Thermoelectric material

A technology of thermoelectric materials and cubic crystals, applied in the direction of thermoelectric device lead-out wire materials, copper compounds, inorganic chemistry, etc., can solve the problems of unsuitable thermoelectric materials and low ZT value, and achieve stable thermoelectric conversion performance and excellent thermoelectric conversion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

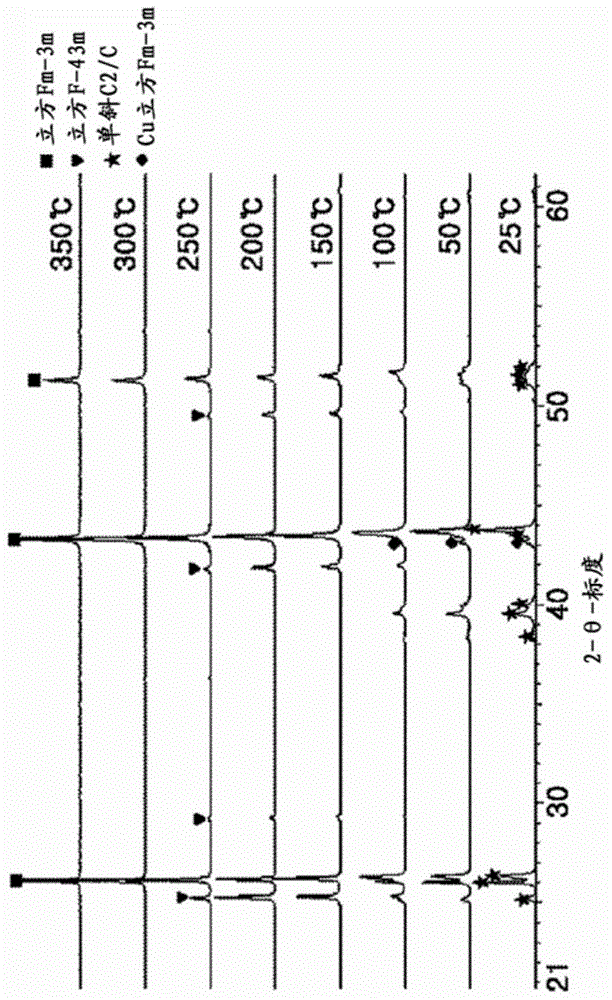

Method used

Image

Examples

Embodiment 1

[0129] Based on the chemical formula Cu 2.01 Se Cu and Se in powder form were weighed and placed in an alumina mortar followed by mixing. The mixed materials were placed in a die to form a pellet which was placed in a fused silica tube and vacuum sealed. Furthermore, the product was placed in a box furnace and heated at 500° C. for 15 hours, and after heating, the product was slowly cooled to room temperature to obtain a compound.

[0130] In addition, the Cu 2.01 A Se compound was filled in a die for hot pressing, and hot pressing sintering was performed under vacuum at 650° C. to obtain a sample of Example 1. In this case, the sintered density is at least 98% of theoretical.

Embodiment 2

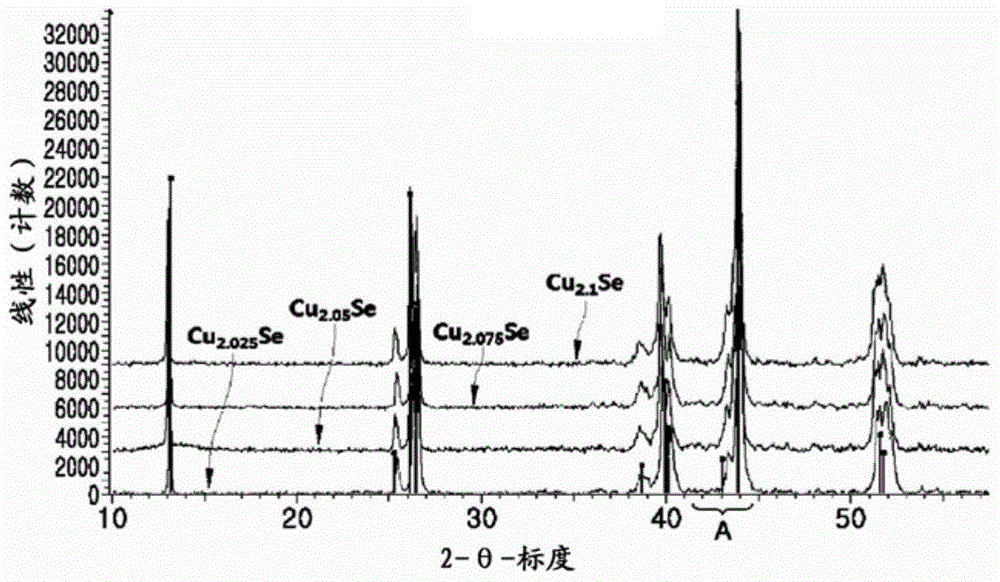

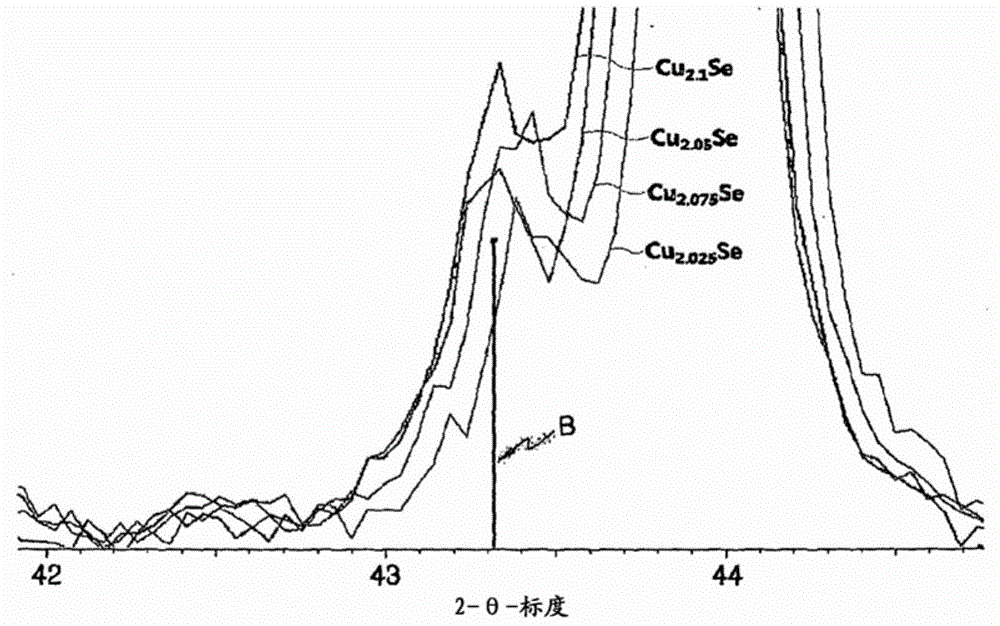

[0132] Based on the chemical formula Cu 2.025 Se Weighed Cu and Se in powder form, mixed and synthesized by the same procedure as in Example 1 to obtain a compound. Furthermore, this compound was sintered by the same procedure as in Example 1 to obtain a sample of Example 2.

Embodiment 3

[0134] Based on the chemical formula Cu 2.05 Se Weighed Cu and Se in powder form, mixed and synthesized by the same procedure as in Example 1 to obtain a compound. In addition, the compound was sintered by the same procedure as in Example 1 to obtain a sample of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com