Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "High Seebeck coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

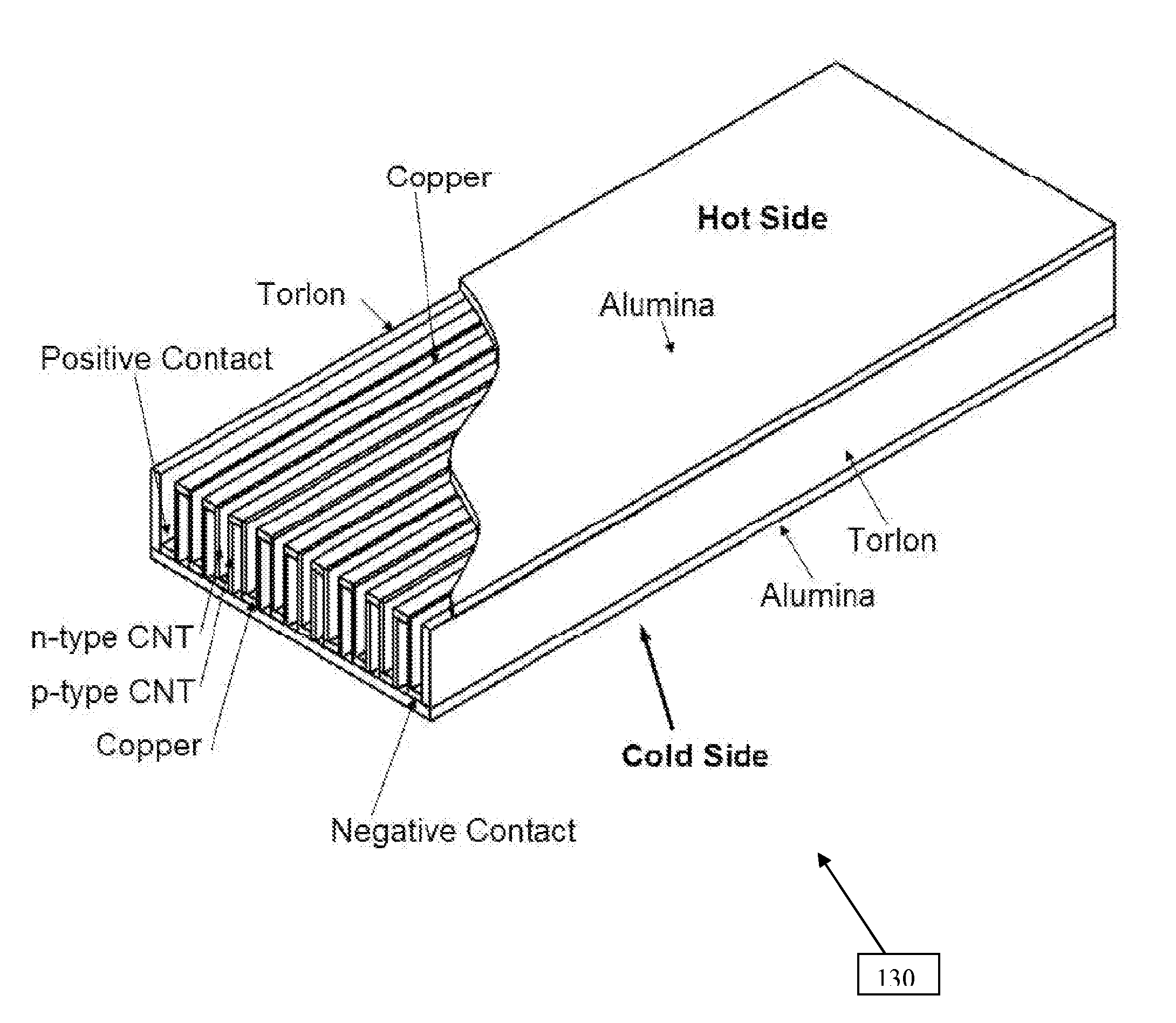

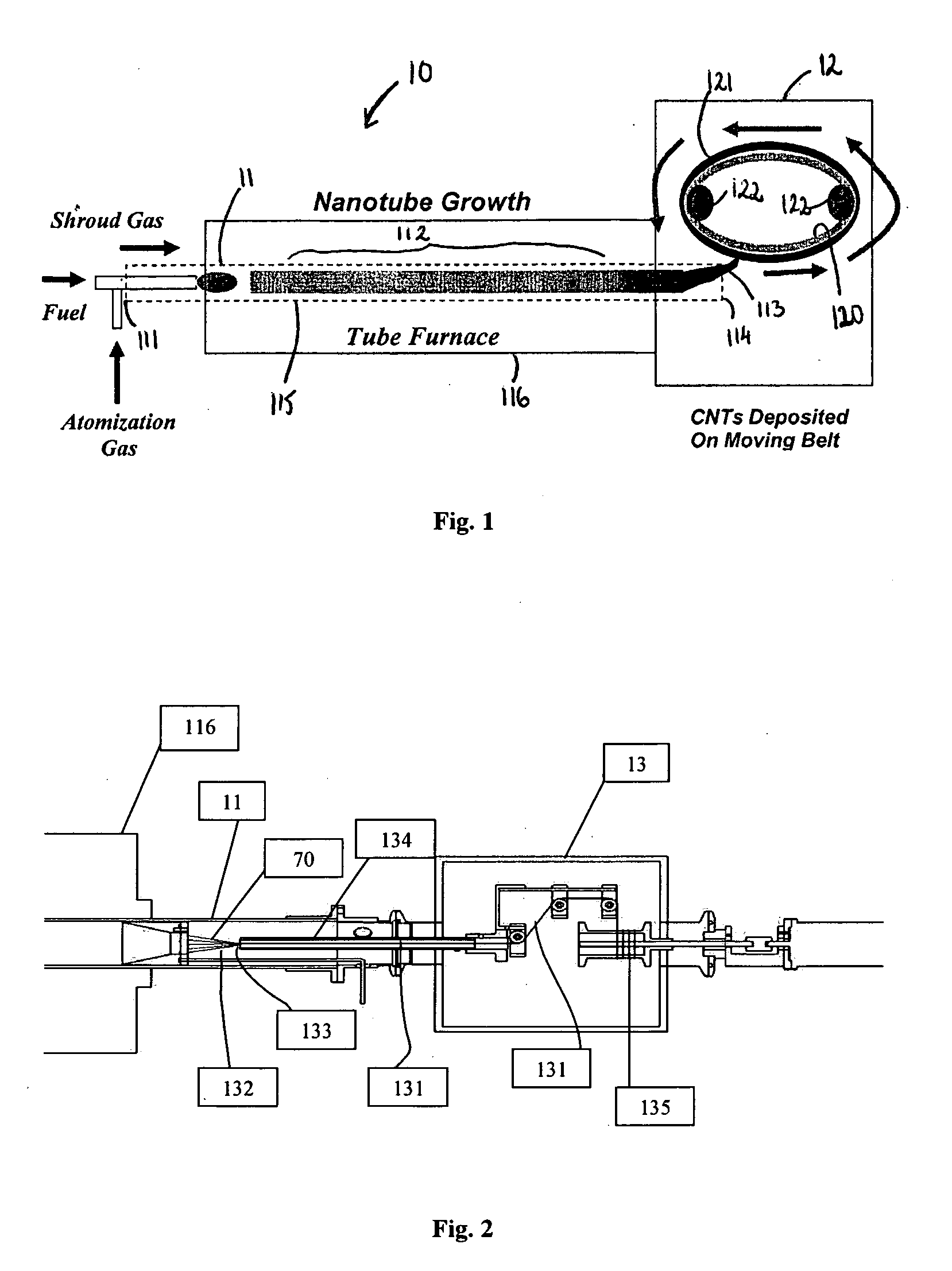

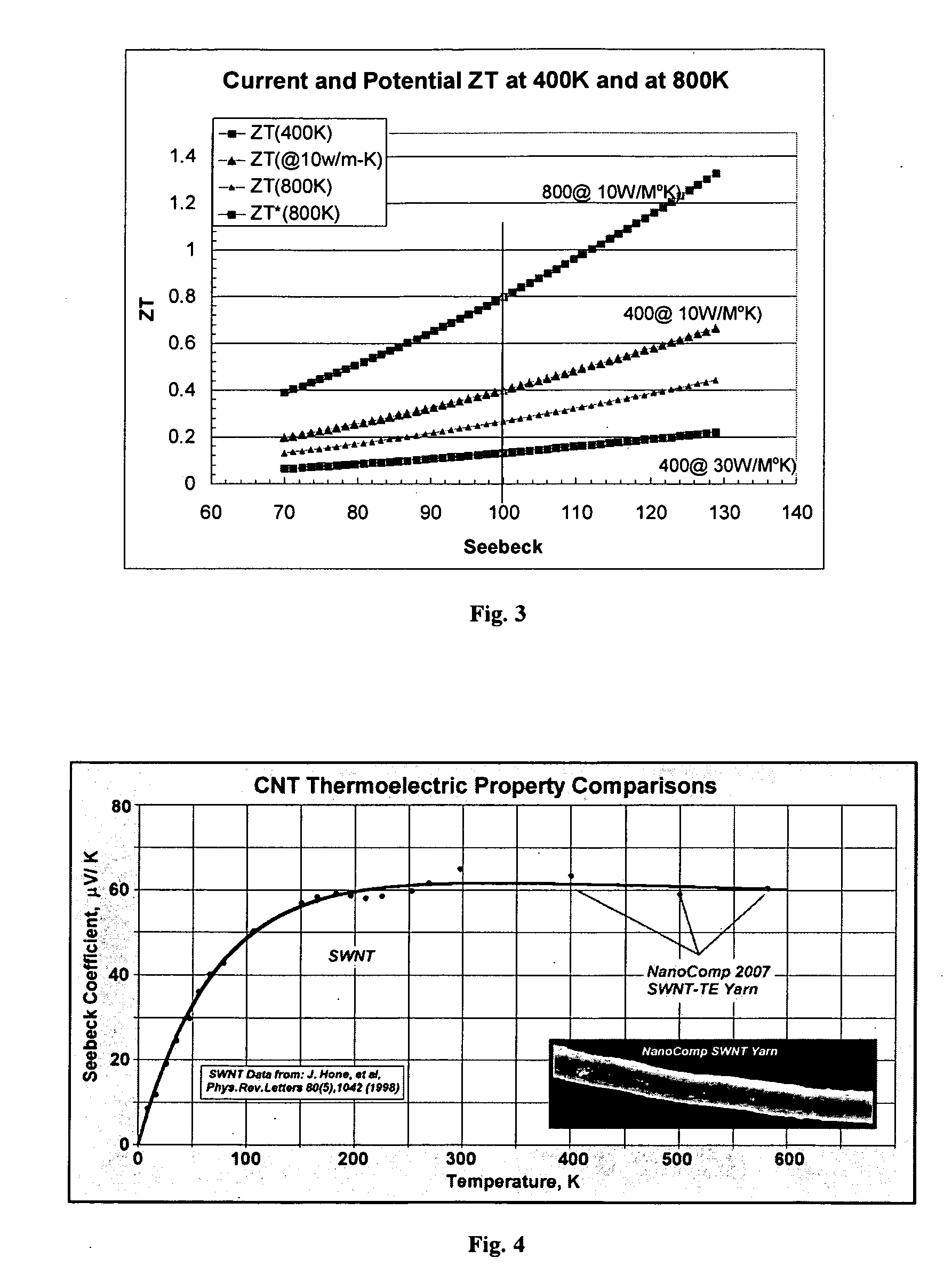

Nanostructured Material-Based Thermoelectric Generators

InactiveUS20090044848A1Improvement factorRaise the transition temperatureAuxillary drivesFrom solar energyCarbon nanotubeEngineering

A thermoelectric device that can exhibit substantially high specific power density is provided. The device includes core having a p-type element made from carbon nanotube and an n-type element. The device also includes a heat plate in and a cool plate, between which the core can be positioned. The design of the thermoelectric device allows the device to operate at substantially high temperature and to generate substantially high power output, despite being light weight. A method for making the thermoelectric device is also provided.

Owner:NANCOMP TECHNOLOGIES INC

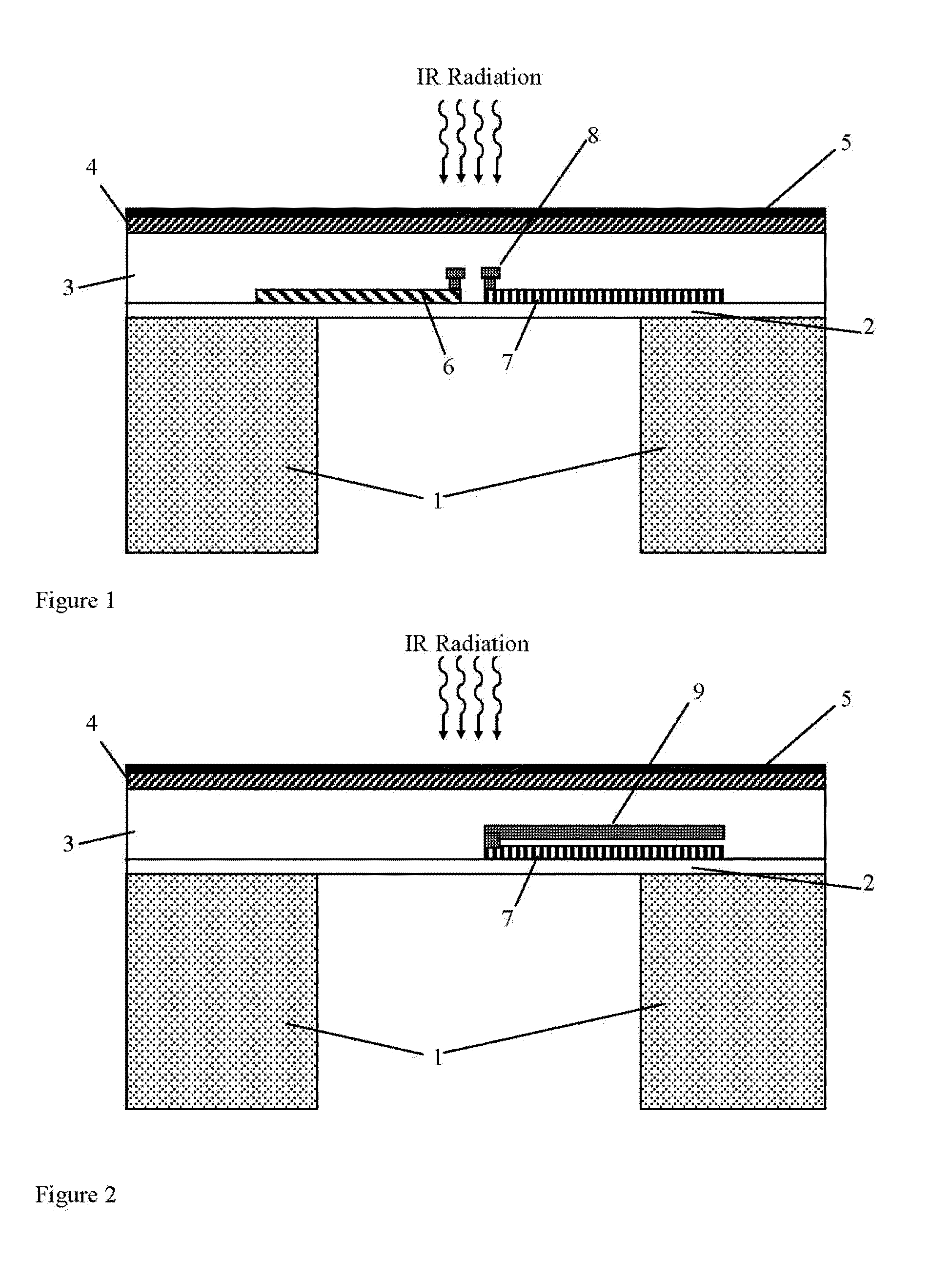

IR detector

ActiveUS8552380B1Improve performanceHigh emissivitySolid-state devicesMaterial analysis by optical meansDielectric membraneThermopile

An IR detector in the form of a thermopile including one or more thermocouples on a dielectric membrane supported by a silicon substrate. Each thermocouple is composed of two materials, at least one of which is p-doped or n-doped single crystal silicon. The device is formed in an SOI process. The device is advantageous as the use of single crystal silicon reduces the noise in the output signal, allows higher reproducibility of the geometrical and physical properties of the layer and in addition, the use of an SOI process allows a temperature sensor, as well as circuitry to be fabricated on the same chip. The detector can also have an IR filter wafer bonded onto it and / or have arrays of thermopiles to increase the sensitivity. The devices can also be integrated with an IR source on the same silicon chip and packaged to form a complete and miniaturised NDIR sensor.

Owner:AMS SENSORS UK LTD

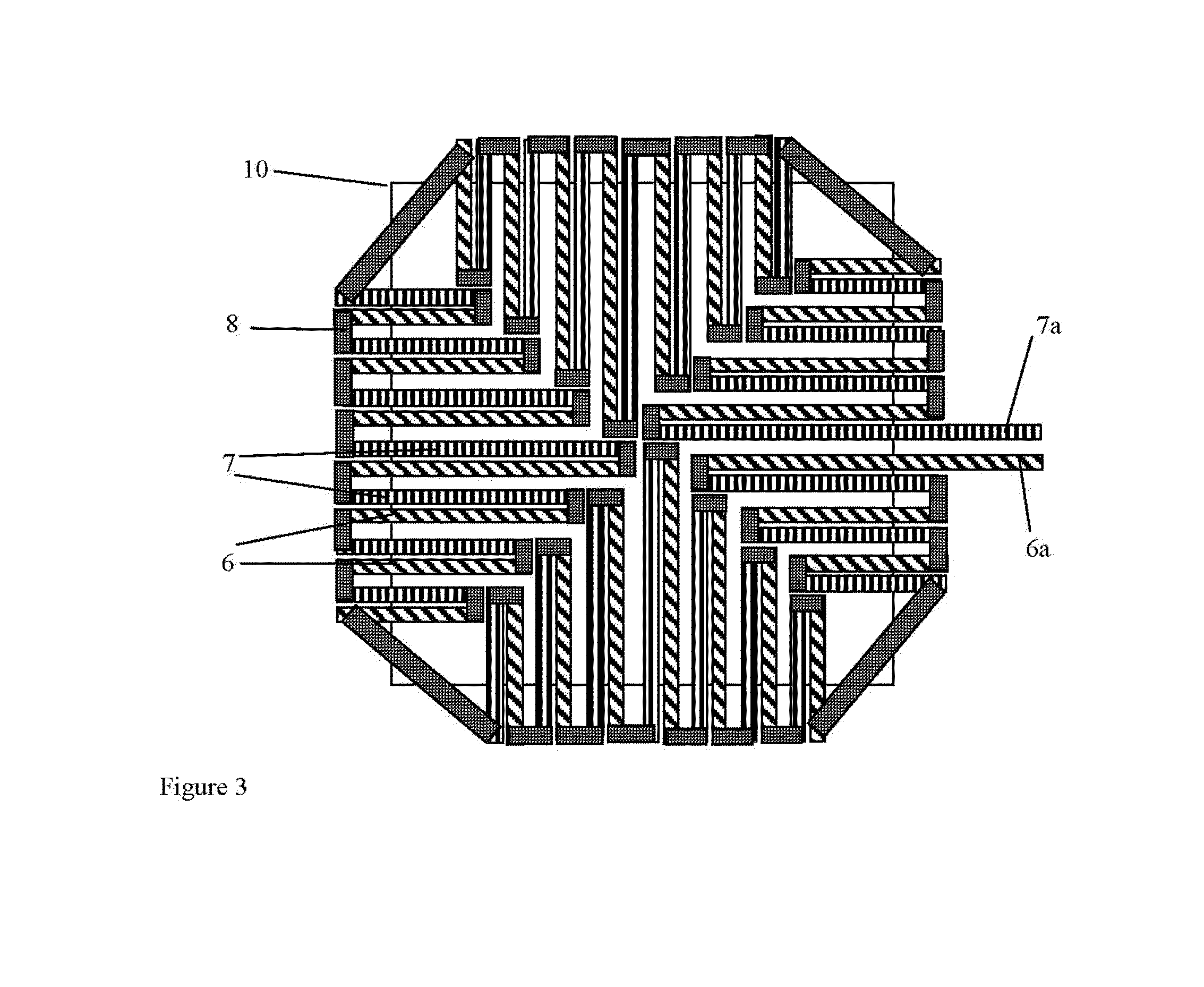

Nano-complex thermoelectric material, and thermoelectric module and thermoelectric apparatus including the same

ActiveUS20130269739A1High Seebeck coefficientImprove conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsWork function

A thermoelectric material including: a thermoelectric matrix; and a plurality of metal nanoparticles disposed in the thermoelectric matrix, wherein a difference between a work function of thermoelectric matrix and a work function of a metal particle of the metal nanoparticles is about −1.0 electron volt to about 1.0 electron volt.

Owner:SAMSUNG ELECTRONICS CO LTD

Graphene quantum dot/carbon nanotube/PEDOT:PSS composite film and preparation method thereof

The invention discloses a graphene quantum dot / carbon nanotube / PEDOT:PSS composite film and a preparation method thereof. The preparation method includes blending graphene quantum dots and carbon nanotubes in water sufficiently to form a graphene quantum dot / carbon nanotube hybrid, and dispersing the hybrid to an electroconductive polymer PEDOT:PSS to form the graphene quantum dot / carbon nanotube / PEDOT:PSS composite film. The graphene quantum dot / carbon nanotube / PEDOT:PSS composite film and the preparation method thereof have the advantages that both the graphene quantum dots and the carbon nanotubes structurally comprise large delocalized pi-bonds, a graphene quantum dot layer is modified on the wall of each of the carbon nanotubes through pi-pi conjugation, and accordingly excellent water solubility is achieved; the graphene quantum dot / carbon nanotube hybrid is evenly dispersed into a PEDOT:PSS water solution through uniform dispersity of the graphene quantum dots and the PEDOT:PSS in water, and the graphene quantum dots, the carbon nanotubes and PEDOT:PSS are combined together uniformly and effectively with the aid of pi-pi interaction between the graphene quantum dots and PEDOT, so that the graphene quantum dot / carbon nanotube / PEDOT:PSS composite film is formed. The graphene quantum dot / carbon nanotube / PEDOT:PSS composite film is excellent in electroconductivity, high in Seebeck coefficient and low in heat conduction coefficient.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

High efficiency thermoelectric materials based on metal/semiconductor nanocomposites

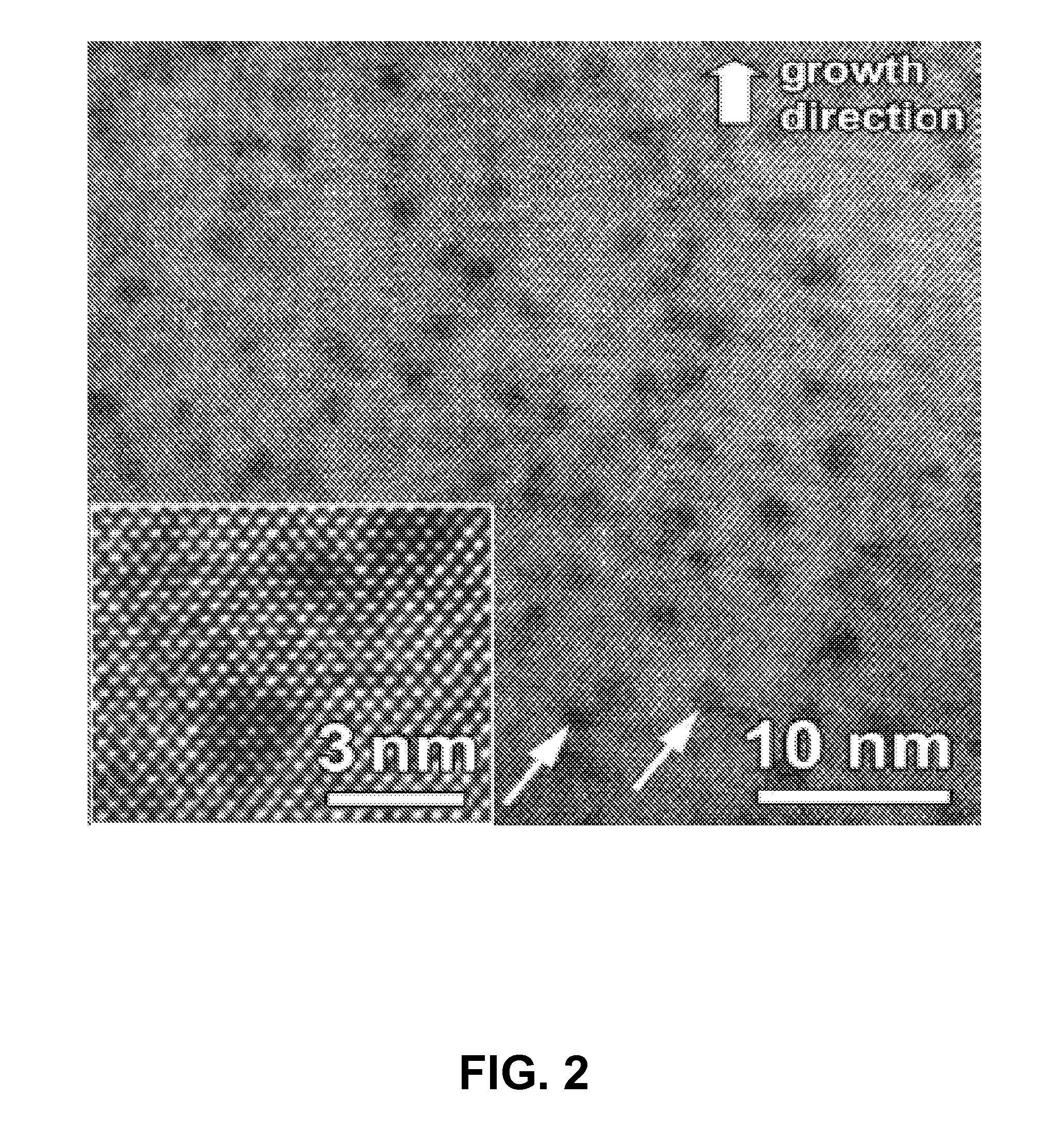

ActiveUS20080001127A1Improve conductivityLarge coefficientConductive materialSemiconductor/solid-state device manufacturingThermoelectric materialsAlloy

Composite epitaxial materials that comprise semimetallic ErAs nanoparticles or nanoislands epitaxially embedded in a semiconducting In0.53Ga0.47As matrix both as superlattices and randomly distributed throughout the matrix are disclosed. The presence of these particles increases the free electron concentration in the material while providing scattering centers for phonons. Electron concentration, mobility, and Seebeck coefficient of these materials are discussed and their potential for use in thermoelectric power generators is postulated. These composite materials in accordance with the present invention have high electrical conductivity, low thermal conductivity, and a high Seebeck coefficient. The ErAs nanoislands provides additional scattering mechanism for the mid to long wavelength phonon—the combination reduces the thermal conductivity below the alloy limit.

Owner:RGT UNIV OF CALIFORNIA

Method of manufacturing thermoelectric conversion material

InactiveUS20150380624A1High Seebeck coefficientImprove reliabilityElectric furnaceThermoelectric device junction materialsAlloyThermoelectric conversion

A method of manufacturing a thermoelectric conversion material expressed by a chemical formula X3T3Z4 (X comprises one or more elements selected from Zr, Hf, Y, La, Nb, and Ta, while including at least Zr or Hf; T comprises one or more elements selected from Ni, Co, Cu, Rh, Pd, Ir, and Pt, while including at least Ni; Z comprises one or more elements selected from Sb, Ge, and Sn, while including at least Sb), the method comprising: preparing materials containing elements, which are the X including selected elements, the T including selected elements, and the Z including selected elements; forming an alloy A by melting the materials containing the all selected elements except for Sb; and forming an alloy B by melting the alloy A and the material containing Sb.

Owner:PANASONIC CORP

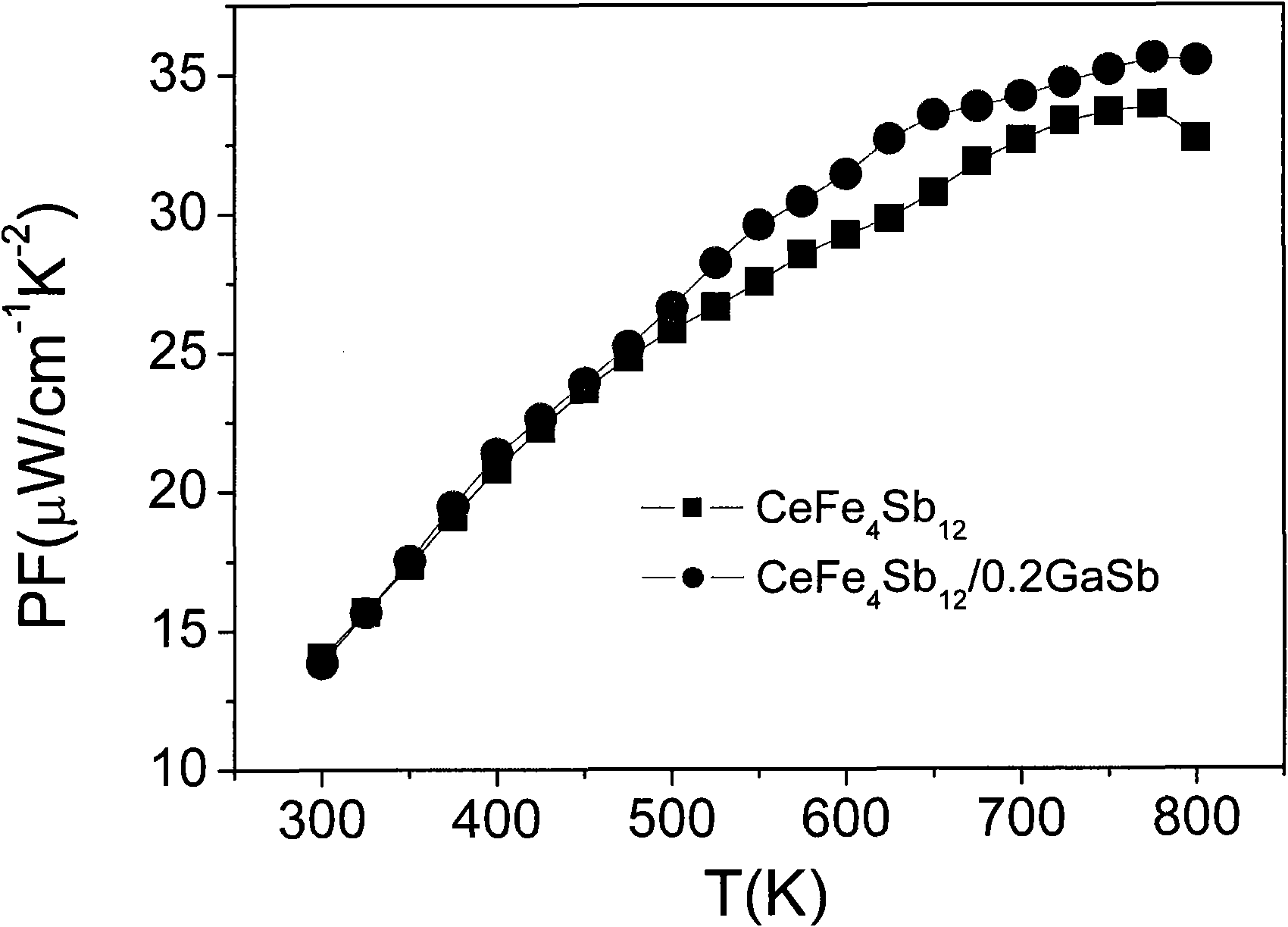

Hole compensation type skutterudite thermoelectric material and preparation method therefore

ActiveCN102881814AIncrease filling volumeHigh conductanceIron compoundsCobalt compoundsSkutteruditeElectron number

The invention relates to a hole compensation type skutterrudite thermoelectric material and a preparation method of the hole compensation type skutterudite thermoelectric material. The hole compensation type skutterudite thermoelectric material is shown in the following description: RyA(4-x)BxSb12 / z NC, wherein x is equal to or greater than 0.01 and equal to or less than 0.5, y is equal to or greater than 0.01 and equal to or less than 1 and z is equal to or greater than 0% and equal to or less than 10%; R is selected from at least one of the following group of elements: Ca, Ba, La, Ce, Pr, Nd and Yb; A is selected from at least one of the following group of elements: Fe, Co and Ni; B is selected from at least one of the following group of transition metal elements: Ti, V, Cr, Mn, Fe, Nb, Mo, Tc and Ru, and electron number of the element B is less than that of the element A; and NC is in phase II, wherein z is mole% in the phase II of the thermoelectric material. The invention also provides the preparation method of the hole compensation type skutterrudite thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Method for preparing silver antimony tellurium and silver telluride based on-site composite thermoelectric material

InactiveCN101532097ALow thermal conductivityImprove thermoelectric performanceThermoelectric device manufacture/treatmentChemical compositionAntimony

The invention discloses a method for preparing silver antimony tellurium and silver telluride based on-site composite thermoelectric material, including the steps: weighing silver, antimony and tellurium according to the formula: Agx Sb2-xTe3-x, wherein x being 086 to 0.95, enveloping the same in a vacuum quartz tube, heating to 1000 to 1100 DEG C for fully fusing, keeping for 600 to 1000 minutes, cooling at the speed of 1 DEG C per minute to 900 DEG C, placing the quartz tube into the liquid nitrogen for quenching, obtaining the castingsolid material, ball milling and crushing, obtaining the block thermoelectric alloy. The invention has simple process, lower cost, short period and adaptability for mass productuion, the prepared block silver antimony tellurium and silver telluride based on-site composite thermoelectric material has lower thermal conductivity and higher Seebeck coefficient, thus obtaining higher room-temperature thermoelectricalmerit.

Owner:ZHEJIANG UNIV

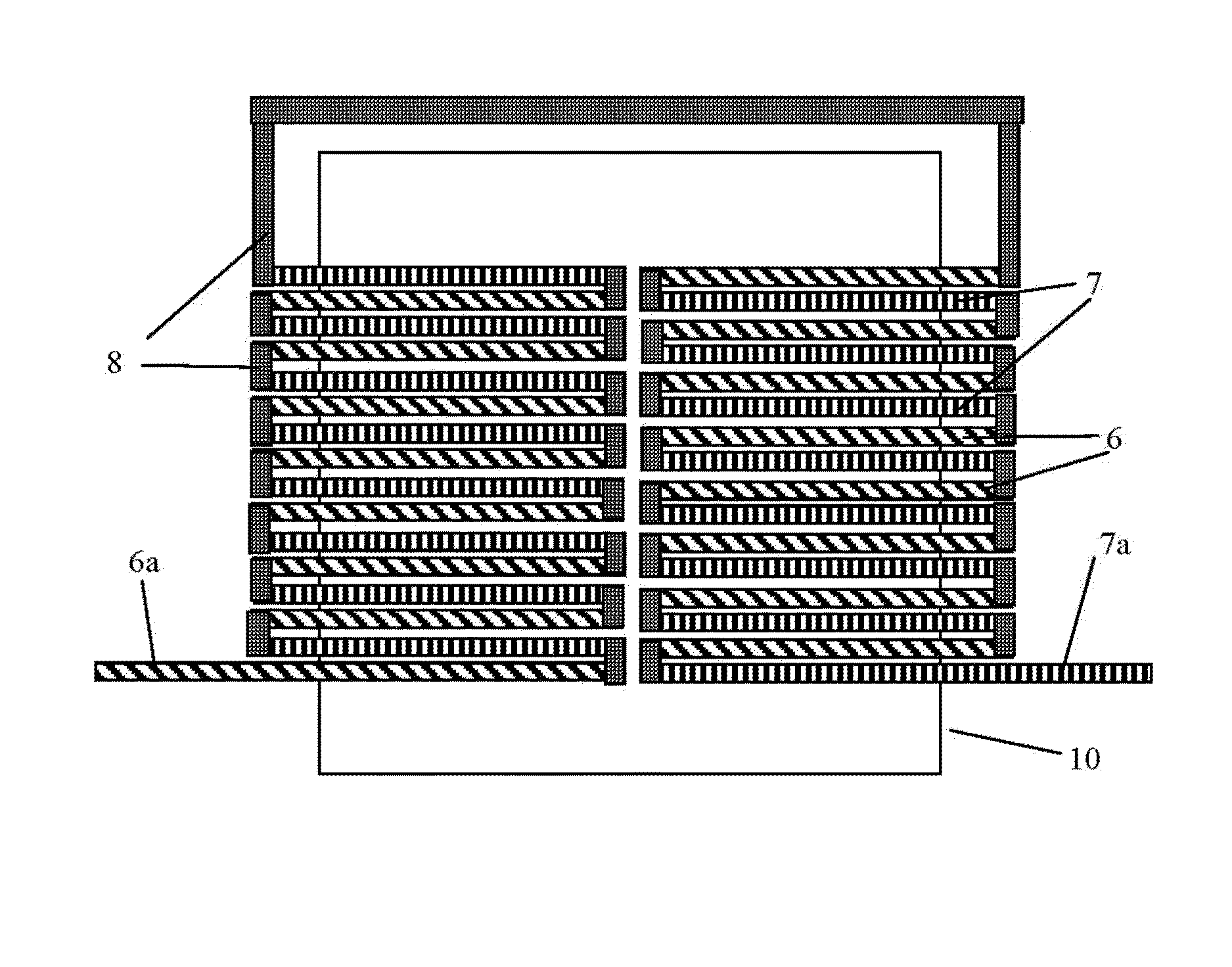

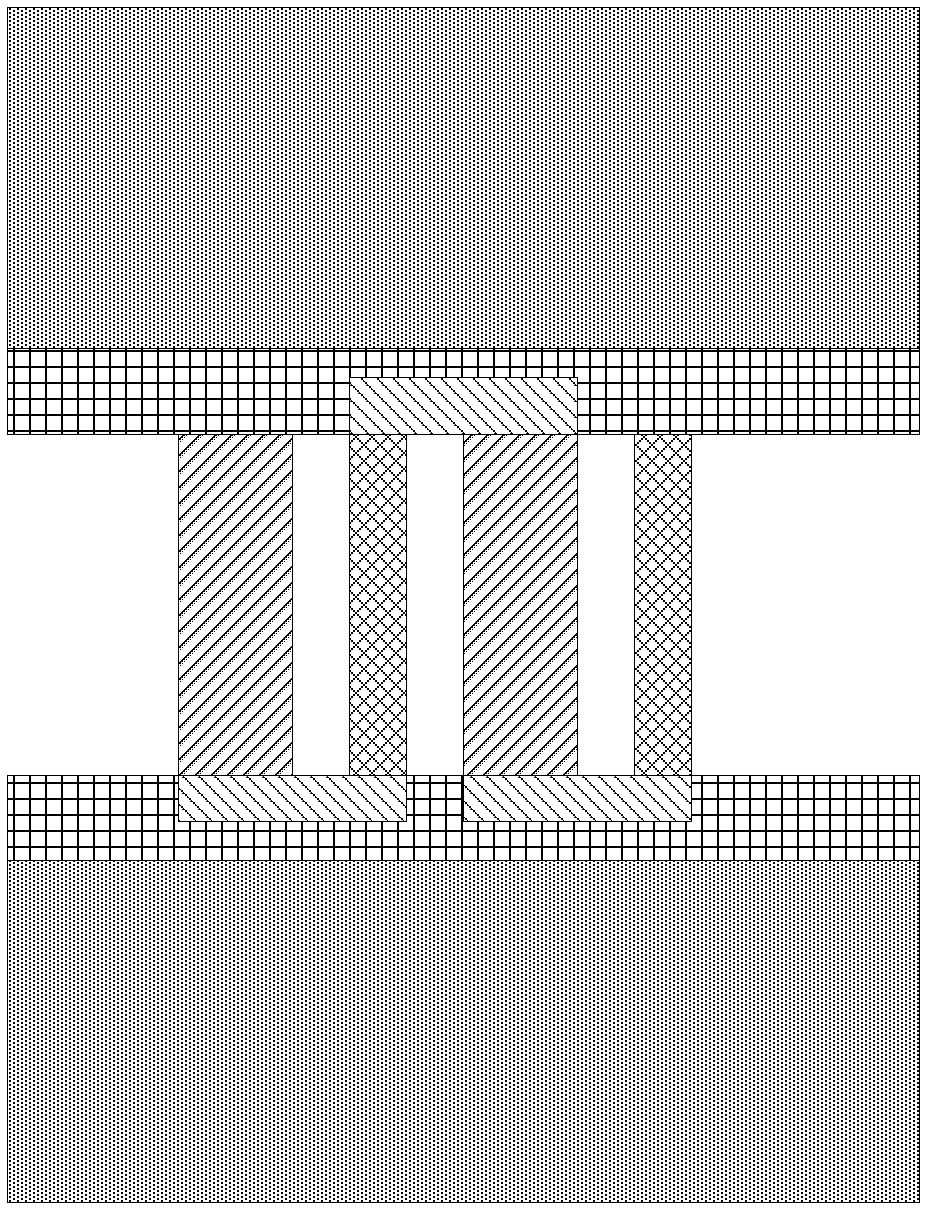

Three-dimensional thermoelectricity energy collector and manufacturing method thereof

InactiveCN103296190ASimple manufacturing processHigh Seebeck coefficientThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentInsulation layerManufacturing technology

The invention provides a three-dimensional thermoelectricity energy collector and a manufacturing method thereof. A plurality of grooves and silicon columns among the grooves are formed on low-resistance silicon in an etching mode, then an insulation layer is formed on the surfaces of the grooves, a thermoelectricity column is manufactured through a thin film deposition technology, a thermocouple pair is formed by the thermoelectricity column and adjacent silicon columns, a metal arranged wire is manufactured through technologies such as etching deposition, and manufacturing of the three-dimensional thermoelectricity energy collector is completed through technologies such as substrate thinning and substrate supporting in a bonding mode. According to the three-dimensional thermoelectricity energy collector and the manufacturing method thereof, a thermocouple pair structure is manufactured only through the one-time thin film deposition technology, and the manufacturing technology is simplified. Silicon is selected as a component of the thermocouple pair, and the fact that the thermocouple pair has the high Seebeck coefficient is guaranteed. The thermocouple pair of the vertical column-shaped structure is used, mechanical stability of the thermoelectricity energy collector is improved, the thermocouple structure, an upper supporting substrate and a lower supporting substrate are bound by wafer level binding, and accordingly manufacturing efficiency is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

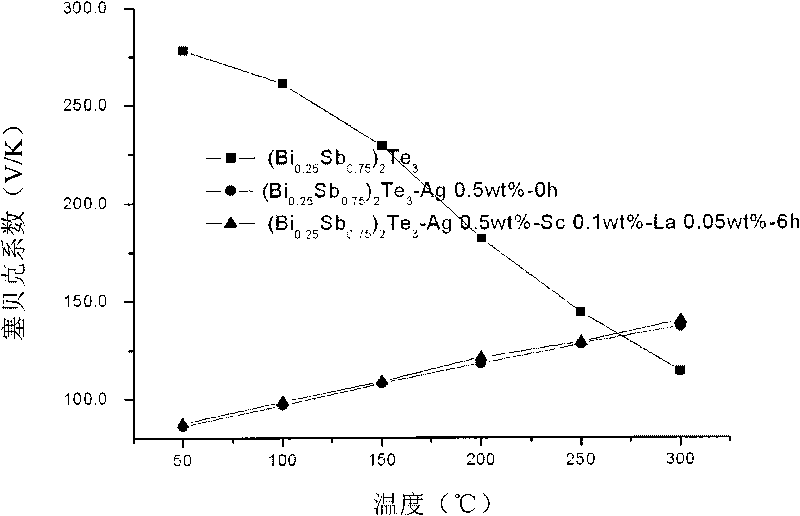

Thermoelectric materials

InactiveCN101740713ALow thermal diffusivityHigh Seebeck coefficientThermoelectric device junction materialsLow noiseMetallurgy

Disclosed herein is a thermoelectric material for intermediate- and low-temperature applications, in which any one or a mixture of two or more selected from among La, Sc and MM is added to a Ag-containing metallic thermoelectric material or semiconductor thermoelectric material. The thermoelectric material has a low thermal diffusivity, a high Seebeck coefficient, a low specific resistivity, a high power factor and a low thermal conductivity, and thus has a high dimensionless figure of merit, thus showing very excellent thermoelectric properties. The thermoelectric material provide thermoelectric sensors having high sensitivity and low noise and, in addition, is widely used as a thermoelectric material for intermediate- and low-temperature applications, because it shows excellent thermoelectric performance in the intermediate- and low-temperature range.

Owner:KOREA ELECTROTECH RES INST

P-type skutterudite material and preparation method thereof

ActiveCN102373348AIncreased maximum theoretical conversion efficiencyHigh thermoelectric figure of meritThermoelectric device manufacture/treatmentThermoelectric device junction materialsSkutteruditeChemistry

The invention relates to a p-type skutterudite material and a preparation method thereof. The invention provides the p-type skutterudite material which has a chemical formula as represented by IyFe4-xMxSb12 / z(phi), wherein, I is one kind or more kinds of filling atoms in a skutterudite phase, the filling amount y of the filling atoms is no less than 0.01 and no more than 1, M is one kind or more kinds of dopant atoms, the dopant amount x of the dopant atoms is no less than 0 and less than 4, phi is one kind or more kinds of second phases, the molar ratio z of phi is no less than 0 and no morethan 0.5, and second phase sediment disperses in the skutterudite phase. The invention also provides the preparation method for the p-type skutterudite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

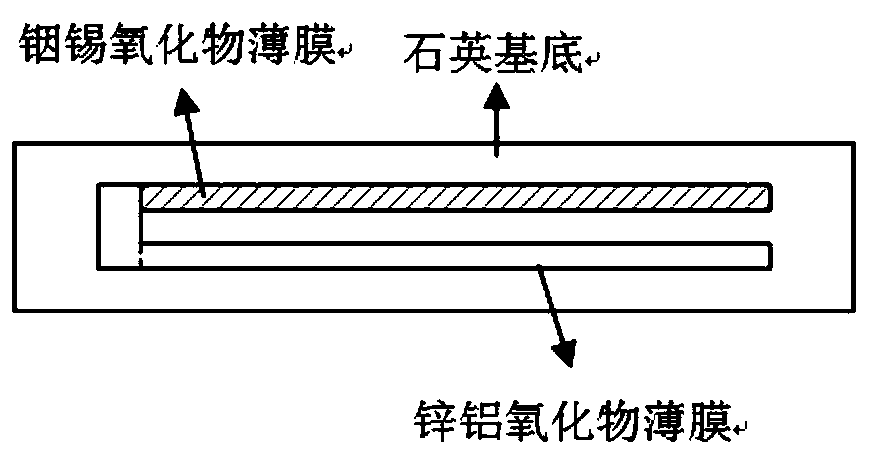

Application of preferred indium tin oxide with (400) crystal plane on transparent thin-film thermocouple

InactiveCN110004410AHigh Seebeck coefficientEasy to makeThermometers using electric/magnetic elementsVacuum evaporation coatingThin film thermocouplesSputtering

The invention relates to the application of a preferred indium tin oxide with a (400) crystal plane on a transparent thin-film thermocouple, and belongs to the technical field of thin-film thermocouples. A preferred body-centered cubic ferromanganese ore phase polycrystalline indium tin oxide with the (400) crystal plane is made into a pole of the transparent thin-film thermocouple by magnetron sputtering; and the power density of magnetron sputtering is 4.8-8.0W / cm<2>. The indium tin oxide transparent thin-film thermocouple has a relatively high Seebeck coefficient by controlling the preferred orientation of the indium tin oxide thin-film obtained by magnetron sputtering.

Owner:DALIAN JIAOTONG UNIVERSITY

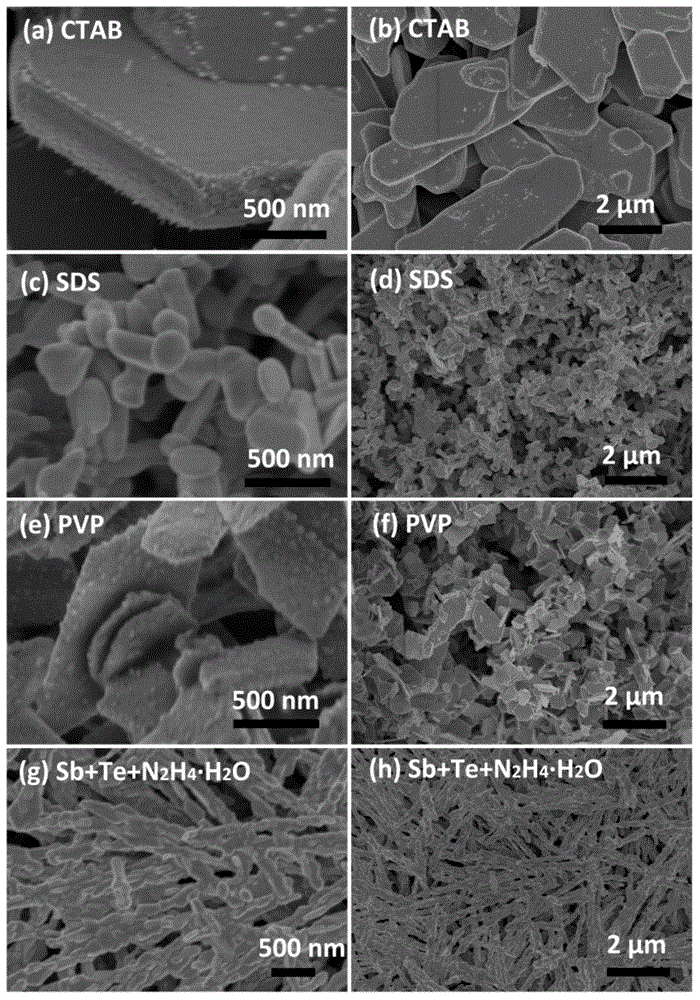

Method for preparing high thermoelectrical antimony telluride micro-nano crystal and block material thereof

InactiveCN104310320AEfficient removalPrevent oxidationMaterial nanotechnologyMetal selenides/telluridesMicro nanoPolyol

The invention discloses a method for preparing a high thermoelectrical antimony telluride micro-nano crystal and a block material thereof. The method comprises the following steps: dissolving an antimony precursor into polyol, then mixing the obtained solution with a tellurium precursor and a complexing agent, heating the mixed solution at a temperature of 140 to 180 under stirring, cooling to a temperature of 100 to 120 DEG C, adding a reducing agent, carrying out reactions at a temperature of 120 to 180 DEG C for 6 to 48 hours so as to obtain precipitate, washing the obtained precipitate by waterless ethanol until the washing liquid is neutral, drying the washed precipitate in vacuum so as to obtain antimony telluride micro-nano crystal, cold-pressing the obtained antimony telluride crystal into a sheet, and then carrying out annealing for 2 to 24 hours at a temperature of 300 to 400 DEG C in an atmosphere of mixed gas composed of Ar and H2 with a volume ratio of 92%:8% so as to obtain an antimony telluride block material. The obtained antimony telluride micro-nano crystal and block material thereof have the characteristics of high purity and good thermoelectrical property. Moreover the preparation method has the advantages of simpleness, low cost, easiness in repeating, and suitability for massive production, and thus has a good commercialization prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

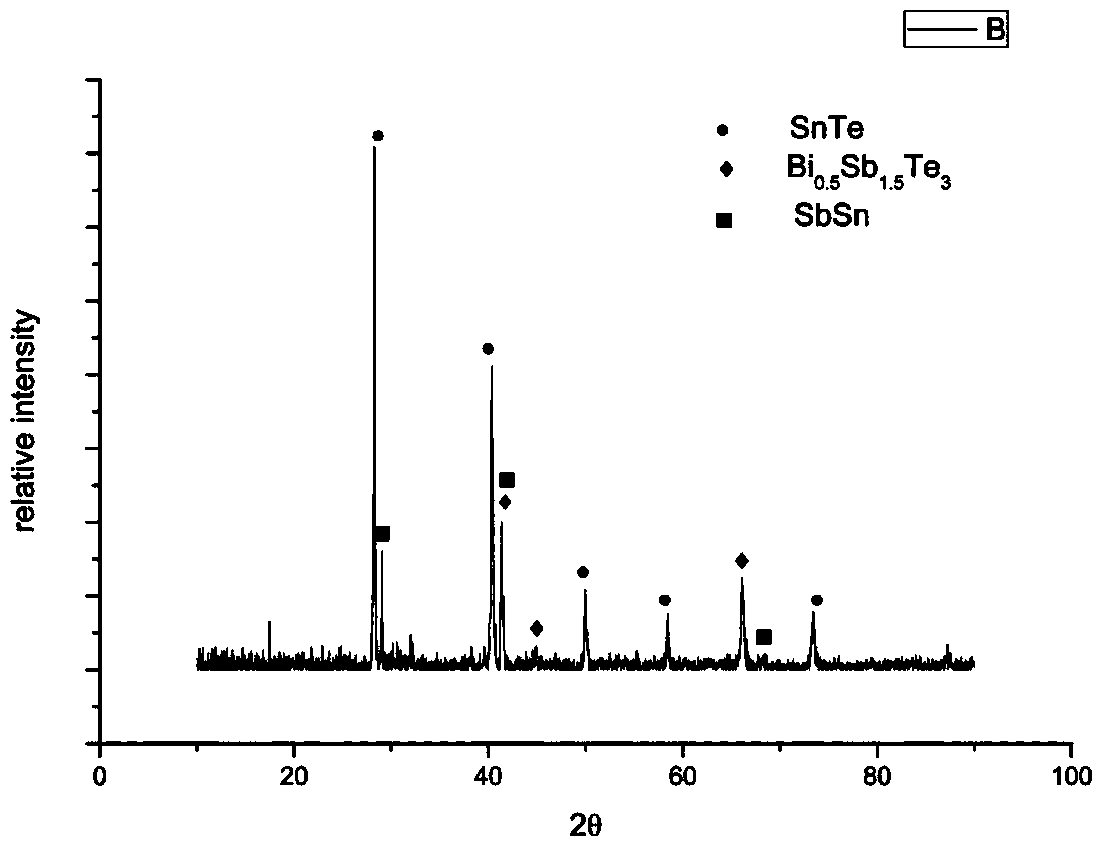

Preparation method for p-type Bi0.5Sb1.5Te3-based nano-porous thermoelectric composite material

ActiveCN104078557AHigh Seebeck coefficientLow thermal conductivityMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsReaction temperature

The invention provides a preparation method for a p-type Bi0.5Sb1.5Te3-based nano-porous thermoelectric composite material. The method includes the steps that 3-5-micrometer Sn welding paste is spread on a p-type thermoelectric material Bi0.5Sb1.5Te3, the p-type thermoelectric material Bi0.5Sb1.5Te3 is placed on a heating table, a liquid phase wetting reaction is conducted in the Ar gas protection atmosphere at the temperature being 260 DEG C, and a uniform mixing layer of the Sn welding paste and a resultant SnTe-SbSn is formed, wherein tin oxidation is avoided due to the fact that the reaction is conducted in the Ar gas atmosphere, and the thickness and the micro-structure of the resultant SnTe-SbSn generated due to the reaction of the mixing layer can be controlled through reaction time and reaction temperature; ultrasonic concussion and acid pickling are conducted on a reaction pair composed of the reacted thermoelectric material Bi0.5Sb1.5Te3 and Sn welding paste, and then the p-type Bi0.5Sb1.5Te3 / porous SnTe-SbSn thermoelectric composite material with uniformly-distributed pores is obtained. The preparation method has the advantages that a SnTe-SbSn layer with uniform 200-500-micrometer nano-pores is acquired through the preparation method, the thickness of a reaction layer is increased to 40 micrometers, the reaction speed is 4.05 micrometers per minute, cost is low, and components can be accurately controlled.

Owner:TIANJIN UNIV

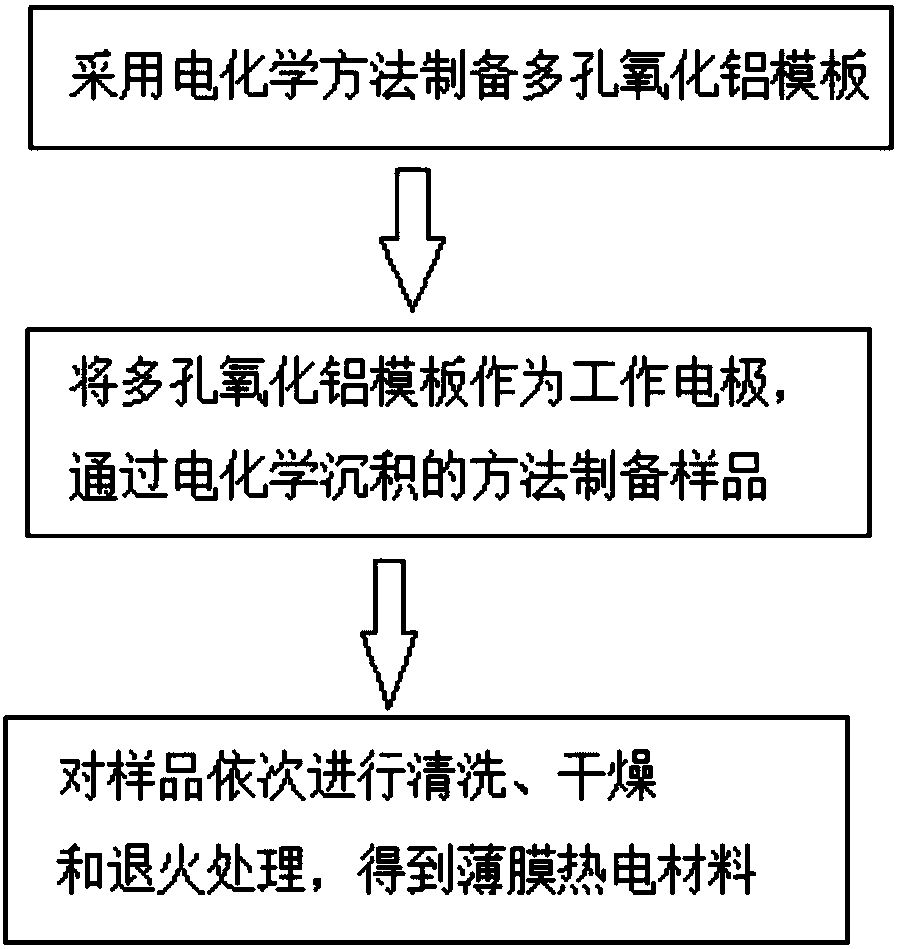

Preparation method of thin-film thermoelectric material

InactiveCN107620100ALow thermal conductivityLow high Seebeck coefficientElectrolytic inorganic material coatingThermoelectric materialsAuxiliary electrode

The invention discloses a preparation method of a thin-film thermoelectric material. The preparation method comprises the following steps: preparing a porous alumina template by adopting an electrochemical method; taking the porous alumina template as a working electrode; putting the working electrode and an auxiliary electrode in an electrolyte, and preparing a sample through an electrochemical deposition method, wherein the electrolyte comprises a precursor, a complexing agent and an additive, and the precursor is a combination of two or three of tellurium dioxide, bismuth nitrate and diantimony trioxide; and subjecting the sample to cleaning, drying and annealing treatment in sequence, so as to obtain the thin-film thermoelectric material. The preparation method disclosed by the invention has the advantages that the thin-film thermoelectric material is low in heat conductivity coefficient, high in electrical conductivity, high in Seebeck coefficient and high in thermoelectric figureof merit.

Owner:滁州玛特智能新材料科技有限公司

High-strength and high-efficiency bismuth telluride block and preparation method and application thereof

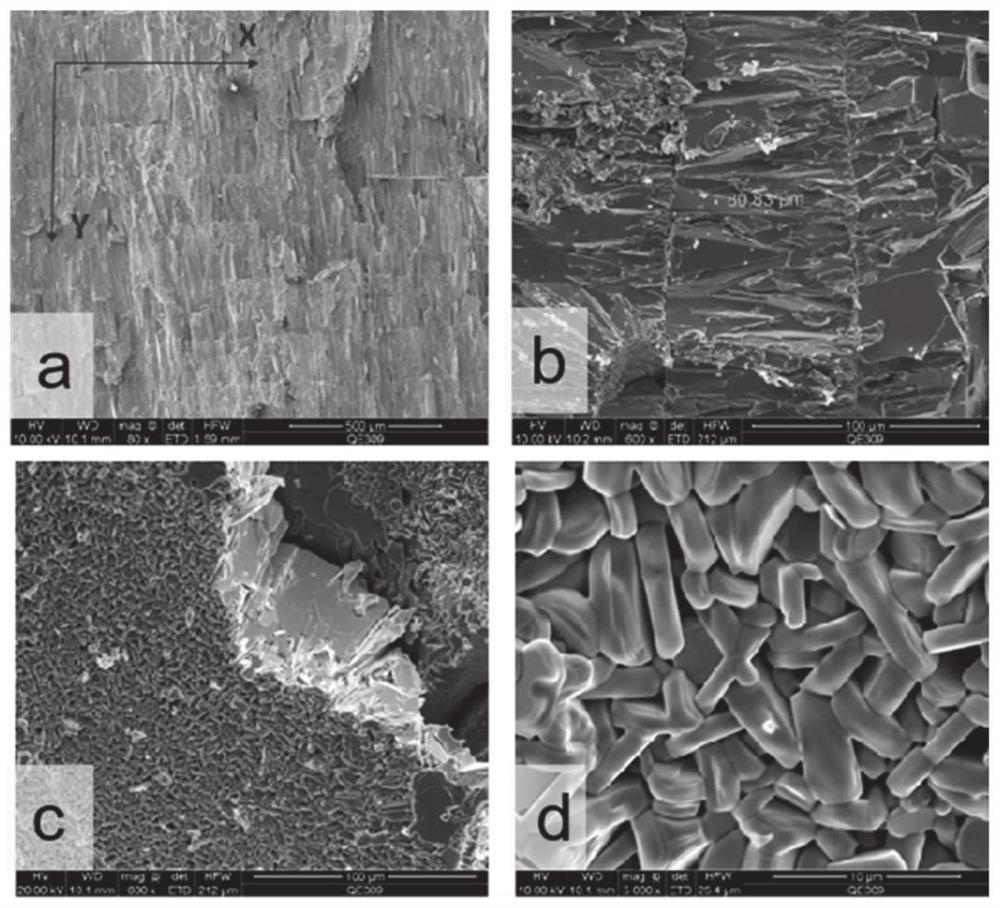

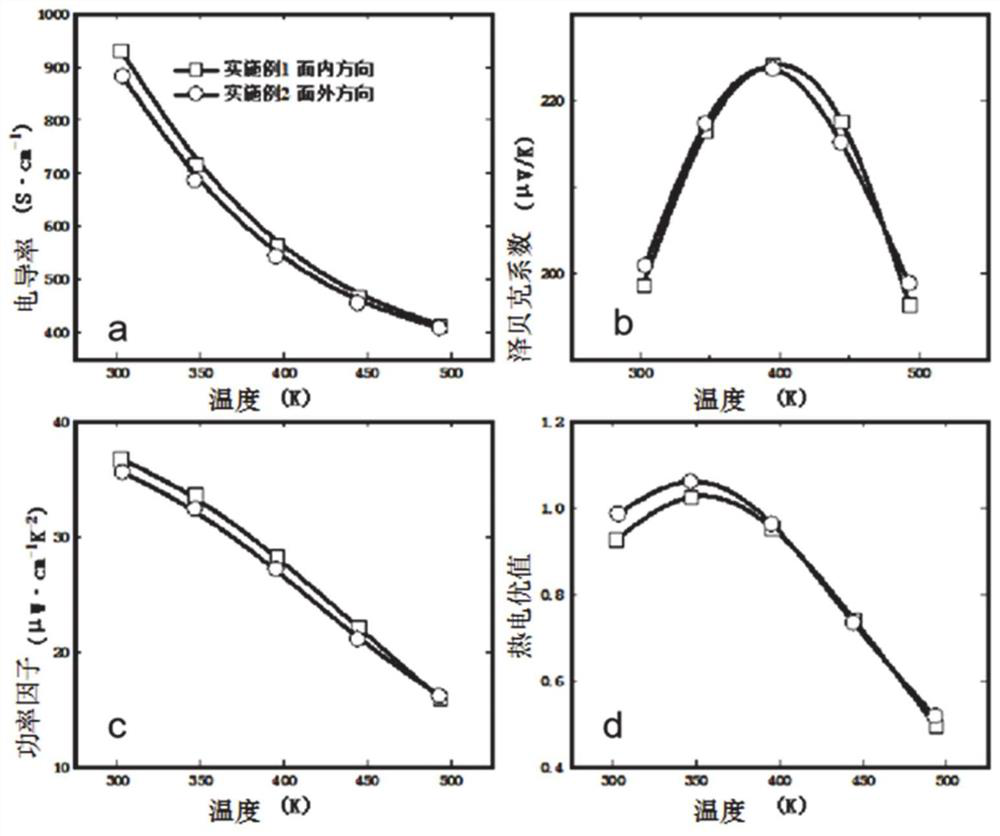

PendingCN113328031AHigh thermoelectric figure of meritImprove uniformityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideThermal deformation

The invention discloses a high-strength and high-efficiency bismuth telluride block. The bismuth telluride block is in a lamellar shape; the bismuth telluride block is a P-type lamellar bismuth telluride block of Bi0.5Sb1.5Te3+x, and the value range of x is 0-0.05, or, the bismuth telluride block is an N-type lamellar bismuth telluride block of Bi2Te3-ySey, and y ranges from 0 to 0.3. The bismuth telluride block is of a special lamellar structure and has the double characteristics of high orientation degree and grain refinement, and the bismuth telluride block can be directly used for vacuum hot pressing sintering or vacuum thermal deformation sintering without being cut and / or ground into powder. And the bismuth telluride-based thermoelectric material with high thermoelectric figure of merit and high strength can be rapidly prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

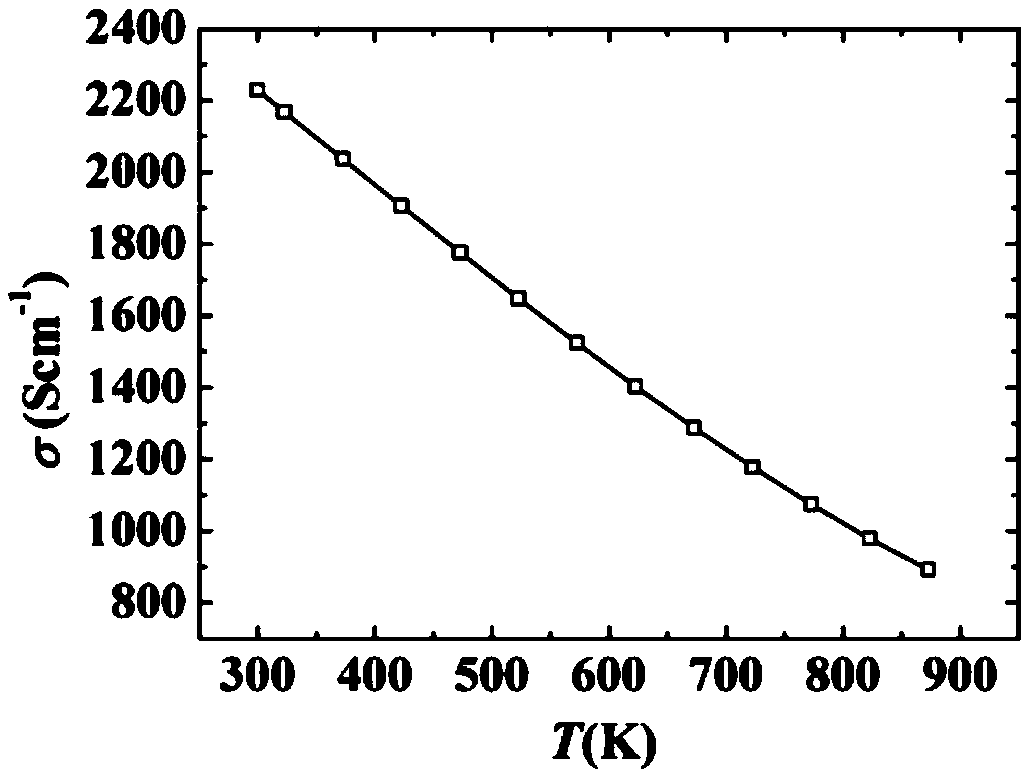

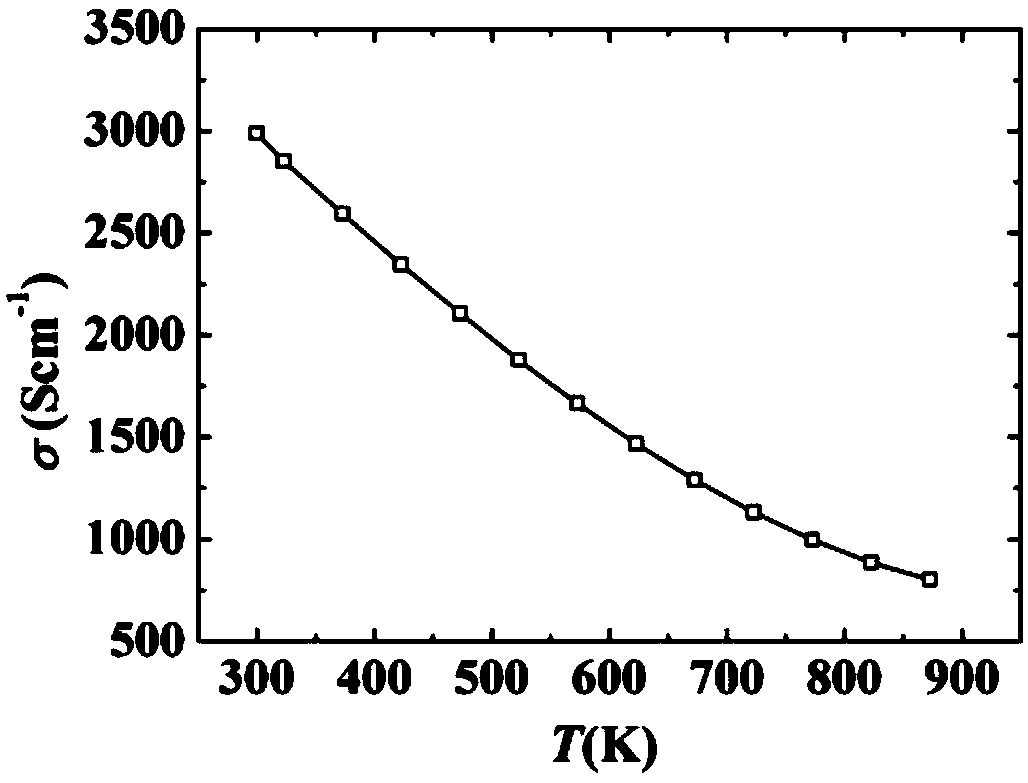

Preparation method for SnTe thermoelectric materials with high output power density and energy conversion efficiency

ActiveCN109585639AHigh Seebeck coefficientHigh power factorThermoelectric device manufacture/treatmentChemical industryMuffle furnaceEnergy conversion efficiency

The present invention relates to a preparation method for SnTe thermoelectric materials with high output power density and energy conversion efficiency, and relates to the preparation method for SnTethermoelectric material. The problem is solved that the output power density and energy conversion efficiency of the current thermoelectric materials cannot be improved at the same time. The preparation method comprises the steps that: 1, according to the stoichiometric ratio of (SnTe)2.94(In2Te3)0.02-(Cu2Te)3x, the Sn powder, the Te powder, the In powder and the Cu powder are weighed; the mixtureis put in a high-temperature muffle furnace to perform heat preservation at a high temperature, then cooling and heat preservation and finally furnace cooling to obtain ingot casting; and 3, the ingot casting is grinded and put in a graphite mold to perform sintering at a certain temperature and pressure to obtain In-Cu co-doped SnTe thermoelectric materials. The preparation method for SnTe thermoelectric materials with high output power density and energy conversion efficiency is suitable for preparation of the SnTe thermoelectric materials with high output power density and energy conversion efficiency.

Owner:HARBIN INST OF TECH

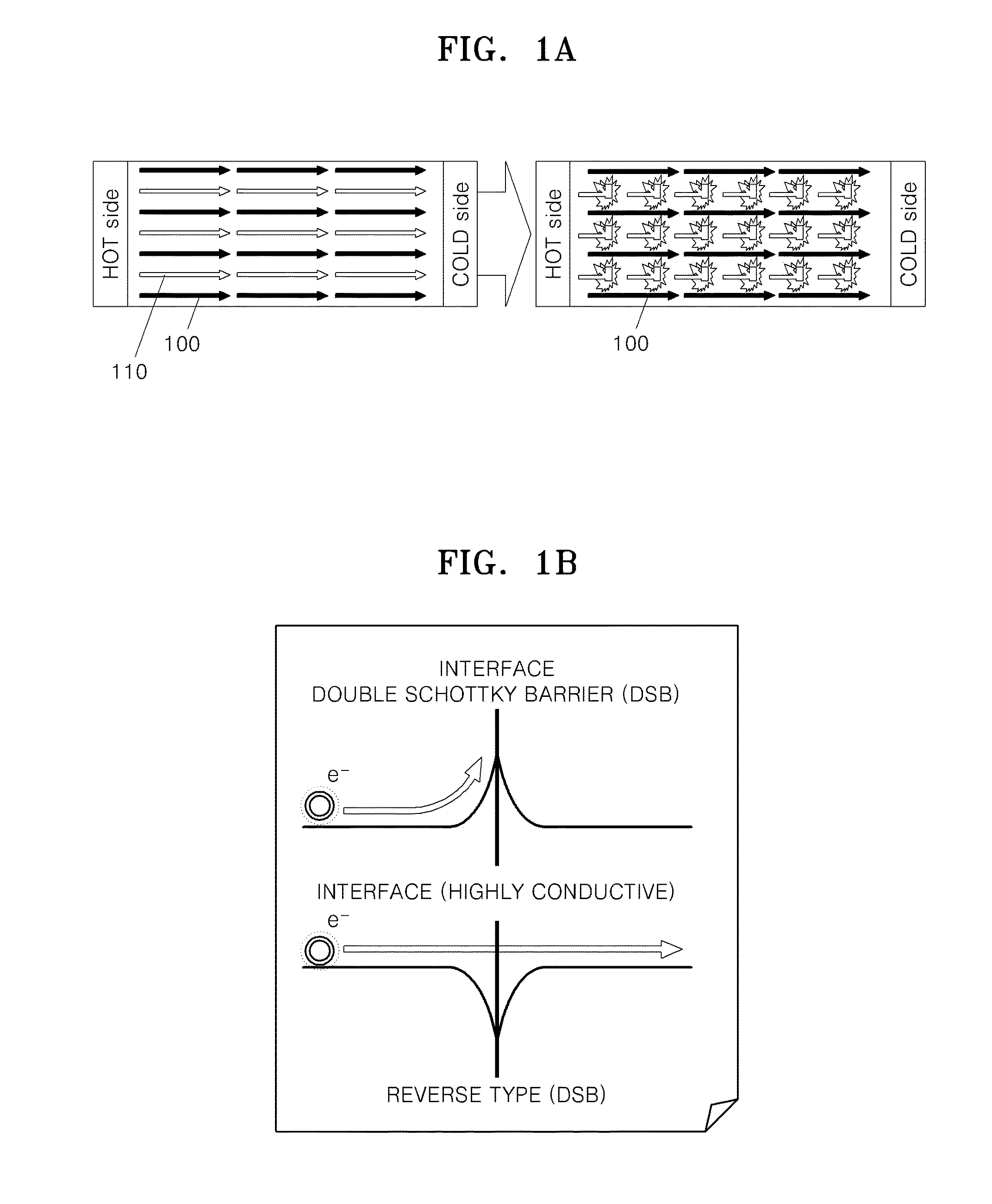

Thermoelectric material

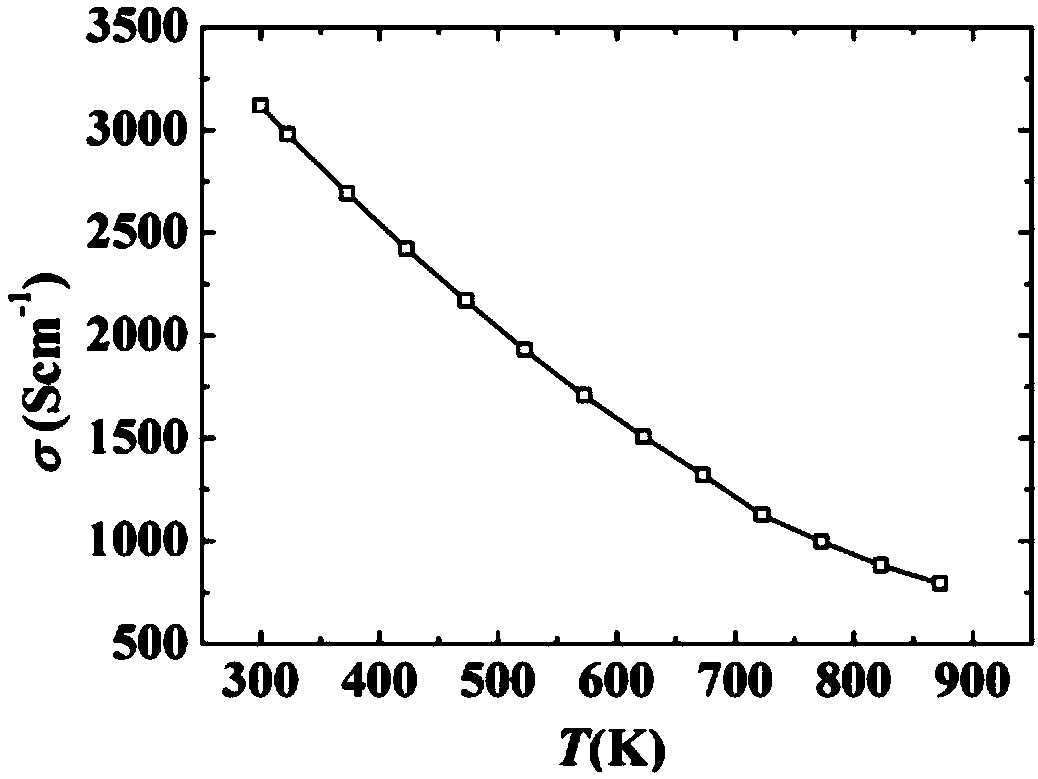

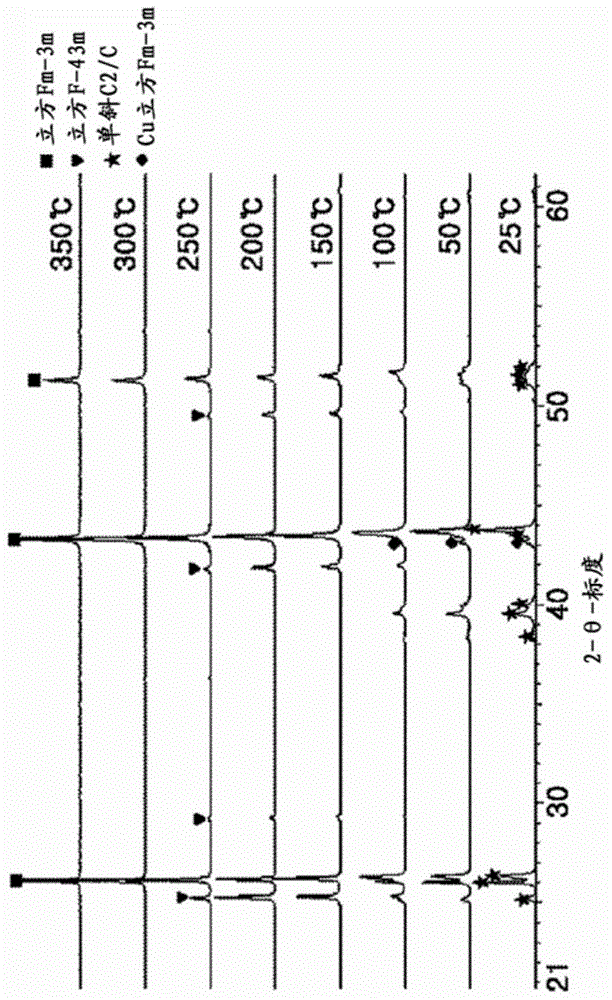

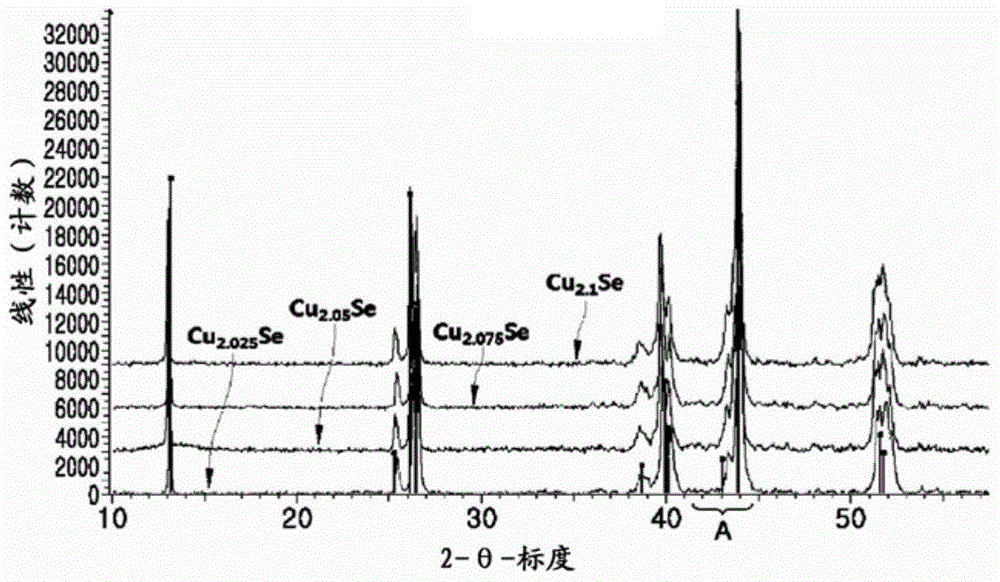

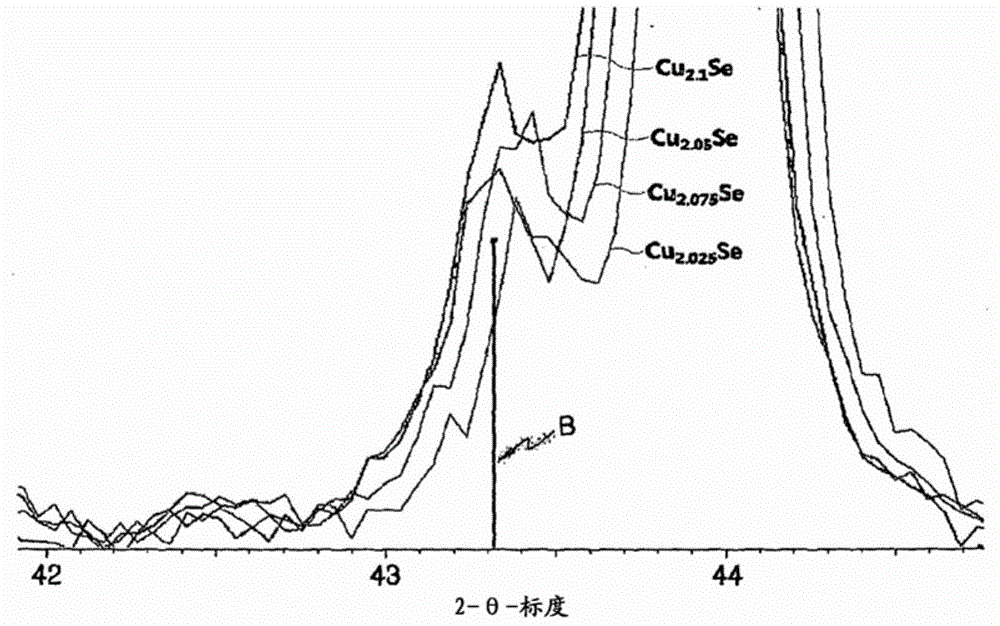

ActiveCN104885241AExcellent thermoelectric conversion performanceIncreased ZT valueCopper compoundsMetal selenides/telluridesThermoelectric materialsCrystal structure

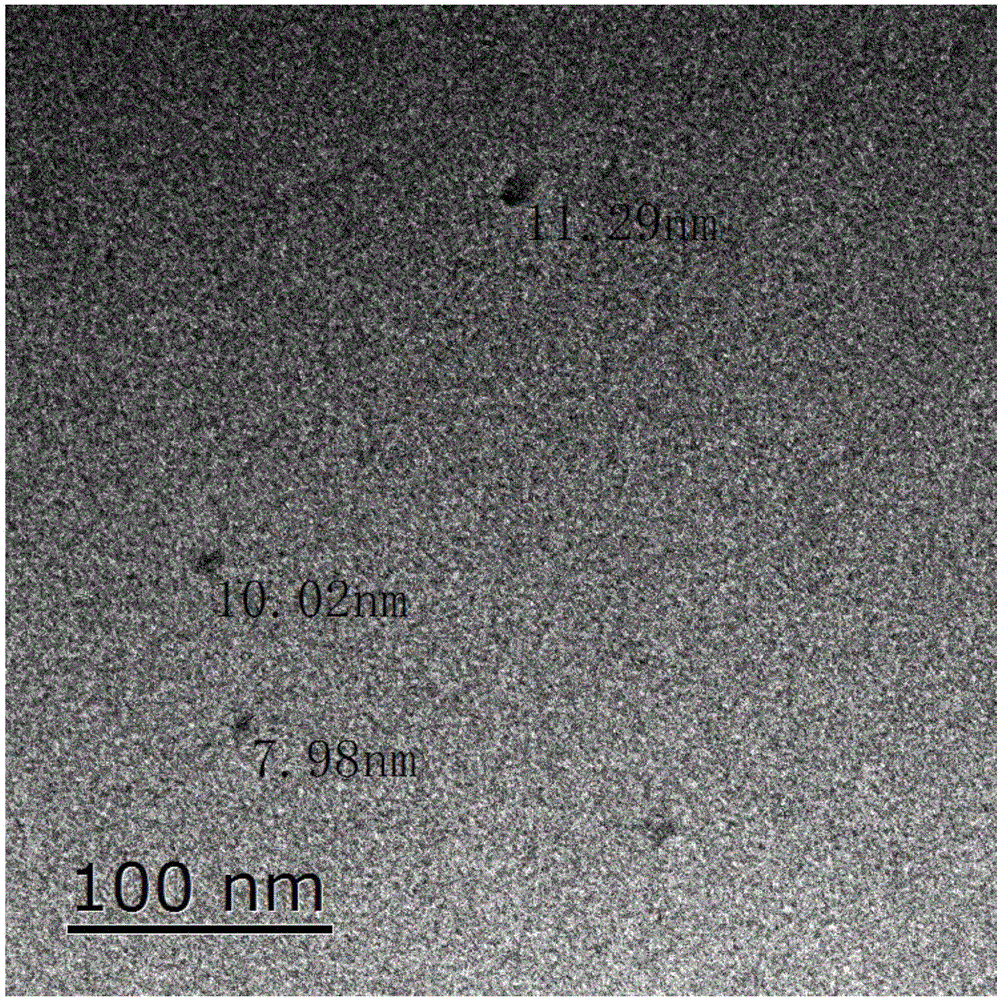

Disclosed is a method of manufacturing a thermoelectric material having high thermoelectric conversion performance at a wide temperature range. The method of manufacturing a thermoelectric material according to the present invention comprises the following steps: forming a mixture by mixing copper and selenium according to the following chemical formula 1: Cu_xSe; and forming the mixture by heat treating the mixture. In chemical formula 1, 2<x<=2.6. The thermoelectric material can include an induced nano DOT (INDOT) as a copper containing particle. Here, INDOT represents a particle with a diameter, for example, between 1 nanometer and 100 nanometers which is spontaneously generated during a thermal material formation process. This nano DOT, that is INDOT, can exist on a grain boundary of a semiconductor.

Owner:LG CHEM LTD

Thermoelectric conversion material and method for producing thermoelectric conversion material

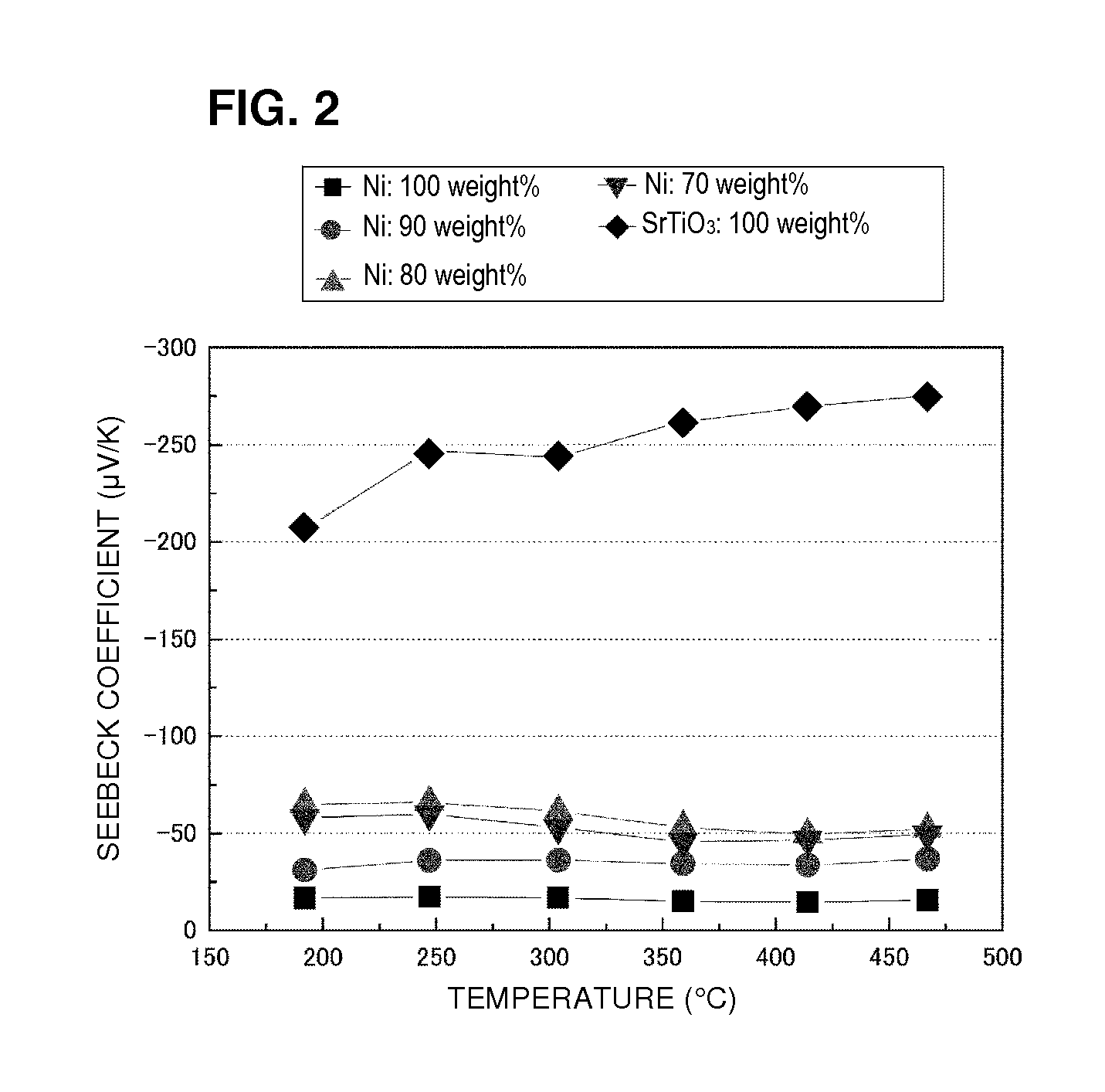

ActiveUS20120305833A1High Seebeck coefficientLower resistanceHeat-exchange elementsThermoelectric device junction materialsRare-earth elementPower factor

An n-type thermoelectric conversion material that has a high Seebeck coefficient, a low electric resistivity, and a large power factor includes, as its main constituent, a metal material mainly containing Ni, and includes an oxide material containing Sr, Ti, and a rare-earth element in the range of about 10 wt % to about 30 wt %. The oxide material is a SrTiO3 based oxide material. For producing the thermoelectric conversion material, through the steps of mixing and grinding a SrTiO3 based oxide material and a Ni metal powder to prepare a mixture, forming this mixture into a shape to prepare a compact, and then firing the compact, the thermoelectric conversion material is obtained.

Owner:MURATA MFG CO LTD

Thermoelectric material and preparation method thereof

InactiveCN111081856AImprove conductivityHigh Seebeck coefficientThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsCerium

The invention provides a thermoelectric material and a preparation method thereof, and belongs to the technical field of thermoelectric materials. The thermoelectric material comprises the following raw material components according to the molar weight ratio: 0.8 to 0.925 mmol of bismuth nitrate pentahydrate, 1.35 to 1.65 mmol of selenium powder, 0.075 to 0.2 mmol of cerium nitrate hexahydrate, 0.53 to 0.65 mmol of ethanolamine and 0.82 to 1 mmol of 2-methoxyethanol; according to the thermoelectric material, Ce < 3 + > of cerium nitrate hexahydrate equivalently replaces a doping mode of Bi < 3+ > in bismuth selenide obtained by selenium powder and bismuth nitrate pentahydrate; interdependence of the seebeck coefficient and the conductivity of the cerium-doped bismuth selenide thermoelectric material is eliminated, and the obtained thermoelectric material has the characteristics of high conductivity, high seebeck coefficient, high quality factor and the like.

Owner:DONGGUAN TIANYI MOTOR

Thermoelectric material

ActiveCN104885240AExcellent thermoelectric conversion performanceLow thermal diffusivityCopper compoundsThermoelectric device junction materialsThermoelectric materialsCopper

Disclosed is a method of manufacturing a thermoelectric material having high thermoelectric conversion performance at a wide temperature range. The method of manufacturing a thermoelectric material according to the present invention comprises the following steps: forming a mixture by mixing copper and selenium according to the following chemical formula 1: Cu_xSe; and forming the mixture by heat treating the mixture. In chemical formula 1, 2<x<=2.6. The thermoelectric material can include an induced nano DOT (INDOT) as a copper containing particle. Here, INDOT represents a particle with a diameter, for example, between 1 nanometer and 100 nanometers which is spontaneously generated during a thermal material formation process. This nano DOT, that is INDOT, can exist on a grain boundary of a semiconductor.

Owner:LG CHEM LTD

Preparation method of poly(p-phenylene) nanoparticle composite ZnO-based thermoelectric material system

InactiveCN102496677ALow thermal conductivityHigh thermal conductivityMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsAlcohol

The invention relates to a preparation method of a poly(p-phenylene) nanoparticle composite ZnO-based thermoelectric material system. The preparation method comprises the following steps of: adding poly(p-phenylene) nanoparticles into sulfuric acid of which the concentration is higher than 85%, stirring for 5-10 minutes at 20-50 DEG C, filtering, washing, drying, and carrying out ball milling on a high-energy ball mill for 0.5-4 hours; dissolving 0.1-10mol% of acetate of dopant ion and 2.20g of zinc acetate into 500ml of diglycol, adding 20ml of water, stirring for 10 minutes at 160-170 DEG C, and standing for 2 hours after a white precipitate appears, thereby obtaining ZnO sol; adding the treated poly(p-phenylene) nanoparticles into the ZnO sol, stirring, dispersing for 30 minutes under the ultrasonic condition, heating to 160-170 DEG C, and reacting for 1 hour; and washing the product with anhydrous alcohol and deionized water many times, drying at 100 DEG C, and carrying out discharge plasma sintering to obtain the blocky poly(p-phenylene) nanoparticle composite ZnO-based thermoelectric material. The preparation method provided by the invention has the characteristics of simple and practicable method, low reaction temperature, short reaction time, low energy consumption, good chemical uniformity and the like.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

S-doped modified BiCuSeO-based thermoelectric material and preparation method thereof

InactiveCN106558648AImprove mobilityHigh power factorThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsS doping

The invention provides S-doped modified BiCuSeO-based thermoelectric material and a preparation method thereof. The thermoelectric material is BiCuSeO1-xSx, x=0.01-0.05. The preparation method comprises two-step solid phase reaction and discharge plasma sintering molding (SPS). The preparation method is simple in technology and easy to operate. Compared with pure phase BiCuSeO, the thermoelectric merit figure ZT of the thermoelectric material BiCuSeO1-xSx is enhanced for more than 50%.

Owner:涂艳丽

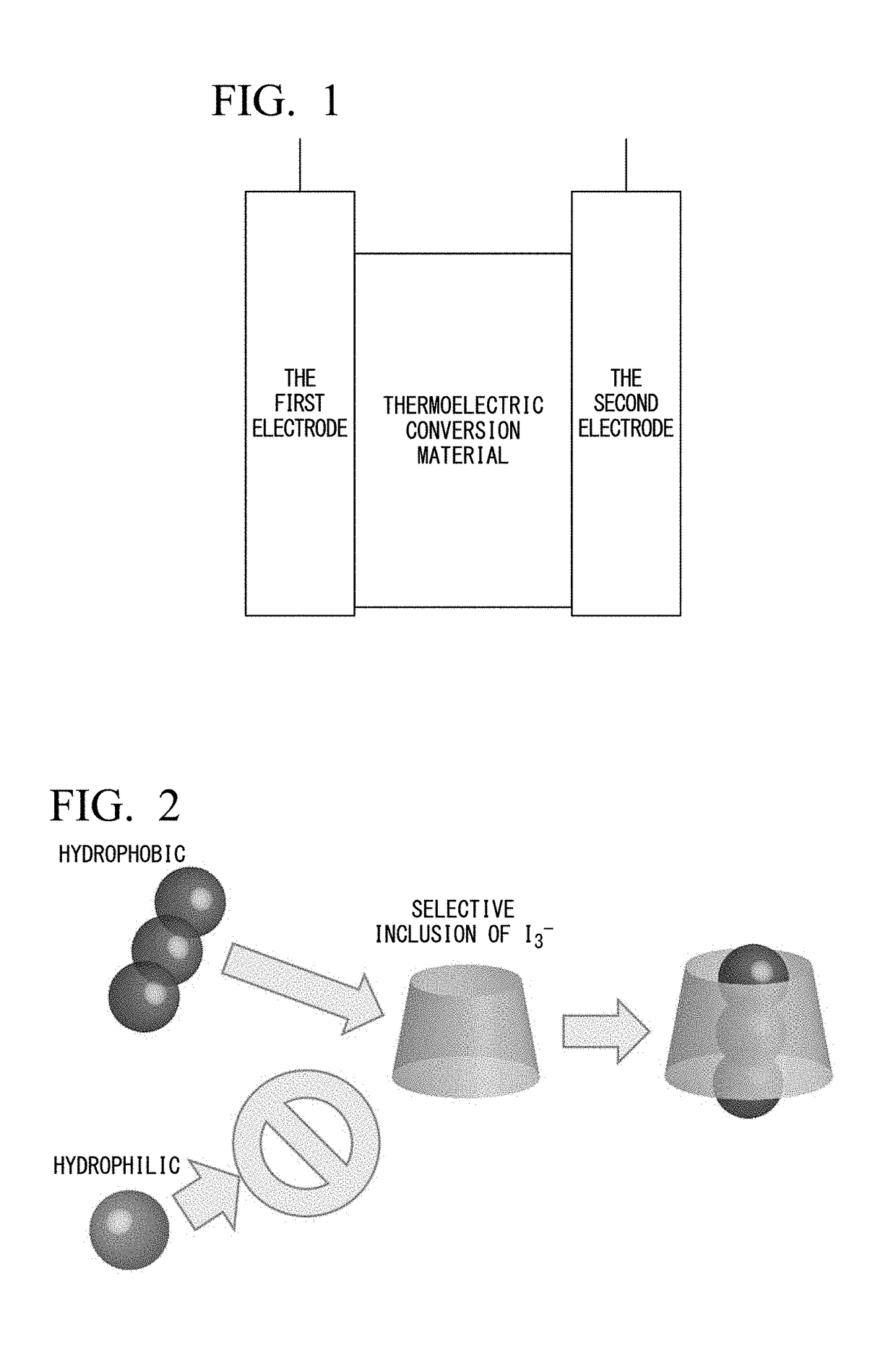

Thermoelectric conversion material, thermoelectric conversion device having the same, thermo-electrochemical cell and thermoelectric sensor

ActiveUS20190081224A1High Seebeck coefficientImprove the overall coefficientDeferred-action cellsThermoelectric device with peltier/seeback effectRedoxThermoelectric conversion

The present invention provides a thermoelectric conversion material having a considerably increased Seebeck coefficient, and a thermoelectric conversion device, a thermo-electrochemical cell and a thermoelectric sensor which include the material. The thermoelectric conversion material of the present invention includes a redox pair and a capture compound which captures only one of the redox pair selectively at low temperature and releases at high temperature.

Owner:JAPAN SCI & TECH CORP

PEDOT: PSS self-supporting thermoelectric film and preparation method thereof

InactiveCN114220909AImprove conductivityHigh Seebeck coefficientThermoelectric device manufacture/treatmentThermoelectric device junction materialsCompound aAqueous solution

The invention relates to a PEDOT: PSS self-supporting thermoelectric film and a preparation method thereof, and the method comprises the steps: coating a substrate with a PEDOT: PSS aqueous solution, then drying, and forming a PEDOT: PSS layer on the substrate to obtain a compound A; the compound A is soaked in an organic polar solvent, PEDOT: PSS outer wall insulation PSS is removed, a PEDOT: PSS film is formed on a substrate, then the organic polar solvent is removed, drying is conducted, and a compound B is obtained; dropwise adding an L-ascorbic acid solution on the compound B to enable the L-ascorbic acid solution to cover the upper surface layer of the compound B, then removing the L-ascorbic acid solution, drying, and removing the substrate to obtain the PEDOT: PSS self-supporting film. L-ascorbic acid is used for treating and adjusting the oxidation level of PEDOT molecules, and the coupling relation between the conductivity and Seebeck coefficient of PEDOT: PSS is tuned, so that a higher power factor is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

Application of indium tin oxide with (400) crystal plane preference on transparent thin film thermocouple

ActiveCN109881153AHigh Seebeck coefficientEasy to makeVacuum evaporation coatingSputtering coatingThin film thermocouplesSputtering

The invention relates to an application of indium tin oxide with (400) crystal plane preference on a transparent thin film thermocouple, and belongs to the technical field of thin film thermocouples.The body-centered cubic ferromanganese phase polycrystalline indium tin oxide with (400) crystal plane preference is made into one pole of the transparent thin film thermocouple by a direct current pulse magnetron sputtering method, and the duty ratio of the direct current pulse magnetron sputtering is 10-40%. According to the application of indium tin oxide with (400) crystal plane preference onthe transparent thin film thermocouple, the preferred orientation of the indium tin oxide film obtained by direct current pulse magnetron sputtering is controlled, so that the indium tin oxide transparent film thermocouple has the higher Zeebek coefficient.

Owner:DALIAN JIAOTONG UNIVERSITY

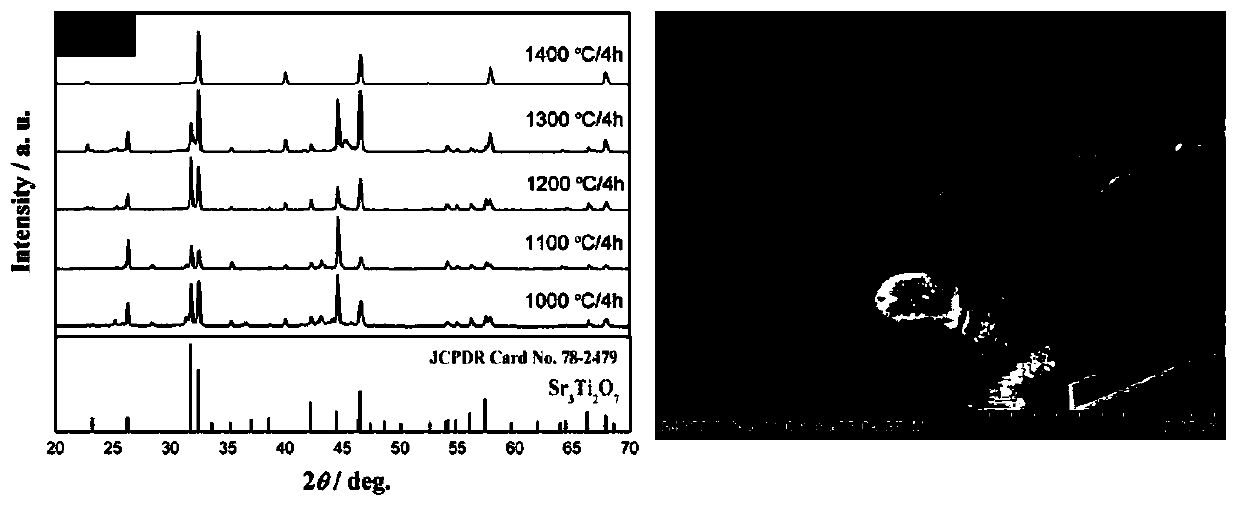

Artificial multi-layer structure strontium titanate thermoelectric material and preparation method thereof

ActiveCN110350076ALow thermal conductivityHigh conductanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsSolid-stateNiobium

The invention relates to the field of composite and thermoelectric material, and provides a preparation method of an artificial multi-layer structure strontium titanate thermoelectric material. The proportion of matrix and embedded phase in the designed structure and the number of stacked surfaces are adjusted to ensure that the material has both high electrical conductivity and low thermal conductivity. The preparation method comprises the following steps: firstly, cubic phase niobium-doped strontium titanate is prepared as a matrix conductive phase by a solid state method under the anoxic condition; then R-P-structure lamellar strontium titanate is prepared as the embedded phase by using a molten salt method; and then a green body is prepared by the cubic phase niobium-doped strontium titanate and the R-P-structure lamellar strontium titanate according to different mas ratios through the curtain coating and other processes and then sintered by the sps method so that the artificial multilayer structure strontium titanate thermoelectric material is obtained. The material has a first-order phonon scattering mechanism formed by the interface between the embedded phase and the matrix,a second-order phonon scattering mechanism formed by directional arrangement of the embedded phase in the matrix and a third-order phonon scattering mechanism formed by a plurality of sub-layer interfaces. The material is enabled to have both high electrical conductivity and low thermal conductivity so as to provide a new idea for improving the thermoelectric performance of the material.

Owner:SHAANXI UNIV OF SCI & TECH

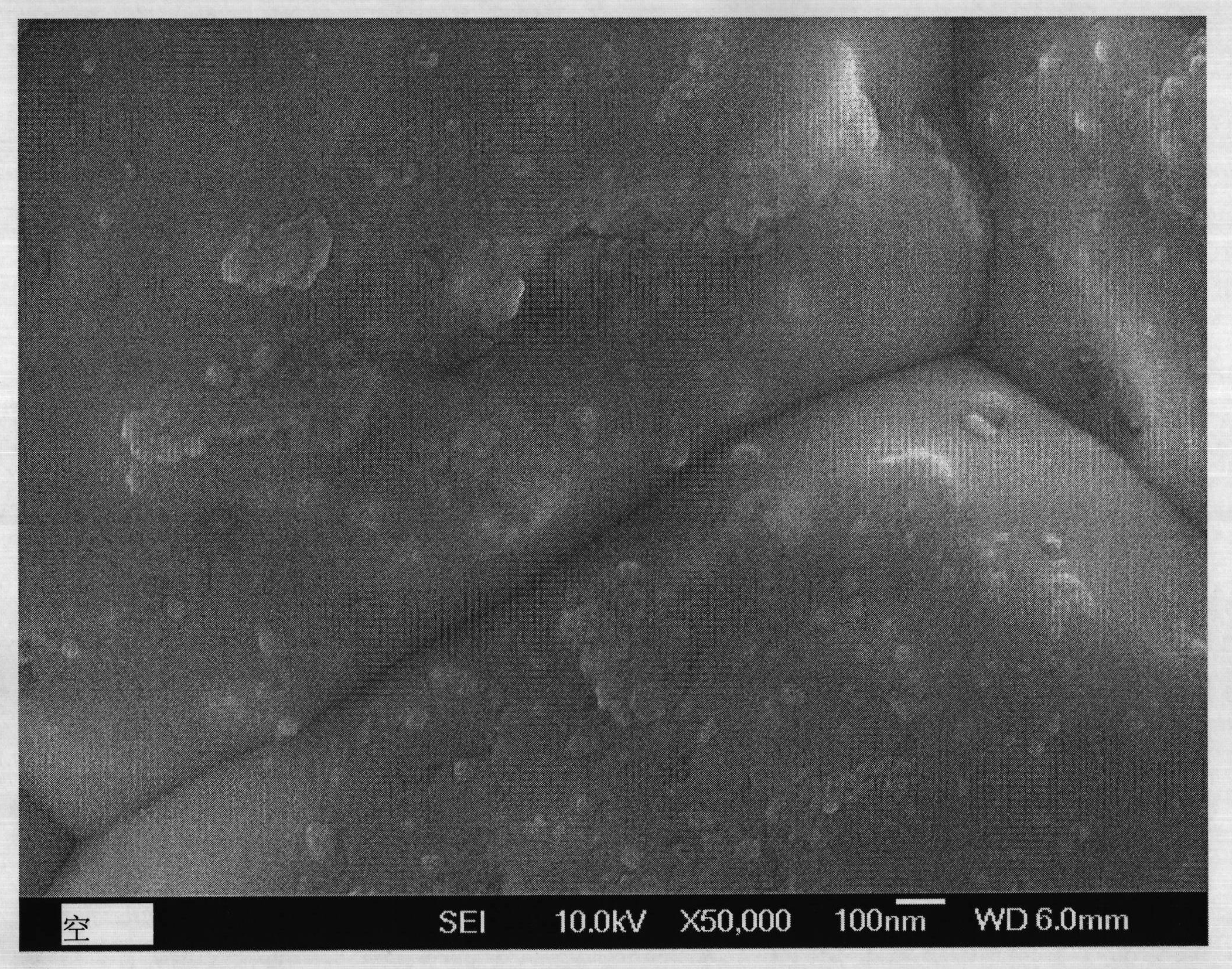

A nanofiber-based flexible high-performance thermoelectric material and its preparation method

InactiveCN102790166BImprove thermoelectric conversion efficiencyImprove flexibilityMaterial nanotechnologyThermoelectric device manufacture/treatmentVulcanizationMaterials science

The invention belongs to the technical field of new energy thermoelectric conversion materials, and specifically relates to a flexible, high thermoelectric figure of merit semiconductor nanostructure material based on electrospinning nanofibers and a preparation method thereof. It uses polymer and silver nitrate composite nanofibers as the base. After reducing the silver nitrate, electroless plating is used to deposit a silver shell on the surface of the fiber. Then, the polymer / silver sulfide is obtained through in-situ oxidation-reduction and sulfide methods. Core-shell nanofiber materials. The nanofiber-based thermoelectric material prepared by the invention has ultra-high Seebeck coefficient and thermoelectric figure of merit, and has good flexibility, which is unmatched by traditional thermoelectric materials. For example, the Seebeck coefficient of polyacrylonitrile / silver sulfide core-shell nanofibers has reached more than 103, the maximum thermoelectric figure of merit has reached 0.9 at a temperature of 340K, and the original flexibility of polyacrylonitrile nanofibers has been retained.

Owner:JILIN UNIV

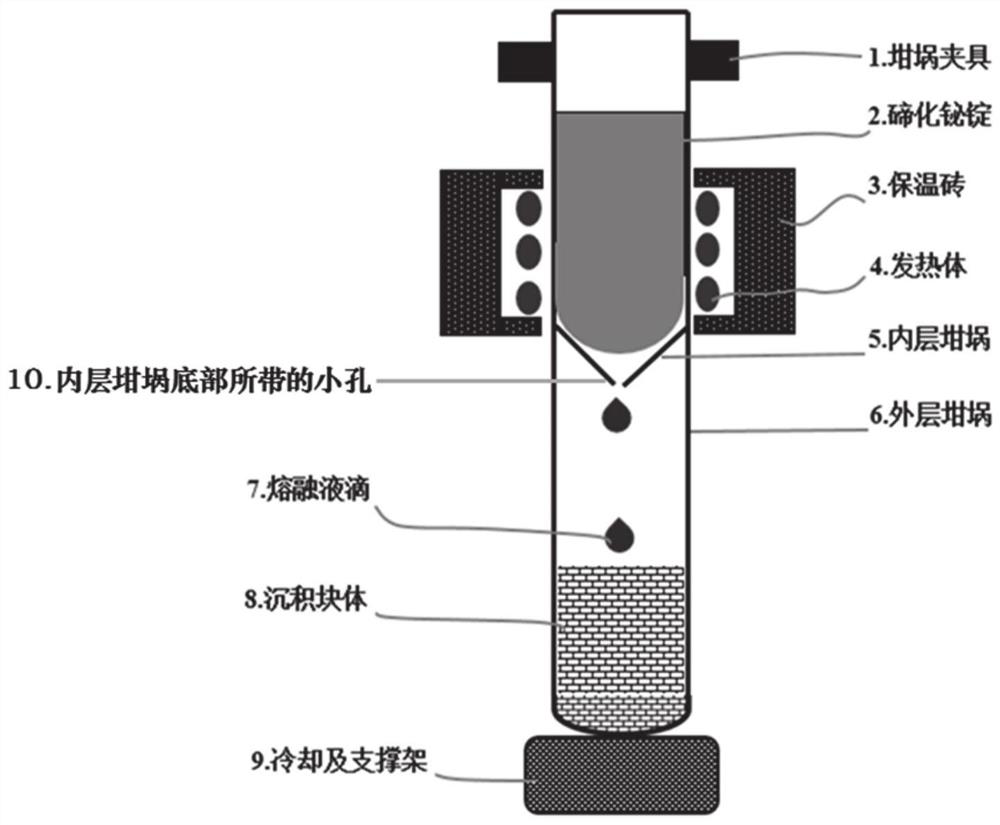

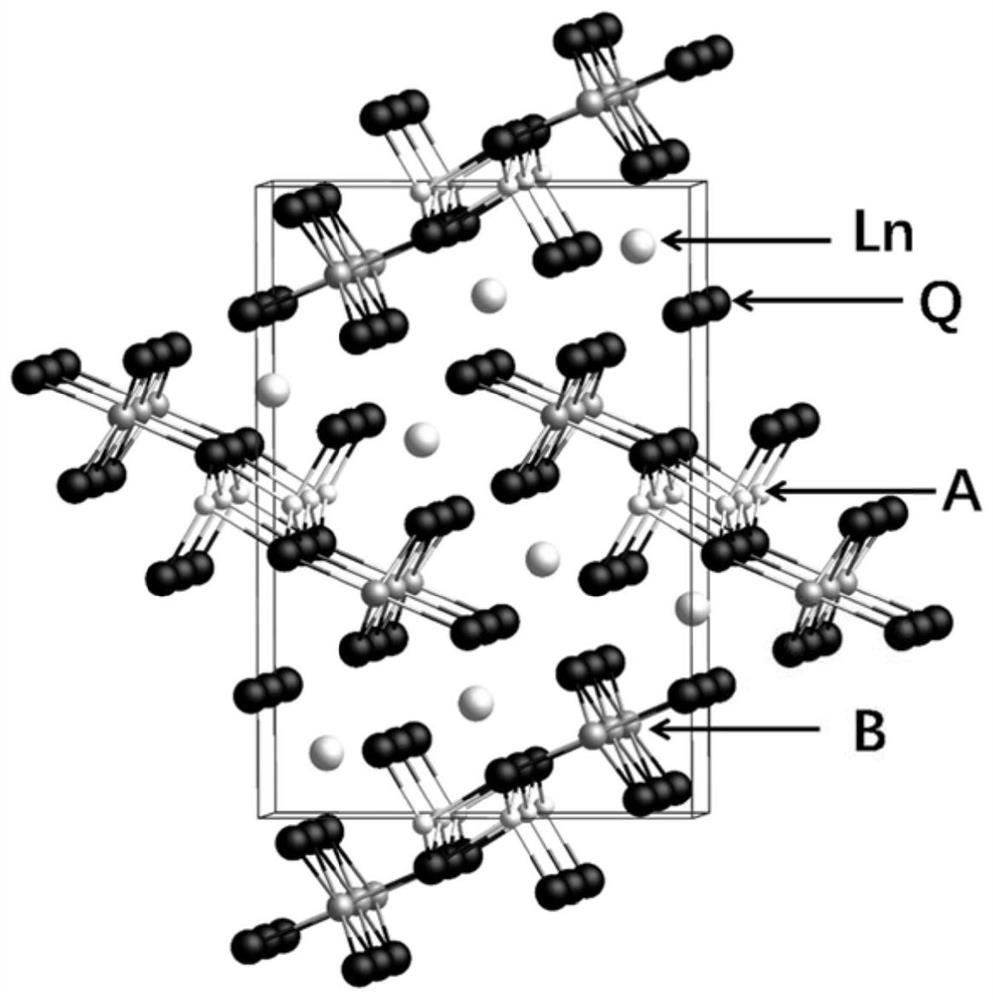

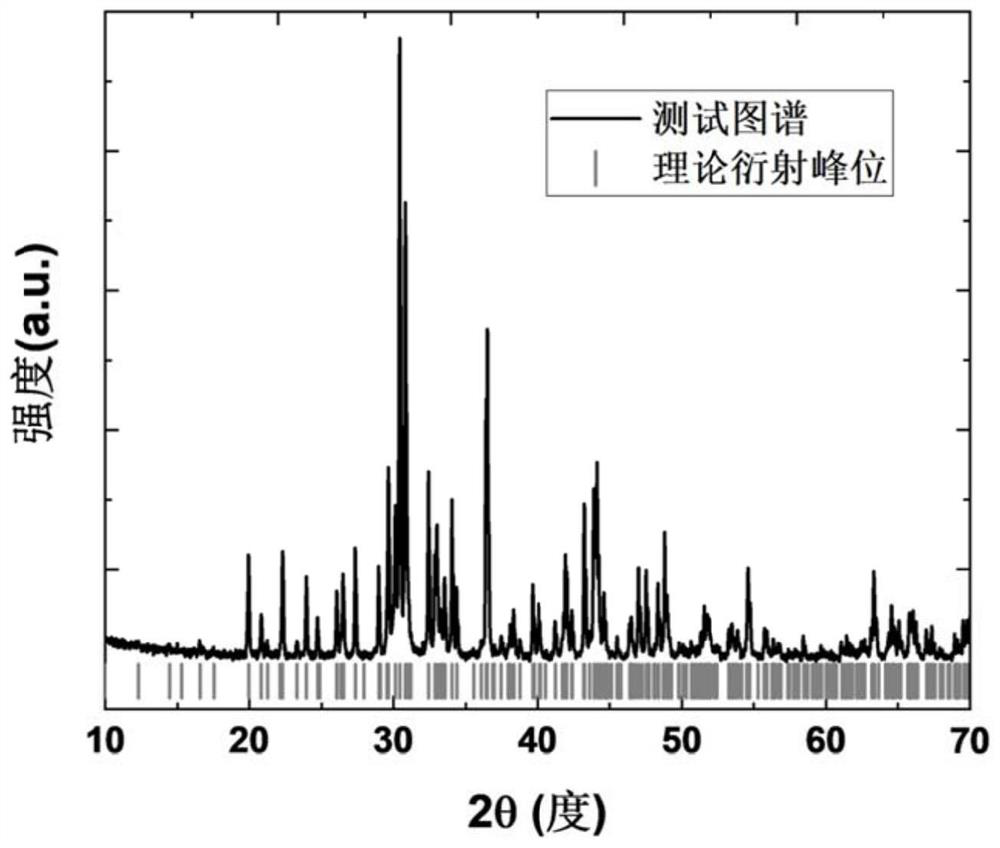

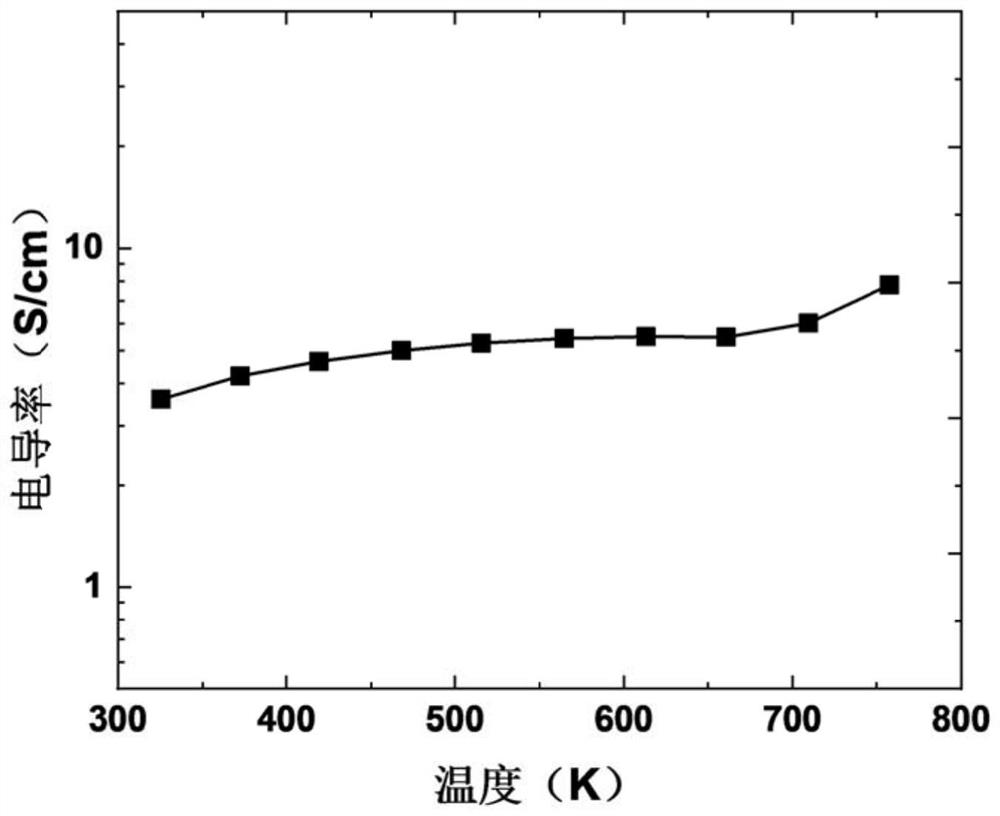

Compound capable of being used for thermoelectric material and preparation method of compound

InactiveCN112725898ASimple preparation processLow costPolycrystalline material growthFrom melt solutionsThermoelectric materialsMetallurgy

The invention provides a compound capable of being used for a thermoelectric material and a preparation method of the compound, the general formula of the compound is Ln2ABQ5, and Ln in the formula is any one or a combination of more than two of trivalent rare earth ions; A is any one or two of Cu or Ag; B is any one or two of Sb or Bi; Q is any one or a combination of more than two of S, Se or Te. The compound capable of being used for the thermoelectric material has a unique chain crystal structure, has the advantages of high seebeck coefficient, high electrical conductivity, low thermal conductivity and the like, and is a thermoelectric material with excellent performance, and the corresponding preparation method is simple in process step and cheap and easily available in raw materials so that the compound is convenient to popularize and apply.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Pyroelectric non-refrigeration self selective frequency infrared detector in stereo double-layer structure

PendingCN107356342AHigh Seebeck coefficientLow thermal conductivityPyrometry using electric radation detectorsWave bandCMOS

The invention discloses a pyroelectric uncooled infrared detector with a three-dimensional double-layer structure, which belongs to the field of infrared detection. The invention includes a silicon substrate, a plurality of thermocouples with a three-dimensional double-layer structure, a self-selecting frequency infrared absorber with a three-layer structure, a contact high electrode, a contact low electrode and a silicon dioxide film, and is compatible with CMOS technology. The invention adopts a thermocouple with a three-dimensional double-layer structure, which has higher space utilization rate, better responsivity, detection sensitivity and noise equivalent power than the traditional planar thermocouple, and greatly improves the performance of the device; A self-selecting frequency infrared absorber with a three-layer structure does not require additional filters, and it absorbs almost 100% of specific wavelength bands.

Owner:成都市亿泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com