Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

a technology of corrosion resistance and alloy, which is applied in the direction of welding/cutting media/materials, manufacturing tools, welding apparatus, etc., can solve the problems of corrosive loss, wear and tear of members and devices, and difficulty in dealing with these conditions, so as to reduce wear resistance and reduce wear resistance. , the effect of preventing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0182]The following description will discuss examples, and in comparison with comparative examples, the effects of the present invention will be clarified. In recent years, along with the price hike of petroleum, import costs of coals have risen in association therewith, and our country, which is lacking resources, is at present worried about fuel price hikes. In particular, in coal thermal plants, iron works and cement factories where enormous amounts of coals are used, the amount of use of expensive good coals is reduced, while the use of mixed coals with inexpensive coarse coals is increased. Among the coarse coals, coals having a great amount of sulfur content are present, and when these are stacked in stock yards outside, they get wet in rain, and have an increase in their moisture content, with the result that sulfur components contained in the coal come to react with water to produce diluted sulfuric acid.

[0183]In one example, a troughing conveyer is used in processes to intr...

PUM

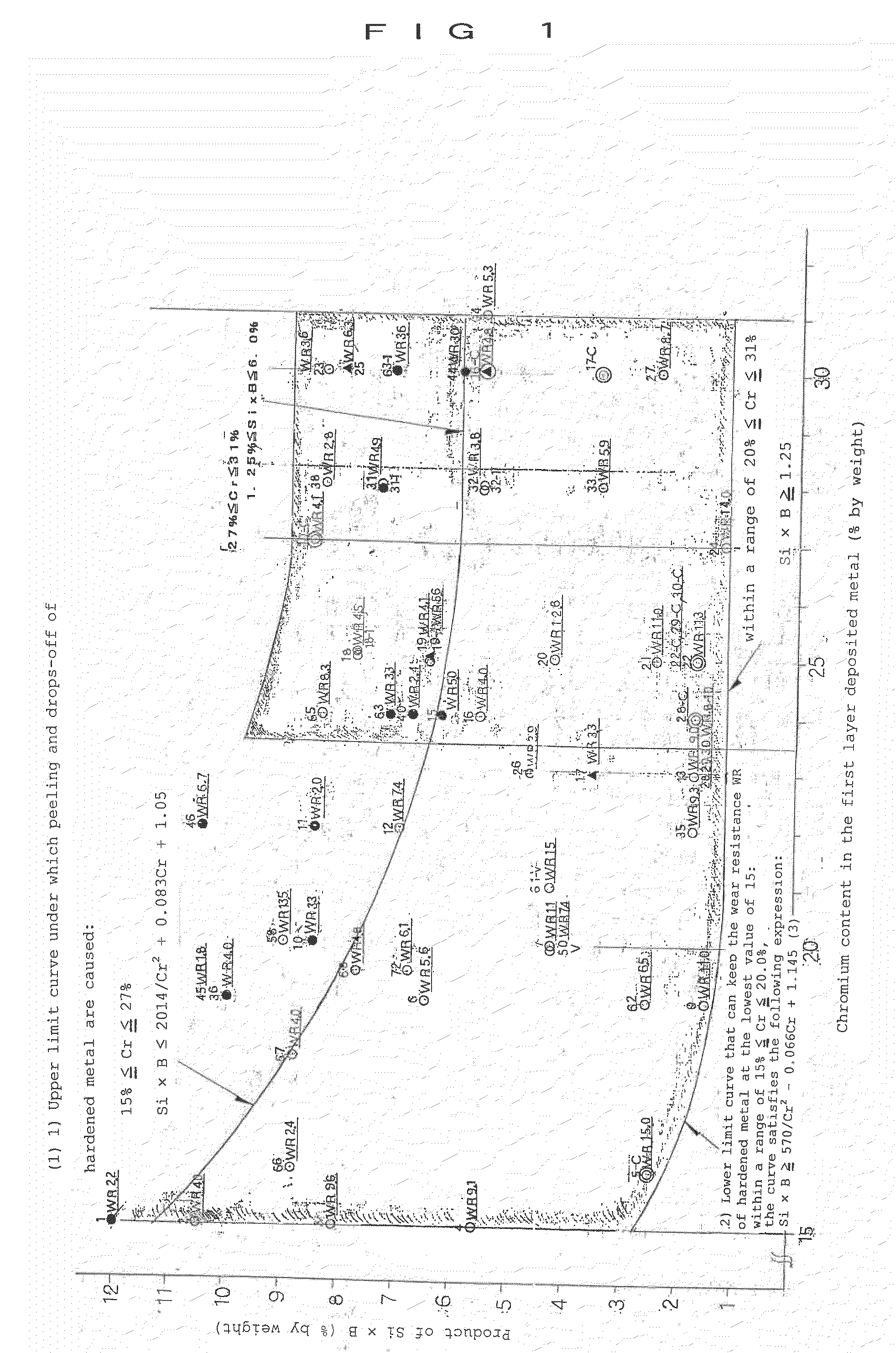

| Property | Measurement | Unit |

|---|---|---|

| wear coefficient | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

| wear coefficient WR | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com