Electromagnetic iron-removing method and device

A technology of electromagnetic iron removal and electromagnetic coil, which is applied in the field of magnetic separation, can solve the problems of equipment price increase, investment cost increase, and influence on the effect of removing ferromagnetic materials, etc., and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

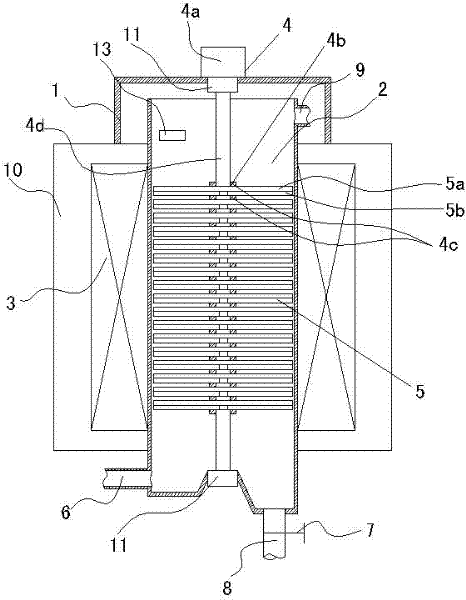

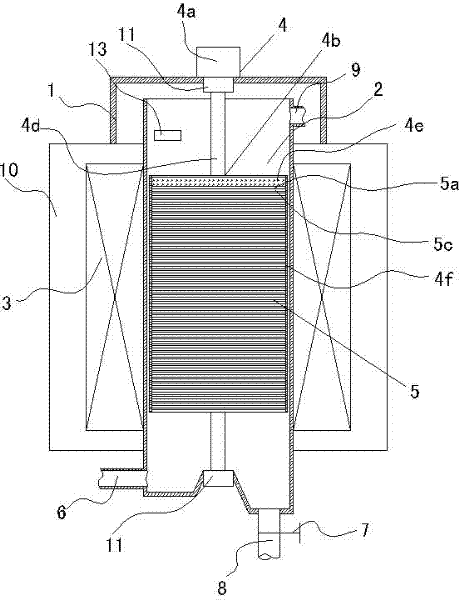

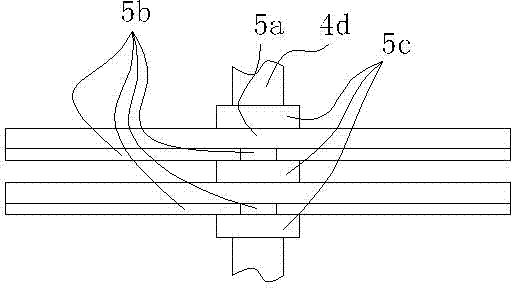

[0015] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0016] As shown in the figure, the electromagnetic iron removal method of the present invention is realized in this way. A soft magnetic medium component with rotating power is arranged in the cylindrical channel surrounding the electromagnetic coil on the four sides. The soft magnetic medium component includes Layers of mesh-shaped soft magnets or soft magnetic steel hair balls that are stacked and separated from each other, when removing ferromagnetic substances in the fluid, energize the electromagnetic coil to make the magnetic field lines pass through the channel along the axis of the cylindrical channel, so that The soft magnetic medium component generates a high-gradient induced magnetic field, and then the fluid is introduced into the cylindrical channel, so that the fluid passes through several layers of reticular soft magnets or soft magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com