Selvage forming device of coeaving machine

A technology for selvedge and loom, applied in loom, selvage opening mechanism, textile and other directions, can solve the problems of difficult high-speed operation of motor and increased motor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

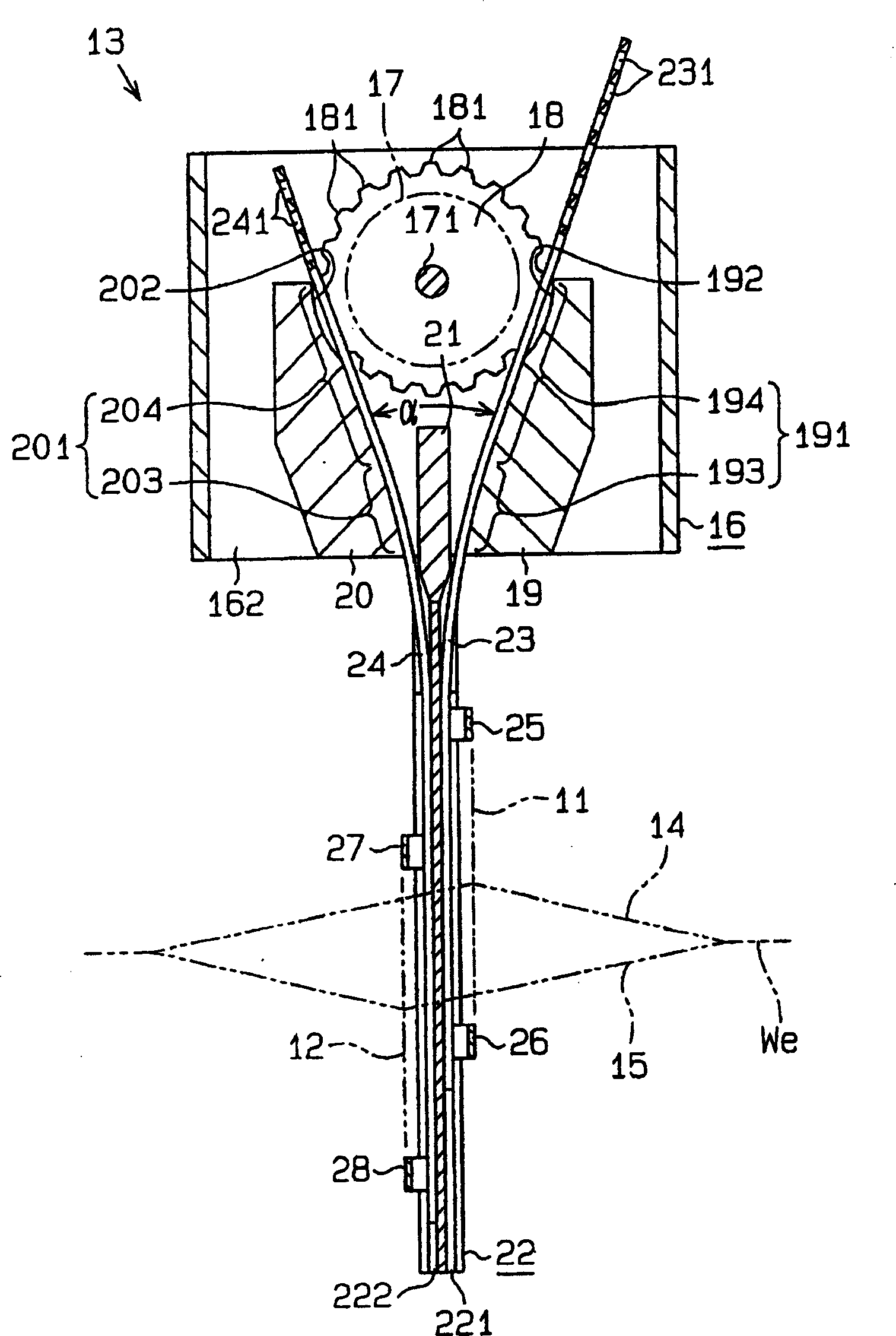

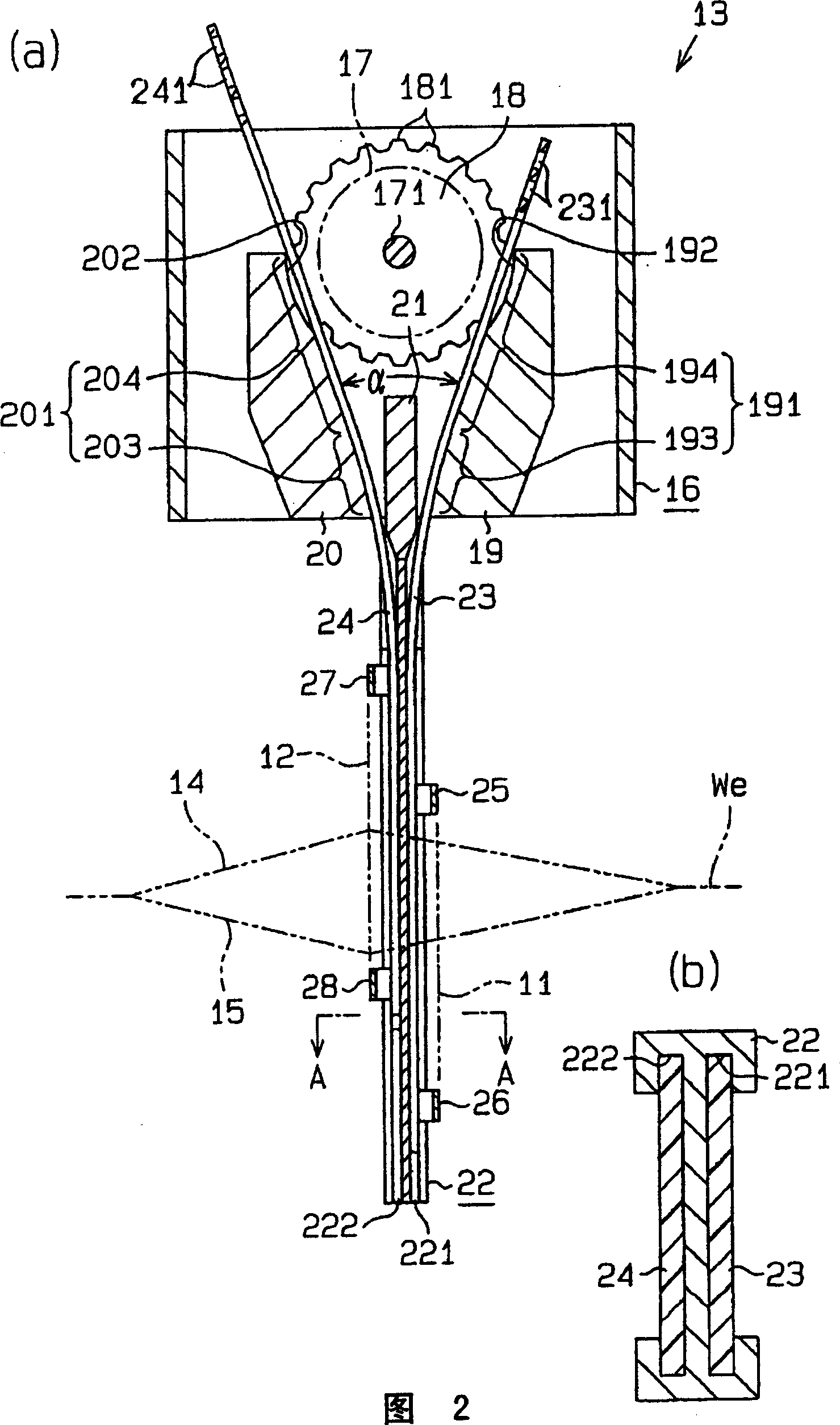

[0016] According to the first embodiment of the present invention, the device for forming the selvedge opening will refer to Figure 1-4 Describe.

[0017] Such as figure 1 As shown in and 2, the first selvedge heddle 11 and the second selvedge heddle 12 move vertically in opposite directions by the reciprocating drive mechanism 13. The movement paths for the first selvedge heddle 11 and the second selvedge heddle 12 are reciprocating paths extending vertically parallel to each other. The selvedge yarn 14 passing through the first selvedge heddle 11 and the selvedge yarn 15 passing through the second selvedge heddle 12 together with the weft introduced therethrough form a selvedge We.

[0018] Such as image 3 with 4 As shown, the motor 17 is connected to the inner wall 161 of the box 16 constituting the reciprocating drive mechanism 13. The upper and lower parts of the box 16 are open. The output shaft 171 of the motor 17 extends through the inner wall 161 and into the box 16. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com