Device using for opening selvedge line of loom

A kind of edge and loom technology, applied in the direction of selvage opening mechanism, textile, textile and papermaking, etc., can solve the problems of easy damage of bearings and shortening the life of opening device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

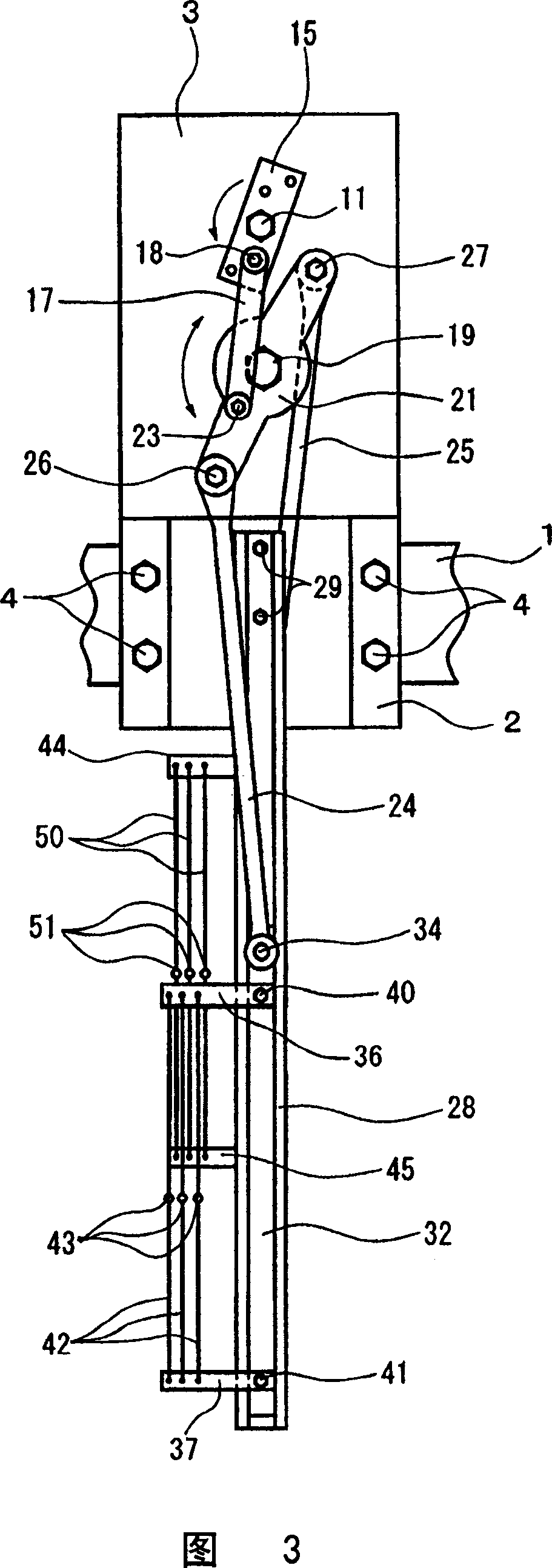

[0015] A first preferred embodiment of the present invention will be described below with reference to FIGS. 1A-3. The device for open selvedge thread of the first embodiment is provided at the end of the heald frame for open warp yarns (not shown) and with respect to the headstock forming the selvedge structure W at the end of the woven fabric (refer to FIG. 2 ) The frame is provided on the front side of the loom. A flat mounting plate 3 and a U-shaped mounting plate 2 are stacked on the rear surface of the upper beam 1 which forms a part of the loom frame in the stated order and is fixed by bolts 4 in a vertically upright state. An L-shaped mounting bracket 5 is fixed on the front surface of the mounting plate 3 by bolts 6 (or the surface of the mounting plate 3 faces the right side of FIG. 2 ).

[0016] A servo motor 7 serving as a drive motor is fixed to the mounting bracket 5 with bolts 8 . A motor shaft 9 protruding from the servo motor 7 toward the mounting plate 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com