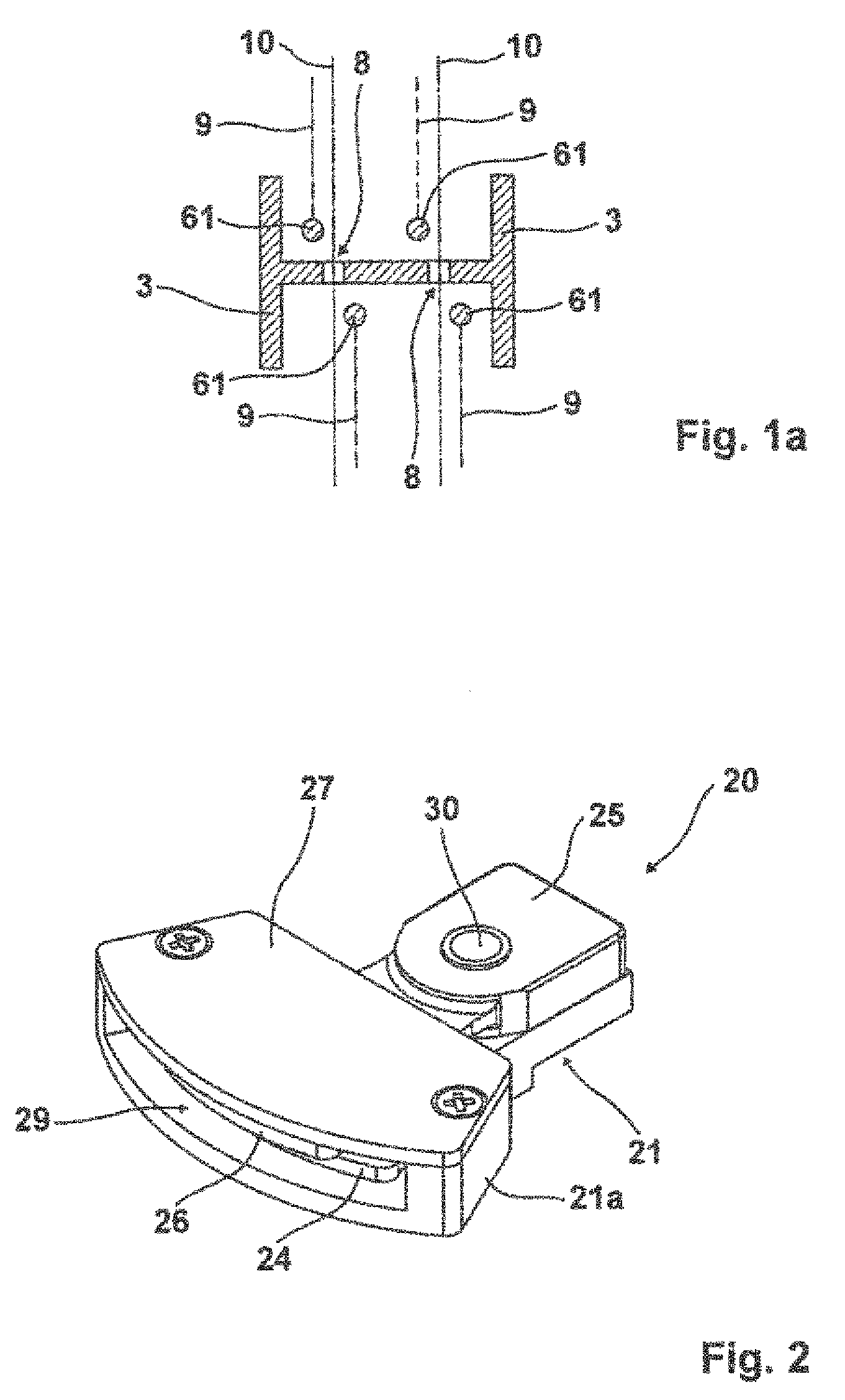

Device for regulating the tension of a thread unwound from a bobbin of a bobbin-holder for a leno selvedge apparatus

The subject matter of the invention is a device for regulating the tension of a thread unwound from a bobbin of a bobbin-holder for a leno selvedge apparatus, said device comprising a brake drum for receiving the bobbin-holder, said brake drum having a brake means and the device being provided with a guide arm for the thread of the bobbin, the brake means (4) comprising a pivotable brake lever (10) having a brake shoe (4) resting against the brake drum (1), with the brake lever (10) having a guide arm (20) provided with an eye (21) for passage of the thread (6) unwound from the bobbin (5).

Owner:GEBR KLOCKER

Device to form a leno selvedge

Owner:GEBR KLOCKER

Heald, especially lifting heald

The subject matter of the invention is a heald (1), more specifically a lifting heald as a part of a leno selvedge device, said heald comprising a head portion and a base portion with a closed or an open eyelet for mounting to a heald frame or to a heald ridge bar (13), said head portion and / or base portion (2, 3) being adapted to be secured stationarily to the heald frame or the heald ridge bar (13), with the head portion (2) and / or the base portion (3) being adapted to be interlockingly fixed to the heald frame or to the heald ridge bar (13) by means of a detent system (11, 12, 13a).

Owner:GEBR KLOCKER

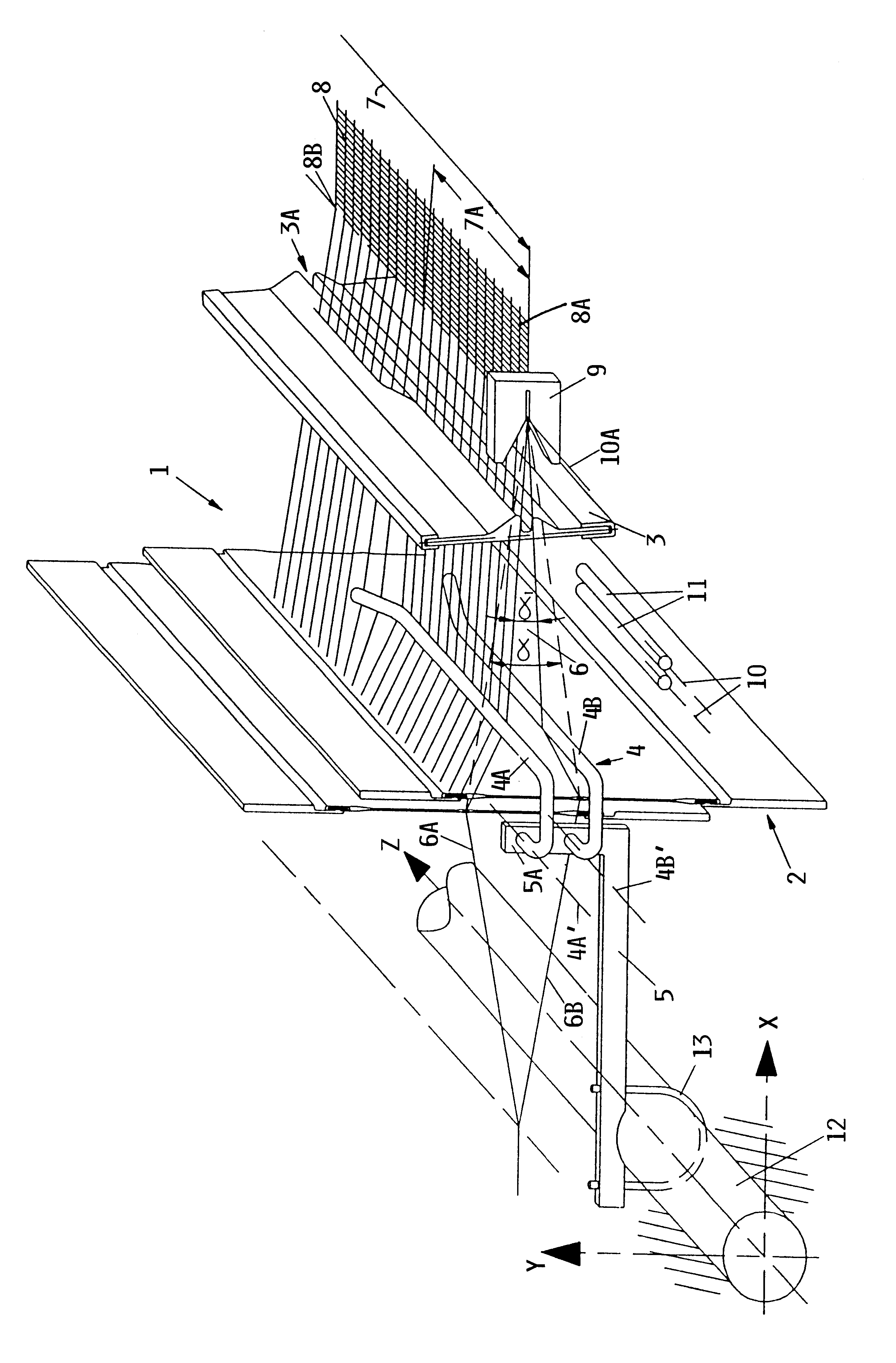

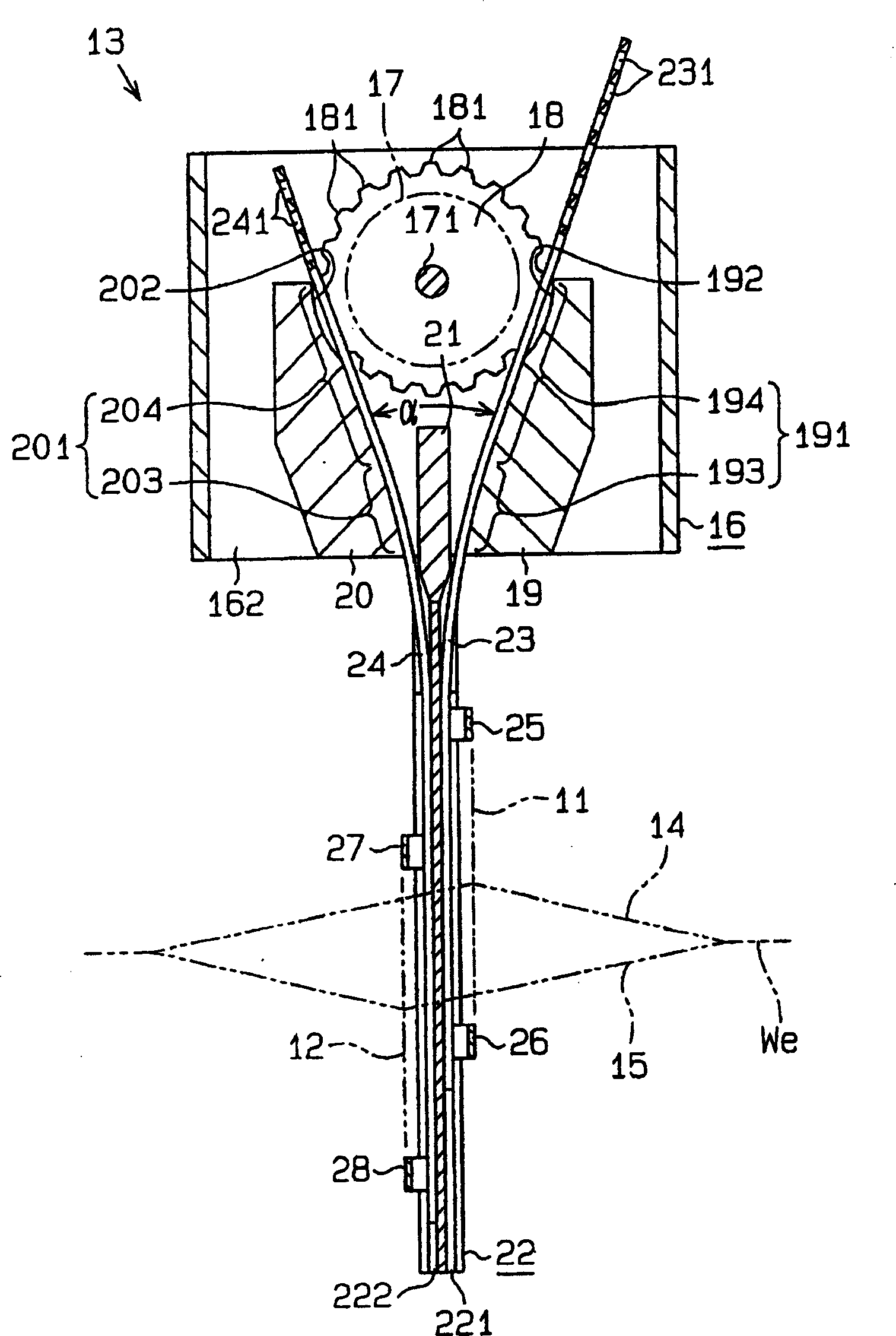

Method and arrangement for limiting the loom shed opening angle

A method and a device limit the normal shed opening angle (alpha) of warp threads in an open loom shed, to a smaller limited shed opening angle (alpha1) that applies to the selvedge warp threads over a selvedge laying-in width at the edge of the fabric. The limited shed opening angle (alpha1) is smaller than the normal shed opening angle (alpha) and is selected to provide optimal positioning and binding-in of the free thread end of a beat-up weft thread that is guided back and laid or tucked into the next open shed to form a high quality laid-in selvedge. The shed opening limit device includes two thread-constraining prongs that extend perpendicularly to the direction of the warp threads at least along the desired laid-in depth of the selvedge. The selvedge warp threads are guided and constrained between the prongs so that the extent of shed opening of the selvedge warp threads is limited to the limited angle (alpha1).

Owner:LINDAUER DORNIER GMBH

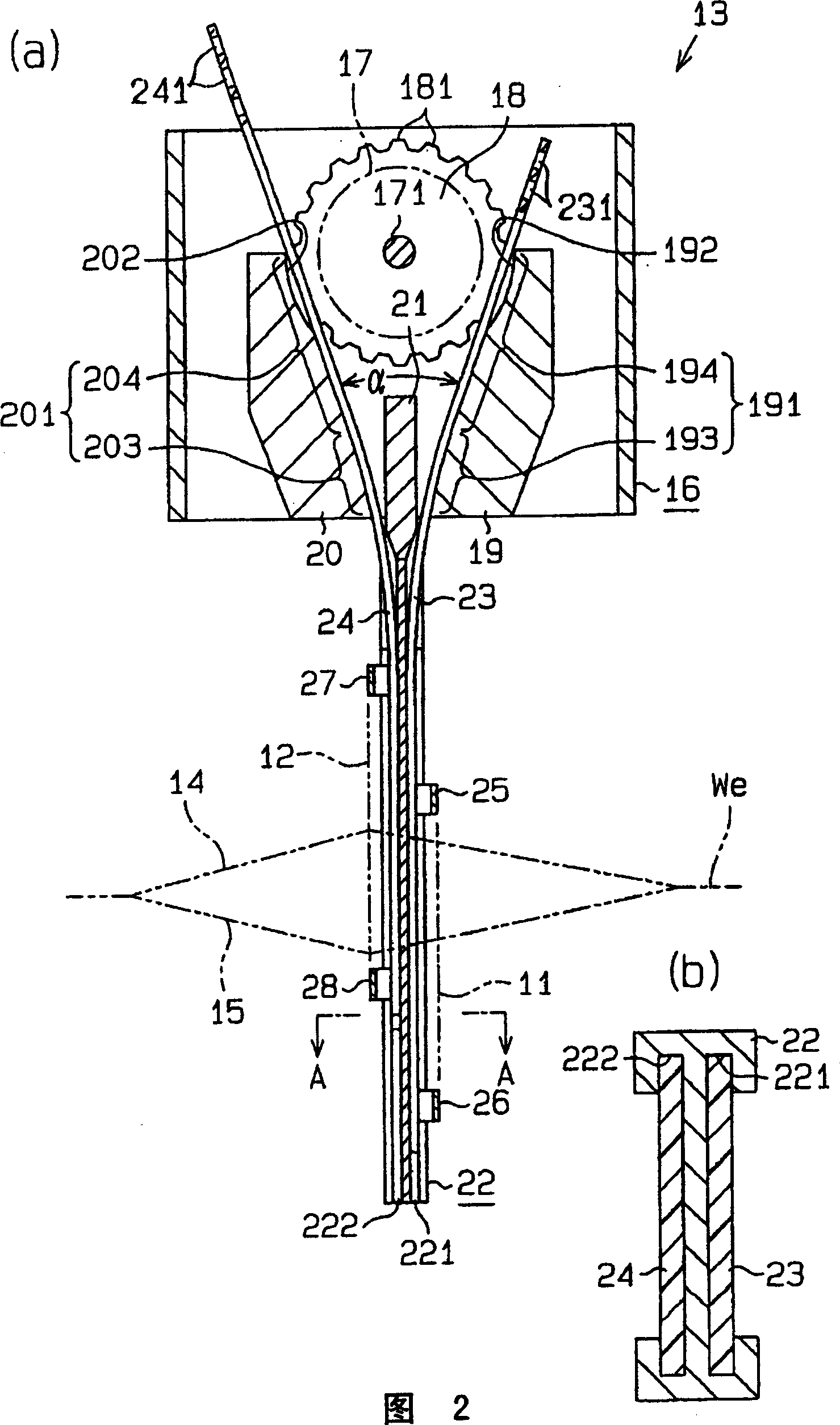

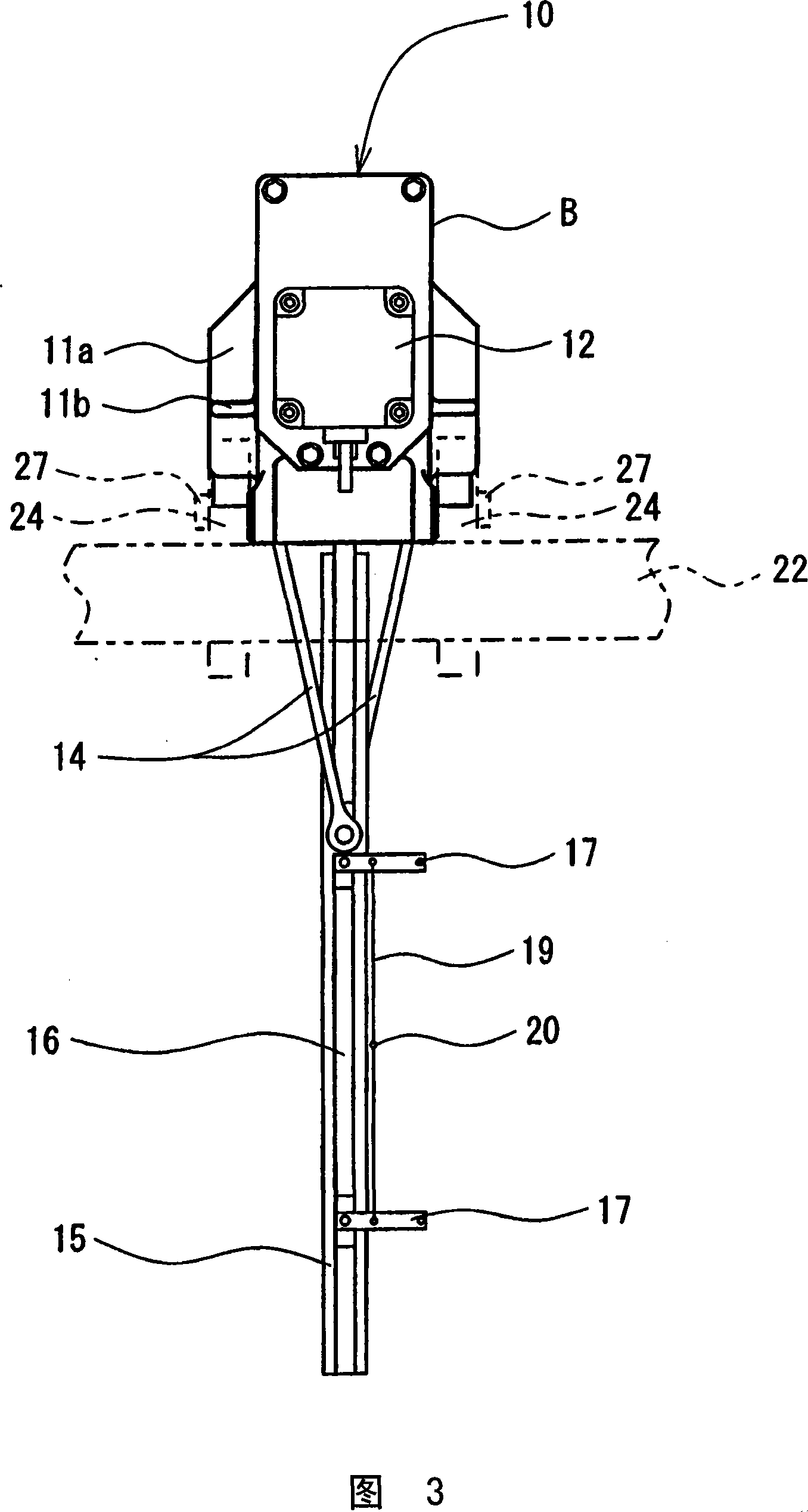

Selvage forming device of coeaving machine

The present invention provides with a list formation device which enlarges the open angle of yarn fringes without interfere the high speeding in a spinning machine. A power delivery tooth 181 of a wheel 18 is rotating by an electric motor 17 and engaging with power bearing holes 231, 234 of a first ligature 23 and a second ligature 24, respectively. An engage position between the first ligature 23 and the wheel 18 is limited by a first position regulation object 19, and the engage position between the second ligature 24 and the wheel 18 is limited by a second position regulation object 19. A part of the ligatures 23, 24 is inserting into guiding slots 221, 222 of a guiding path 22. A warp-lifting device 11 for use in a first side is supported by hooks 25, 26 of the ligature 23, and A warp-lifting device 12 for use in a second side is supported by hooks 27, 28 of the ligature 24.

Owner:TOYOTA IND CORP

Actuator for a shed-forming device for a weaving machine

ActiveCN101171376ALow running costReduce parking timeJacquardsCam shedding mechanismElectric machineryEngineering

The present invention provides an actuator (10) for a shed-forming device for a weaving machine, the actuator (10) being arrangeable for moving at least one warp thread (1), the actuator (10) comprising an artificial muscle (11) having an input for receiving an actuation signal (12), the configuration of the artificial muscle (11) being variable in response to the actuation signal (12) in order to move the at least one warp thread (1). The use of an artificial muscle (11) as an actuator (10) has the benefit of a fast response when a change in configuration is required, reduced power requirements when compared to conventional actuators based on electric motors, compactness, robustness, reduced noise during operation and reduced cost to manufacture.

Owner:PICANOL SUZHOU IND PARK TEXTILE MACHINERY

Device to form a leno selvedge

Owner:GEBR KLOCKER

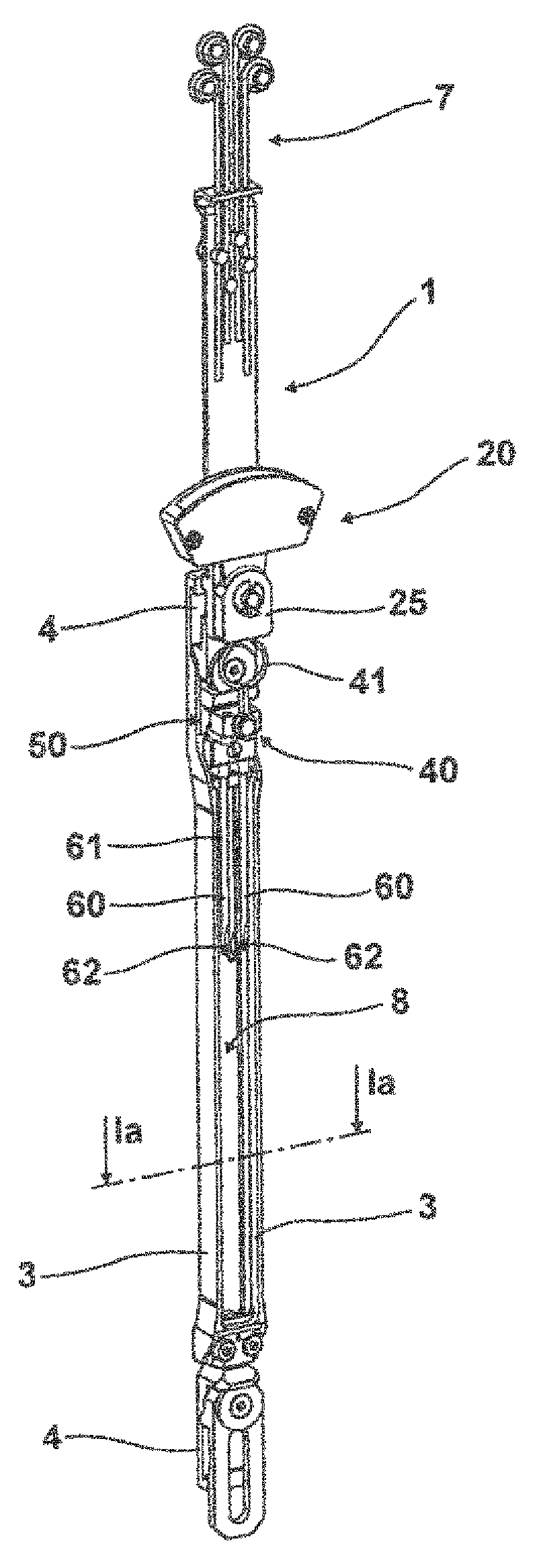

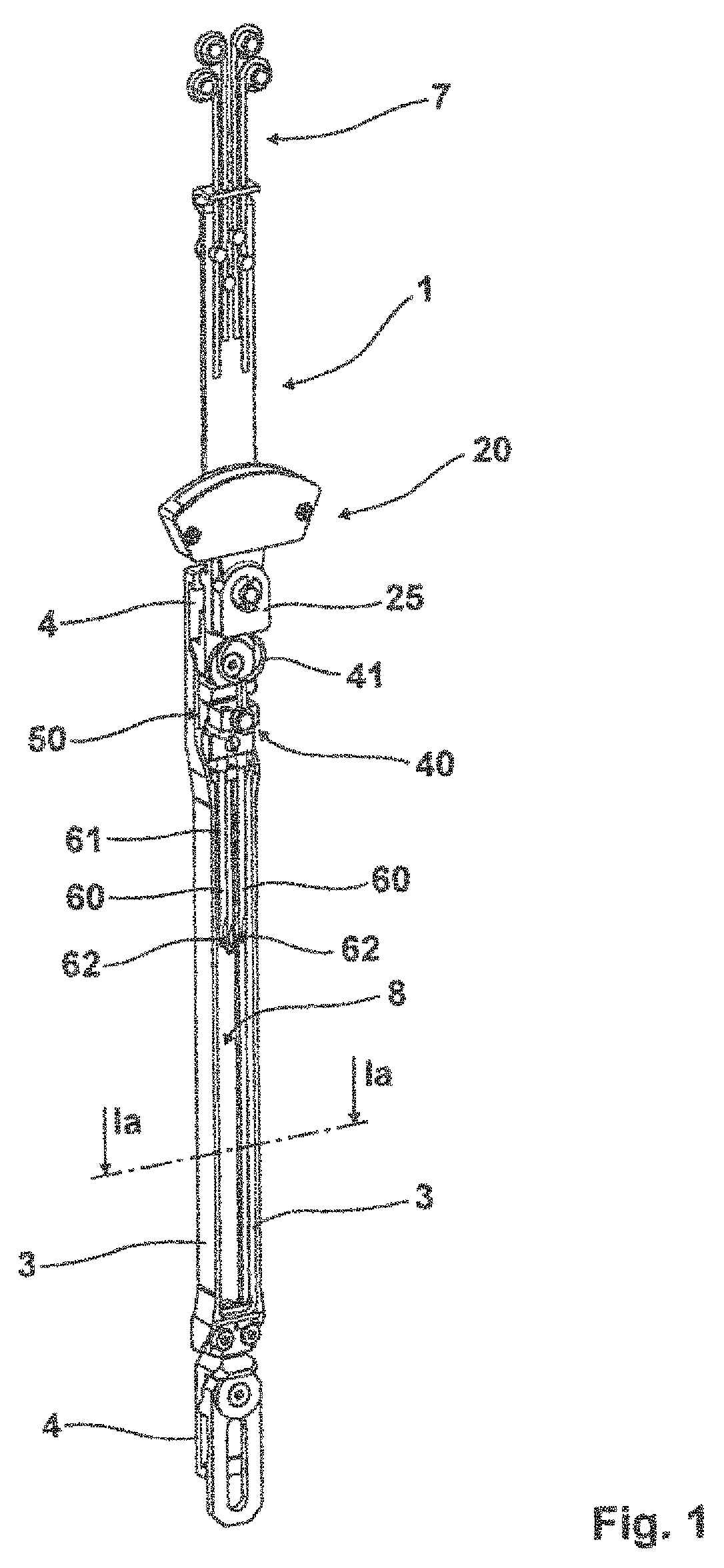

Device for producing a leno selvedge, in particular for shuttleless looms

InactiveUS6098669ASmall massAvoid tearingLeno shedding mechanismSelvedgesEngineeringMechanical engineering

Owner:GEBR KLOCKER

Printing press cylinder flexible jacket covering

A flexible jacket covering for a printing press transfer cylinder having a low density selvage for attaching one edge of the jacket to a hook and loop attachment strip on the transfer cylinder. The covering is cut from fabric woven on a shuttleless loom. The fabric has a reduced density selvage formed by reducing the density of warp threads in the selvage is no more than the warp thread density in the body of the covering fabric and preferably to about half the warp thread density in the body of the fabric.

Owner:PRINTING RES

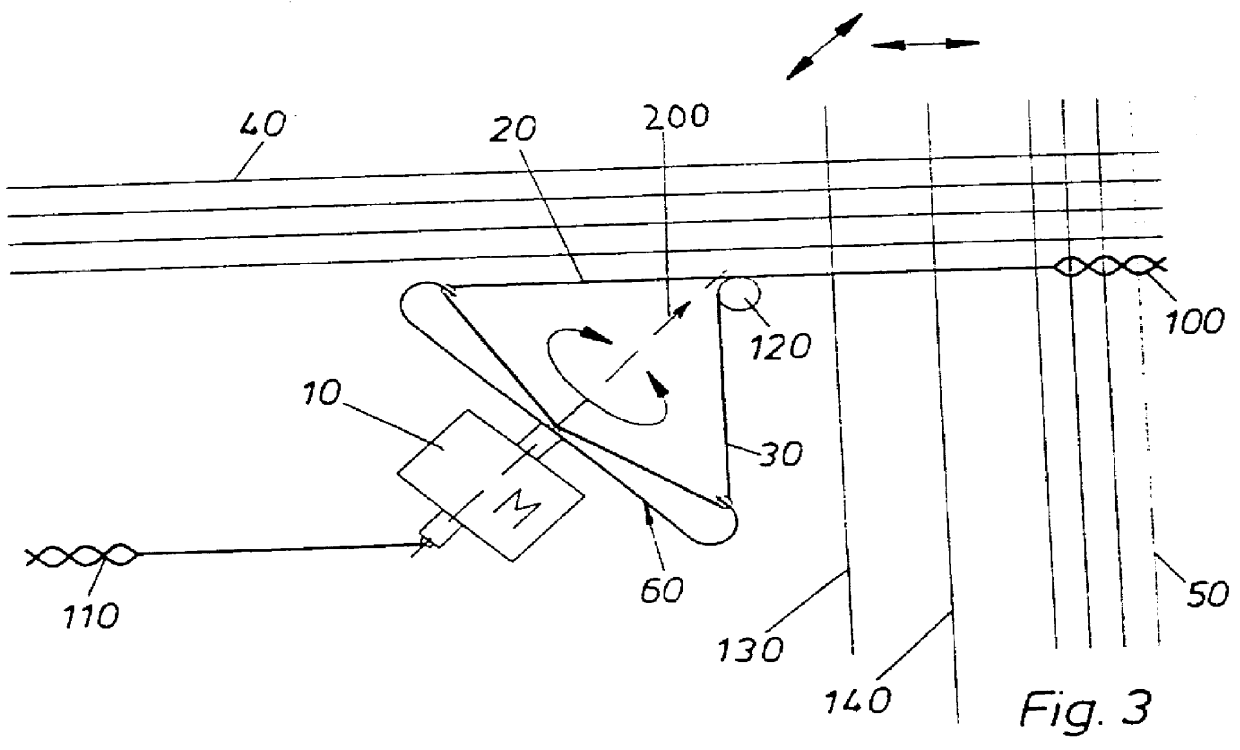

Selvage forming apparatus for loom

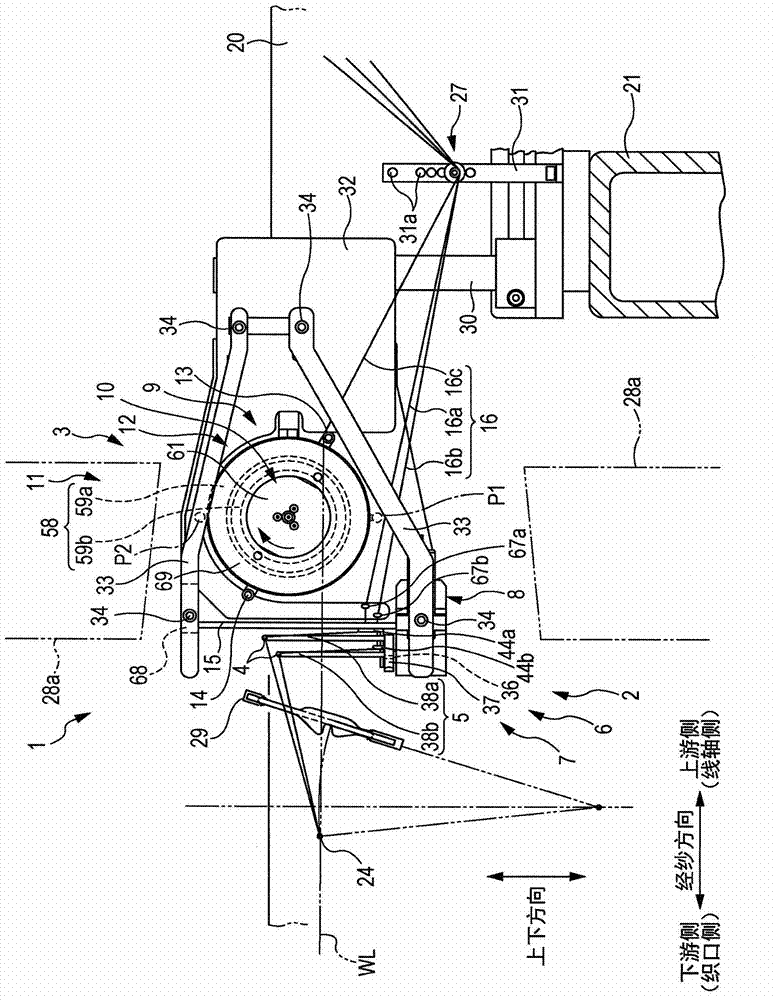

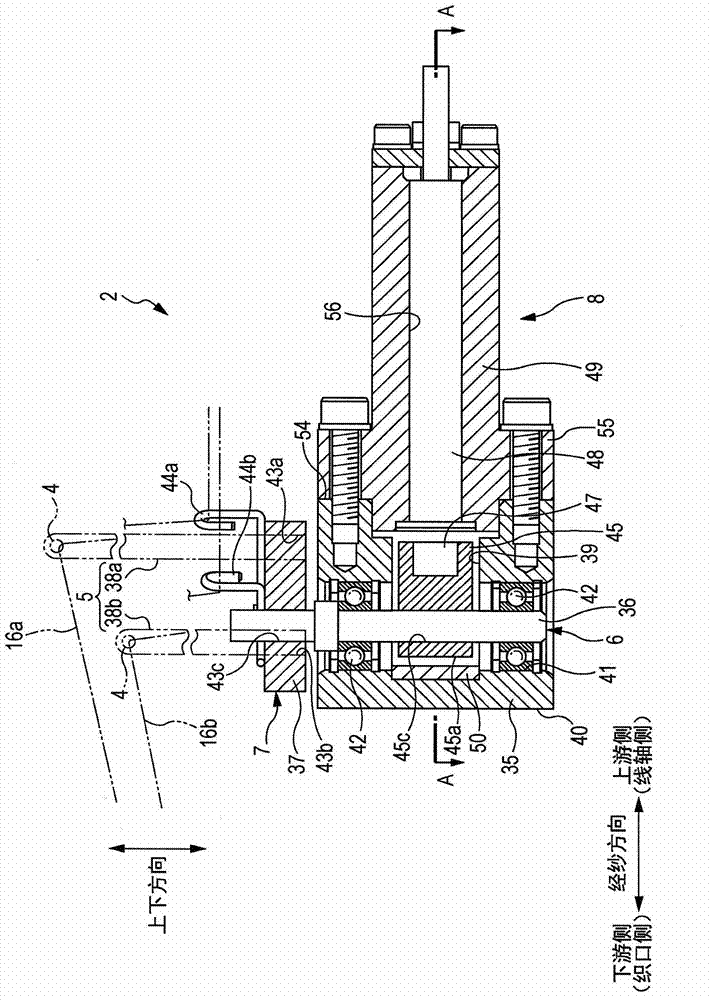

A selvage forming apparatus (1) forms a leno selvage construction by using a first selvage yarn (16a, 16b) and a second selvage yarn (16c). The selvage forming apparatus (1) includes a selvage-yarn-path switching device (2) that moves a path of the first selvage yarn (16a, 16b) in a weaving-width direction and a selvage shedding device (3) that moves a path of the second selvage yarn (16c) in a top-bottom direction. The selvage-yarn-path switching device (2) includes a selvage-yarn guide member (5) having an eyelet (4) through which the first selvage yarn (16a, 16b) is inserted and a first drive device (8) that switches a position of the eyelet (4) between two positions that are on the left and right sides of the second selvage yarn (16c). The selvage shedding device (3) includes an engagement portion (9) that engages with the second selvage yarn (16c) and moves so as to move the path of the second selvage yarn (16c) in the top-bottom direction. The engagement portion (9) moves along a revolution path including positions at which the second selvage yarn (16c) is closer to the first drive device (8) than the eyelet (4) and farther from the first drive device (8) than a tip end of the selvage-yarn guide member (5) in the top-bottom direction at a position of the selvage-yarn guide member (5).

Owner:TSUDAKOMA KOGYO KK

Device for manufacturing a fabric, and fabric

ActiveUS8893750B2More time to yieldReduce the possibilityLeno shedding mechanismLoomsEngineeringMechanical engineering

Owner:GEBR KLOCKER

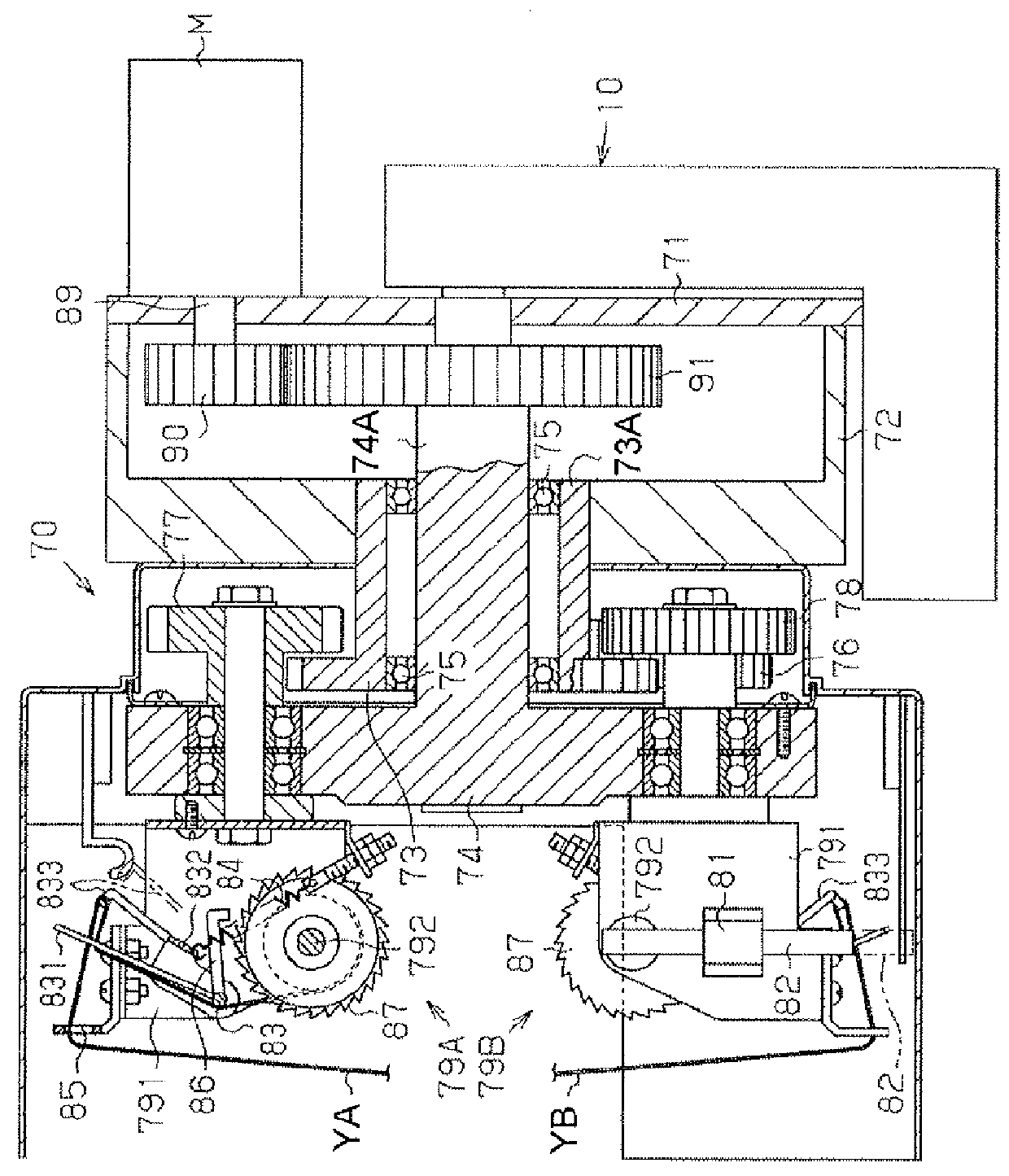

Fluid jet type weaving machine

InactiveCN101768821APrevent rotationEasy to adjustLoomsSelvedge shedding mechanismDrive shaftTooth number

The present invention provides a fluid jet type weaving machine having a planet selvedge apparatus and a catching side-warp opening device corresponding to high-speed running. The fluid jet type weaving machine having a planet selvedge apparatus and a catching side-warp opening device that are supported on one side reverse to picking of the weaving machine is provided with a driving shaft having a half speed ratio of a main shaft, a rotating shaft is driven by the driving shaft to rotate through a rotating transfer mechanism, and a swinging rod is driven by the driving shaft to swing through a sport changeover mechanism. The rotating transfer mechanism comprises a first toothed rotary part that is moveable in the direction of axial cord and is fixed on the driving shaft, and a second toothed rotary part having an identical number of teeth with the first toothed rotary part and being fixed on the rotating axle, and the rotating transfer mechanism is arranged to form that the connectionphase of the rotating shaft with the driving shaft is changeable. The sport changeover mechanism comprises a rotary part for making the swinging rod swing, the rotary part is moveable in the direction of the axial cord, is independent with the first toothed rotary part, is fixed on the driving shaft and is arranged to form that the connection phase of the rotating shaft with the driving shaft is changeable.

Owner:TSUDAKOMA KOGYO KK

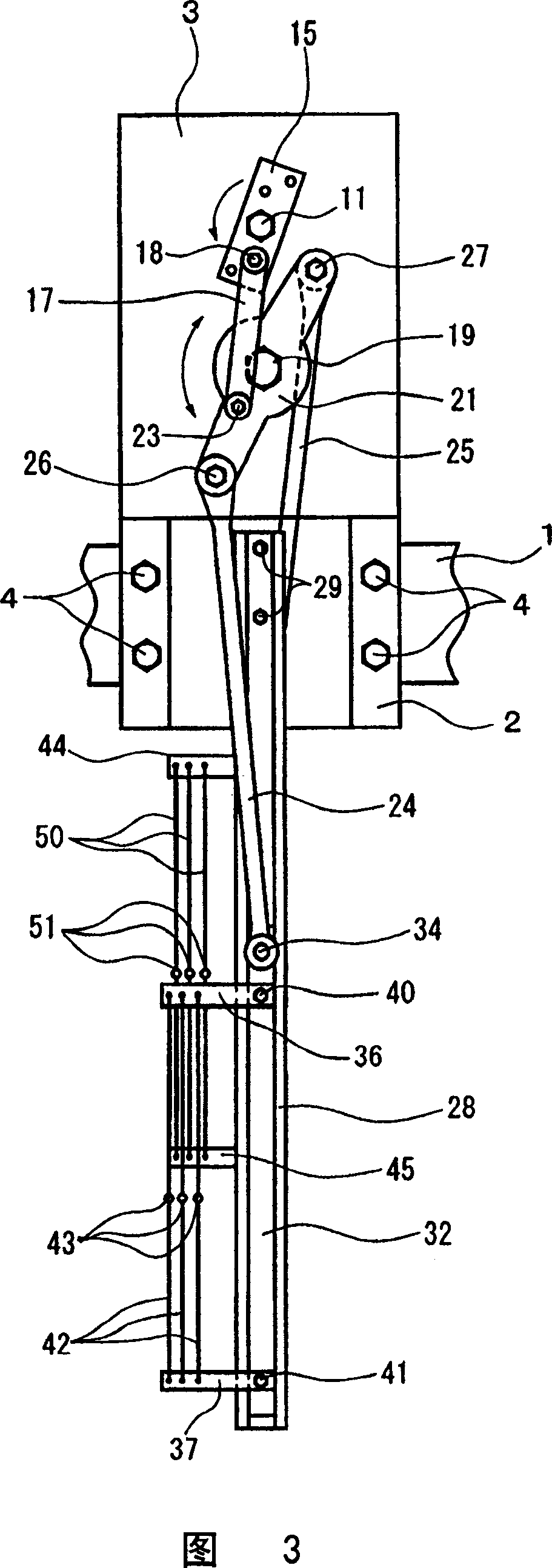

Shedding apparatus for waste selvage in a loom

A shedding apparatus for waste selvage includes a pair of first swing levers and a pair of second swing levers for forming an open shed of selvage yarns. The drive force to the swing levers is transmitted by cranking through a drive shaft which is coaxial with the sun gear of a planetary gear mechanism. The crank mechanism using the cranking includes a crank, first end of which is fixedly connected to the drive shaft for rotation therewith, a drive lever for transmitting a rotational force to the swing levers, and a connecting rod connected between second end of the crank and the drive lever. A ratio between an eccentric distance of the crank and a length of the drive lever is less than 1.

Owner:TOYOTA IND CORP

Thrum yarn shuttle mouth forming device in loom

A selvage yarn shedding device in a loom comprising a heald holding at least two selvedge yarns on one side of a set of warp yarns. Driving force transmitted from a driving motor reciprocates the healds in opposite directions, thereby forming a shed for the selvedge yarn. The heddle is located between a frontmost warp heald frame and a steel frame. The heald may be inclined relative to the frontmost warp heald frame in the front-rear direction of the loom.

Owner:TOYOTA IND CORP

Warp shedding apparatus of loom

A warp shedding apparatus of a loom includes a plurality healds arranged in a weaving width direction of the loom. Each heald has a thread eyelet through which a ground warp yarn is passed and held. The healds are raised and lowered to form a shed. A difference in tension between raised ground warp yarns and lowered ground warp yarns held by the healds located in opposite end portions in the weaving width direction is greater than a difference in tension between raised ground warp yarns and lowered ground warp yarns held by the healds located in a central portion in the weaving width direction.

Owner:TOYOTA IND CORP

Angular servo-motor for the controlled positioning of elements connected to weft or warp yarns in a weaving machine

InactiveCN1953304AEasy to controlEasy to detectLoomsDynamo-electric machinesPower flowReciprocating motion

An angular servo-motor for the controlled positioning of elements connected to weft or warp yarns, in a weaving machine, essentially comprising a position control angular motor, with direct current sent to a 'brushless' rotor (1), the latter connected to a sequence of elements consisting of cables (5) and small heddle-carrier looms (10, 11); the servo-motor in question is capable of conferring an alternating motion to the aforesaid small heddle-carrier looms (10, 11), such to obtain the desired weaves between the weft and warp yarns.

Owner:SMIT S P A UNIPERSONALE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com