Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Poor processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyolefin fibers and method for the production thereof

InactiveUS6811716B1Poor propertyPoor processabilityOther chemical processesFibre typesFiberPolyolefin

A method for producing hydrophobic polyolefin-containing fibers or filaments, in particular cardable staple fibers, using spin finishes applied after spinning and stretching, that comprise at least one water-insoluble ester of a mono-, di-, tri- or tetrahydric alcohol with a molecular weight not exceeding 500 and a branched or straight chain fatty acid with between 12 and 30 carbon atoms, e.g. a water-insoluble ester of ethylene or propylene glycol, glycerol, neopentyl glycol, trimethylolethane or trimethylolpropane and at least one saturated or unsaturated fatty acid residue having 12-24 carbons atoms, an anionic or nonionic antistatic agent preferably being applied after crimping; fibers produced by the method; and nonwovens produced from such fibers.

Owner:FIBERVISIONS LP

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveUS20100189588A1Efficient use of resourcesEffective utilization of rareWelding/cutting media/materialsSoldering mediaChromium carbideHigh carbon

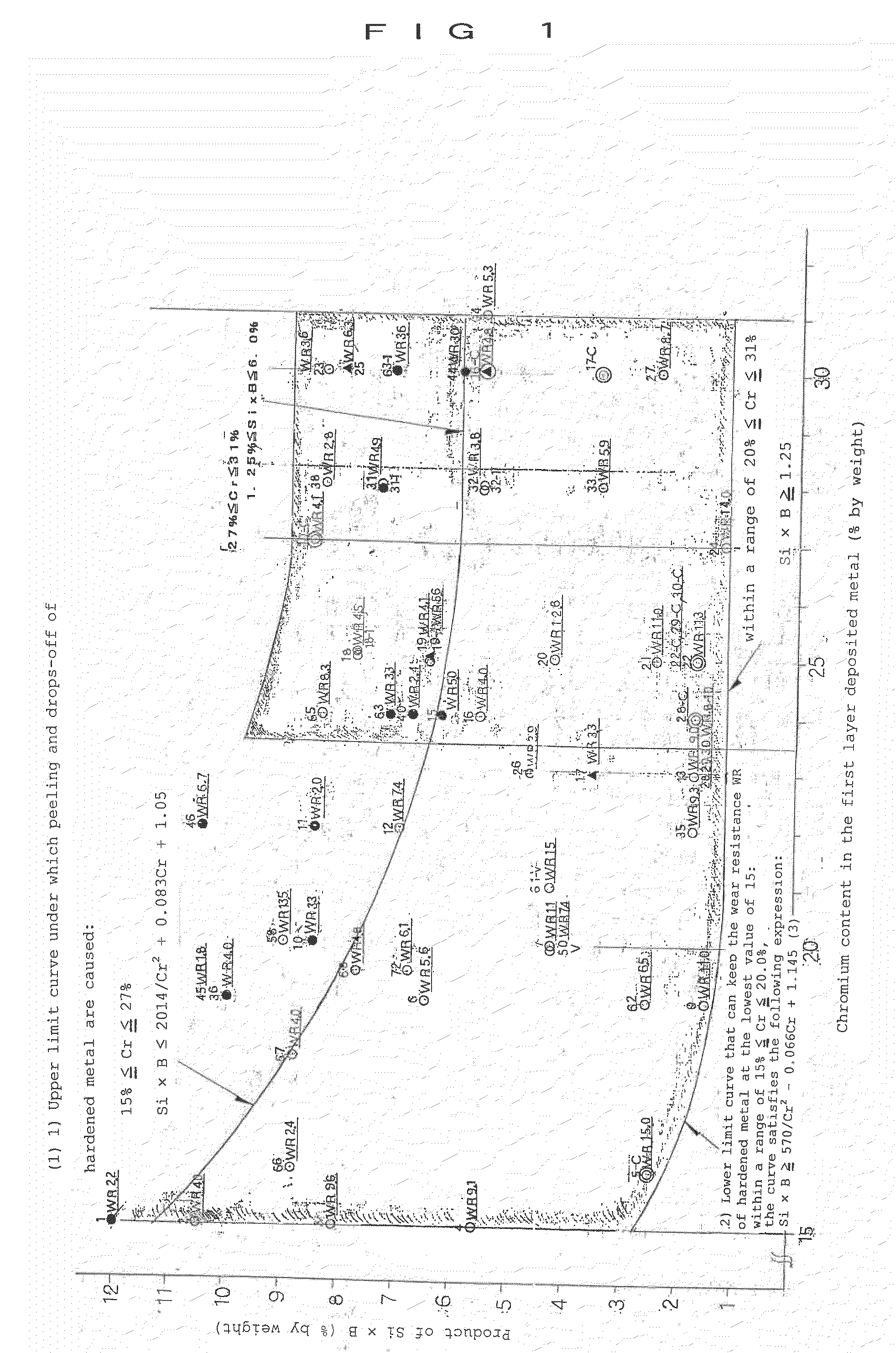

To provide a high-performance, inexpensive low C-high Si-high Cr—B—Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si—containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0≦Nb+V≦8%, and in this structure, within a range of 15% Cr≦Cr<27%, (Si×B)≦2014 / Cr2+0.083Cr+1.05 is satisfied, within a range of 27%≦Cr≦31%, 1.25%≦(Si×B) 6.0% is satisfied, within a range of 15%≦Cr<20%, (Si×B) 570 / Cr2−0.066Cr+1.145 is satisfied, and within a range of 20%≦Cr≦31%, (Si×B)≧1.25 is satisfied.

Owner:ING SHOJI

Method to prepare processable polyimides with reactive endgroups using 1,3-bis (3-aminophenoxy) benzene

InactiveUS6133401AImprove adhesionImprove composite effectSynthetic resin layered productsThin material handlingSolubilityAdhesive

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300 DEG C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NAT AERONAUTICS & SPACE ADMINSTRATION NASA THE

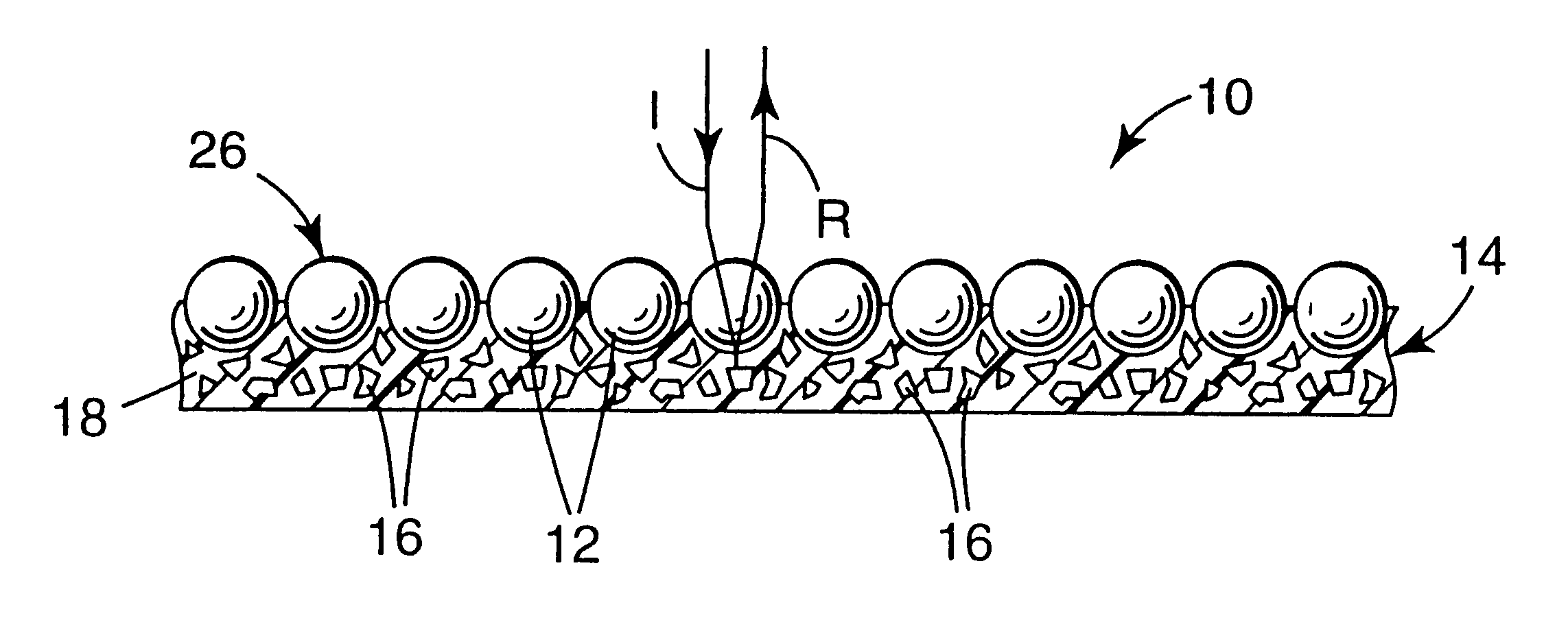

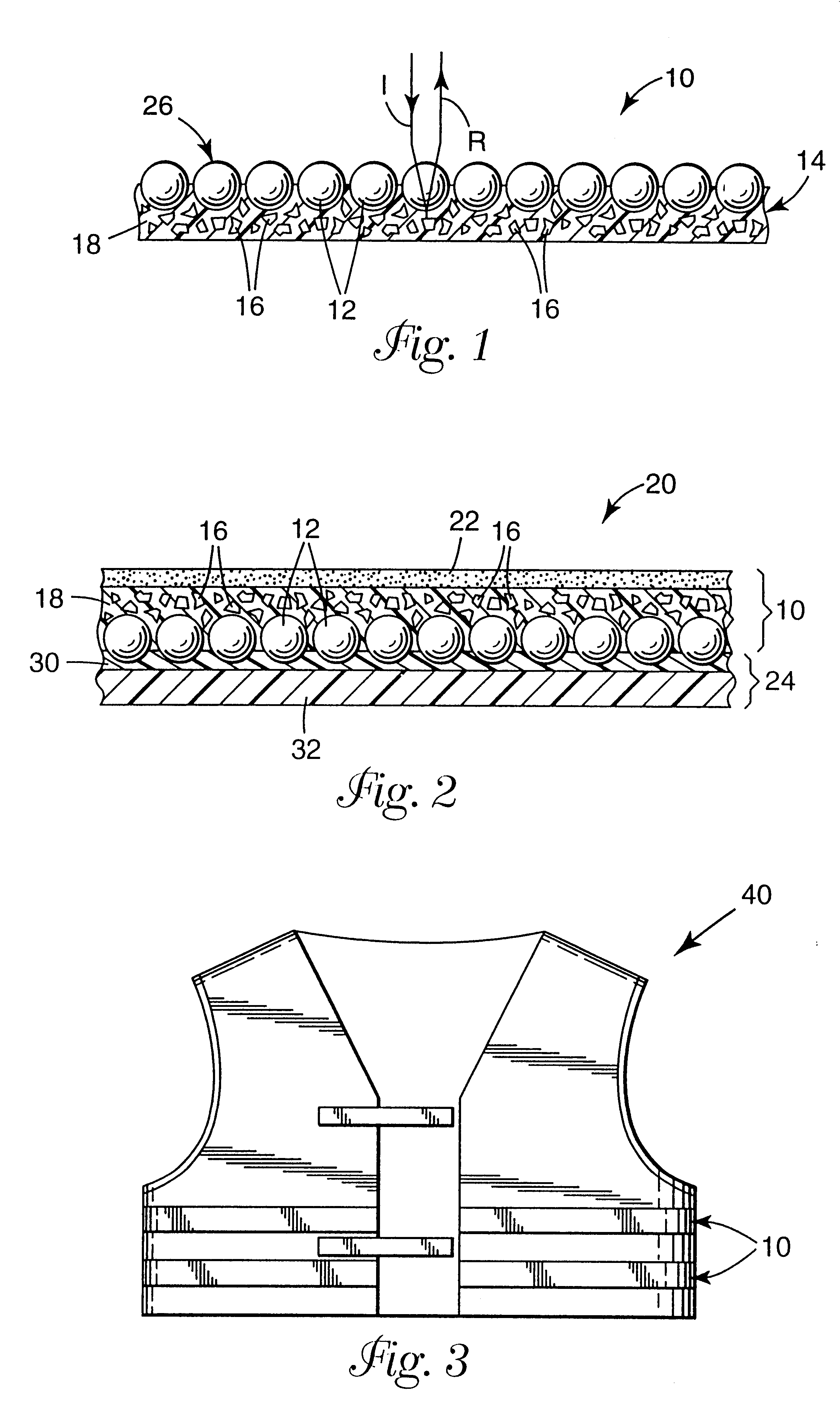

Retroflective article having a colored layer containing reflective flakes and a dye covalently bonded to a polymer

Exposed lens retroreflective article 10 that comprises a colored layer 14 and a layer of optical elements 12 that are partially embedded in the colored layer 14. The colored layer 14 comprises reflective flakes 16 and a dye that is covalently bonded to a polymer 18. The articles can retain their color after multiple industrial wash cycles. The use of a reactive dye, reflective flakes, and / or polymer precursor during the preparation of the colored layer enables a launderably-durable colored retroreflective article to be made without the use of a solvent and without the use of a temporary carrier.

Owner:3M INNOVATIVE PROPERTIES CO

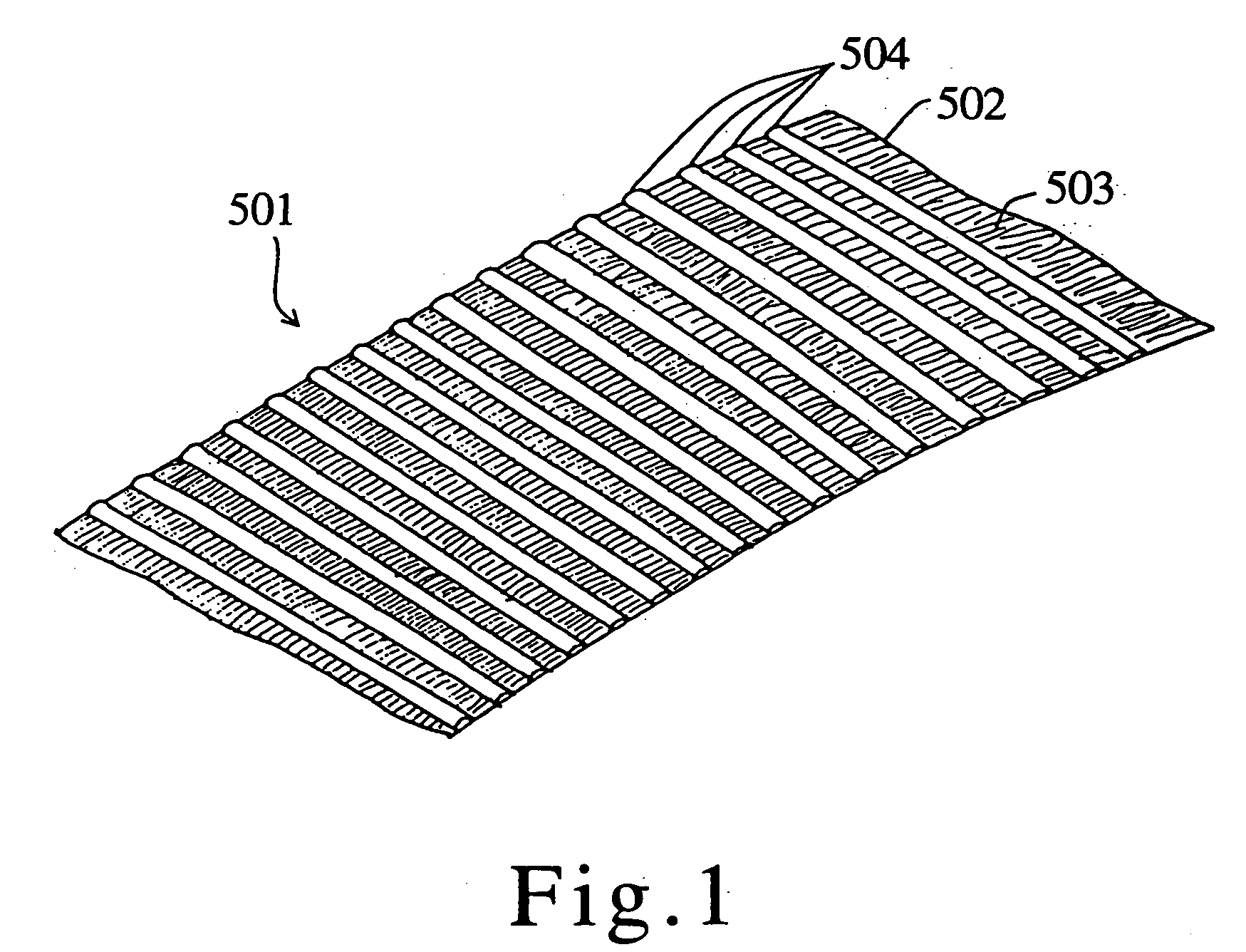

Composite sheet having elasticity, elastic web made from thermoplastic elastomer, and method and apparatus of manufacturing the same

InactiveUS20040166756A1ElasticityAir permeabilitySynthetic resin layered productsWoven fabricsThermoplastic elastomerEngineering

A composite sheet comprises a nonwoven fabric and a rubber elastic material bonded onto the nonwoven fabric. The nonwoven fabric has nonelastic fibers aligned in one direction and has elongation of 100% or higher in a direction perpendicular to the aligned direction of the nonelastic fibers. The rubber elastic material is bonded to the nonwoven fabric in a pattern having orientation perpendicular to the aligned direction of the nonelastic fibers.

Owner:NIPPON PETROCHEMICAL CO LTD +1

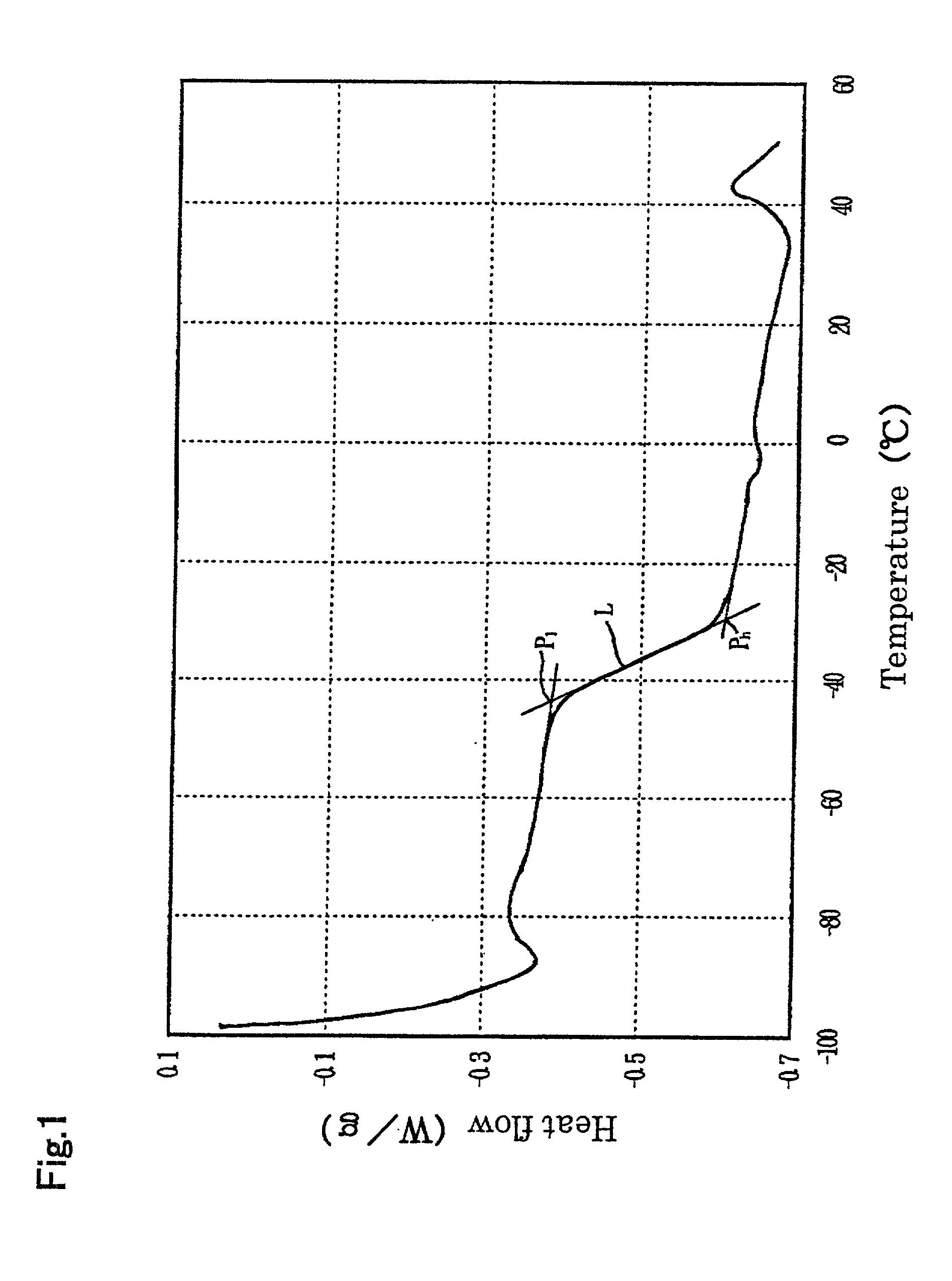

Conjugated diene-based rubber and method of producing the same, oil extended rubber and rubber composition containing the same

InactiveUS6562929B2Low elastic modulusIncreased tan.deltaGroup 4/14 element organic compoundsSpecial tyresPolymer scienceRolling resistance

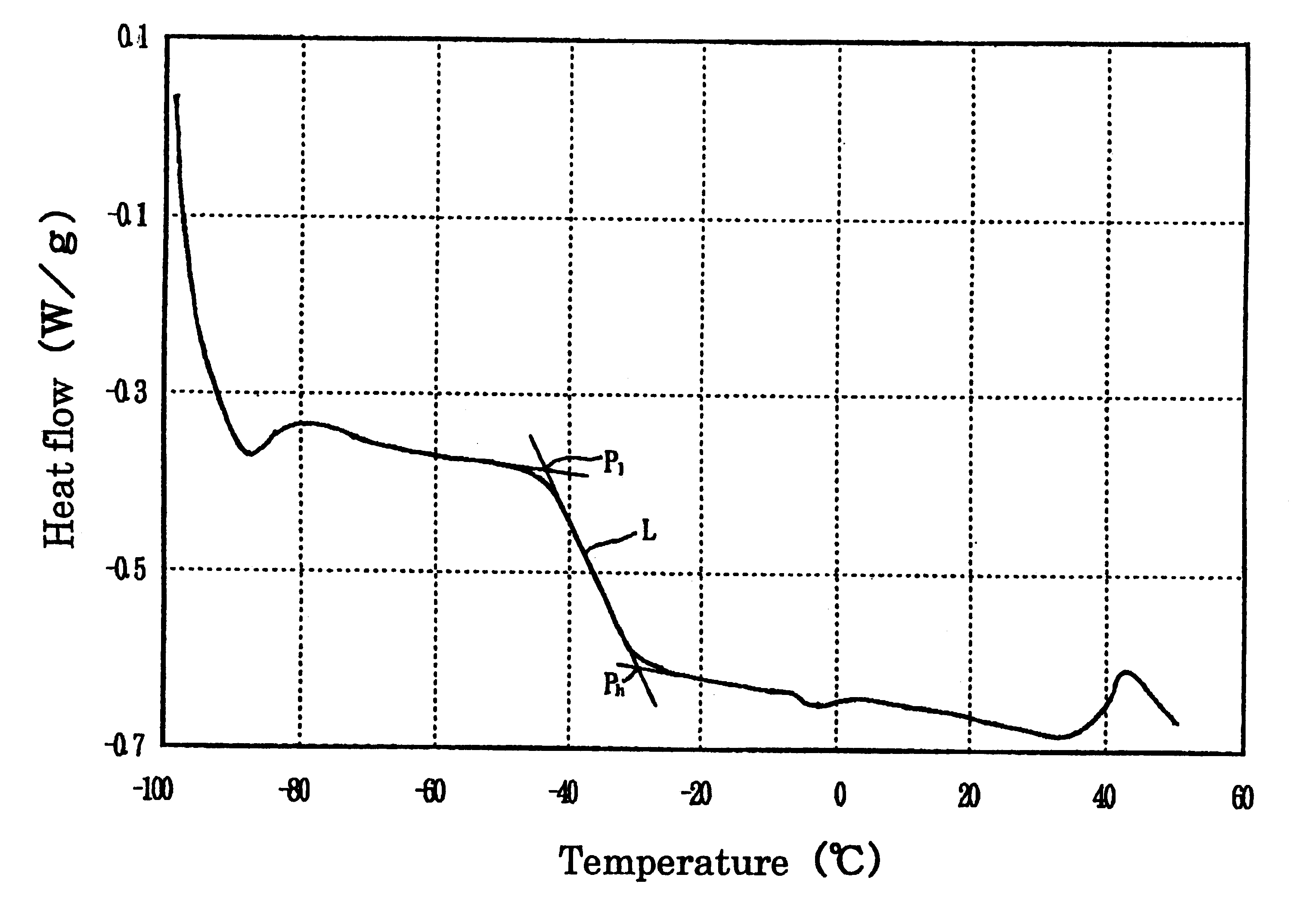

An objective of the invention is to provide a conjugated diene-based rubber having a specific composition and a method of producing the same, an oil extended rubber using the same, as well as a rubber composition capable of being converted into a vulcanized rubber which has a low rolling resistance, an excellent wearing resistance and the like, and is useful, for example, as a tire or the like. A conjugated diene-based rubber in the invention has a glass transition point of -60 to 0° C., an olefinically unsaturated nitrile monomer unit randomly contains in its molecular chain, its repeating units consists of 9 to 30% by mass of an olefinically unsaturated nitrile monomer unit such as acrylonitrile, 10 to 50% by mass of an aromatic vinyl monomer unit such as styrene and 20 to 81% by mass of a conjugated diene monomer unit such as 1,3-butadiene, and its Mooney viscosity [ML1+4(100° C.)] is 20 to 200. An oil extended rubber in the invention comprises 100 parts by mass of the conjugated diene-based rubber and 10 to 60 parts by mass of an extending oil. A rubber composition in the invention comprises a rubber component containing a conjugated diene-based rubber, and an inorganic filler such as a silica and / or a carbon black.

Owner:JSR CORPORATIOON

Conjugated diene-based rubber, oil extended rubber and rubber composition containing the same

InactiveUS20020045691A1Low elastic modulusIncreased tan .deltaGroup 4/14 element organic compoundsSpecial tyresRolling resistancePolymer science

An objective of the invention is to provide a conjugated diene-based rubber having a specific composition and an oil extended rubber using the same, as well as a rubber composition capable of being converted into a vulcanized rubber which has a low rolling resistance, an excellent wearing resistance and the like, and is useful for a tire or the like. A conjugated diene-based rubber in the invention has repeating units consisting of 1 to 30% by mass of an olefinically unsaturated nitrile monomer unit such as acrylonitrile, 10 to 50% by mass of an aromatic vinyl monomer unit such as styrene, 19.9 to 88.9% by mass of a conjugated diene monomer unit such as 1,3-butadiene and 0.1 to 10% by mass of a monomer unit having one polymerizable unsaturated group and at least one functional group selected from the group consisting of an amino group, a hydroxyl group, an epoxy group, a carboxyl group and an alkoxysilyl group, and has a specific glass transition point and a Mooney viscosity [ML1+4(100° C.)]. An oil extended rubber in the invention comprises 100 parts by mass of a conjugated diene-based rubber and 10 to 60 parts by mass of an extending oil. A rubber composition in the invention comprises a conjugated diene-based rubber or an oil extended rubber and an inorganic filler such as a silica.

Owner:JSR CORPORATIOON

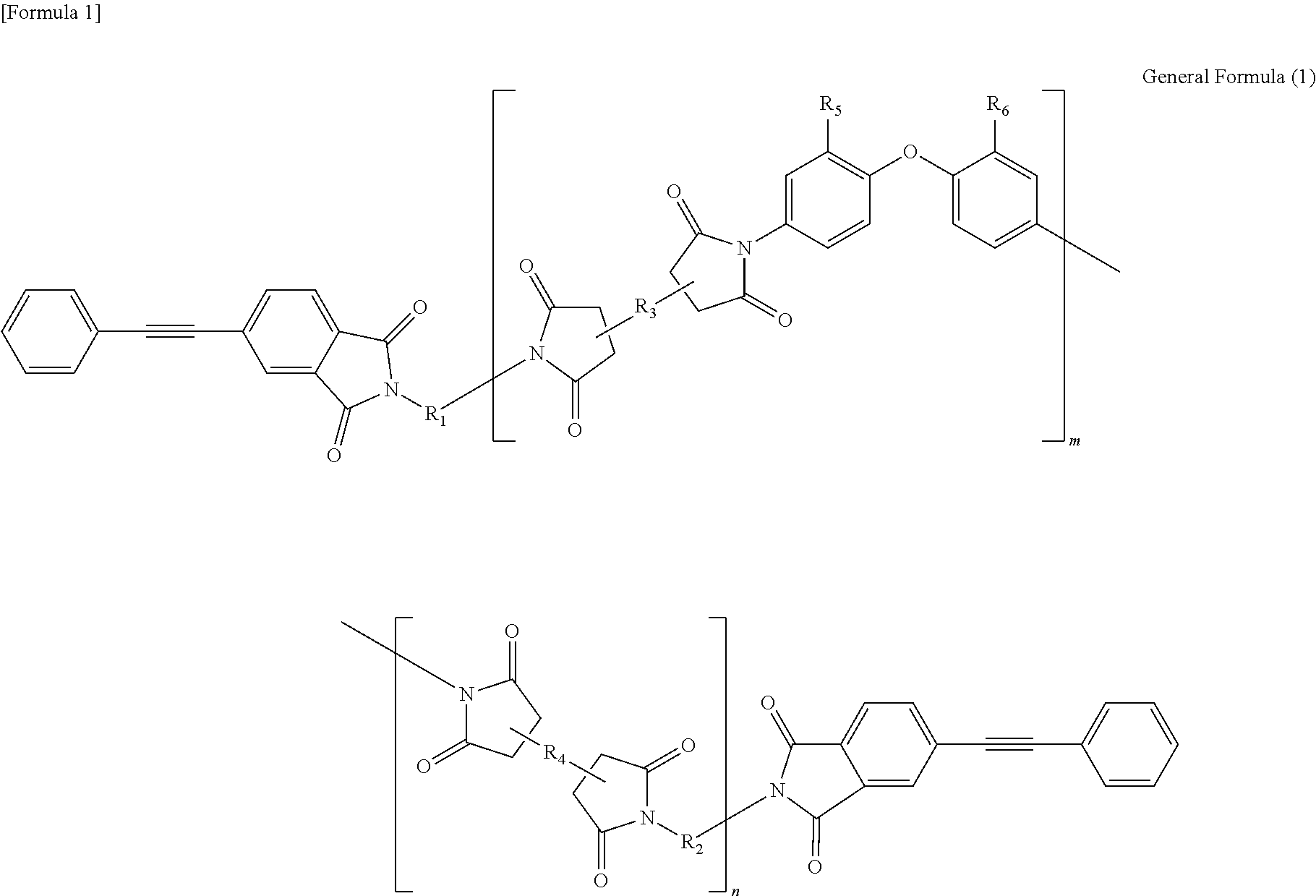

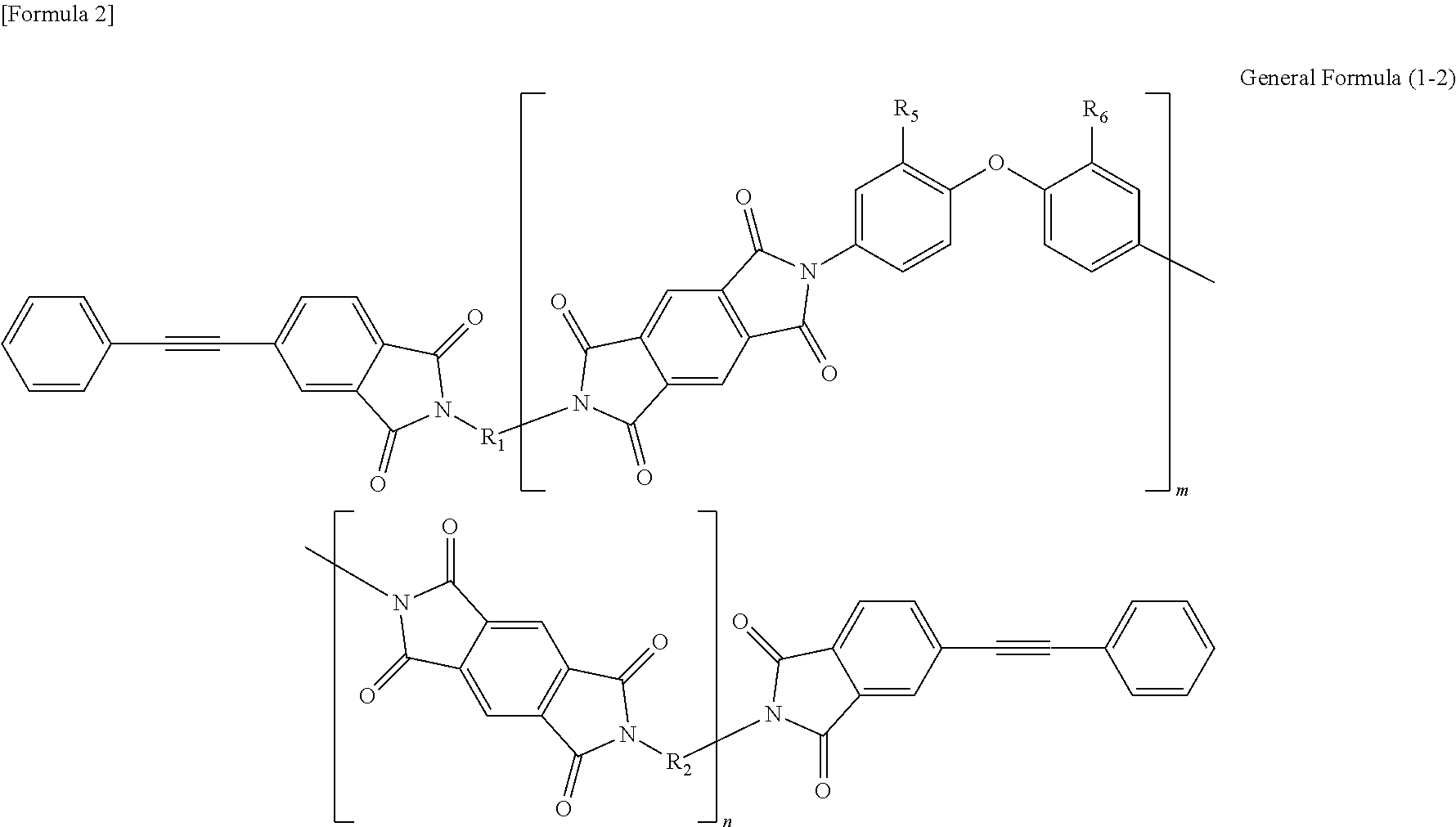

Soluble terminally modified imide oligomer using 2-phenyl-4, 4'-diaminodiphenyl ether, varnish, cured product thereof, imide prepreg thereof, and fiber-reinforced laminate having excellent heat resistance

ActiveUS20110165809A1Low elongation at breakImprove solubilityOrganic chemistryAdhesive processes with surface pretreatmentFiberSolubility

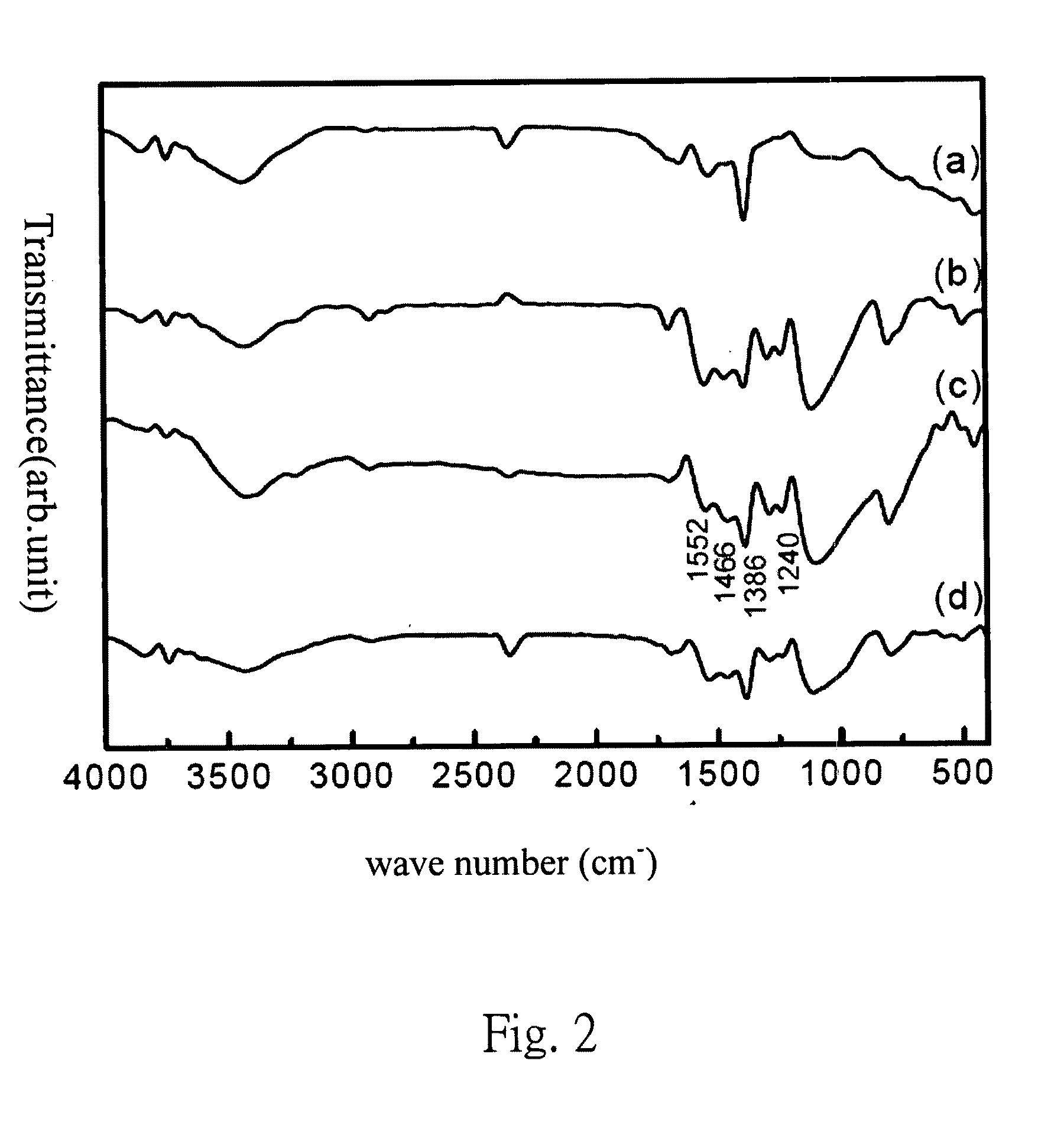

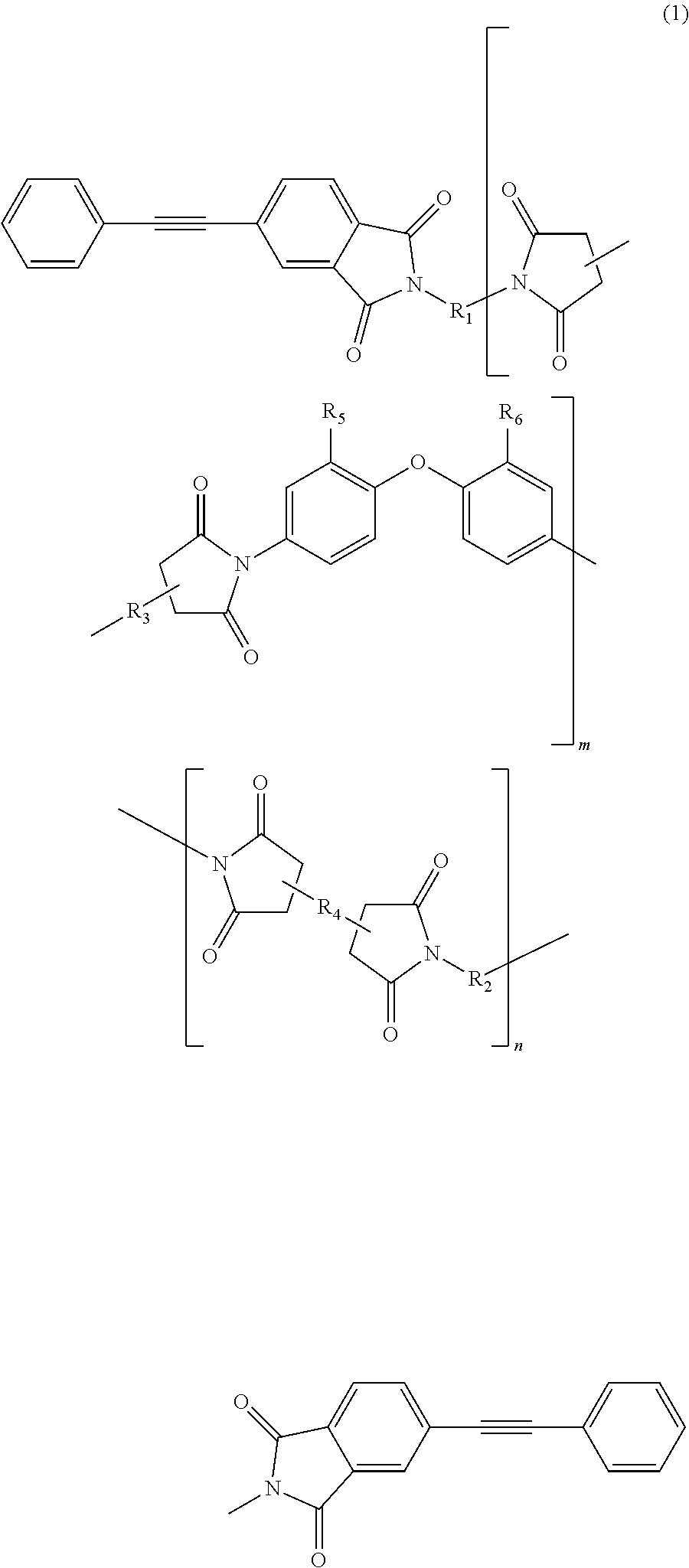

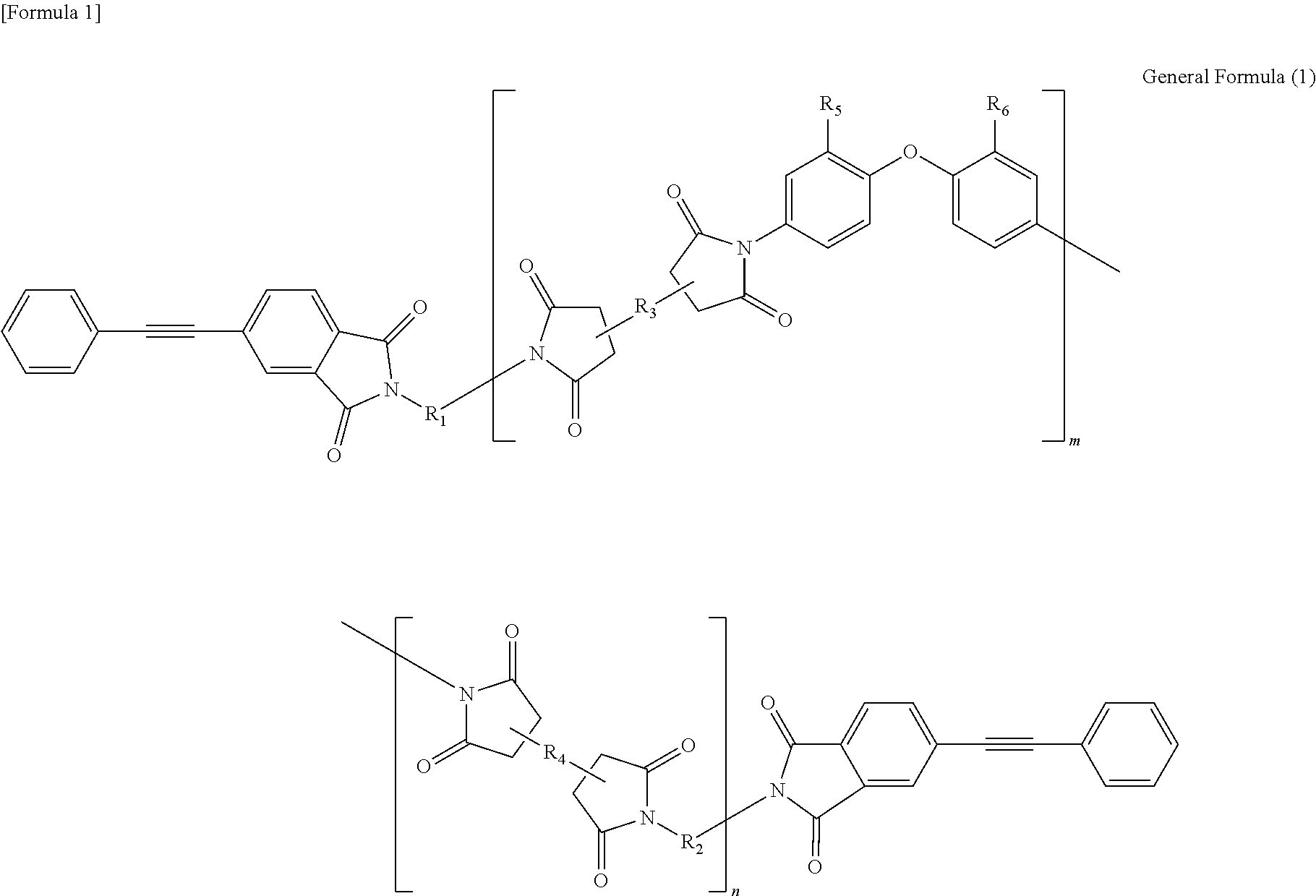

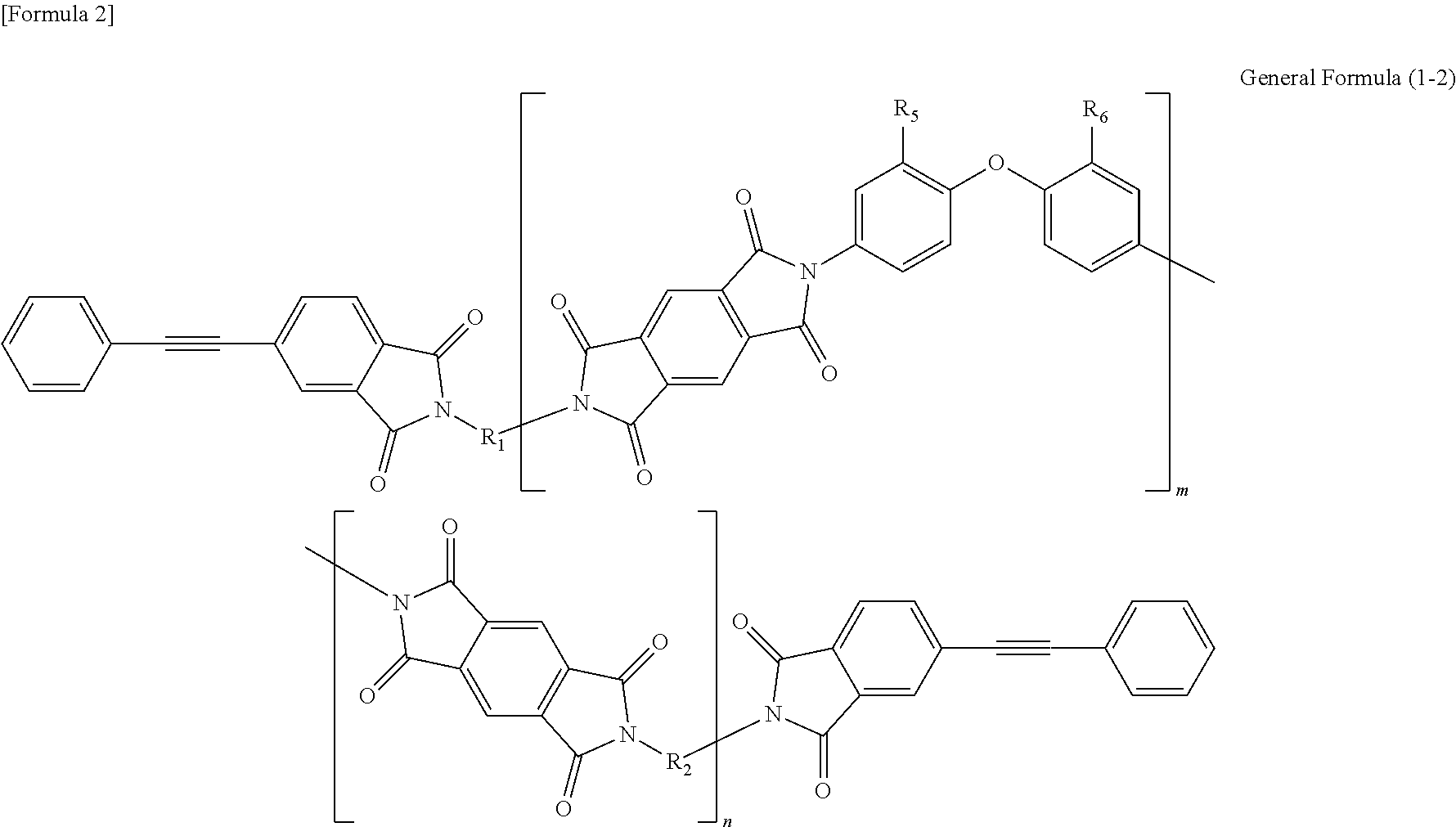

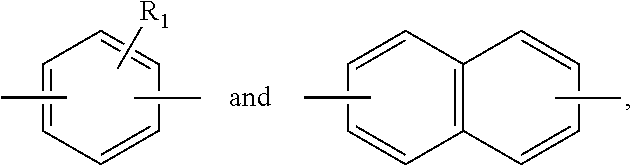

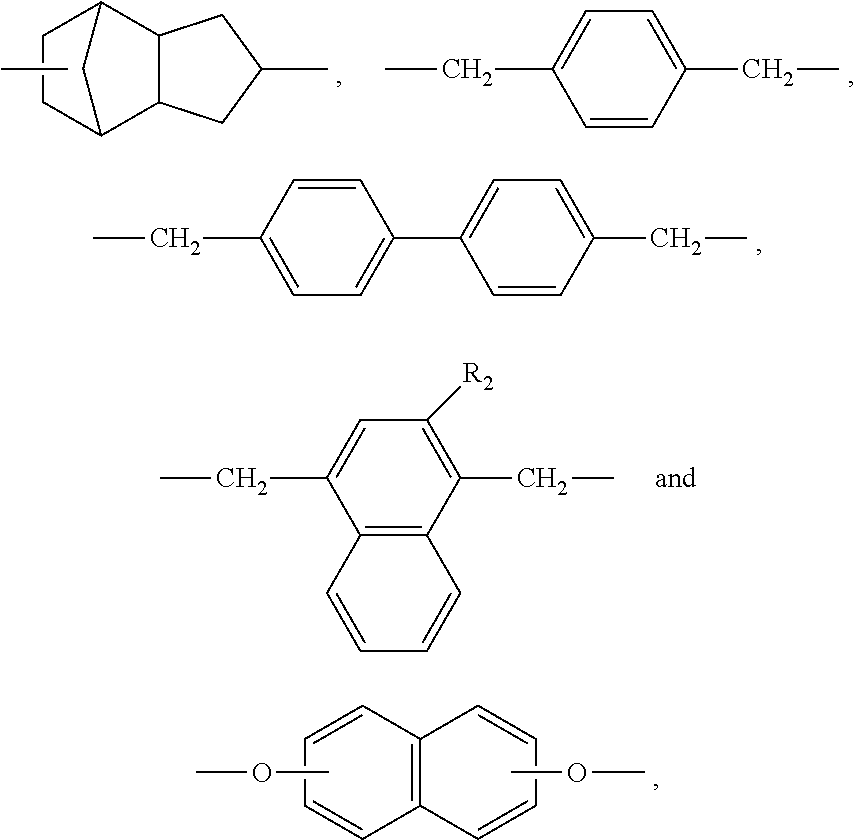

A novel terminally modified imide oligomer having excellent solubility in organic solvents, excellent solution storage stability, and excellent molding properties such as low melt viscosity. Also, a varnish obtained by dissolving the terminally modified imide oligomer in an organic solvent; a cure product obtained by using the terminally modified imide oligomer and having excellent thermal and mechanical characteristics such as heat resistance, elastic modulus, tensile strength at break and tensile elongation at break; a prepreg; and a fiber-reinforced laminate. The soluble terminally modified imide oligomer is represented by general formula (1). In the formula, R1 and R2 each represents a divalent aromatic diamine residue; R3 and R4 each represents a tetravalent aromatic tetracarboxylic acid residue; R5 and R6 each represents a hydrogen atom or a phenyl group, with R5 or R6 being a phenyl group; m and n satisfy the following relations: m≧1, n≧0, 1≦m+n≦20 and 0.05≦m / (m+n)≦1; and the repeating units may be arranged in blocks or randomly.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

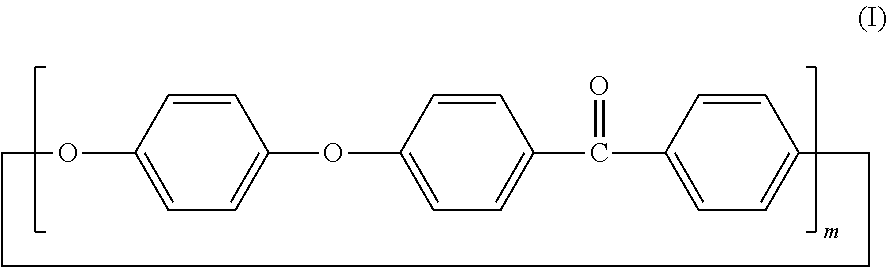

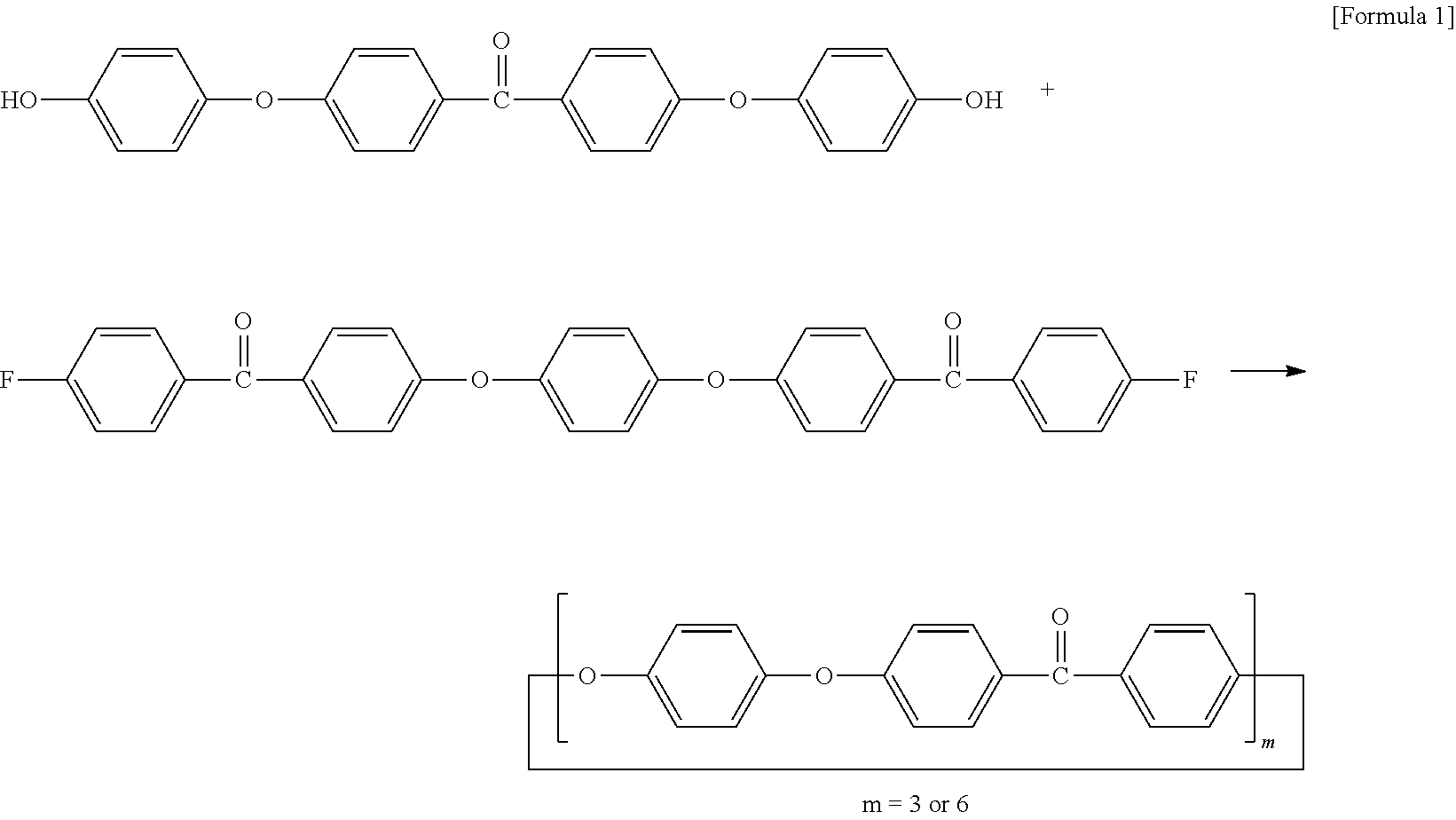

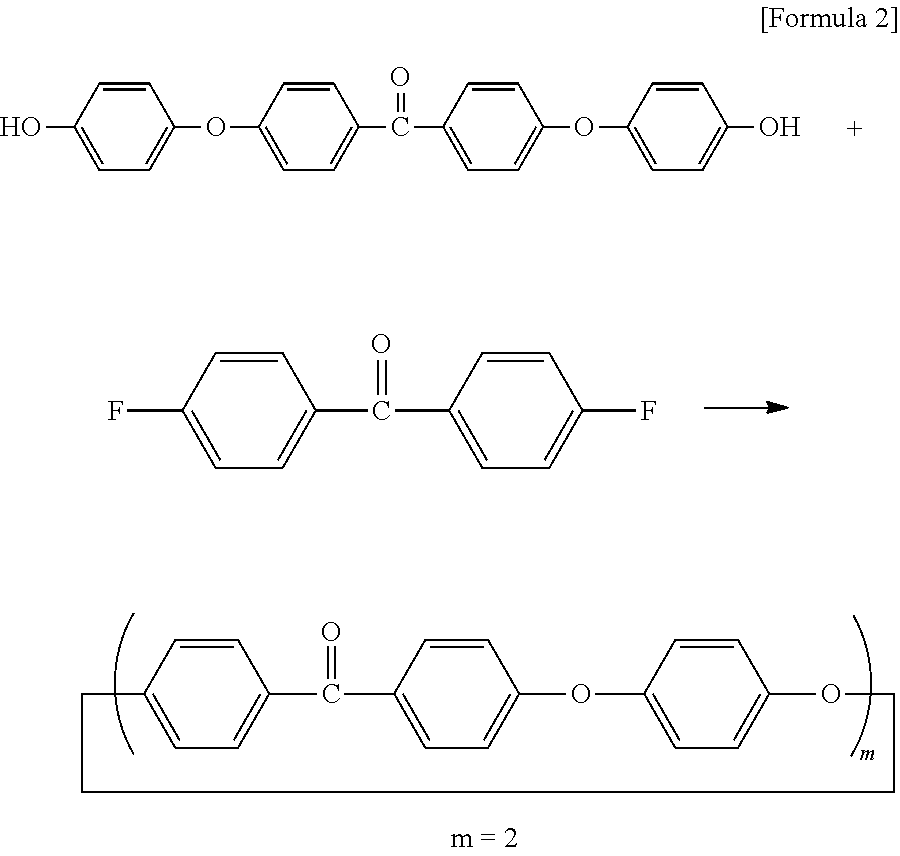

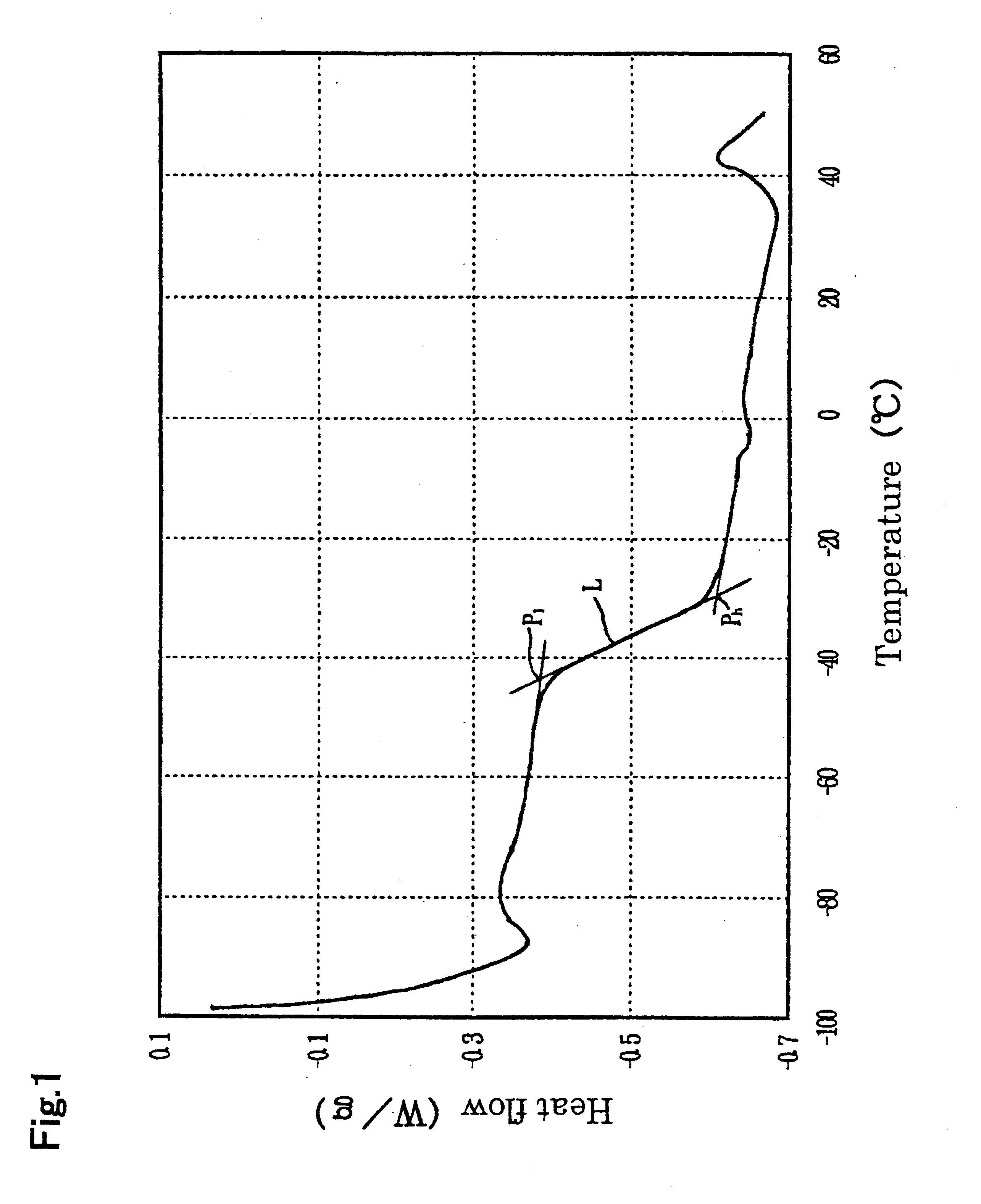

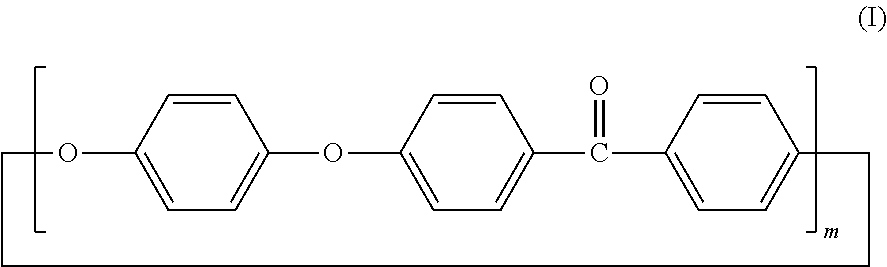

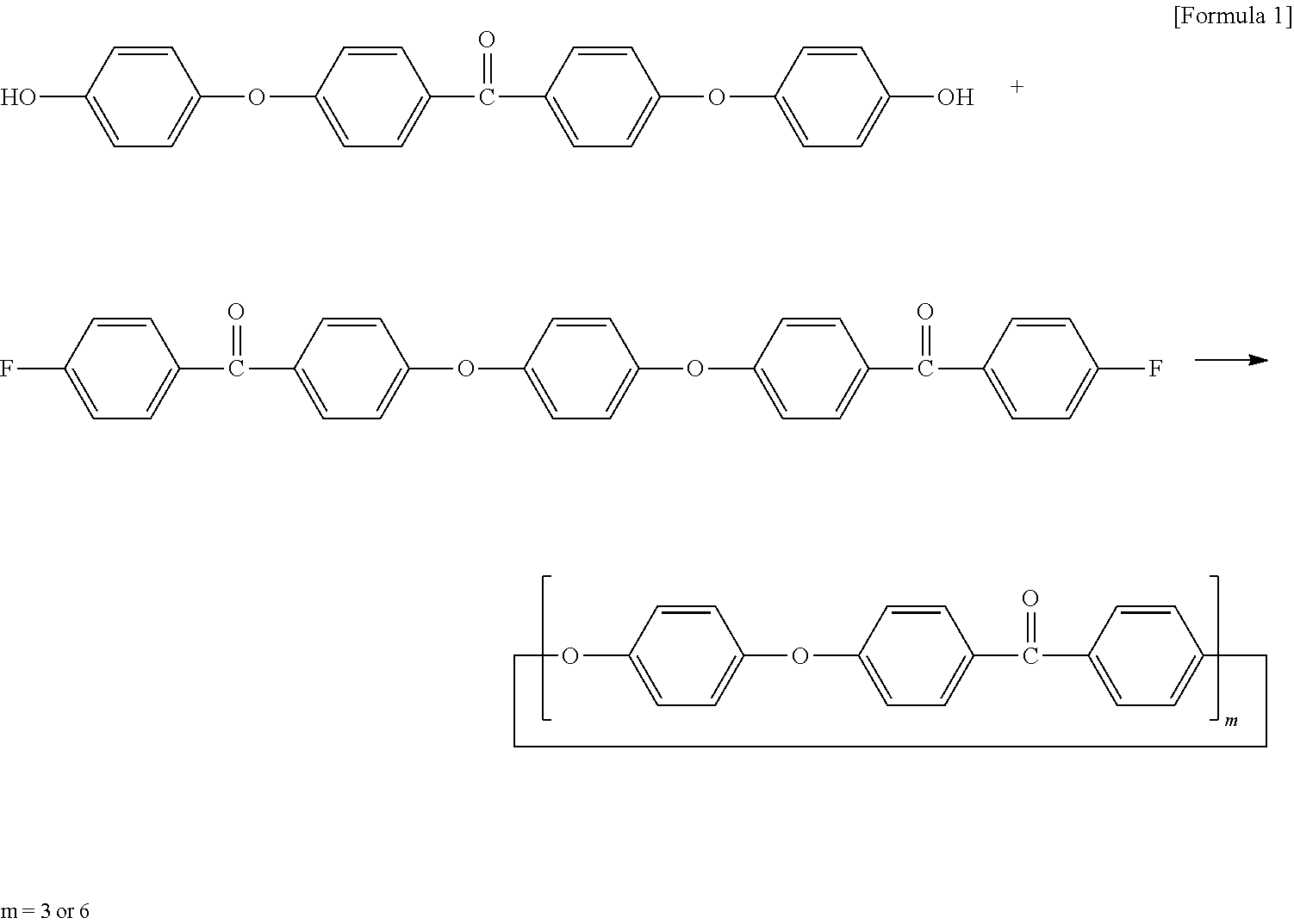

Cyclic polyphenylene ether ether ketone composition and method for producing the same

ActiveUS20120259086A1High melting pointPoor processabilityOrganic chemistryOther chemical processesEtherKetone

A cyclic poly (phenylene ether ether ketone) composition includes not less than 60% by weight of a cyclic poly (phenylene ether ether ketone) represented by the following Formula (I), which is characterized in that the cyclic poly (phenylene ether ether ketone) is a mixture of cyclic poly (phenylene ether ether ketone)s having different repeating numbers (m) and the composition has a melting point of not higher than 270° C.; and a method of producing a poly (phenylene ether ether ketone) characterized by heat-polymerizing the cyclic poly (phenylene ether ether ketone) composition:where m represents an integer of 2 to 40.

Owner:TORAY IND INC

Use of vegetative material as a filler in composite materials

InactiveUS20050165137A1Poor processabilityKeep for a long timeWood treatment detailsHuskMaterials science

The present invention provides a filler for use in composite materials wherein said filler comprises a vegetative-based material and wherein said vegetative-based material can be fresh or carbonised. In one particularly preferred embodiment the present invention utilises carbonised rice husk. In a further aspect of the present invention there is provided a process for the production of a carbonised vegetative-based filler wherein said process comprises burning a fresh vegetative-based material at about 800° C. for about 4 seconds.

Owner:CONTRACT RES & DEV M +1

Conjugated diene-based rubber, oil extended rubber and rubber composition containing the same

InactiveUS6703470B2Low elastic modulusIncreased tan .deltaGroup 4/14 element organic compoundsSpecial tyresRolling resistancePolymer science

An objective of the invention is to provide a conjugated diene-based rubber having a specific composition and an oil extended rubber using the same, as well as a rubber composition capable of being converted into a vulcanized rubber which has a low rolling resistance, an excellent wearing resistance and the like, and is useful for a tire or the like. A conjugated diene-based rubber in the invention has repeating units consisting of 1 to 30% by mass of an olefinically unsaturated nitrile monomer unit such as acrylonitrile, 10 to 50% by mass of an aromatic vinyl monomer unit such as styrene, 19.9 to 88.9% by mass of a conjugated diene monomer unit such as 1,3-butadiene and 0.1 to 10% by mass of a monomer unit having one polymerizable unsaturated group and at least one functional group selected from the group consisting of an amino group, a hydroxyl group, an epoxy group, a carboxyl group and an alkoxysilyl group, and has a specific glass transition point and a Mooney viscosity [ML1+4(100° C.)]. An oil extended rubber in the invention comprises 100 parts by mass of a conjugated diene-based rubber and 10 to 60 parts by mass of an extending oil. A rubber composition in the invention comprises a conjugated diene-based rubber or an oil extended rubber and an inorganic filler such as a silica.

Owner:JSR CORPORATIOON

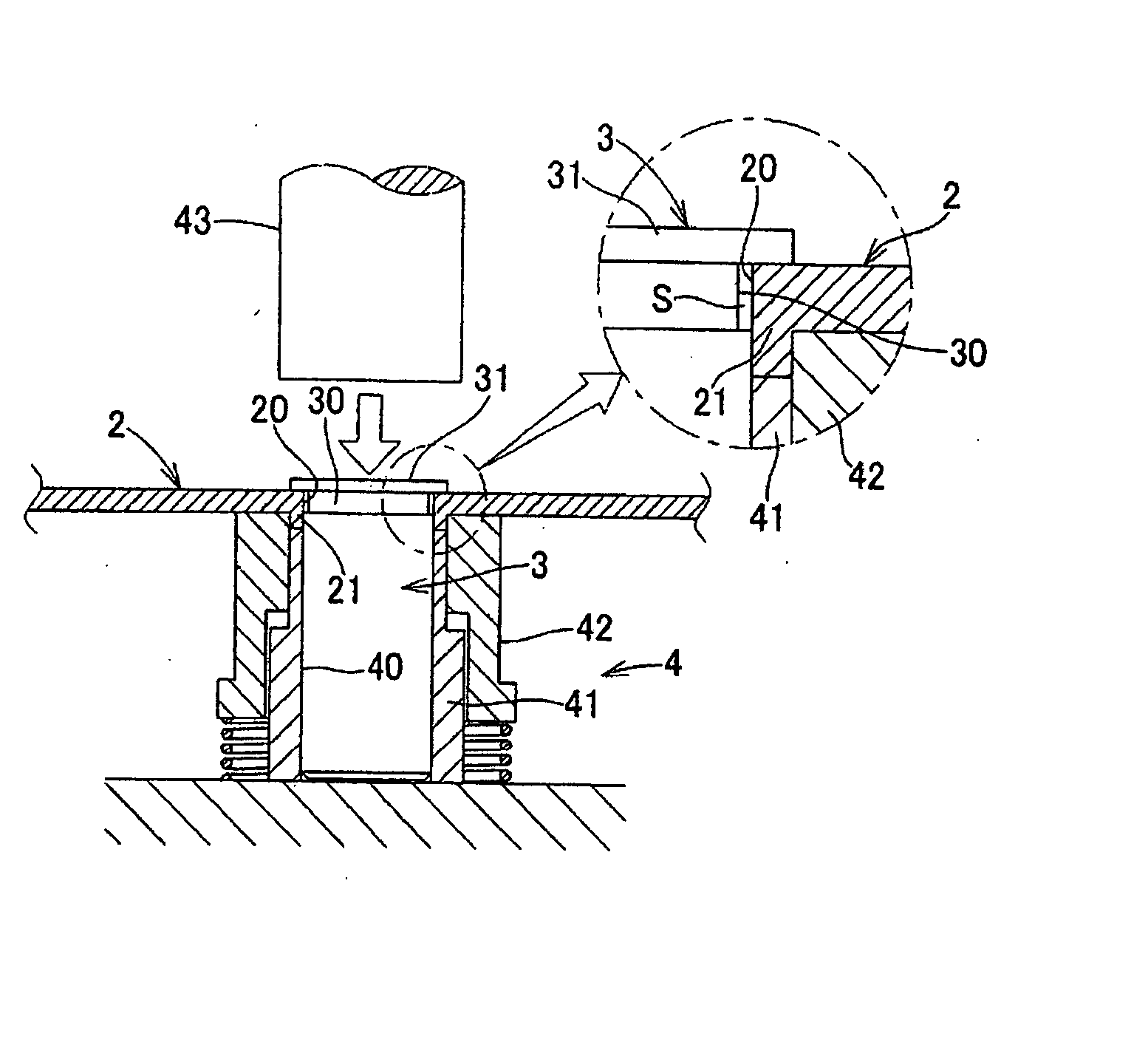

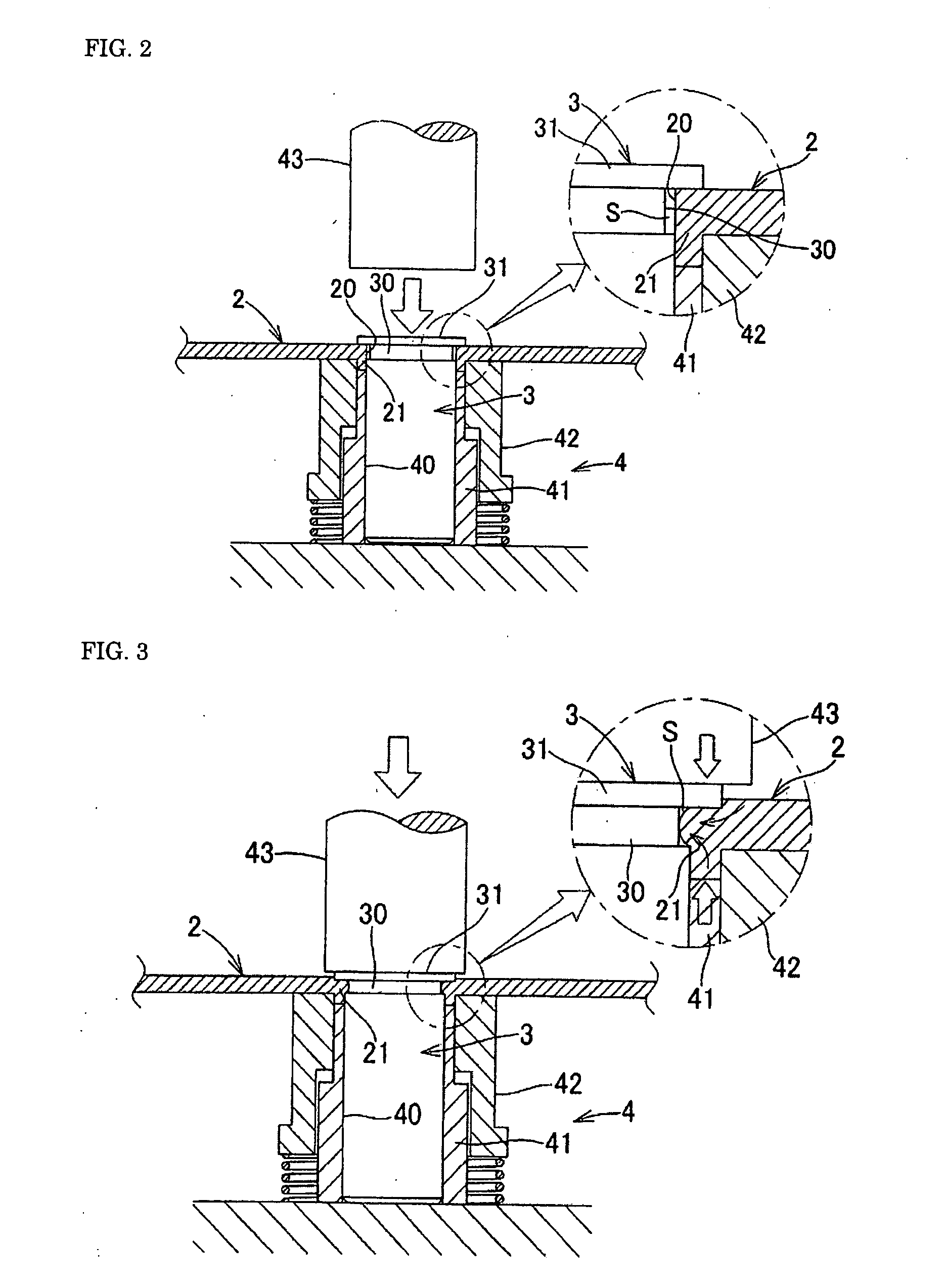

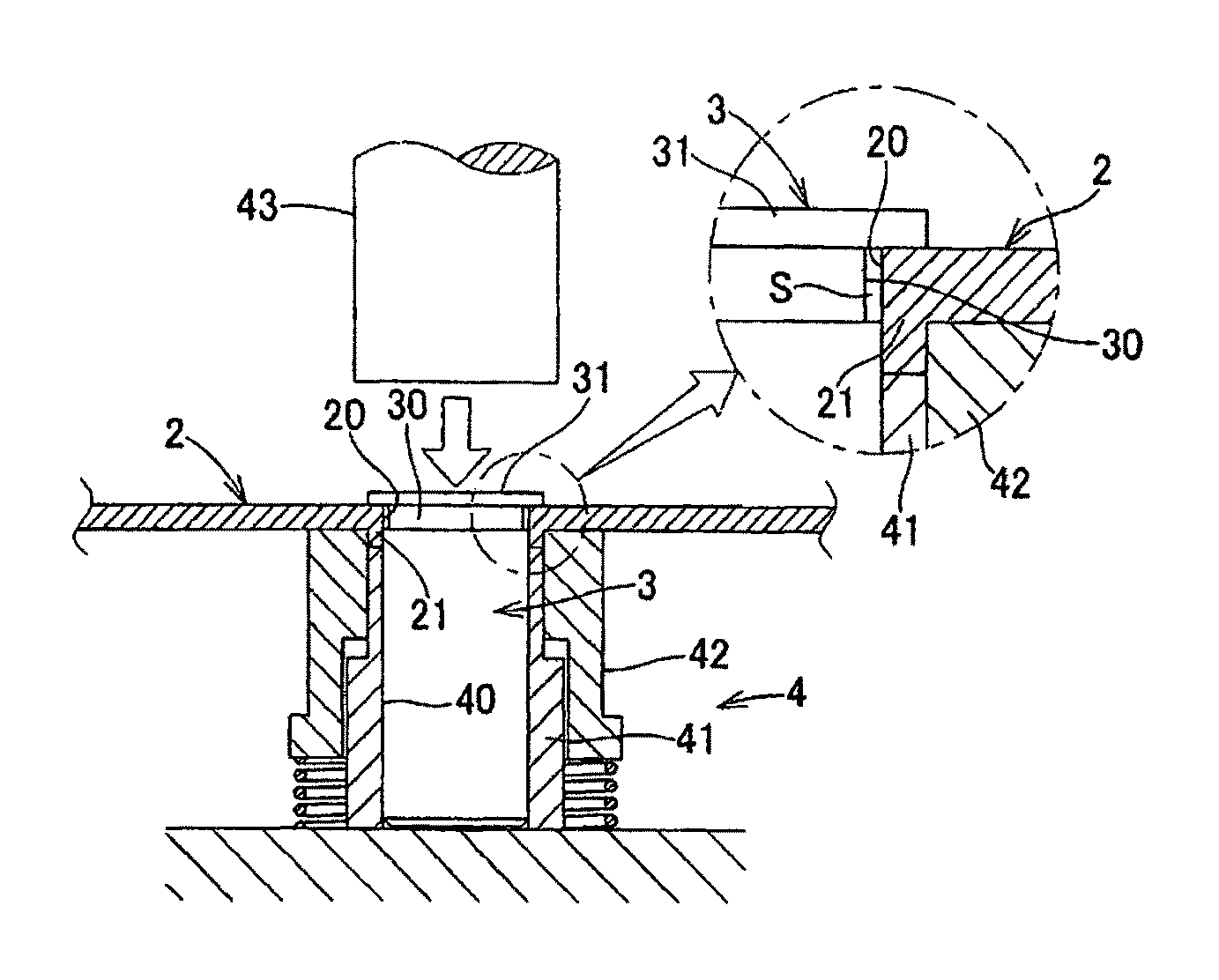

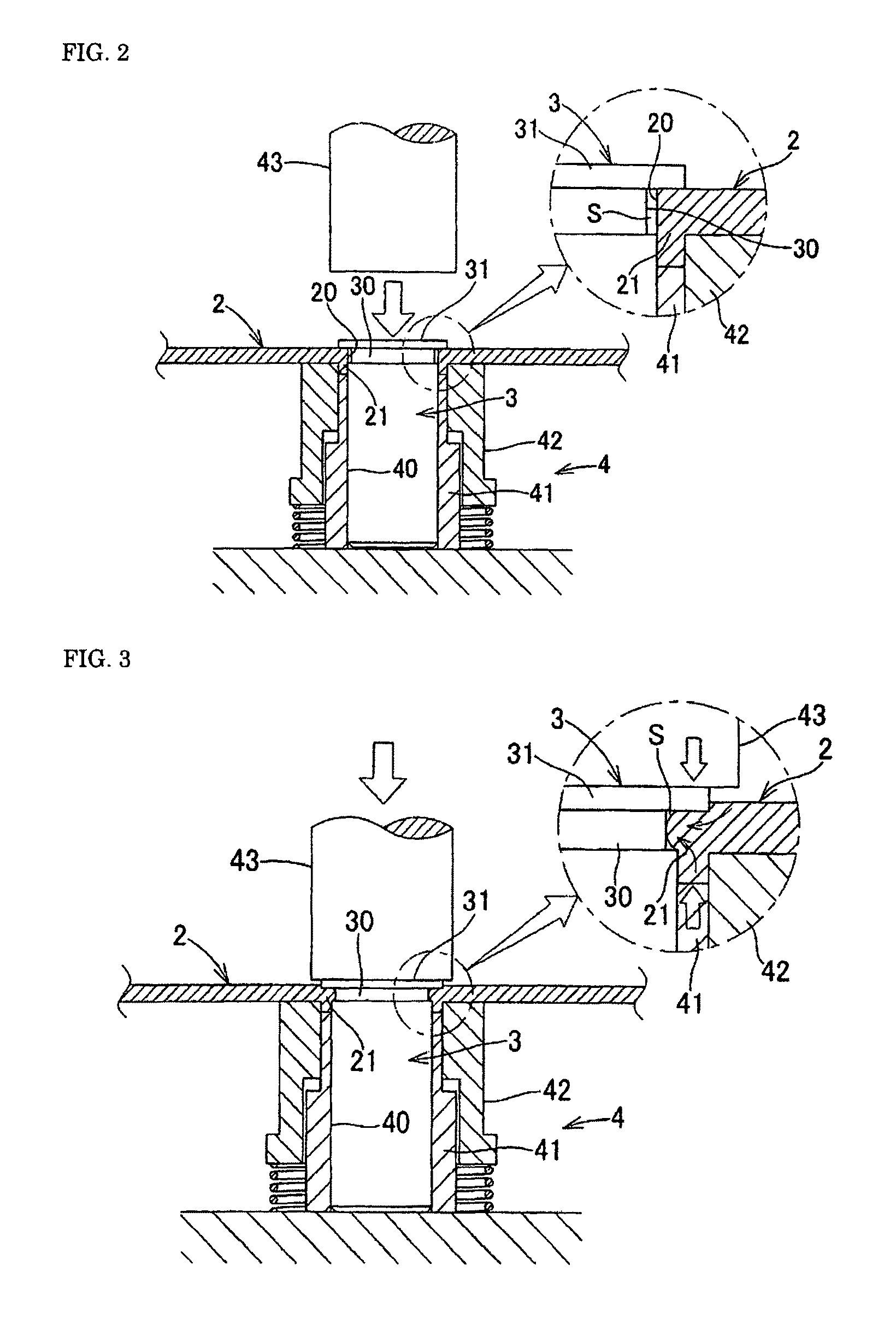

Manufacturing method of caulking-assembled part

ActiveUS20070226984A1Reduce manufacturing costHigh strengthDomestic articlesMetal working apparatusEngineeringMechanical engineering

The present invention provides a caulked assembly to be manufactured at low cost, and maintain sufficient caulking strength, and the manufacturing method and apparatus thereof. The manufacturing method comprises steps of forming a mounting hole for inserting and assembling a columnar body in a metal plate body, and forming a thick part along an inner circumferential edge of a mounting hole; forming a circumferential groove with a predetermined depth at an assembled position of a outer circumferential surface of the columnar body inserted into the mounting hole; inserting the columnar body into the mounting hole to set to the assembled position where the thick part is opposed to the circumferential groove; and caulking for compressively pressing the thick part from an axial direction of the columnar body to plastically deform the thick part in a center direction of the mounting hole to bite the thick part into the circumferential groove.

Owner:JAPAN

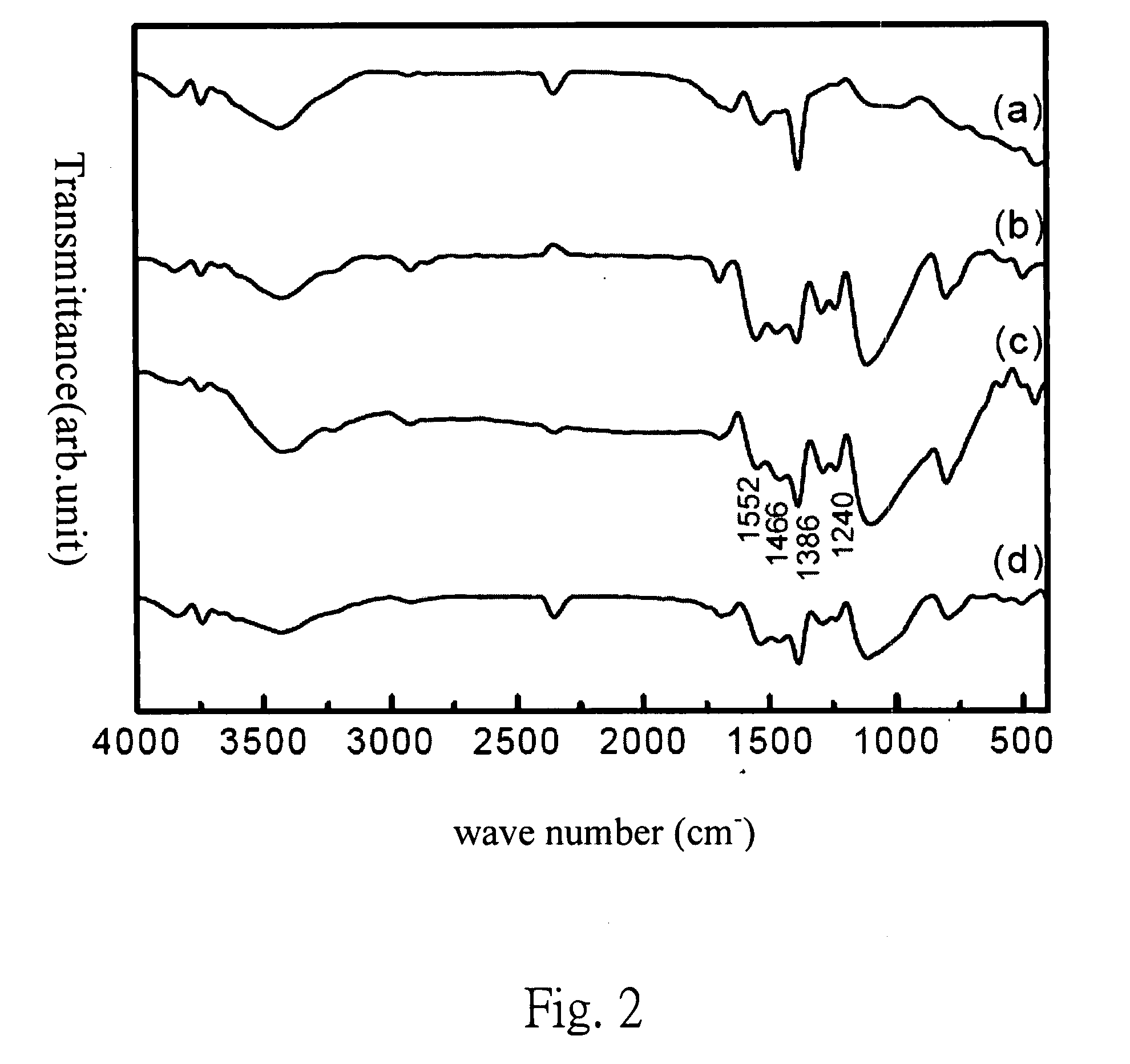

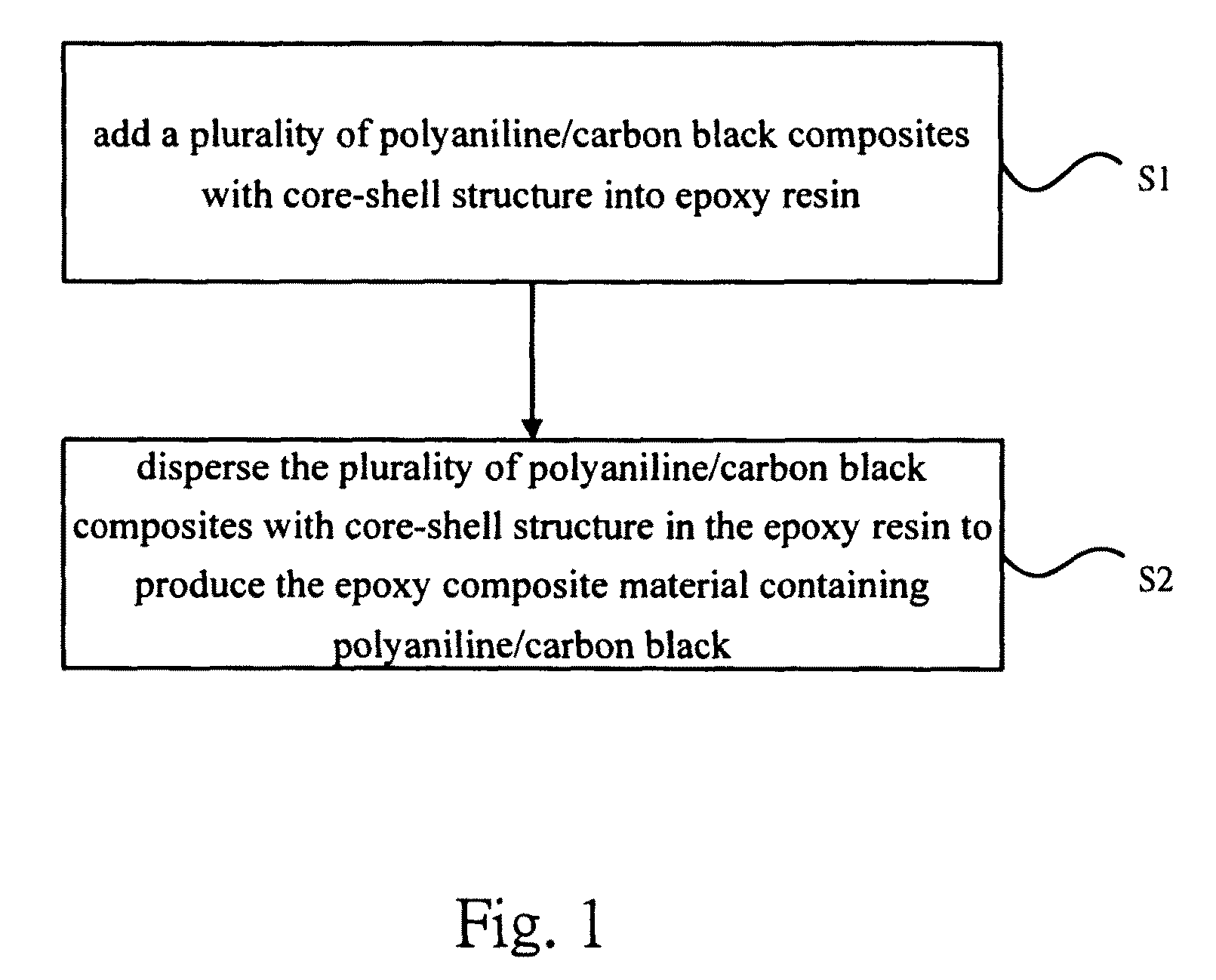

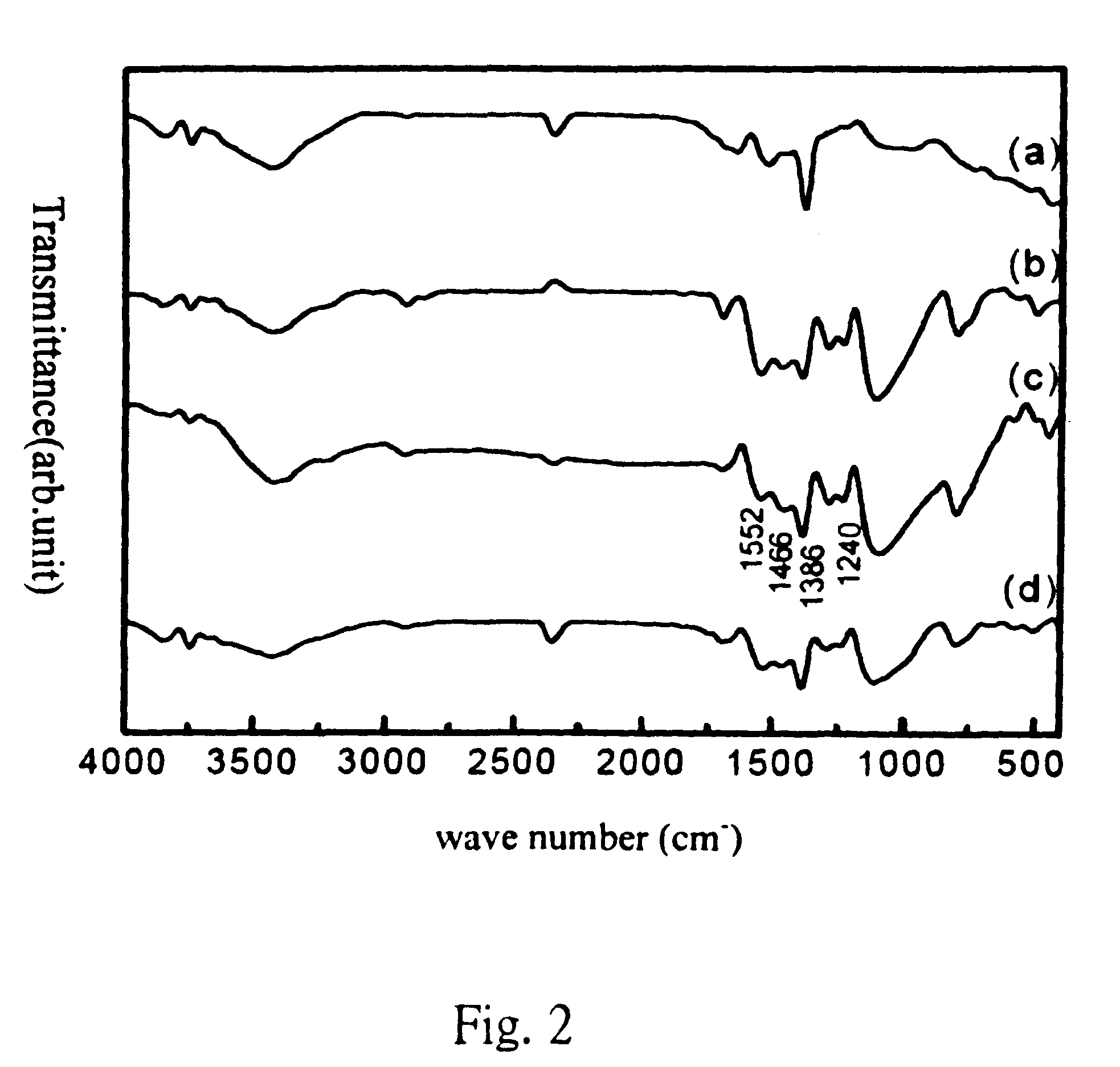

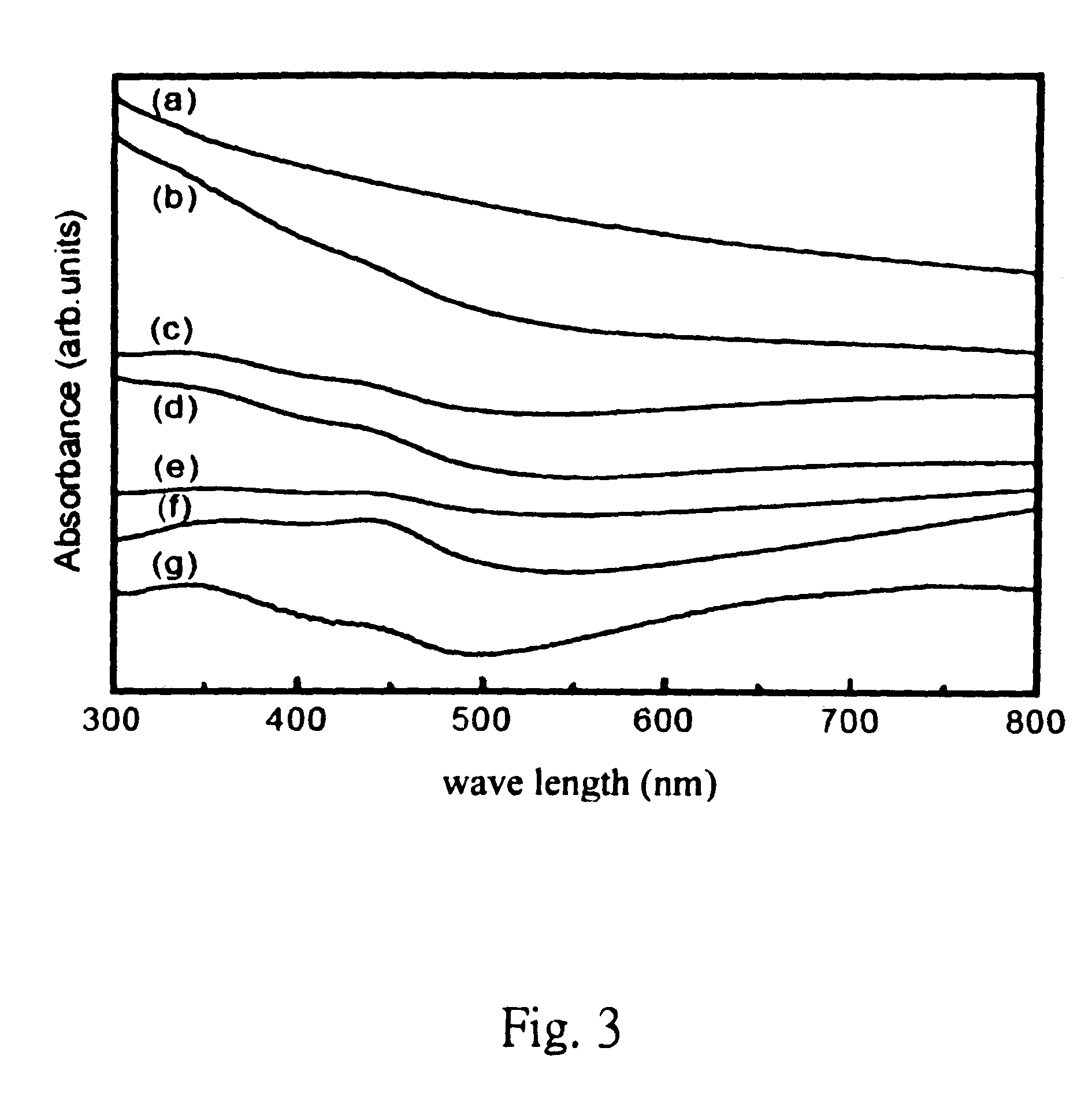

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090109791A1High absorption effectImprove conductivityNon-metal conductorsShaking/oscillating/vibrating mixersMicrowaveConductive coating

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

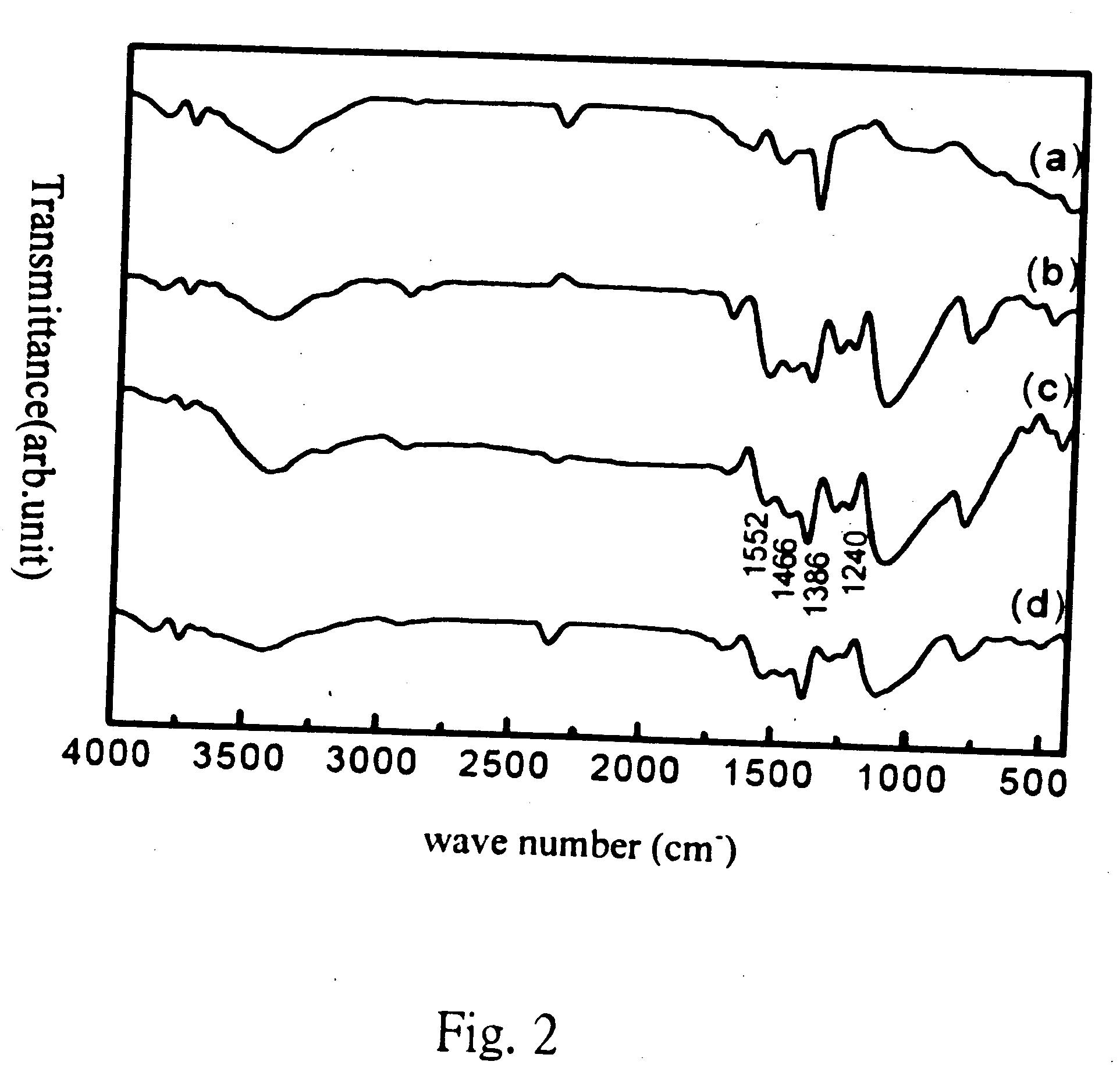

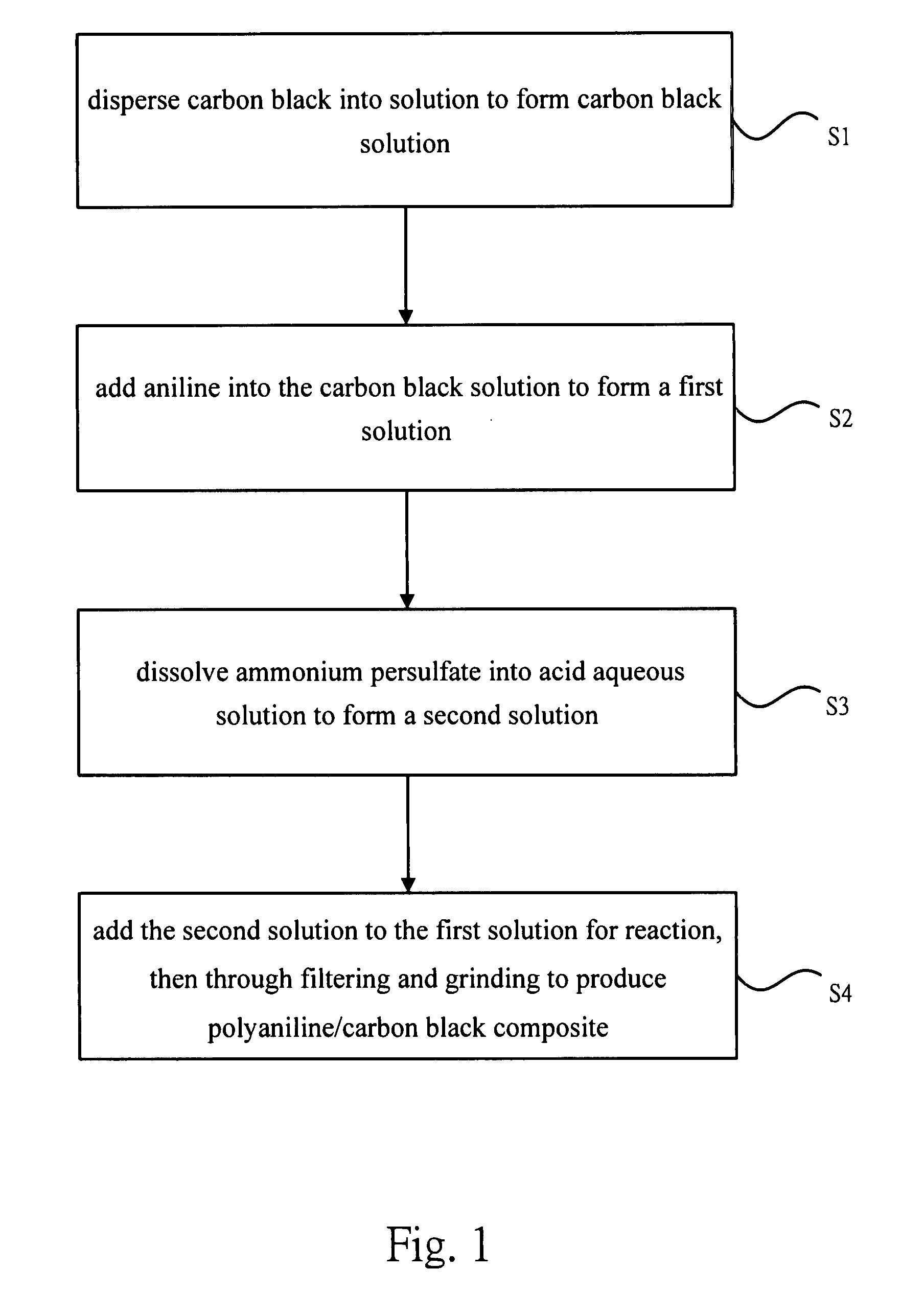

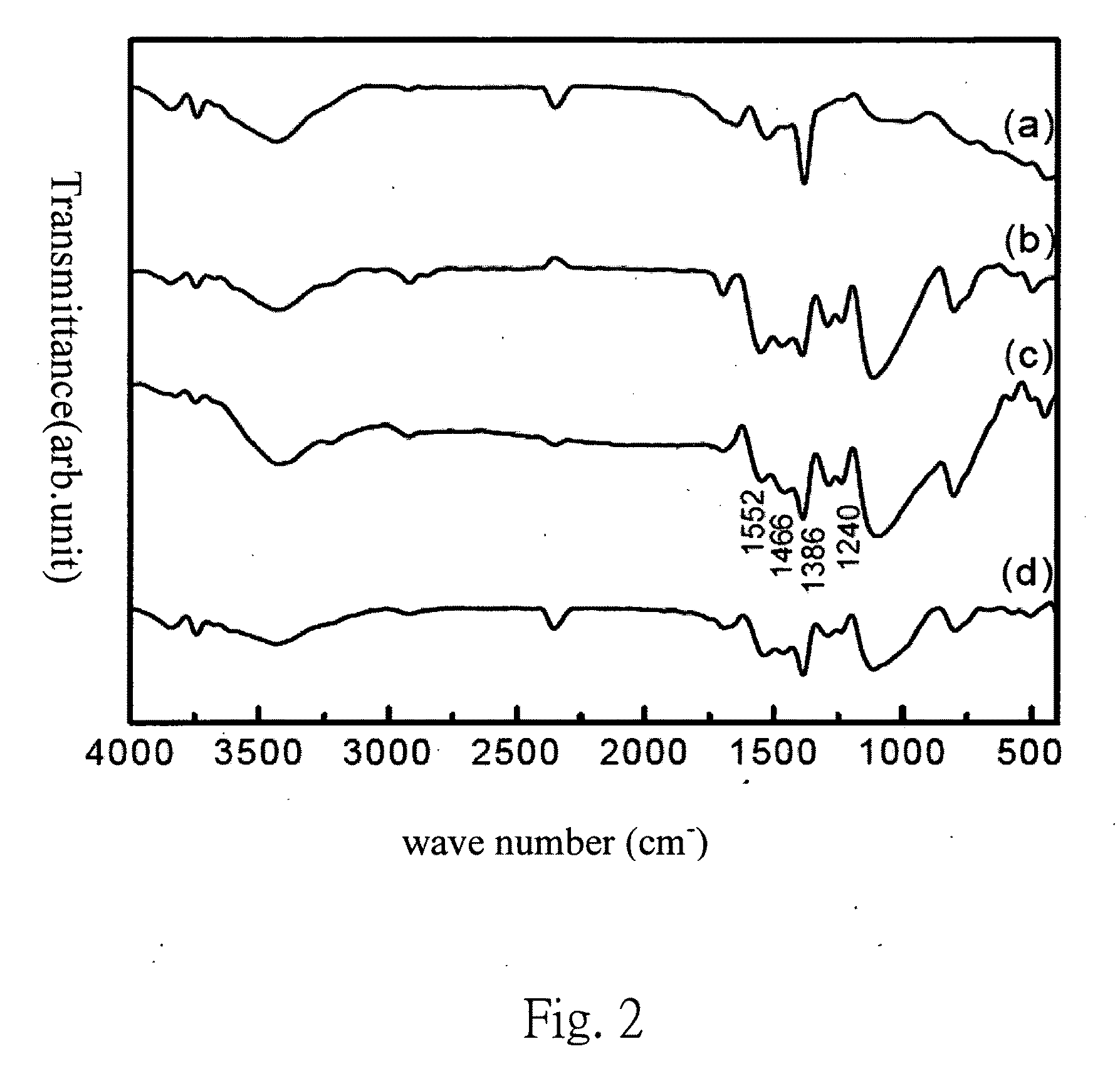

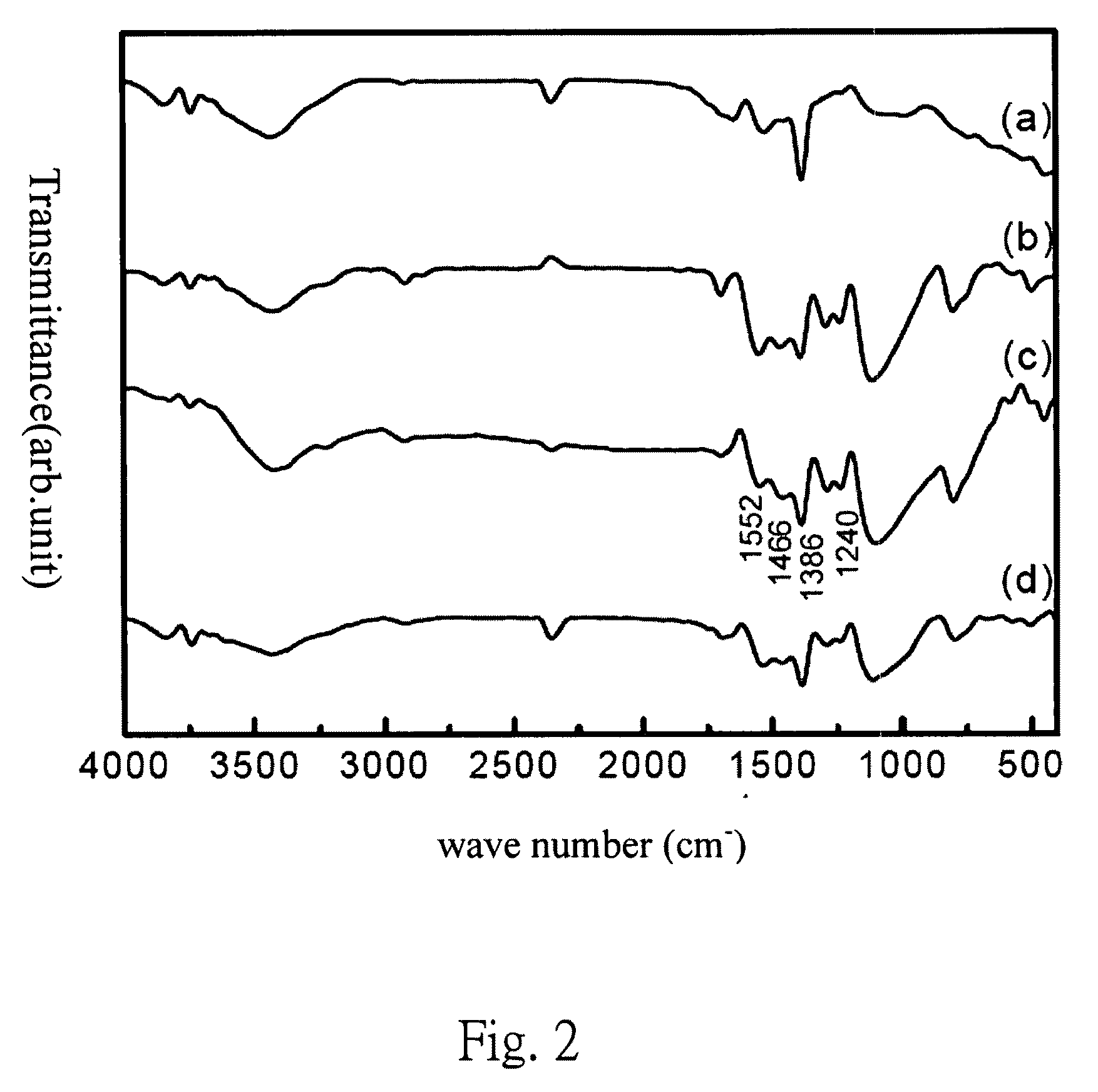

Polyaniline/carbon black composite and preparation method thereof

InactiveUS20090110932A1Improve conductivityOvercomes shortcomingConductive materialSynthetic resin layered productsCarbon blackAqueous solution

A polyaniline / carbon black composite and a preparation method thereof are disclosed The polyaniline / carbon black composite is formed by polyaniline covering carbon black and is with core-shell structure while the polyaniline / carbon black composite contains 10-30 wt. % of carbon black. The preparation method of polyaniline / carbon black composite includes the steps of: disperse carbon black into solution to form carbon black solution, add aniline into the carbon black solution to form a first solution; dissolve ammonium persulfate into acid aqueous solution to form a second solution; add the second solution to the first solution, after reaction, through filtering and grinding to produce polyaniline / carbon black composite.

Owner:CHUNG-SHAN INSTITUTE OF SCIENCE & TECHNOLOGY; MINISTRY OF NATIONAL DEFENSE

Use of vegetative material as a filler in composite materials

InactiveUS20050165140A1Poor processabilityKeep for a long timeWood treatment detailsBuilding insulationsHuskMaterials science

Owner:TADGELL DAVID JOHN +1

Conjugated diene-based rubber and method of producing the same, oil extended rubber and rubber composition containing the same

InactiveUS20020052435A1Low elastic modulusIncreased tan.deltaGroup 4/14 element organic compoundsSpecial tyresMonomer compositionPolymer science

Owner:JSR CORPORATIOON

Ethylene-alpha-olefin copolymer

InactiveUS7557172B2Low mechanical strengthDeterioration of processabilityAlpha-olefinUltimate tensile strength

Owner:SUMITOMO CHEM CO LTD

Caulked assembly of metal plate body with columnar body, caulked assembly of resin molded body with columnar body, and method for producing the same

ActiveUS7918007B2Reduce manufacturing costHigh strengthDomestic articlesMetal working apparatusEngineeringMechanical engineering

The present invention provides a caulked assembly to be manufactured at low cost, and maintain sufficient caulking strength, and the manufacturing method and apparatus thereof. The manufacturing method comprises steps of forming a mounting hole for inserting and assembling a columnar body in a metal plate body, and forming a thick part along an inner circumferential edge of a mounting hole; forming a circumferential groove with a predetermined depth at an assembled position of a outer circumferential surface of the columnar body inserted into the mounting hole; inserting the columnar body into the mounting hole to set to the assembled position where the thick part is opposed to the circumferential groove; and caulking for compressively pressing the thick part from an axial direction of the columnar body to plastically deform the thick part in a center direction of the mounting hole to bite the thick part into the circumferential groove.

Owner:JAPAN

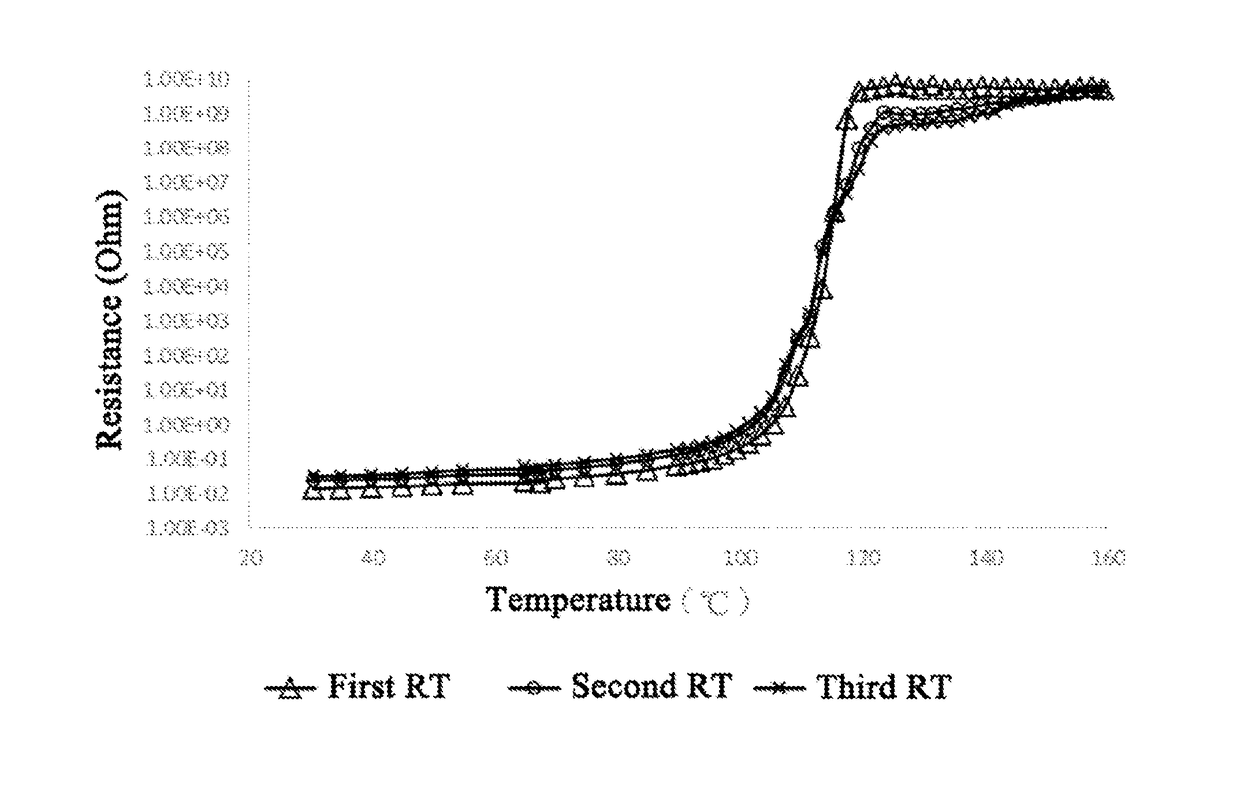

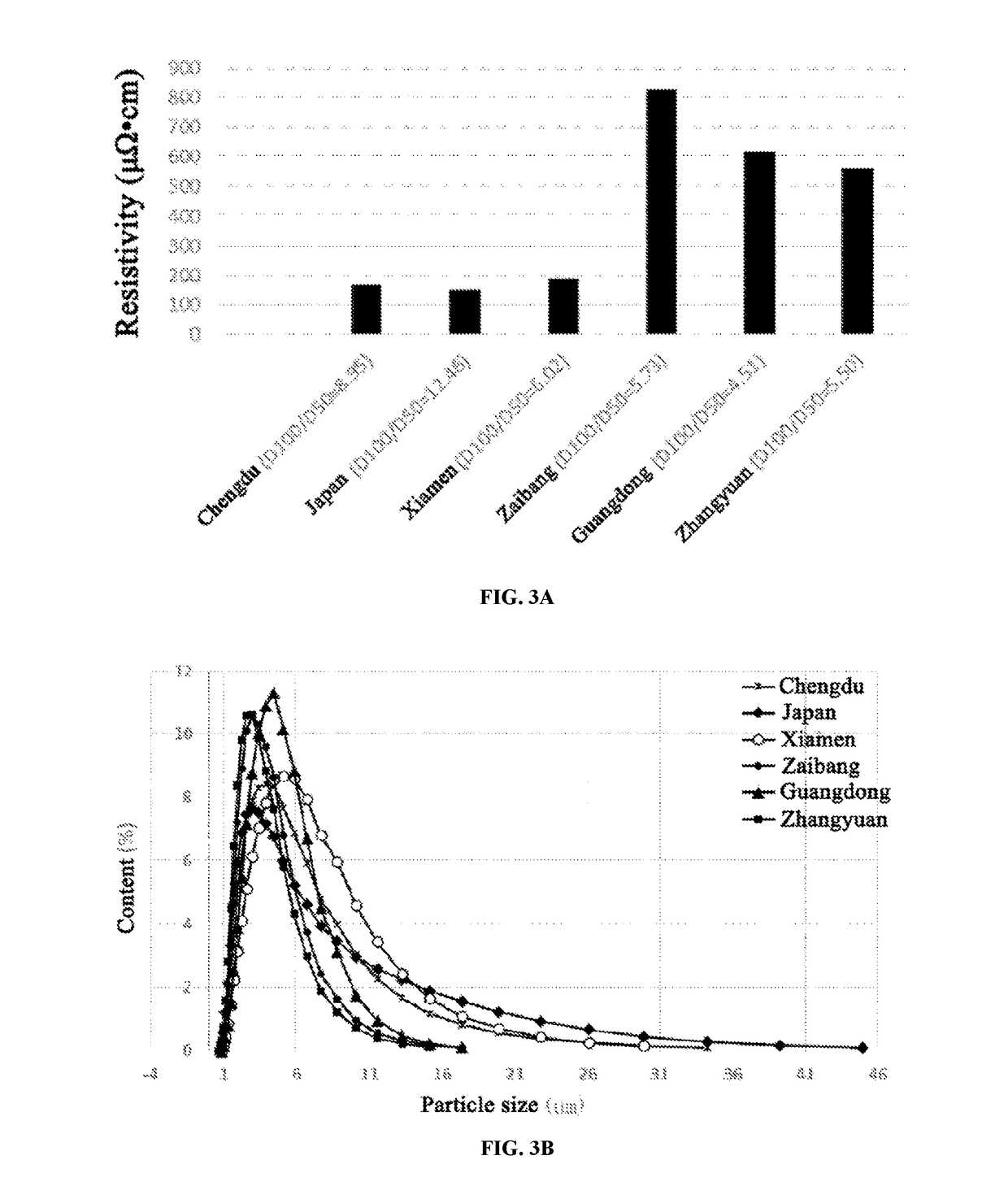

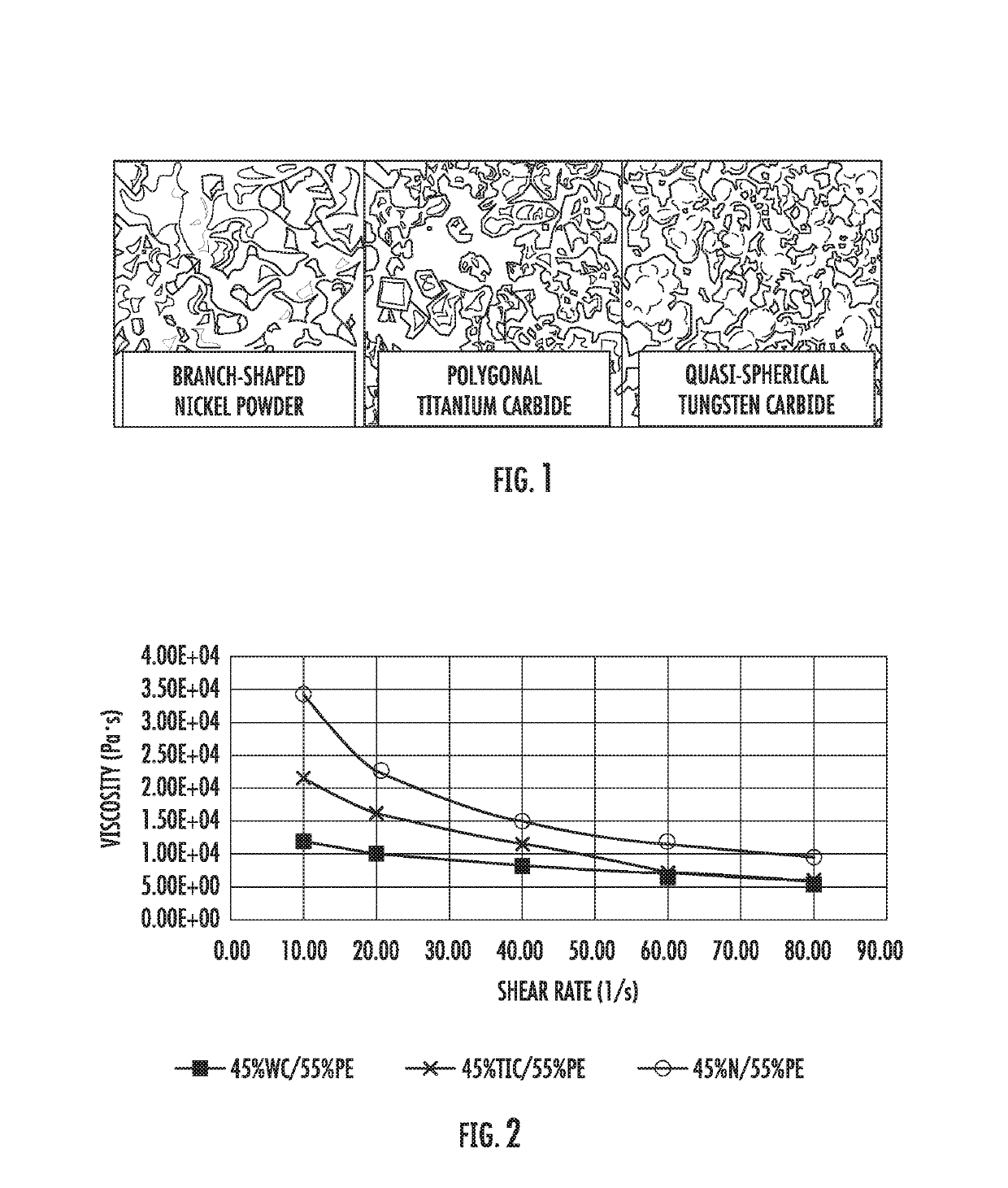

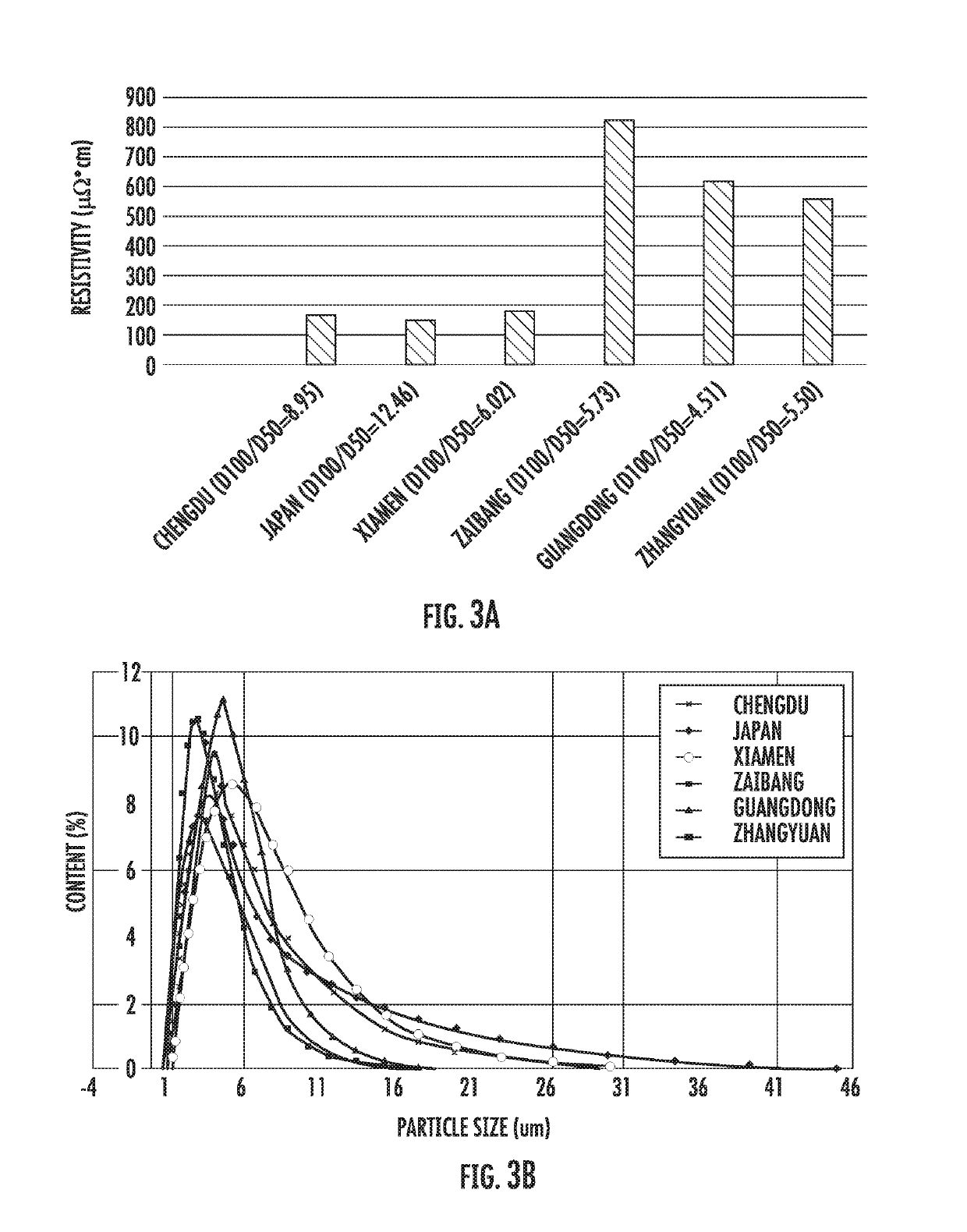

Conductive polymer composition, conductive polymer sheet, electrical device, and their preparation methods

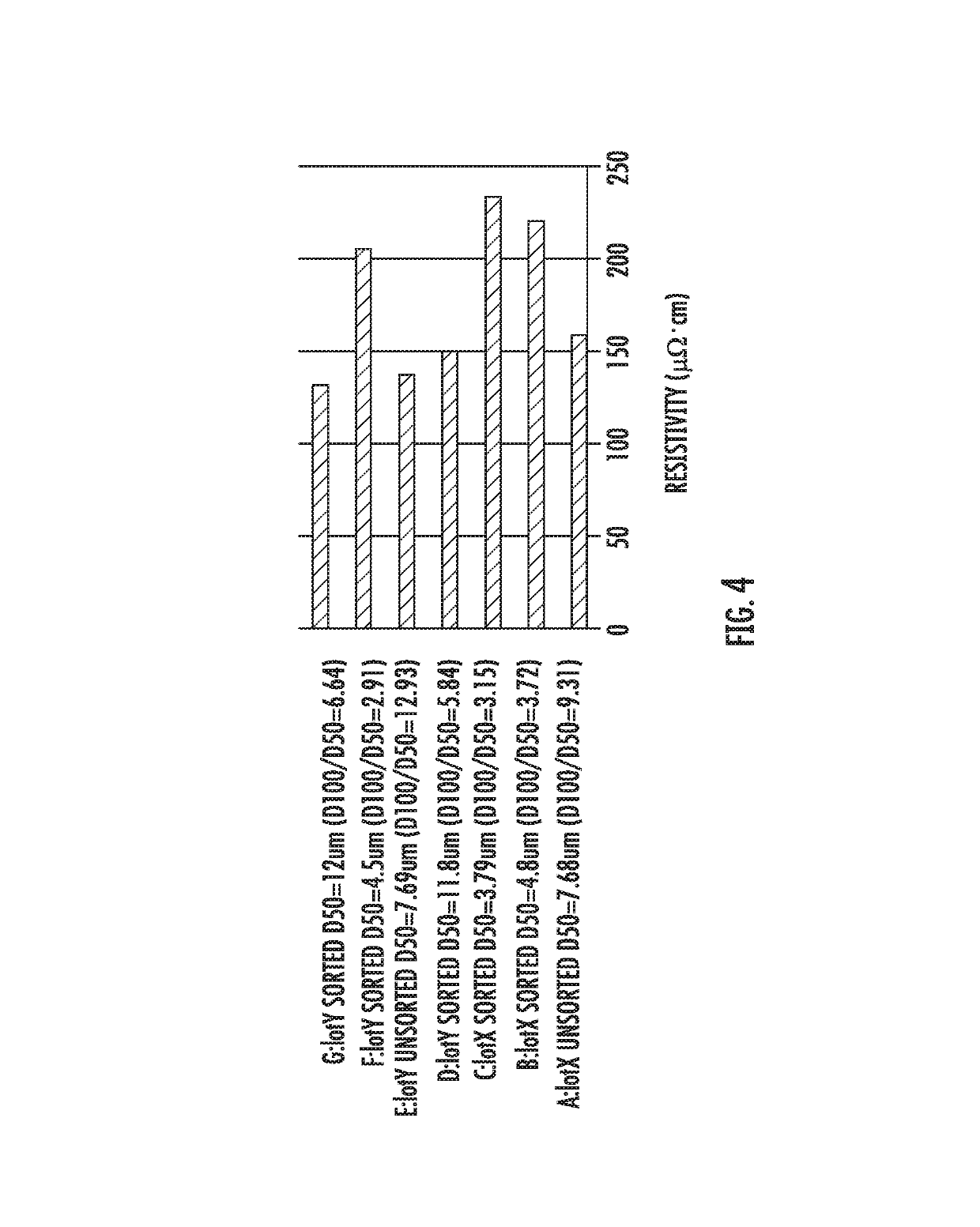

ActiveUS20180186964A1Increase resistancePoor processabilityNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsPolymer sciencePolyolefin

The present invention provides a conductive polymer composition, a conductive polymer sheet, an electrical device, and their preparation methods. The conductive polymer composition of the present invention includes a polymer and a conductive powder at a volume ratio of 35:65 to 65:35. The polymer includes at least one semicrystalline polymer selected from polyolefin, a copolymer of at least one olefin and at least one non-olefinic monomer copolymerizable therewith, and a thermoformable fluorine-containing polymer. The stated conductive powder includes at least one powder of a transition metal carbide, a transition metal carbon silicide, a transition metal carbon aluminide, and a transition metal carbon stannide. And the stated size distribution of the conductive powder satisfies: 20>D100 / D50>6, where D50 denotes a corresponding particle size when a cumulative particle-size distribution percent in the conductive powder reaches 50%, and D100 denotes a maximum particle size. The stated conductive polymer composition has excellent processability, and can be used for preparing a PPTC device with ultralow resistance and stability in air without an oxygen barrier coating.

Owner:LITTELFUSE INC +1

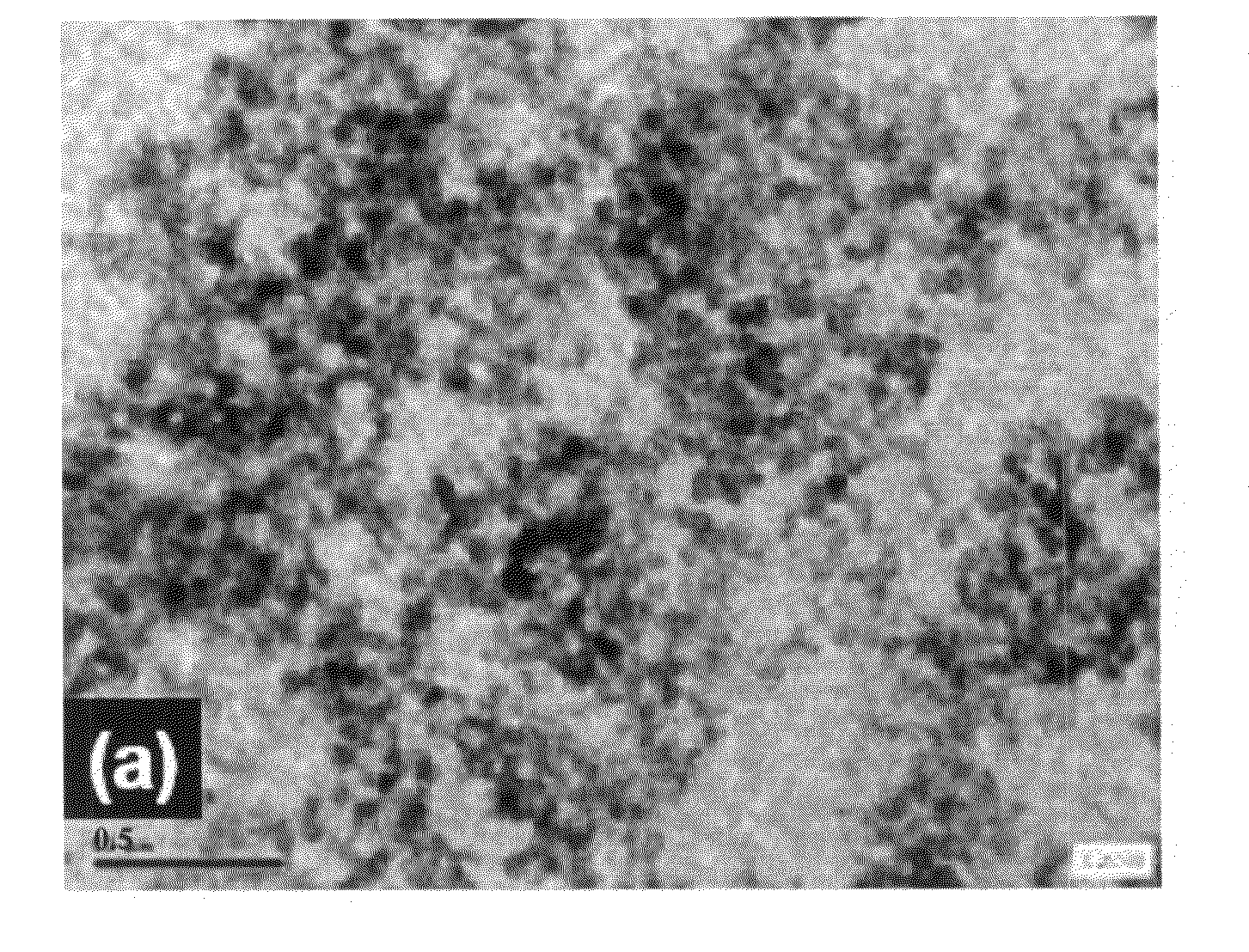

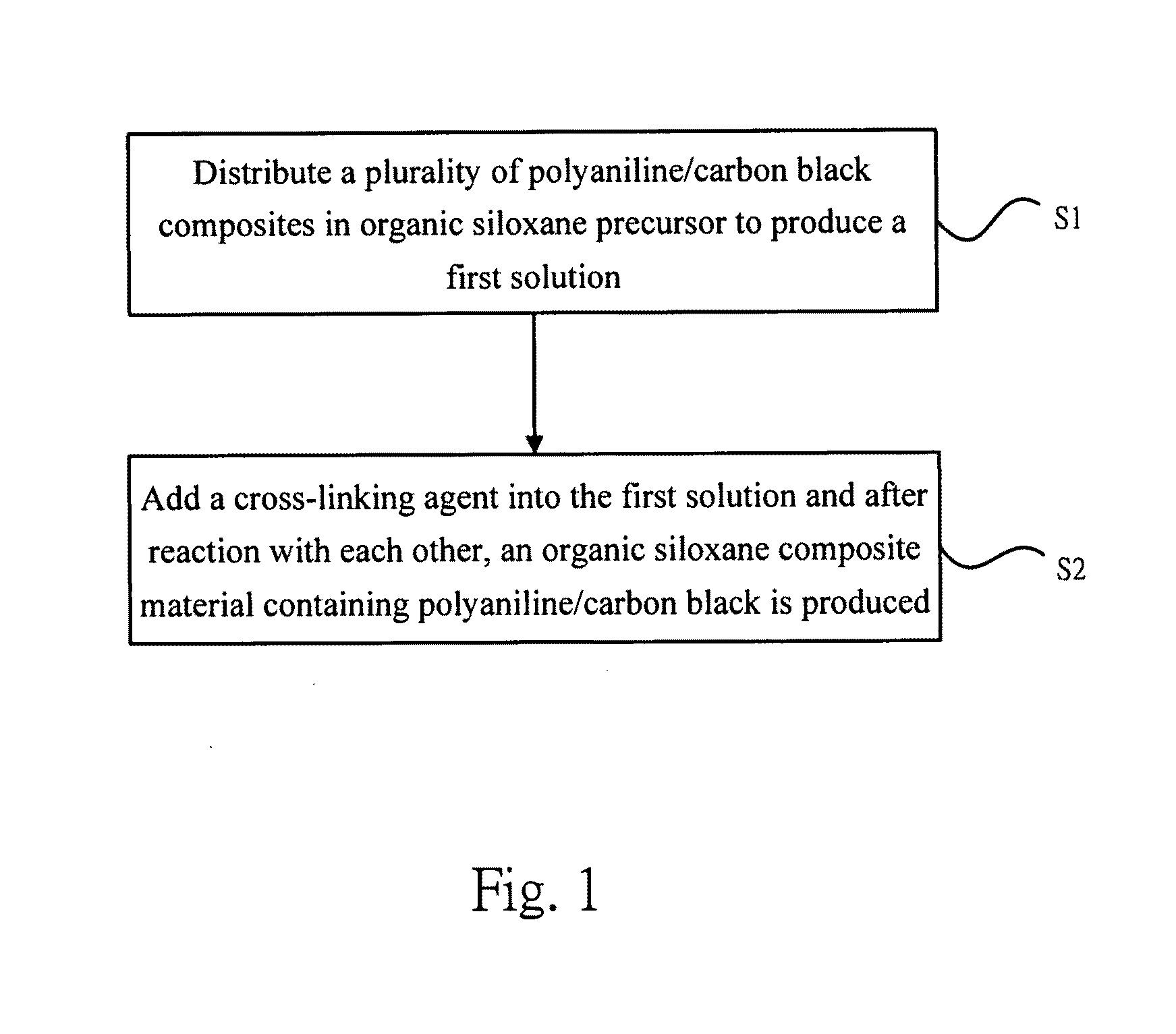

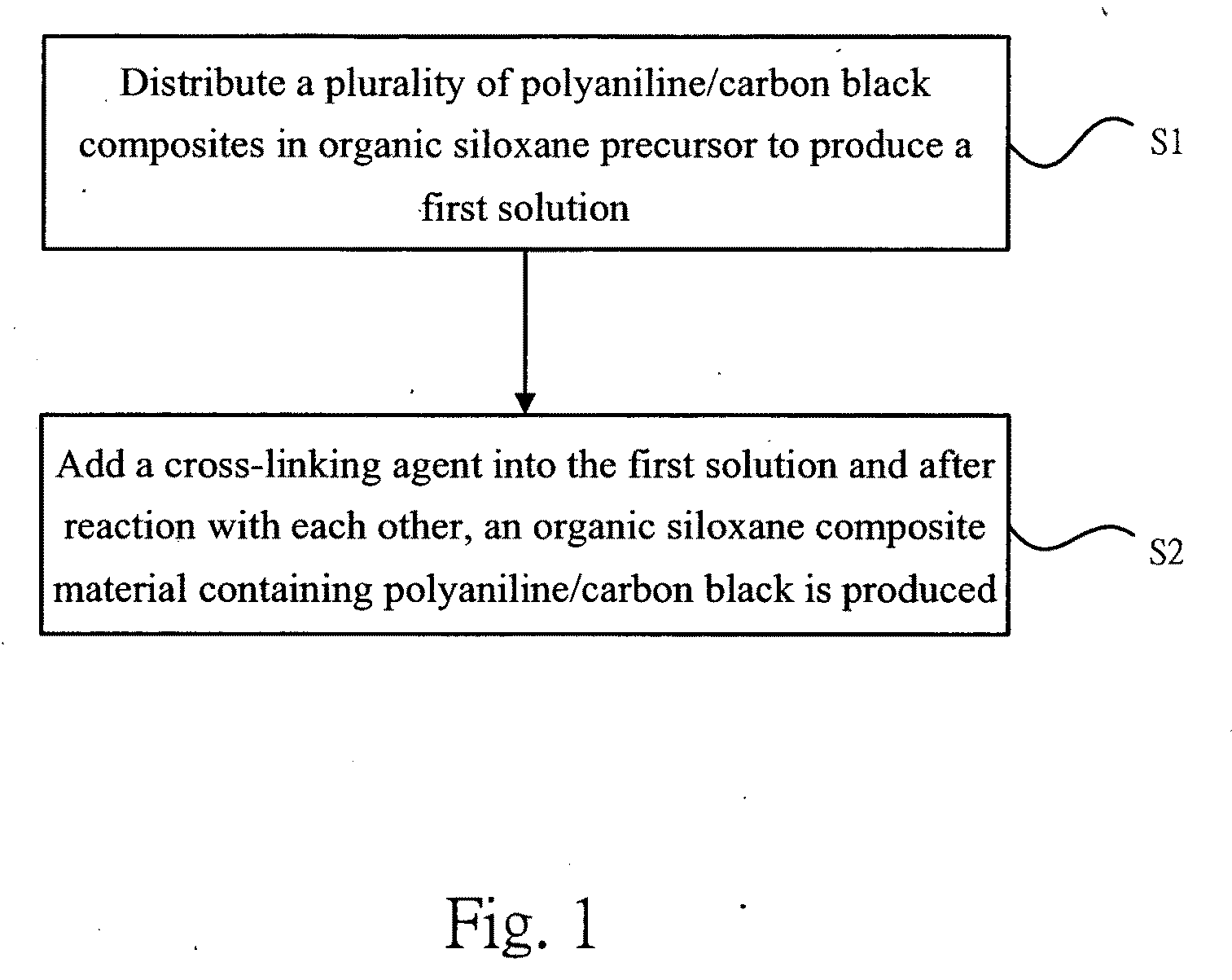

Organic siloxane composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090110931A1Improve conductivityImprove corrosion resistanceNon-metal conductorsSynthetic resin layered productsCross-linkPolyaniline

An organic siloxane composite material containing polyaniline / carbon black and a preparation method thereof are disclosed. The organic siloxane composite material containing polyaniline / carbon black consists of a plurality of polyaniline / carbon black composites distributed in organic siloxane precursor while the organic siloxane composite material containing polyaniline / carbon black includes from 10 to 30 weight percent of polyaniline / carbon black composites. The preparation method of organic siloxane composite material containing polyaniline / carbon black includes the steps of: distributing a plurality of polyaniline / carbon black composites in organic siloxane precursor to produce a first solution; and adding a cross-linking agent into the first solution, after reaction with each other, an organic siloxane composite material containing polyaniline / carbon black is produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Ink composition for steel material, having excellent adhesion, method for manufacturing printed steel sheet by using same, and printed steel sheet manufactured thereby

An ink composition for a printed steel sheet, having excellent adhesion to a steel sheet, processability, solvent resistance, and the like, a method for manufacturing a printed steel sheet using the same, and a printed steel sheet manufactured thereby, are provided. The ink composition for a steel material includes 10 to 30 parts by weight of a mixture of a urethane acrylate oligomer and another type of acrylate oligomer different from the urethane acrylate oligomer, 65 to 80 parts by weight of a radiation curable monomer which is a mixture of a monofunctional radiation curable monomer and a di- or more functional radiation curable monomer, 1 to 10 parts by weight of a photoinitiator, and 0.01 to 10 parts by weight of an adhesion promoter.

Owner:INKTEC CO LTD

Soluble terminally modified imide oligomer using 2-phenyl-4, 4′-diaminodiphenyl ether, varnish, cured product thereof, imide prepreg thereof, and fiber-reinforced laminate having excellent heat resistance

ActiveUS8846552B2Poor processabilityImprove balanceOrganic chemistryAdhesive processes with surface pretreatmentFiberSolubility

A novel terminally modified imide oligomer having excellent solubility in organic solvents, excellent solution storage stability, and excellent molding properties such as low melt viscosity. Also, a varnish obtained by dissolving the terminally modified imide oligomer in an organic solvent; a cure product obtained by using the terminally modified imide oligomer and having excellent thermal and mechanical characteristics such as heat resistance, elastic modulus, tensile strength at break and tensile elongation at break; a prepreg; and a fiber-reinforced laminate. The soluble terminally modified imide oligomer is represented by general formula (1). In the formula, R1 and R2 each represents a divalent aromatic diamine residue; R3 and R4 each represents a tetravalent aromatic tetracarboxylic acid residue; R5 and R6 each represents a hydrogen atom or a phenyl group, with R5 or R6 being a phenyl group; m and n satisfy the following relations: m≧1, n≧0, 1≦m+n≦20 and 0.05≦m / (m+n)≦1; and the repeating units may be arranged in blocks or randomly.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

Organic siloxane composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090131580A1Improve conductivityImprove corrosion resistanceNon-metal conductorsConductive materialCross-linkPolyaniline

An organic siloxane composite material containing polyaniline / carbon black and a preparation method thereof are disclosed. The organic siloxane composite material containing polyaniline / carbon black consists of a plurality of polyaniline / carbon black composites distributed in organic siloxane precursor while the organic siloxane composite material containing polyaniline / carbon black includes from 10 to 30 weight percent of polyaniline / carbon black composites. The preparation method of organic siloxane composite material containing polyaniline / carbon black includes the steps of: distributing a plurality of polyaniline / carbon black composites in organic siloxane precursor to produce a first solution; and adding a cross-linking agent into the first solution, after reaction with each other, an organic siloxane composite material containing polyaniline / carbon black is produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

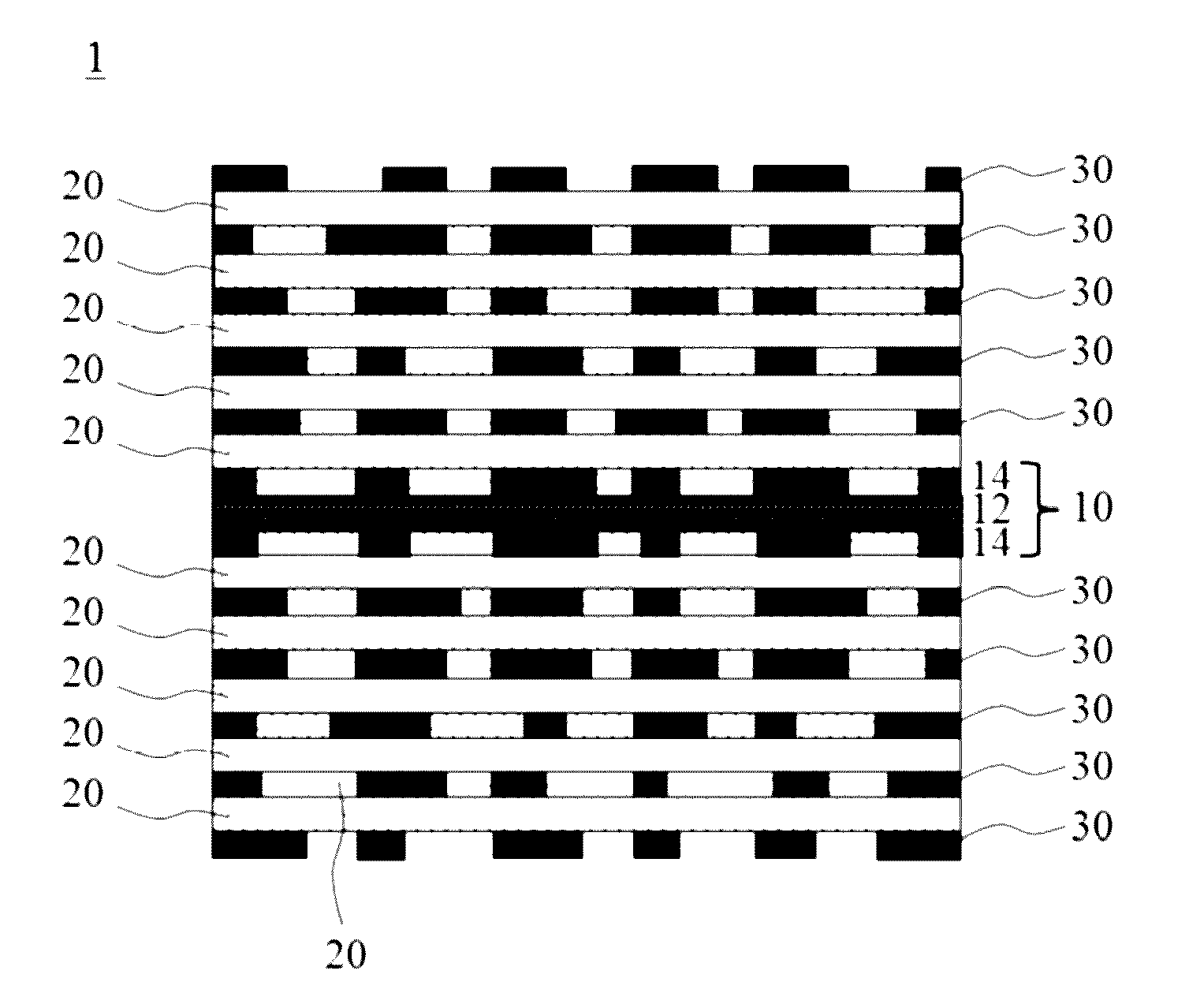

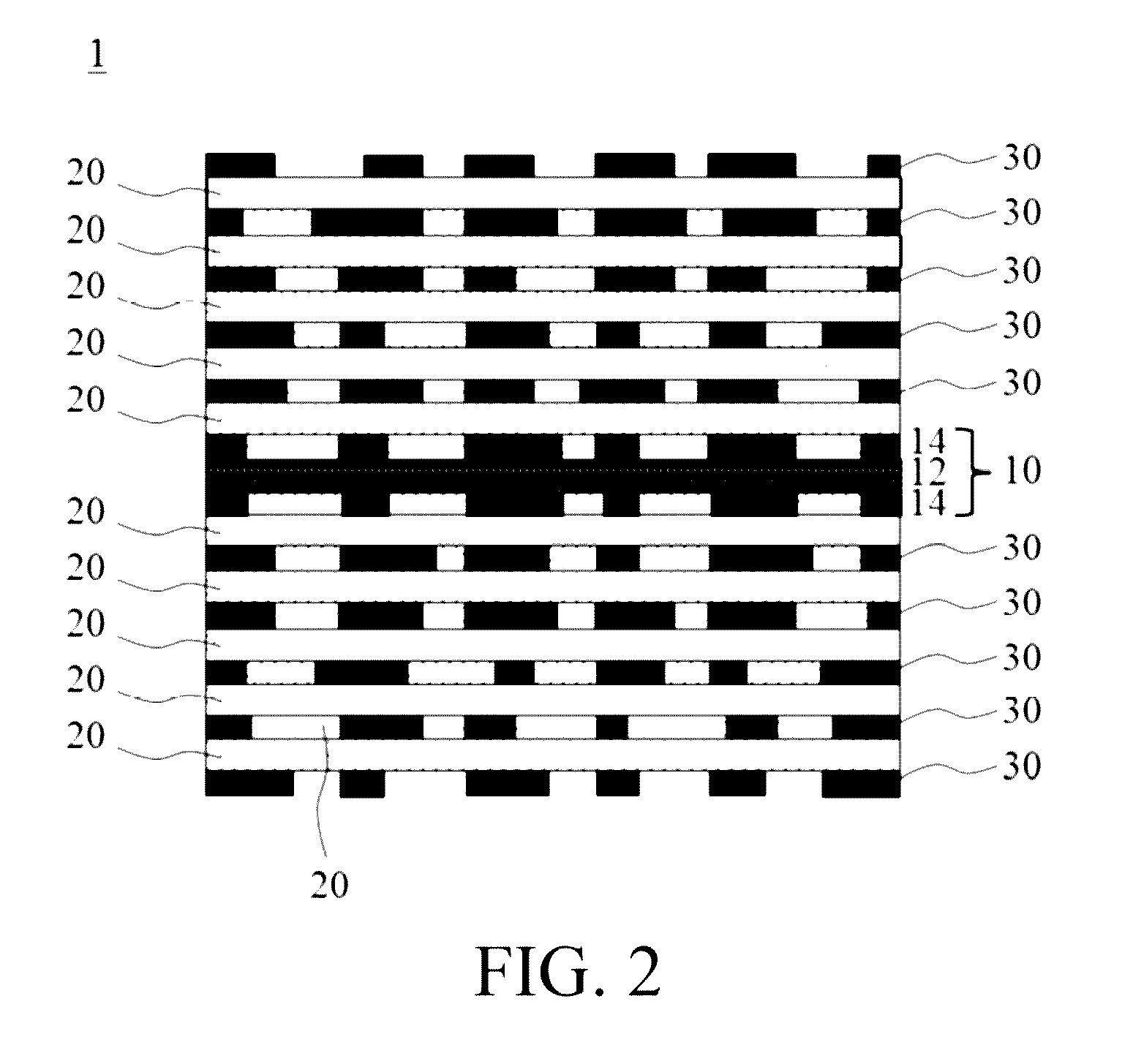

Multi-layer printed circuit boards with dimensional stability

ActiveUS9545018B2Good dimensional stabilityPoor dimensional stabilityPrinted circuit aspectsPrinted circuits stress/warp reductionInsulation layerEngineering

A multi-layer printed circuit board comprises: a core comprising a core insulation layer and traces formed on two sides of the core insulation layer; a plurality of insulation layers sequentially formed at two sides of the core; and a plurality of trace layers respectively formed between two insulation layers and on the outmost insulation layers; wherein the core insulation layer contains a resin material different from that of the insulation layers, such that the core insulation layer has a dimensional stability superior to that of the insulation layers.

Owner:ELITE MATERIAL

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS7799850B2Improve conductivityHigh effectNon-metal conductorsConductive materialMicrowaveConductive coating

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

Modified conjugated diene-based polymer, modified rubber composition containing same, and method for preparing modified conjugated diene-based polymer

ActiveUS9834619B2High tensile strengthImprove modification efficiencyHydrocarbon solventsActive polymer

Disclosed are a method of preparing a modified conjugated diene-based polymer, a modified conjugated diene-based polymer prepared thereby, a rubber composition including the modified conjugated diene-based polymer, and a tire including the rubber composition. The method of preparing the modified conjugated diene-based polymer includes (a) polymerizing a vinyl aromatic monomer and a conjugated diene monomer through continuous solution polymerization using a multifunctional anionic polymerization initiator in the presence of a hydrocarbon solvent, thus forming an active polymer having a reactive end; and (b) coupling or linking the reactive end of the active polymer with an alkylamino alkoxy silane compound.

Owner:LG CHEM LTD

Halogen-free thermosetting resin composition, prepreg and laminate for printed circuit boards using the same

InactiveUS20180126701A1High in phosphorusEfficacy of halogen-free flame retardancySynthetic resin layered productsElectrical equipmentHalogenHeat resistance

The present invention relates to a halogen-free thermosetting resin composition, a prepreg and a laminate for printed circuit boards using the same. The halogen-free thermosetting resin composition comprises, based on 100 parts by weight of organic solids, (A) from 16 to 42 parts by weight of a halogen-free epoxy resin, (B) from 1.5 to 4.8 parts by weight of a compound containing dihydrobenzoxazine ring; (C) from 10 to 28 parts by weight of a phosphorus-containing bisphenol curing agent, wherein the phosphorus-containing bisphenol curing agent has a weight average molecular weight of 1000-6500, and (D) from 30 to 70 parts by weight of silicon dioxide. The prepreg and laminate for printed circuit boards prepared from the halogen-free thermosetting resin composition have high glass transition temperature, excellent dielectric performances, low water absorption, high heat resistance and better processability, and can achieve halogen-free flame retardancy and UL94 V-0.

Owner:GUANGDONG SHENGYI SCI TECH

Conductive polymer composition, conductive polymer sheet, electrical device, and their preparation methods

ActiveUS10280279B2Increase resistancePoor processabilityNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsPolyolefinPolymer science

The present invention provides a conductive polymer composition, a conductive polymer sheet, an electrical device, and their preparation methods. The conductive polymer composition of the present invention includes a polymer and a conductive powder at a volume ratio of 35:65 to 65:35. The polymer includes at least one semicrystalline polymer selected from polyolefin, a copolymer of at least one olefin and at least one non-olefinic monomer copolymerizable therewith, and a thermoformable fluorine-containing polymer. The stated conductive powder includes at least one powder of a transition metal carbide, a transition metal carbon silicide, a transition metal carbon aluminide, and a transition metal carbon stannide. And the stated size distribution of the conductive powder satisfies: 20>D100 / D50>6, where D50 denotes a corresponding particle size when a cumulative particle-size distribution percent in the conductive powder reaches 50%, and D100 denotes a maximum particle size. The stated conductive polymer composition has excellent processability, and can be used for preparing a PPTC device with ultralow resistance and stability in air without an oxygen barrier coating.

Owner:LITTELFUSE INC +1

Epoxy composite material containing polyaniline/carbon black and preparation method thereof

ActiveUS20090111922A1High absorption effectImprove conductivityNon-metal conductorsConductive materialConductive coatingPolyaniline

An epoxy composite material containing polyaniline / carbon black and preparation method thereof are disclosed. The epoxy composite material containing polyaniline / carbon black includes a plurality of polyaniline / carbon black composite with core-shell structure distributed in epoxy resin while polyaniline covers on surface of nanoscale carbon black to form the polyaniline / carbon black composite with core-shell structure. The polyaniline / carbon black composite with core-shell structure contains 10˜30 wt. % of nanoscale carbon black. A method for preparing an epoxy composite material containing polyaniline / carbon black includes steps of: adding a plurality of polyaniline / carbon black composites with core-shell structure into epoxy resin; and dispersing the plurality of polyaniline / carbon black composites with core-shell structure in the epoxy resin to produce the epoxy composite material containing polyaniline / carbon black being applied to conductive coating or microwave absorbing elements.

Owner:NAT CHUNG SHAN INST SCI & TECH

Cyclic polyphenylene ether ether ketone composition and method for producing the same

ActiveUS8987406B2High melting pointPoor processabilityOrganic chemistryOther chemical processesEtherKetone

A cyclic poly (phenylene ether ether ketone) composition includes not less than 60% by weight of a cyclic poly (phenylene ether ether ketone) represented by the following Formula (I), which is characterized in that the cyclic poly (phenylene ether ether ketone) is a mixture of cyclic poly (phenylene ether ether ketone)s having different repeating numbers (m) and the composition has a melting point of not higher than 270° C.; and a method of producing a poly (phenylene ether ether ketone) characterized by heat-polymerizing the cyclic poly (phenylene ether ether ketone) composition:where m represents an integer of 2 to 40.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com