Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

A technology of nano-modification and fan blades, which is applied in the field of composite membranes, can solve the problems that nano-modified PTFE membranes cannot be firmly composited with fan blades, achieve excellent UV resistance and complex climate performance, facilitate engineering construction, and expand the selection range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

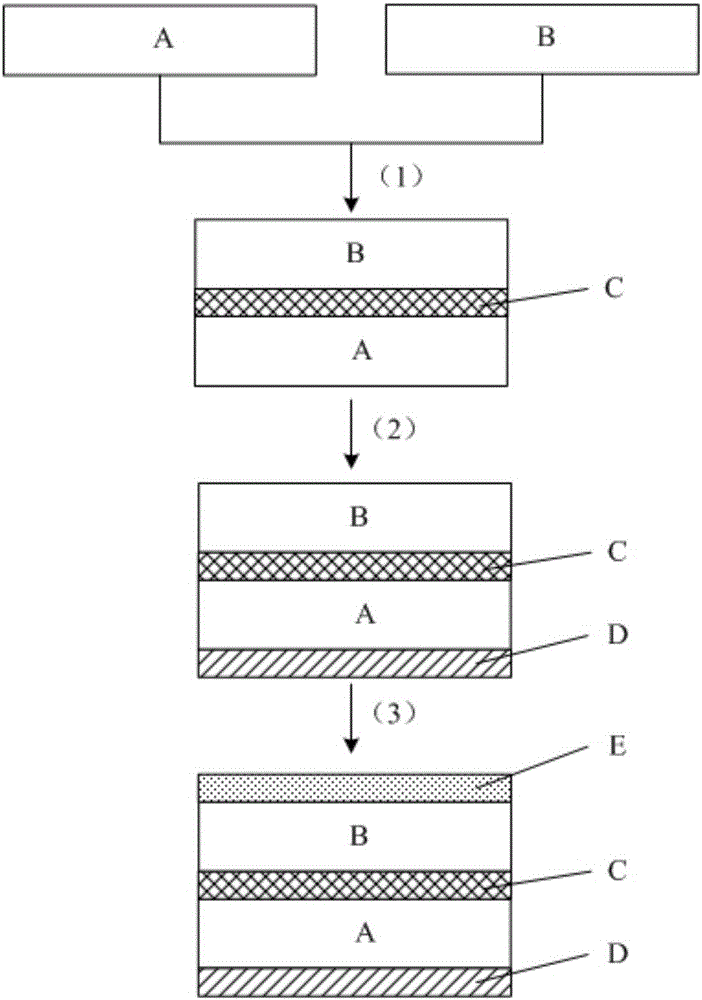

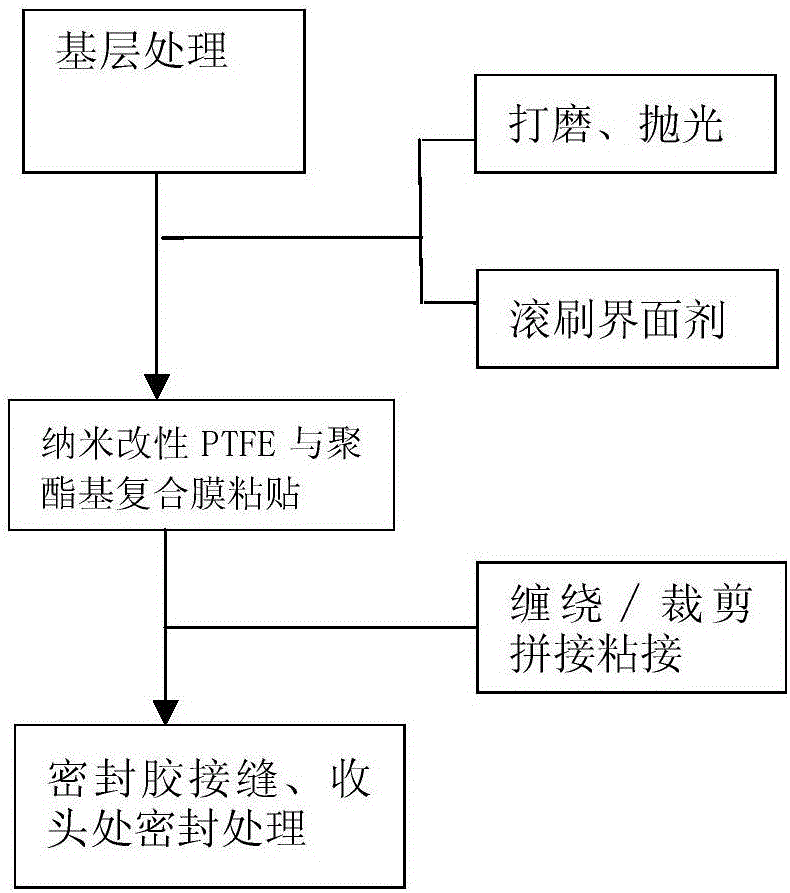

[0055] This embodiment is a preparation method of nano-modified PTFE and polyester-based composite film for preventing ice coating of fan blades. The process is as follows figure 1 shown, including the following steps:

[0056] First, spray the nanomaterial B solution on the front surface of the PTFE membrane A on the spraying hot press, dry at 90°C, and then undergo thermomechanical rolling. The mechanical rolling is roller rolling, and the line pressure is 2.0 Kg / mm. , the rolling temperature was 170 °C, and the time was 1.2 min. The nanomaterial modified PTFE membrane was prepared. The nanomaterial solution consisted of 3.0 Kg antimony-doped tin oxide nanocrystals, 3.0 Kg nano-titania, 5.0 Kg nano-silicon carbide, 2.0 Kg pentaerythritol tris-(3-aziridinyl)-propionate and 87.0 Kg AG-710, Stir well at room temperature to prepare a nanomaterial solution.

[0057] Secondly, on the hot-pressing compounding machine, under the action of the bonding compound C and hot-pressing, ...

Embodiment 2

[0061] This embodiment is a method for preparing a nano-modified PTFE and polyester-based composite film for anti-icing of fan blades. The process is as follows figure 1 shown, including the following steps:

[0062] First, on the spraying hot press, spray the nanomaterial B solution on the surface of the PTFE membrane A, dry it at 95°C, and then undergo thermomechanical rolling treatment. The mechanical rolling is roller rolling, and the line pressure is 2.5 Kg / mm , the rolling temperature is 165°C, and the time is 1.5min. A nanomaterial-modified PTFE membrane is prepared. The nanomaterial solution consists of 4.0 Kg antimony-doped tin oxide nanocrystals, 3.5 Kg nano-titanium dioxide, 4.5 Kg nano-silicon carbide, 2.5 Kg pentaerythritol tris-(3-aziridinyl)-propionate and 85.5 Kg AG-710, Stir evenly at room temperature to prepare a nanomaterial solution.

[0063] Secondly, on the hot-press laminating machine, under the action of the bonding compound agent C and hot pressing,...

Embodiment 3

[0067] This embodiment is a method for preparing a nano-modified PTFE and polyester-based composite film for anti-icing of fan blades. The process is as follows figure 1 shown, including the following steps:

[0068] First, on the spraying hot press, spray the nanomaterial B solution on the front of the PTFE membrane A surface, dry it at 100°C, and then undergo thermomechanical rolling treatment. The mechanical rolling is roller rolling, and the line pressure is 2.5 Kg / mm , the rolling temperature is 180°C, and the time is 1.0min. A nanomaterial-modified PTFE membrane is prepared. The nanomaterial solution consisted of 3.5 Kg antimony-doped tin oxide nanocrystals, 3.5 Kg nano-titanium dioxide, 4.0 Kg nano-silicon carbide, 2.2 Kg pentaerythritol tris-(3-aziridinyl)-propionate and 86.8 Kg AG-710, Stir evenly at room temperature to prepare a nanomaterial solution.

[0069] Secondly, on the hot-press laminating machine, under the action of the bonding compound agent C and hot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com