Polyurethane material with protein adsorption resistance and cell adhesion resistance and preparing method thereof

A polyurethane material, anti-protein adsorption technology, applied in catheters and other directions, can solve the problem of incomplete elucidation of protein adsorption, and achieve the effects of good anti-cell adhesion function, easy control, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

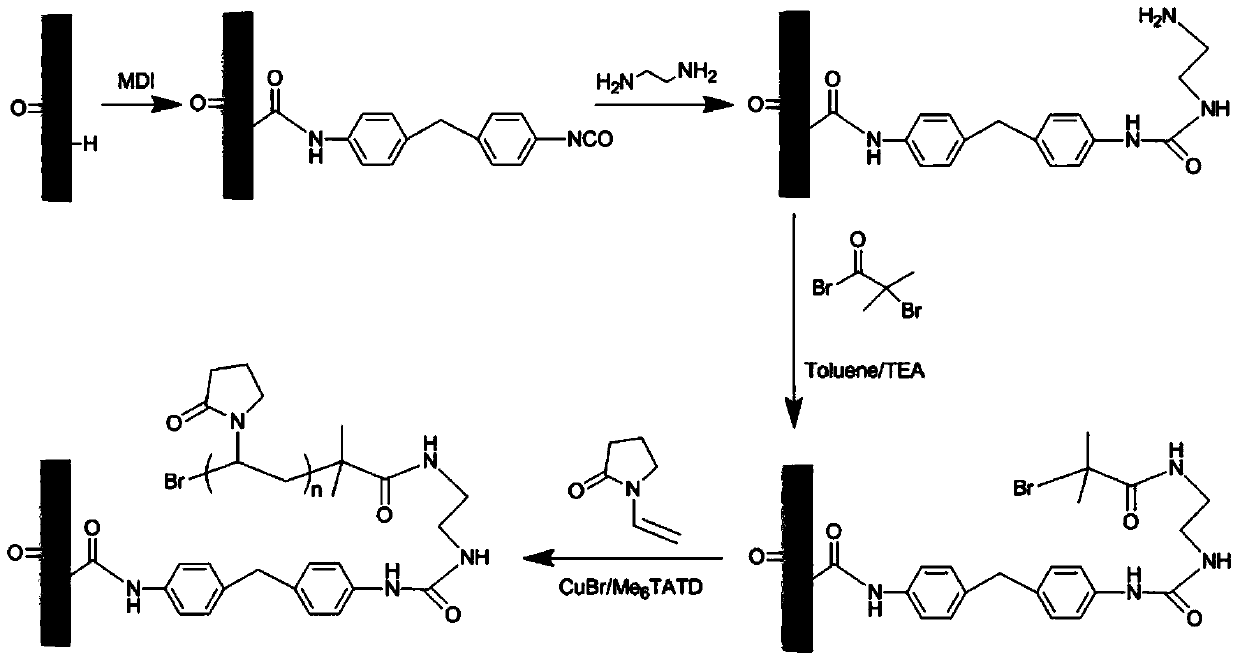

[0033] Preparation of polyurethane material with anti-protein adsorption and anti-cell adhesion functions

[0034] Preparation of Polyurethane (PU) Diaphragm

[0035] The preparation method of the PU film is as follows: a certain amount of Pellethane2363-80AE (product of Lubrizol company) is dissolved in N,N-dimethylacetamide (DMAc), stirred to make it evenly mixed, and made into 5% (W / V) PU solution. After stirring and dissolving completely, pour it into a glass mold, vacuumize to remove the air bubbles in the solution, then adjust the temperature to 65°C and dry for 48 hours. After the solvent is completely volatilized, the PU film is obtained, and a small PU circular diaphragm with a diameter of 6.0 mm is made with a puncher. Clean with deionized water and ethanol ultrasonically in turn, dry in vacuum and store in a desiccator for later use.

[0036] Preparation of PU-NCO membrane surface

[0037] Add the PU diaphragm to 200mL of 7.5% by mass percent of 4,4'-diphenylmet...

Embodiment 2

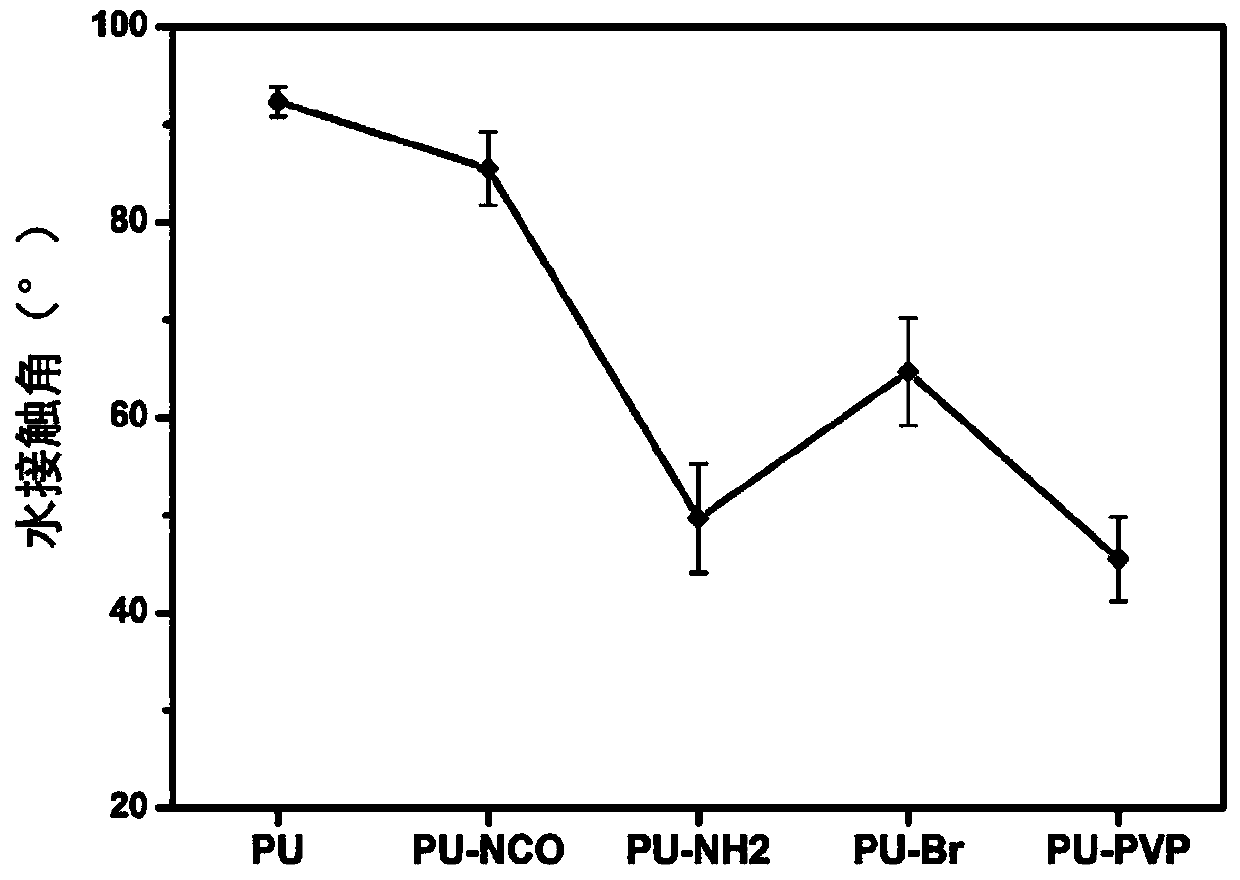

[0045] Measurement of water contact angle of polyurethane materials with anti-protein adsorption and anti-cell adhesion functions

[0046] A contact angle measuring instrument was used to test the hydrophilic change of the surface of the PU membrane at various stages of modification. The instrument used was a JC2000D water contact angle measuring instrument, and the results were obtained by using the angle measurement method. The specific operation of the water contact angle test is to fix the polyurethane film to be tested on the glass slide (the polyurethane film to be tested is the polyurethane material with anti-protein adsorption and anti-cell adhesion functions obtained in Example 1), and then drop Put 2 μL of deionized water on the membrane, and measure the left and right angles between the membrane and the water droplet after being stabilized for 10 seconds, and record them. The test results of samples in each stage are the mean and standard deviation of five parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com