A kind of preparation method of natural Eucommia wood-plastic composite material

A wood-plastic composite material and Eucommia wood technology, which is applied in the field of preparation of natural Eucommia wood-plastic composite materials, can solve the problems of reduced performance of composite materials, poor mechanical properties of compatibilizers, etc., and achieves low moisture absorption rate, good dimensional stability, The effect of low hygroscopic expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

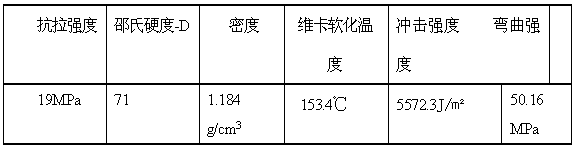

Examples

Embodiment

[0028] (1) Dry the coarse wood chips at 100°C for 8 hours, and then crush them with a high-speed pulverizer for 5 to 10 minutes to refine the coarse wood powder.

[0029] (2) Add 150 parts of Eucommia wood powder to 100 parts of pure polypropylene, 1 part of antioxidant 1010, 30 parts of talcum powder, 1 part of paraffin, 20 parts of polypropylene grafted maleic anhydride (PP-g-MAH), Put in a high speed mixer and mix well.

[0030] (3) Put the mixed sample into a twin-screw extruder, and extrude it at a certain temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com