Method and device for determining the rotary position of a rotating element

A technology of rotating elements and rotating positions, which is applied to electrical elements, special recording/indicating devices, and transmission of sensing components using electromagnetic/magnetic devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

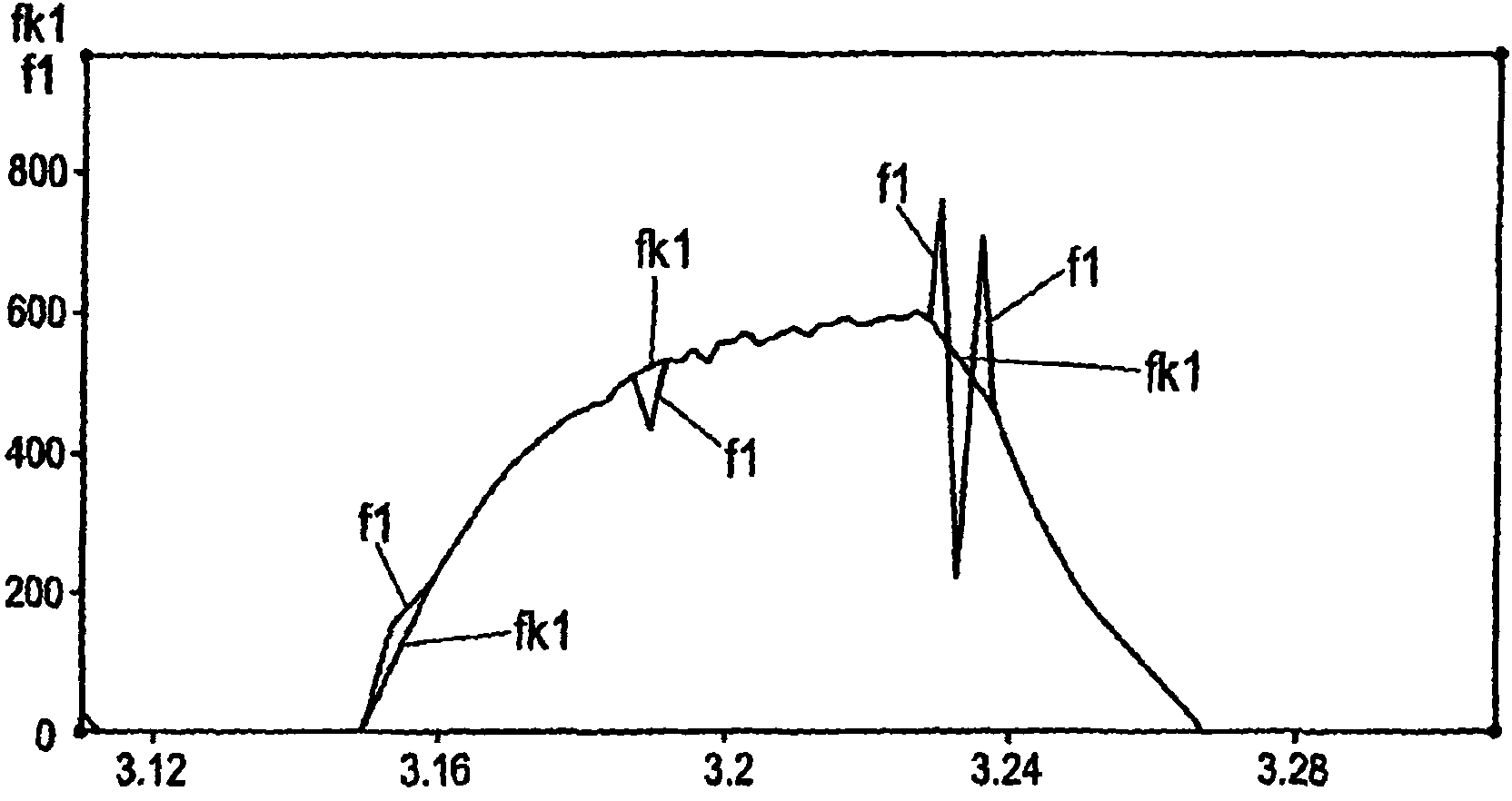

[0040] figure 1 An example of an erroneous frequency waveform f1 as a result of sensorless measurements and an exemplary corrected frequency waveform fk1 are shown. Here, the associated signal amplitudes are plotted over time.

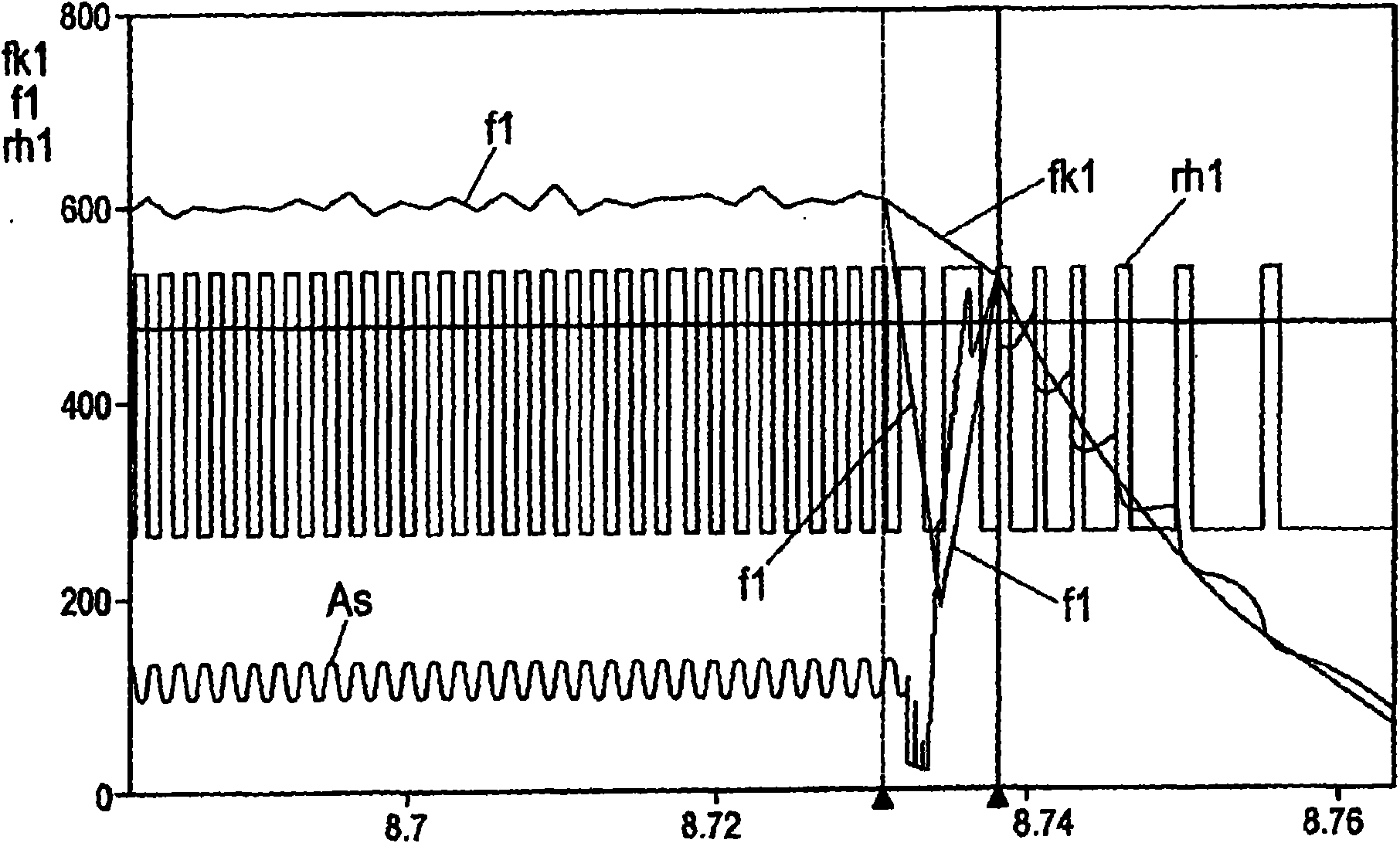

[0041] figure 2 An example of an output signal rh1 of a ripple counting filter for detecting current ripples in the armature current As is shown. In this case, the corresponding frequency signal or frequency waveform f1 is shown in addition to the armature current As, and the corrected frequency signal or corrected frequency waveform fk1 is shown in the region of the error. Here again, in this case, the amplitudes of the individual signals over time are shown.

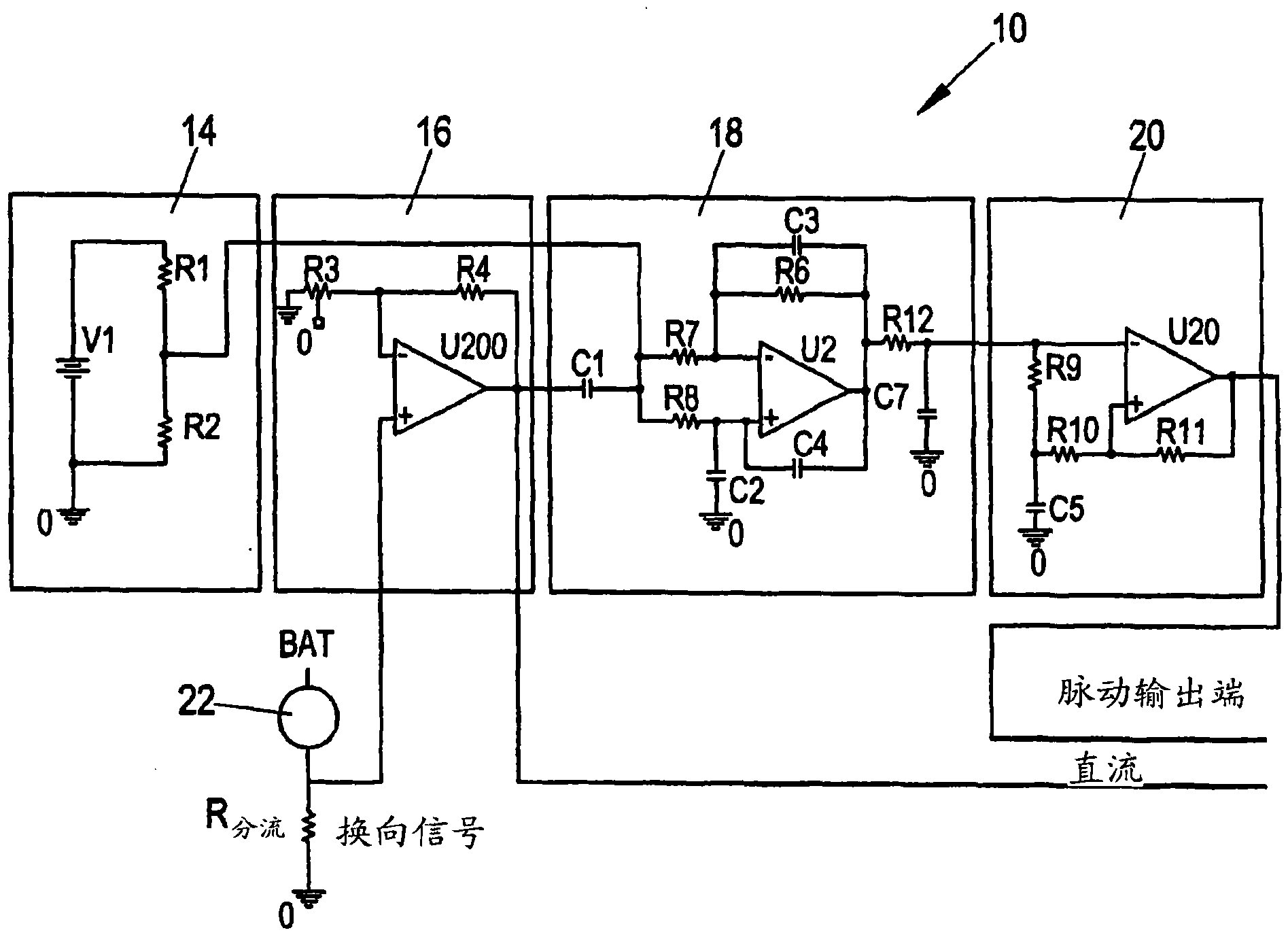

[0042] A related device for determining the rotational position of a rotary element assigned to or driven by an electric machine, in particular a DC commutated electric machine, includes means for detecting current ripples contained in the armature current of the electric machine. Here, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com