Thermoelectric materials

A thermoelectric material, low temperature technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device, circuit, etc., can solve the problems of low sensitivity, low noise, low thermal conductivity, low Seebeck coefficient, and weakened thermoelectric performance. The effect of low thermal conductivity and good thermoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

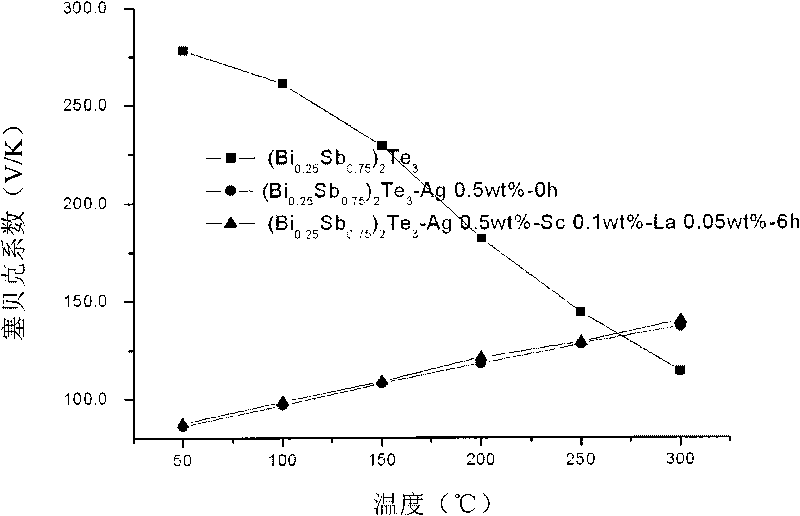

[0021] The present invention relates to a medium and low temperature thermoelectric material for thermoelectric elements suitable for thermoelectric cooling and thermoelectric power generation. The medium and low temperature thermoelectric material is formed by adding specific components to metal thermoelectric materials or semiconductor thermoelectric materials. Thermoelectric materials for medium and low temperature in the medium and low temperature region. The above "for medium and low temperature" means that it not only exhibits excellent thermoelectric performance in the low temperature range below 100°C, but also exhibits excellent thermoelectric performance in the middle temperature range of about 100°C-300°C.

[0022] The above-mentioned metal thermoelectric materials add group 6(VI b) elements to well-known thermoelectric materials such as chalcogen-based Bi or Pb compounds, and the Bi 2 Te 3 , PbTe or Bi 2 Te 3 , PbTe and other substances are added with semi-metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com