A powder metallurgy brake pad matched with a carbon-ceramic brake disc and its preparation method

A technology of carbon-ceramic brake discs and brake pads, applied in metal processing equipment, friction linings, mechanical equipment, etc., to achieve significant economic and environmental benefits, fast heating, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

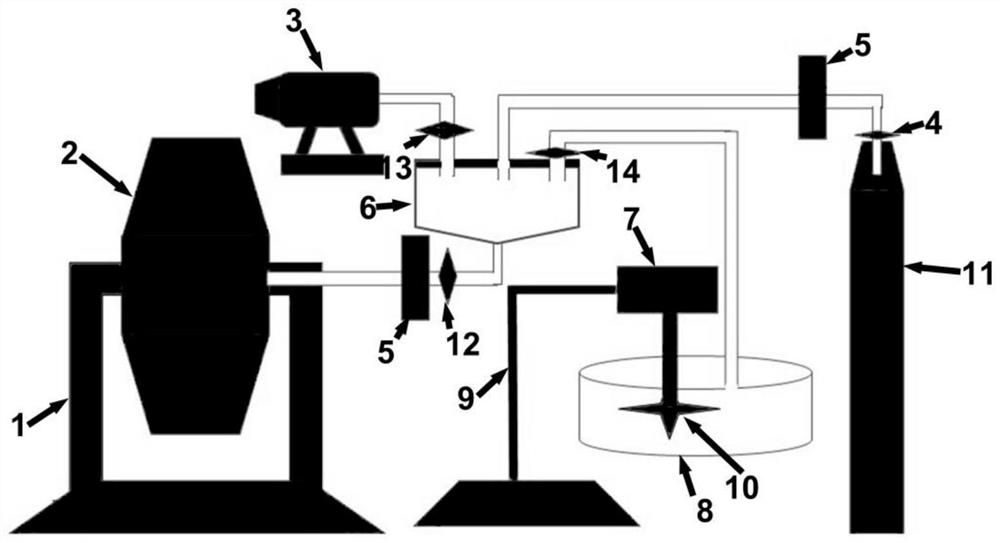

Method used

Image

Examples

Embodiment 1

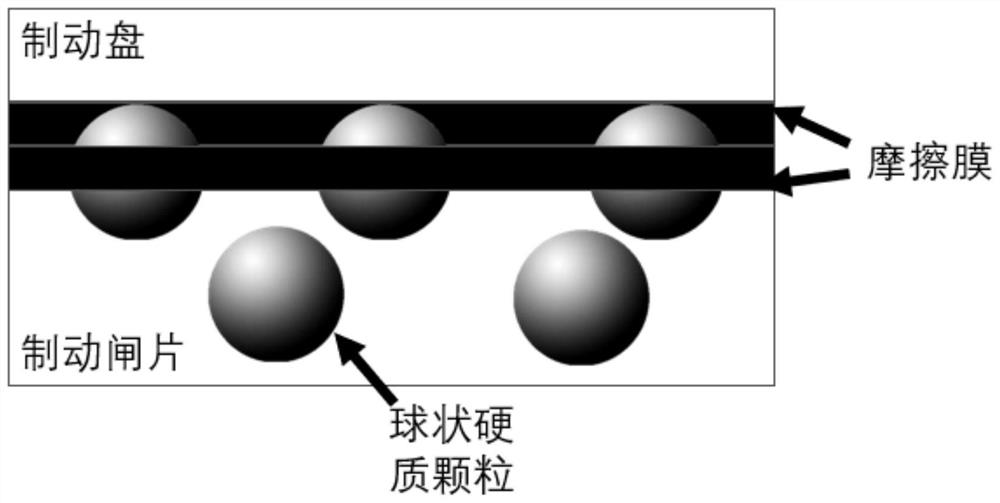

[0033] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0034] Iron powder: 50 parts by weight; copper powder: 15 parts by weight; flake graphite, 9 parts by weight; graphene: 0.4 parts by weight; ferrous sulfide powder: 8 parts by weight; spherical mixed hard powder: 17.6 parts by weight;

[0035] The spherical hard metal powder includes chromium powder: 3 parts by weight; molybdenum powder: 3 parts by weight; ferrochrome powder: 4 parts by weight; ferromolybdenum powder: 4 parts by weight.

[0036] The spherical ceramic powder includes silicon carbide: 3 parts by weight; titanium dioxide: 0.6 parts by weight.

[0037] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene is 2...

Embodiment 2

[0042] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0043] Iron powder: 55 parts by weight; Copper powder: 12 parts by weight; Flake graphite, 12 parts by weight; Graphene: 0.5 parts by weight; Ferrous sulfide powder: 7 parts by weight; Spherical mixed hard powder: 13.5 parts by weight;

[0044] The spherical hard metal powder includes chromium powder: 2 parts by weight; molybdenum powder: 2 parts by weight; ferrochrome powder: 3 parts by weight; ferromolybdenum powder: 3 parts by weight.

[0045] The spherical ceramic powder includes silicon carbide: 2.5 parts by weight; titanium dioxide: 0.5 parts by weight.

[0046] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene i...

Embodiment 3

[0051] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0052] Iron powder: 45 parts by weight; Copper powder: 18 parts by weight; Flake graphite, 8 parts by weight; Graphene: 0.3 parts by weight; Ferrous sulfide powder: 10 parts by weight; Spherical mixed hard powder: 18.7 parts by weight;

[0053] The spherical hard metal powder includes chromium powder: 2.1 parts by weight; molybdenum powder: 2.1 parts by weight; ferrochrome powder: 5 parts by weight; ferromolybdenum powder: 5 parts by weight.

[0054] The spherical ceramic powder includes silicon carbide: 3.5 parts by weight; titanium dioxide: 1 part by weight.

[0055] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com