Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Antimony telluride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony telluride is an inorganic compound with the chemical formula Sb₂Te₃. As is true of other pnictogen chalcogenide layered materials, it is a grey crystalline solid with layered structure. Layers consist of two atomic sheets of antimony and three atomic sheets of tellurium and are held together by weak van der Waals forces. Sb₂Te₃ is a narrow-gap semiconductor with a band gap 0.21 eV; it is also a topological insulator, and thus exhibits thickness-dependent physical properties.

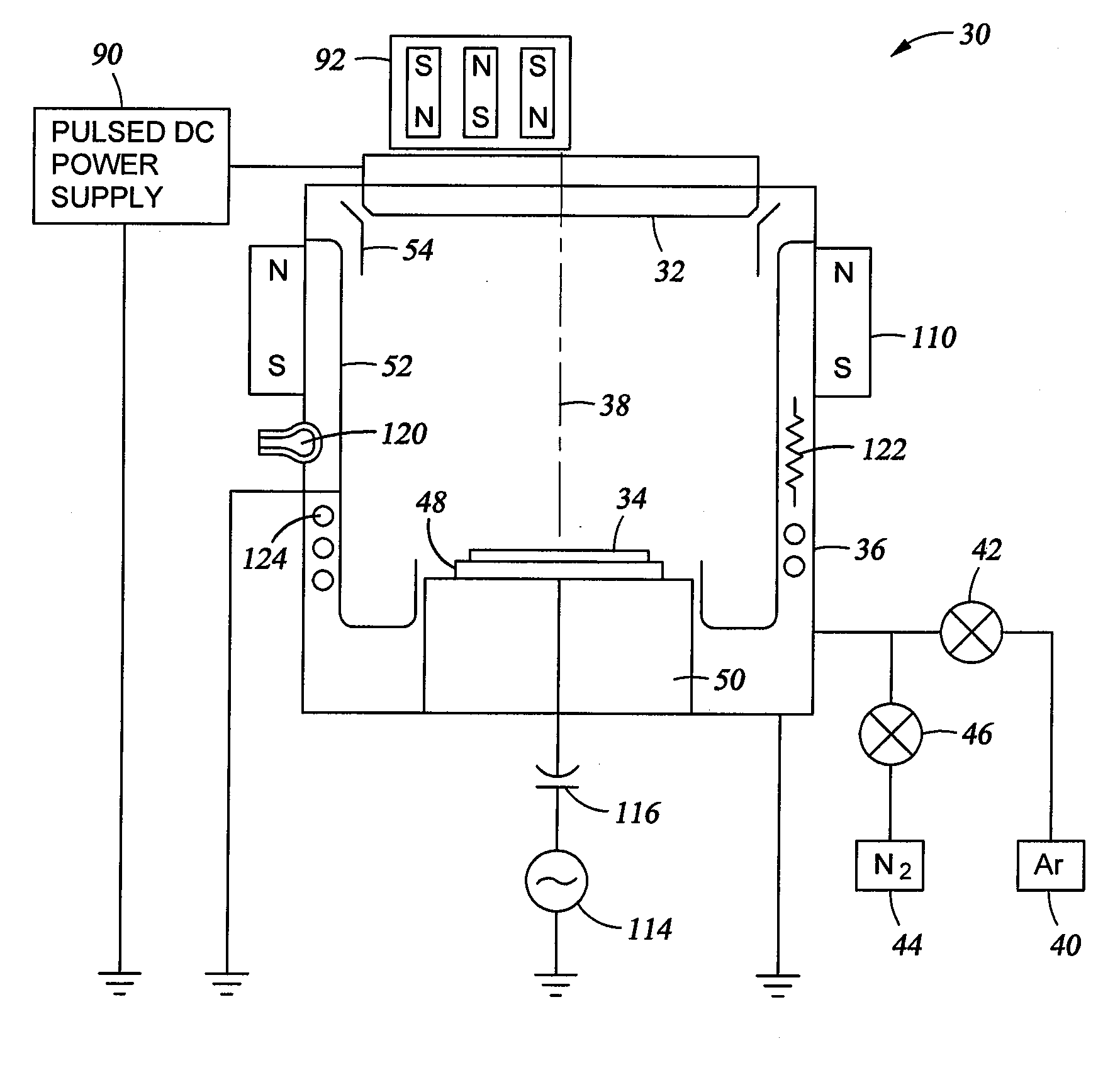

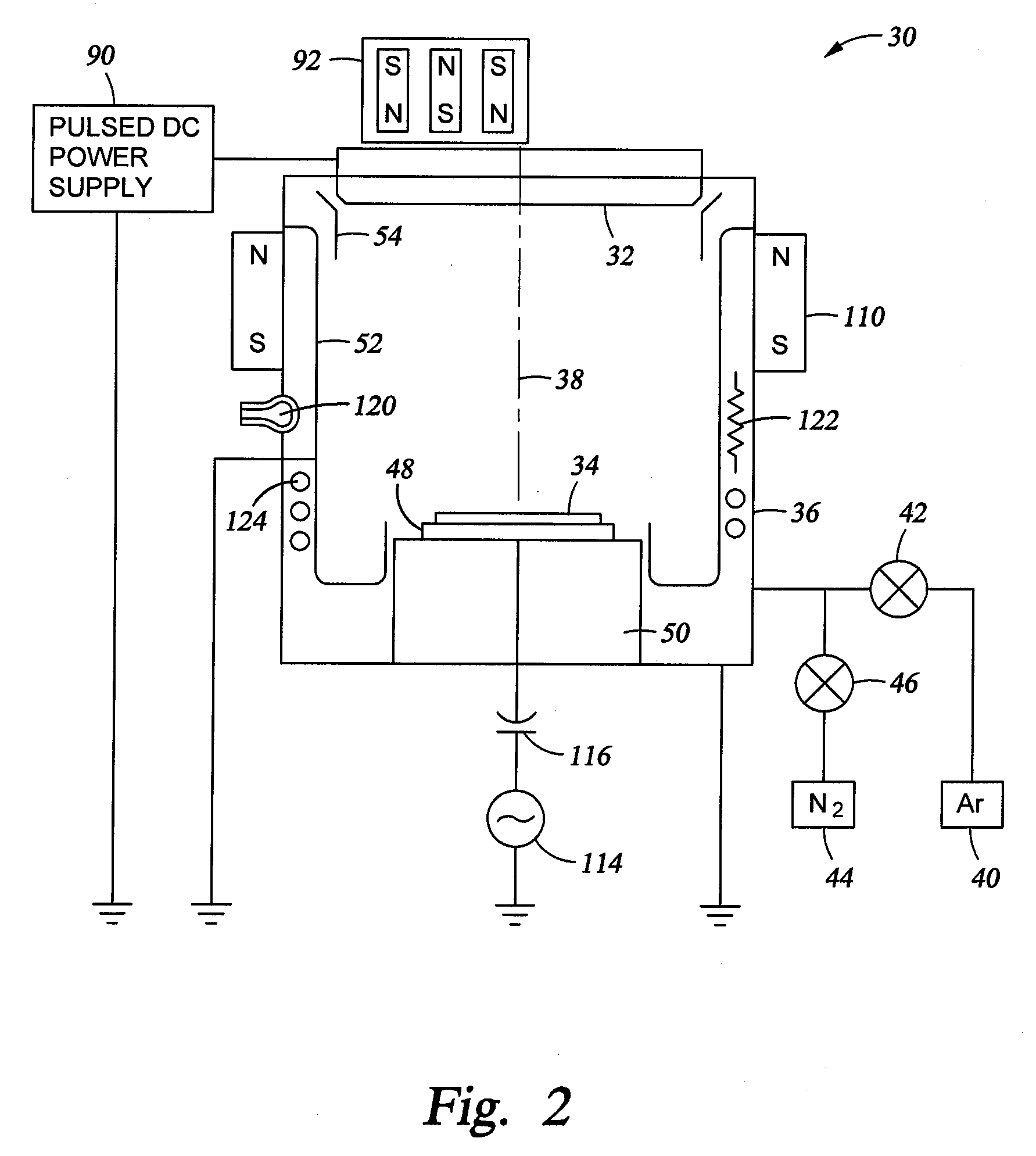

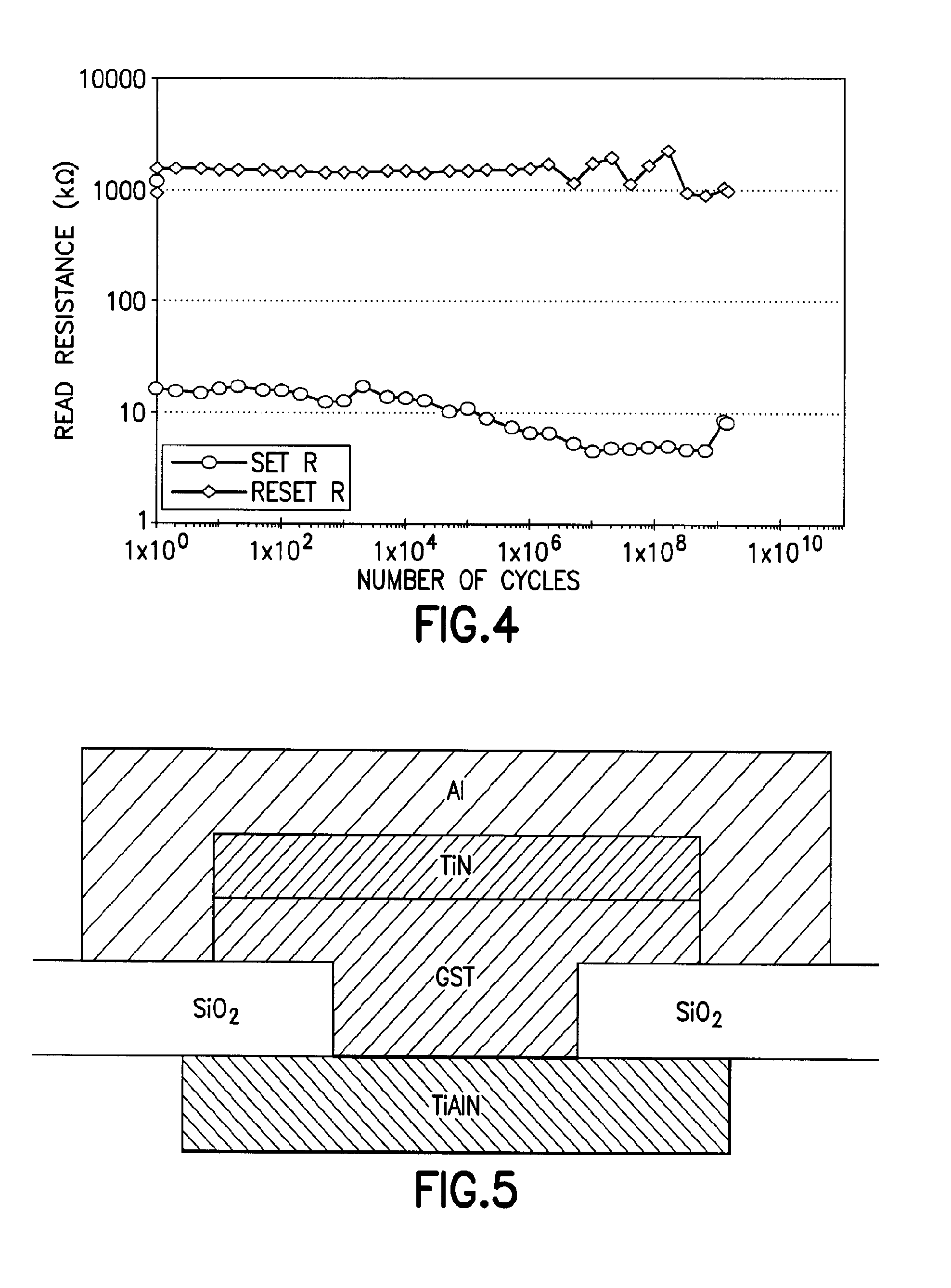

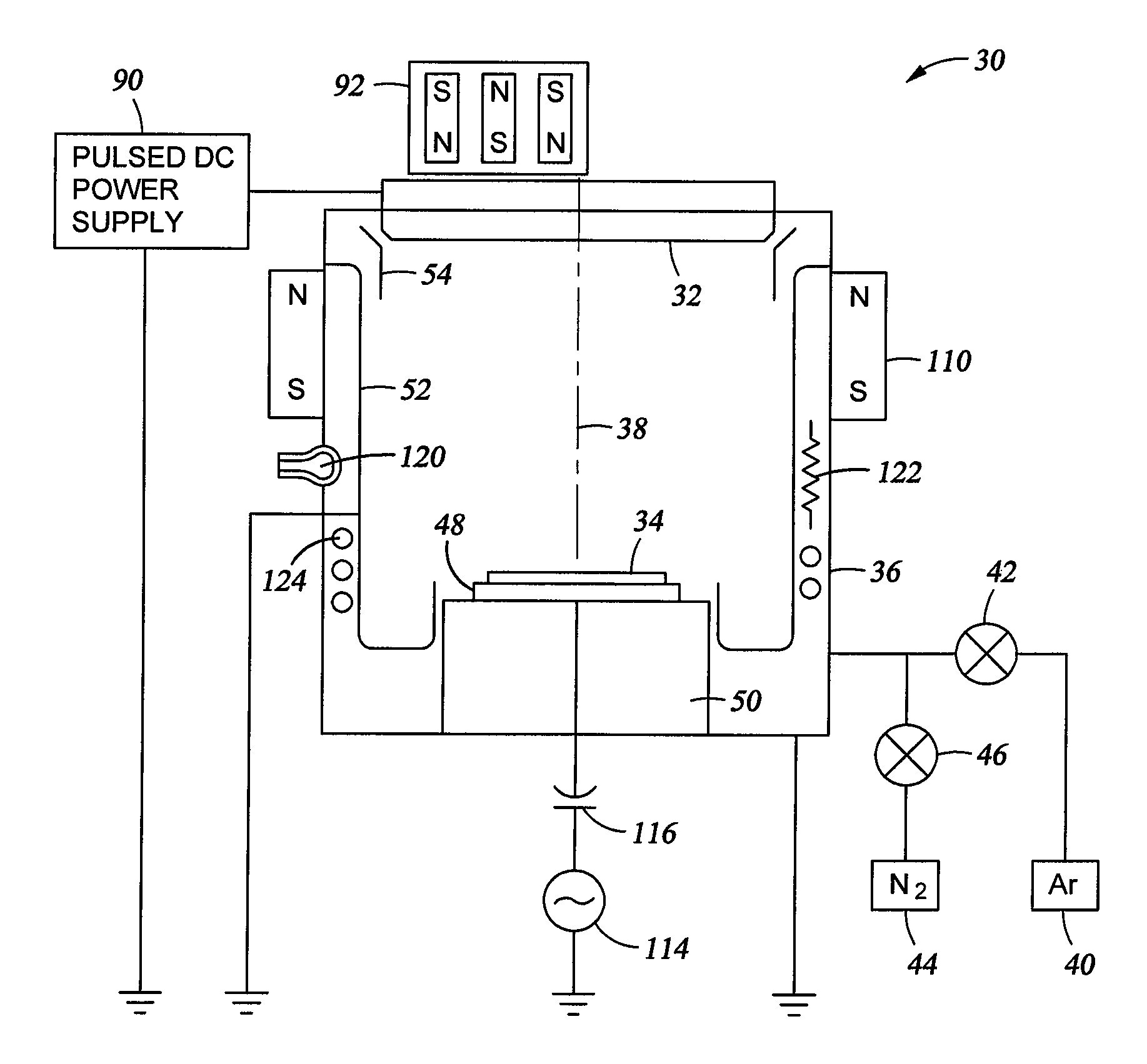

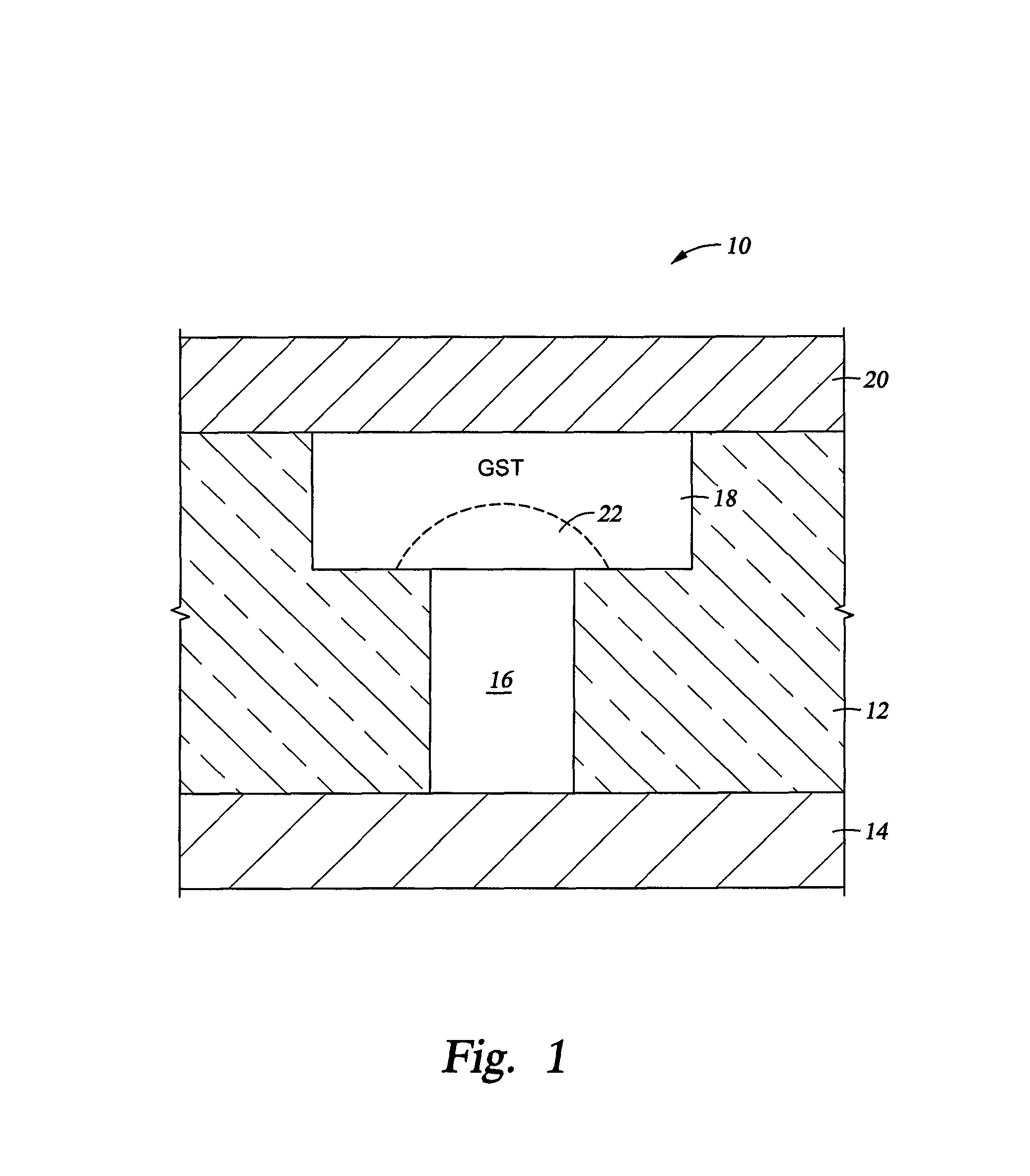

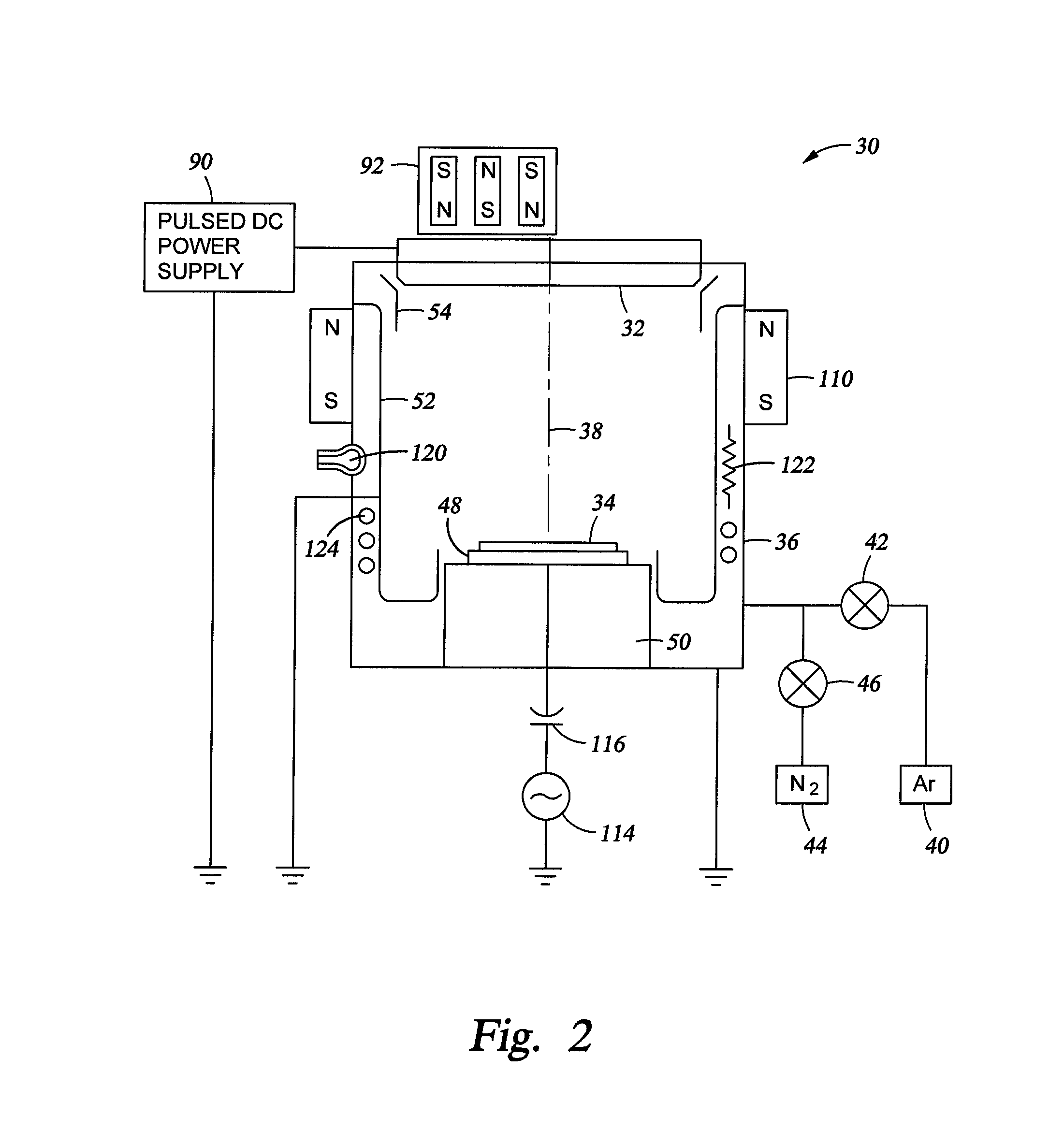

Sputtering of thermally resistive materials including metal chalcogenides

ActiveUS20080099326A1Reduce heat loadLow thermal conductivityVacuum evaporation coatingSputtering coatingPhase-change memoryMetal chalcogenides

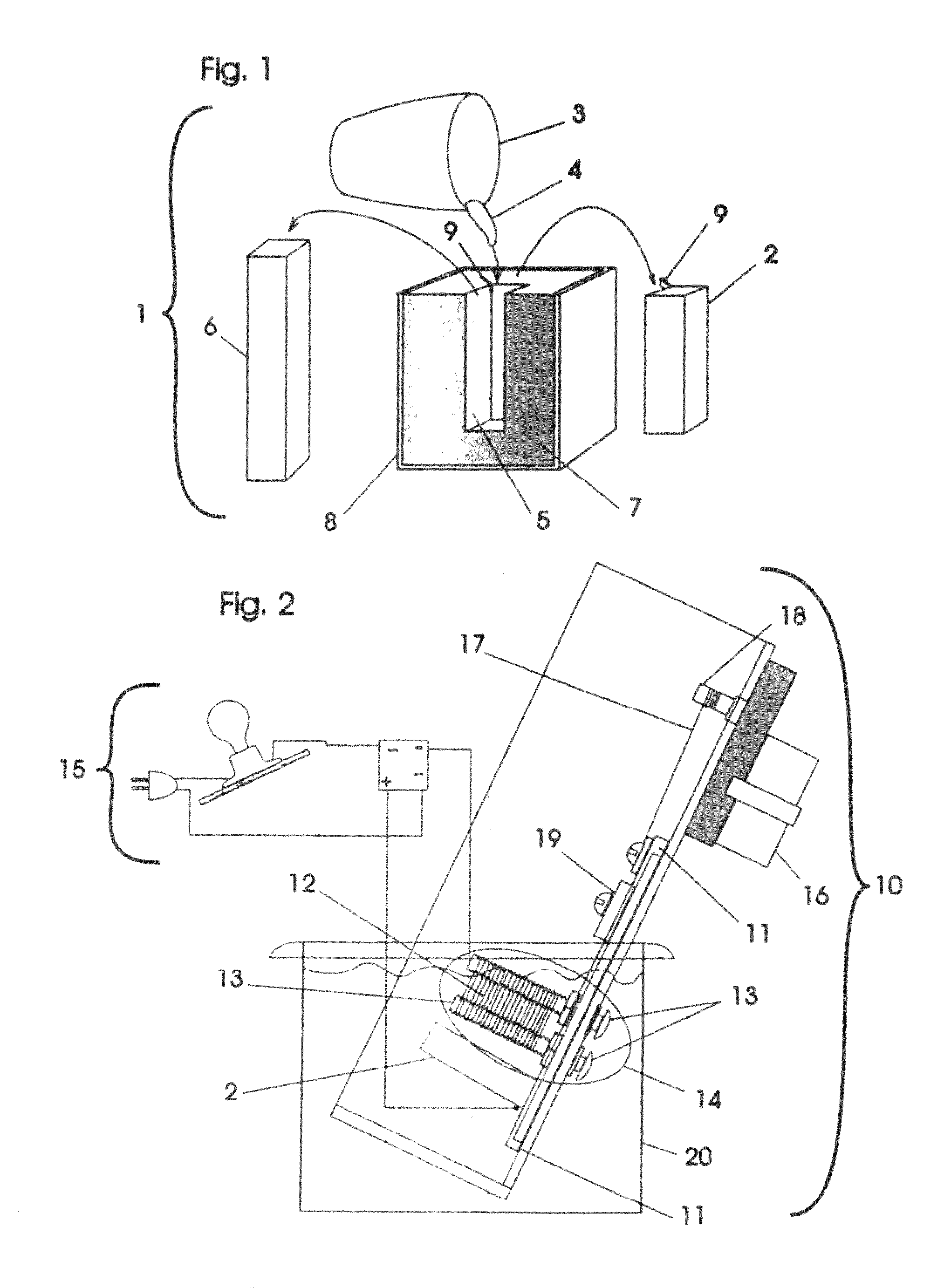

A plasma sputtering method for metal chalcogenides, such as germanium antimony telluride (GST), useful in forming phase-change memories. The substrate is held at a selected temperature at which the material deposits in either an amorphous or crystalline form. GST has a low-temperature amorphous range and a high-temperature crystalline range separated by a transition band of 105-120° C. Bipolar pulsed sputtering with less than 50% positive pulses of less than 10:s pulse width cleans the target while maintain the sputtering plasma. The temperature of chamber shields is maintained at a temperature favoring crystalline deposition or they may be coated with arc-spray aluminum or with crystallographically aligned copper or aluminum.

Owner:APPLIED MATERIALS INC

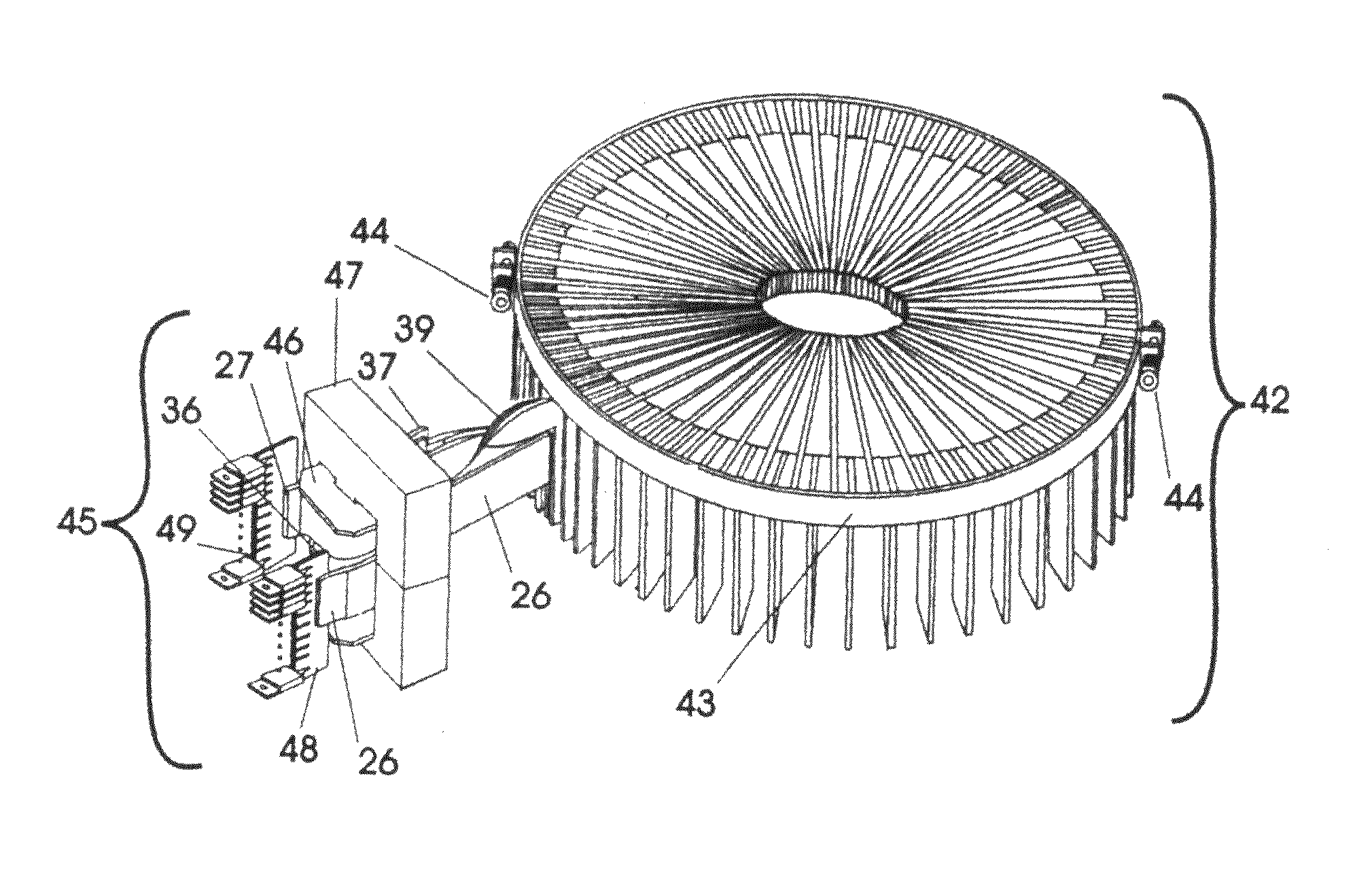

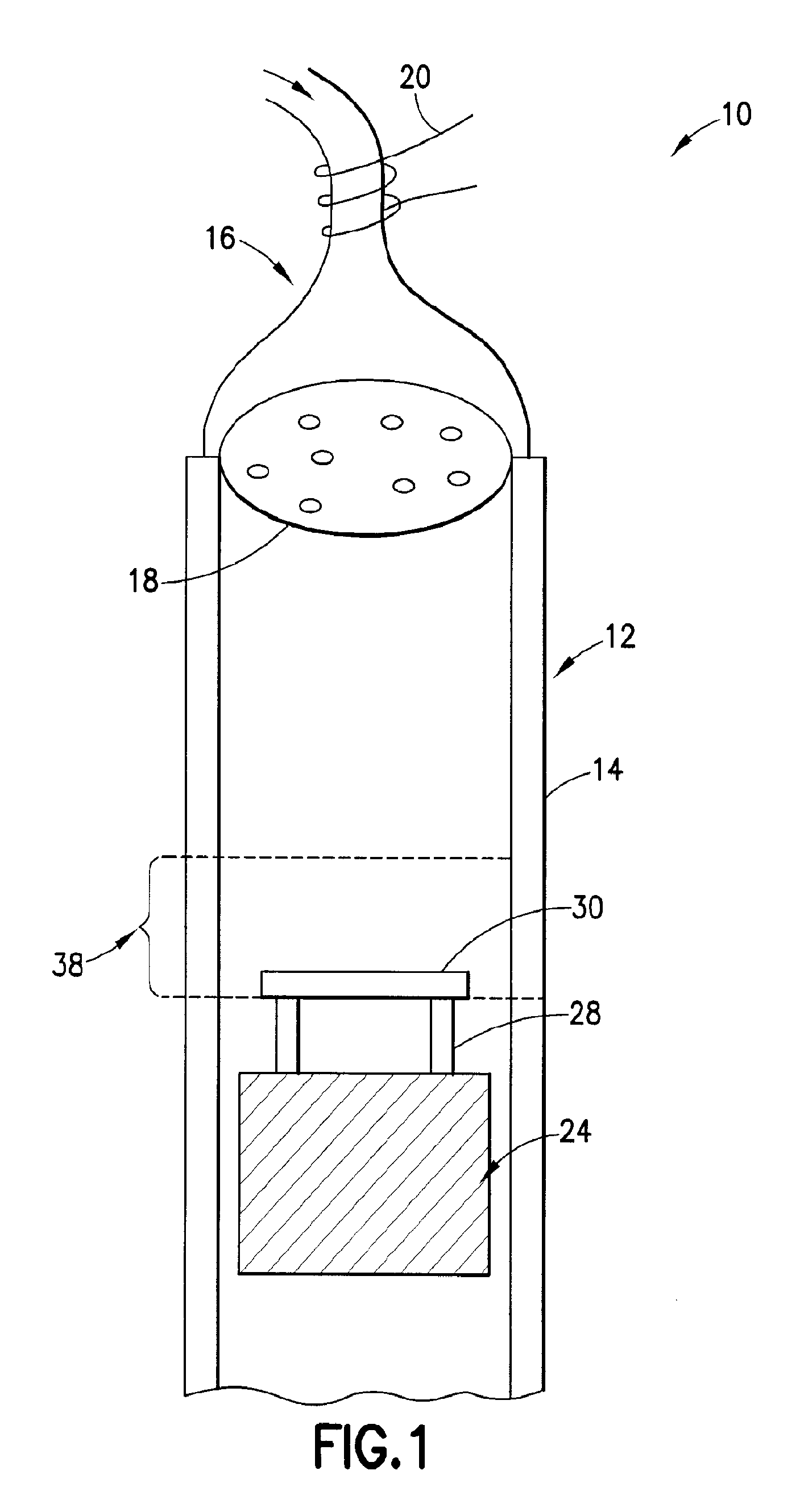

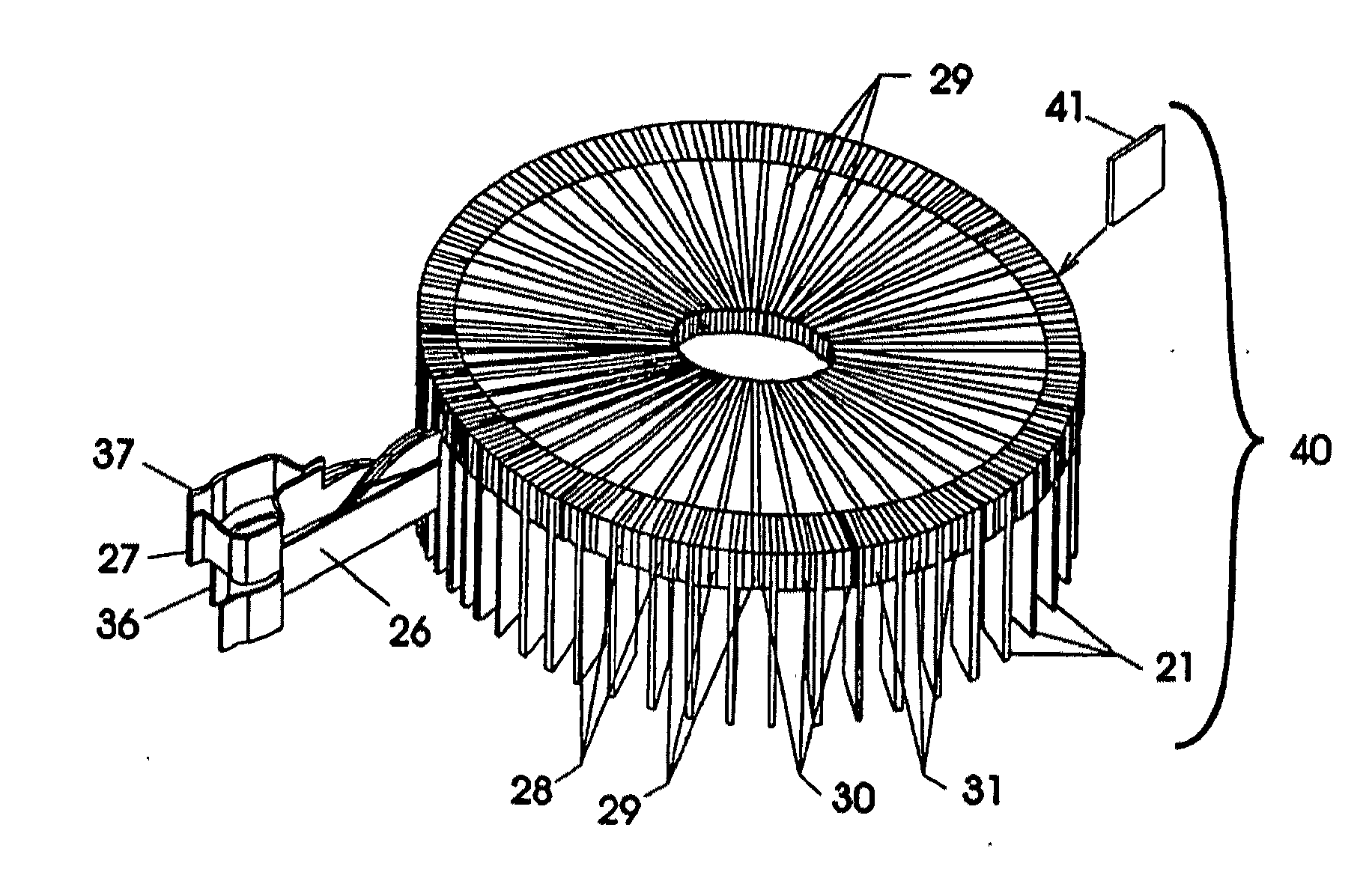

Solid state thermoelectric power converter

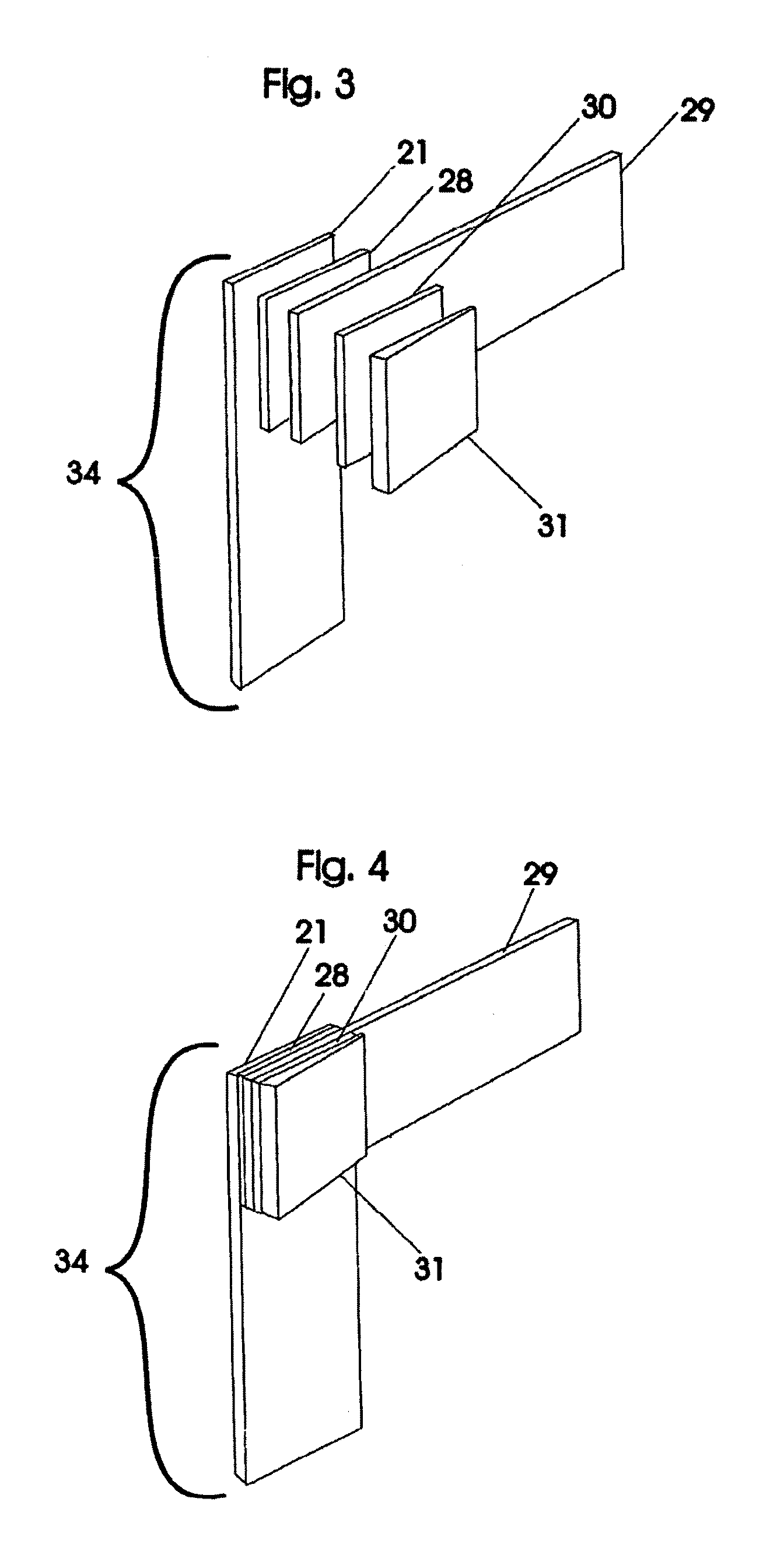

InactiveUS8101846B1Replacement is neededImprove efficiencyThermoelectric device with peltier/seeback effectMOSFETEngineering

High efficiency conversion of heat energy to electrical energy is achieved using a ring of metallic components and anodically sliced, reduced barriers, high purity n-type and p-type semiconductor wafers. Energy produced by heating one set of fins and cooling another set is extracted from a ring of bismuth telluride based n-type wafers and antimony telluride based p-type wafers using make-before-break control of MOSfet switch banks. Standard AC frequencies and DC output result from rectification of make-before-break high frequency switched very high currents in the ring and a DC to AC converter. Solar energy stored in porcelain fragments extends the time that solar energy can be used as the heat source for the thermoelectric generator device.

Owner:TE ENERGY LLC A FLORIDA LLC

Preparation method of porous carbon-coated antimony telluride nanosheet and application thereof as negative electrode material of metal ion battery

ActiveCN109659540AEasy to prepareRaw materials are cheap and easy to getNegative electrodesSecondary cellsLithiumPorous carbon

The invention discloses a preparation method of a porous carbon-coated antimony telluride nanosheet, and an application of the porous carbon-coated antimony telluride nanosheet as a negative electrodematerial of a metal ion battery. The preparation method is characterized by comprising the steps of: firstly, acquiring an antimony telluride nanosheet by adopting a hydrothermal method; secondly, coating the antimony telluride nanosheet with resorcinol-formaldehyde resin by adopting a liquid phase reaction technology; and finally, converting the resorcinol-formaldehyde resin into porous carbon through high-temperature carbonization, and acquiring the porous carbon-coated antimony telluride nanosheet. The preparation method of the product is simple, the used raw materials are cheap and easy to obtain, the porous carbon-coated antimony telluride nanosheet shows good cyclic stability and high cycle specific capacity when applied to the metal (lithium, sodium) ion battery, and the electrochemical performance is excellent.

Owner:HEFEI UNIV OF TECH

Metal telluride nanocrystals and synthesis thereof

InactiveUS20080036101A1Material nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsCarboxylic saltCarboxylic acid

A process for synthesizing a metal telluride is provided that includes the dissolution of a metal precursor in a solvent containing a ligand to form a metal-ligand complex soluble in the solvent. The metal-ligand complex is then reacted with a telluride-containing reagent to form metal telluride domains having a mean linear dimension of from 2 to 40 nanometers. NaHTe represents a well-suited telluride reagent. A composition is provided that includes a plurality of metal telluride crystalline domains(PbTe)1-x-y(SnTe)x(Bi2Te3)y (I)having a mean linear dimension of from 2 to 40 nanometers inclusive where x is between 0 and 1 inclusive and y is between 0 and 1 inclusive with the proviso that x+y is less than or equal to 1. Each of the metal telluride crystalline domains has a surface passivated with a saccharide moiety or a polydentate carboxylate. A densified mass having a density of greater than 95% of the theoretical density includes a plurality of lead telluride, tin telluride, bismuth telluride, or a combination thereof of domains having a mean linear dimension of from 2 to 40 nanometers inclusive that have been subjected to hot isotactic pressing.

Owner:TOYOTA MOTOR CO LTD +1

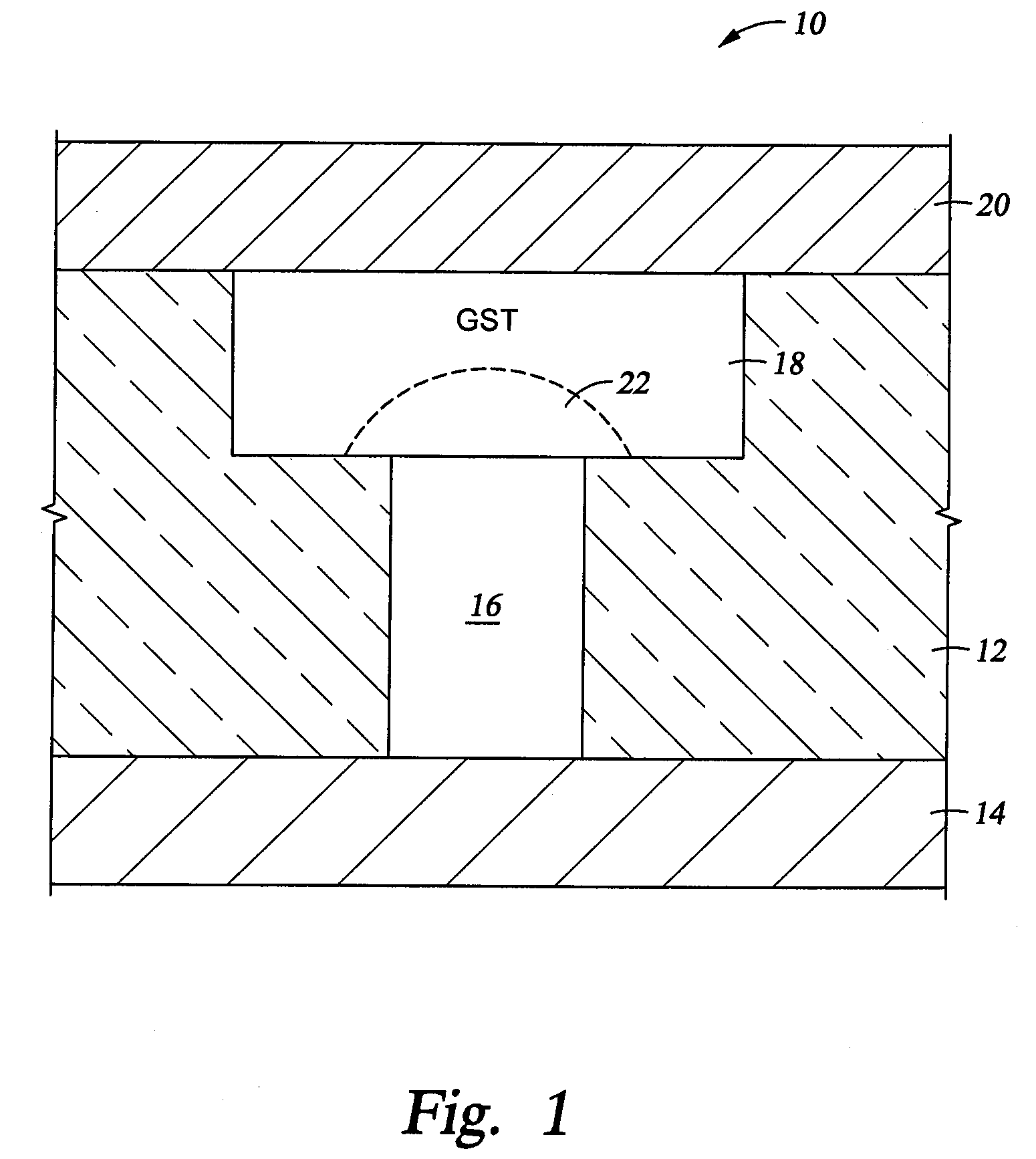

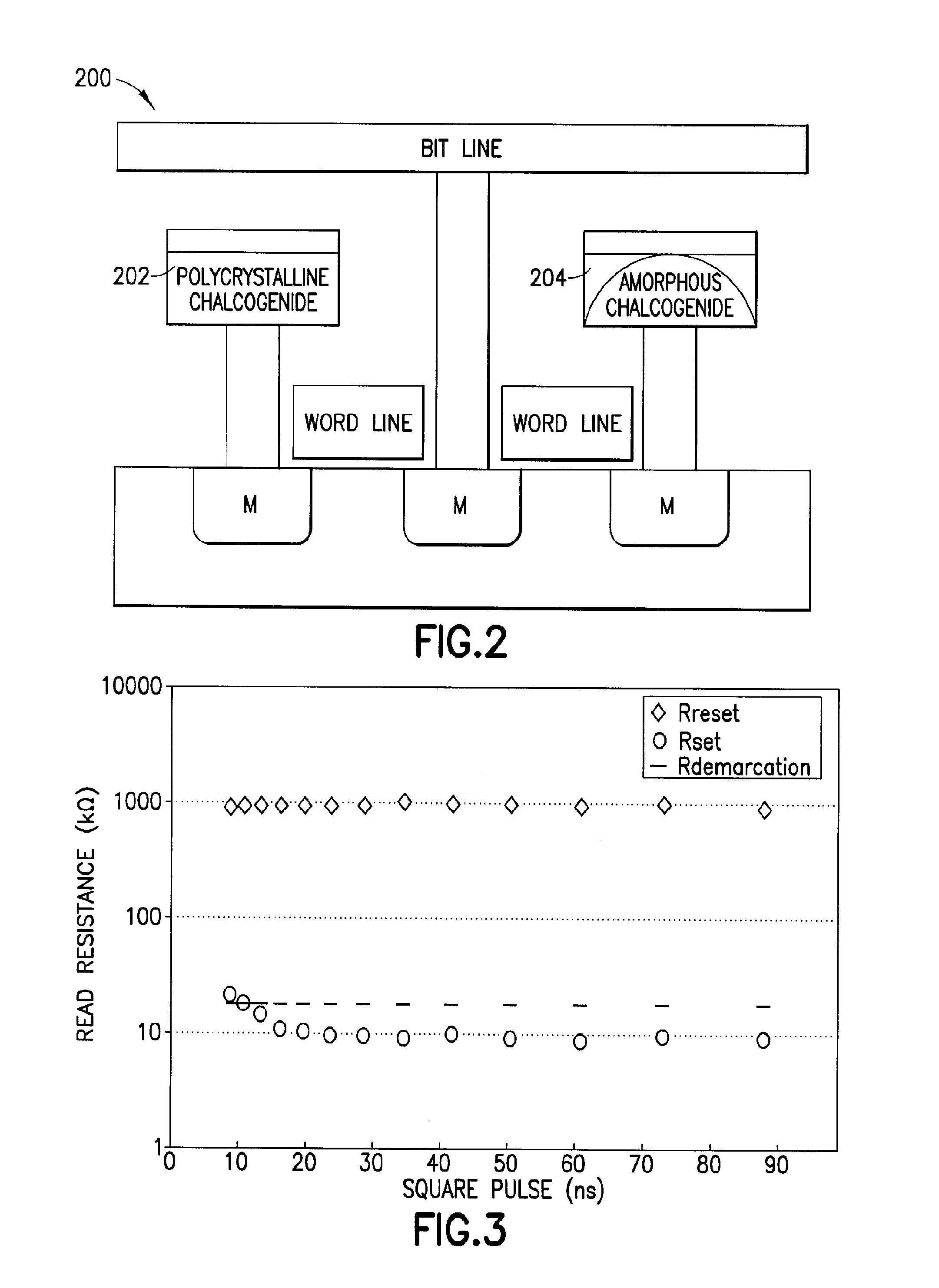

Germanium antimony telluride materials and devices incorporating same

ActiveUS20130112933A1Increase setting speedAdd settingsSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesPhase-change memoryRandom access memory

A chalcogenide alloy composition, having an atomic composition comprising from 34 to 45 Ge, from 2 to 16% Sb, from 48 to 55% Te, from 3 to 15% carbon and from 1 to 10% nitrogen, wherein all atomic percentages of all components of the film total to 100 atomic %. Material of such composition is useful to form phase change films, e.g., as conformally coated on a phase change memory device substrate to fabricate a phase change random access memory cell.

Owner:SAMSUNG ELECTRONICS CO LTD

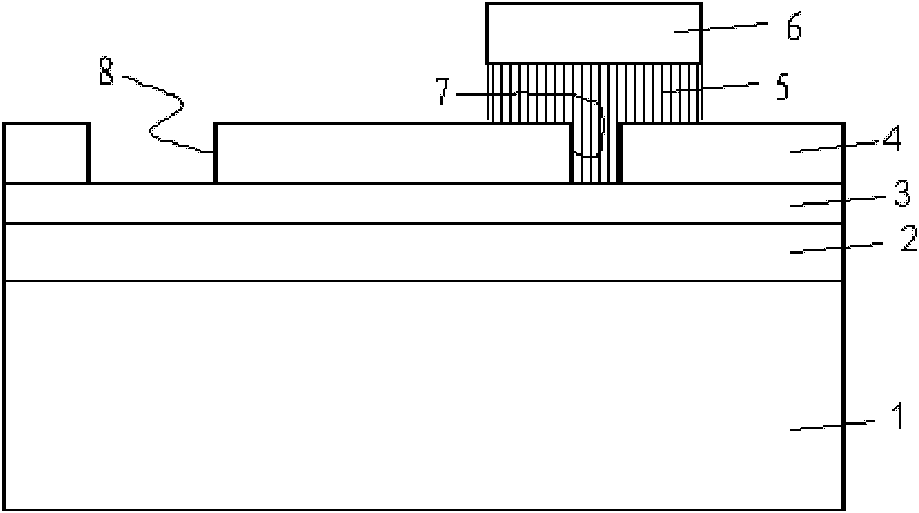

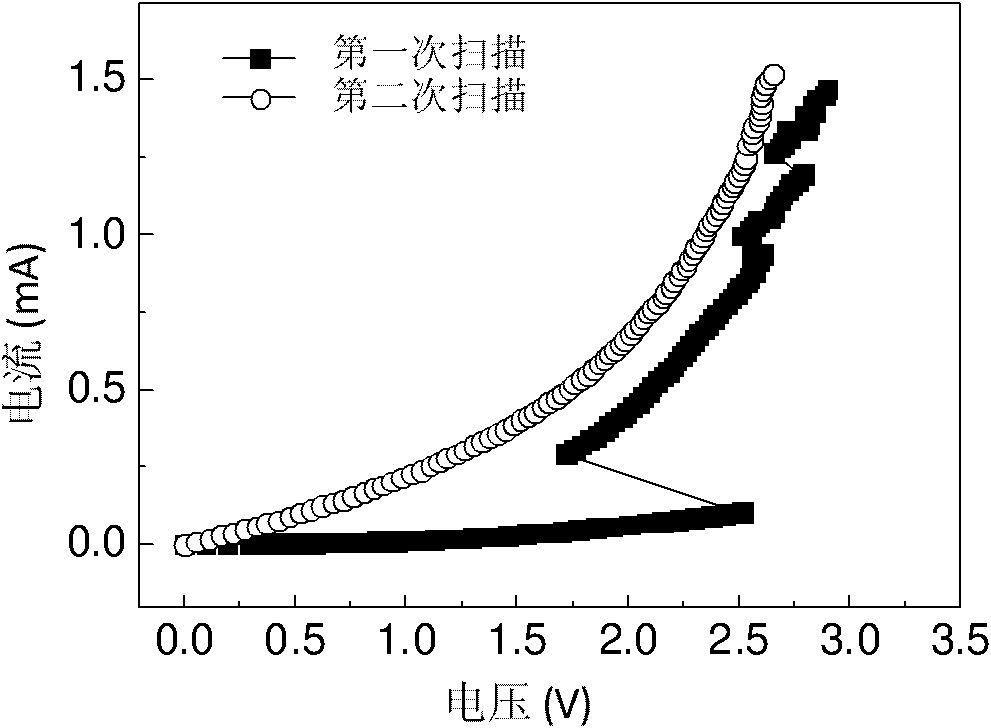

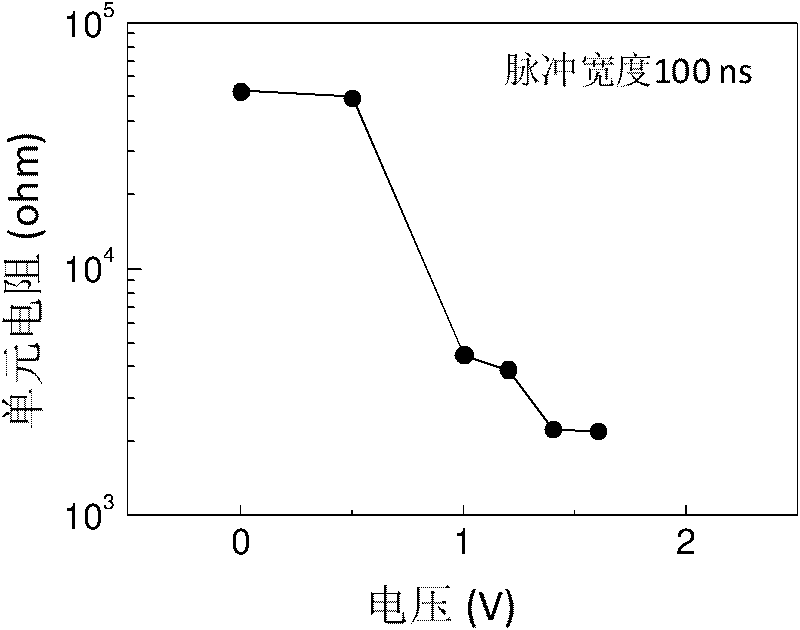

Phase change storage device based on antimony telluride composite phase change material and preparation method thereof

InactiveCN101916823AAchieve reversible transformationHigh speed crystallizationElectrical apparatusPhase changeAntimony telluride

The invention relates to a phase change storage device based on an antimony telluride composite phase change material and a preparation method thereof, belonging to the field of computer technology. The device comprises a substrate, a lower electrode, a heat generation electrode layer, an insulating layer, a phase change material layer and an upper electrode, wherein the phase change material layer is a composite phase change material layer containing antimony telluride and silicon nitride; the atom percent content range of the silicon nitride is 0.5-30; and the proportional range of Sb atoms and Te atoms in the phase change material layer is 80 / 20-30 / 70. The composite phase change material layer which has high crystallization velocity and higher heat generation efficiency is used by the phase change storage device of the invention, thus the operation velocity of the phase change storage device can be improved, and the RESET operation current of the phase change storage device can be lowered.

Owner:SHANGHAI JIAO TONG UNIV

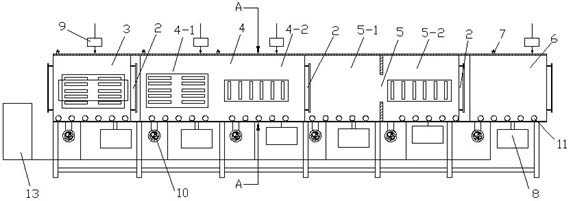

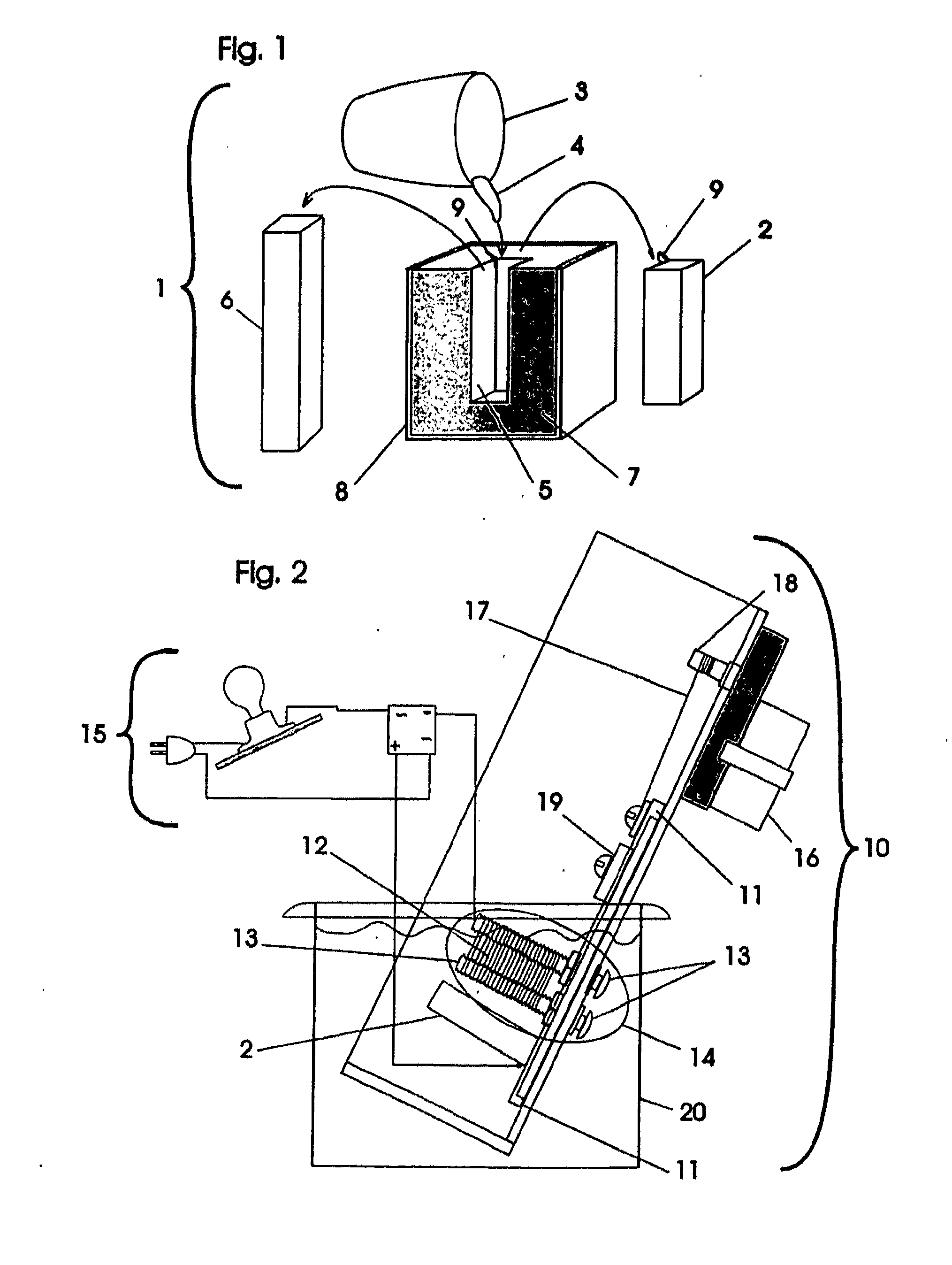

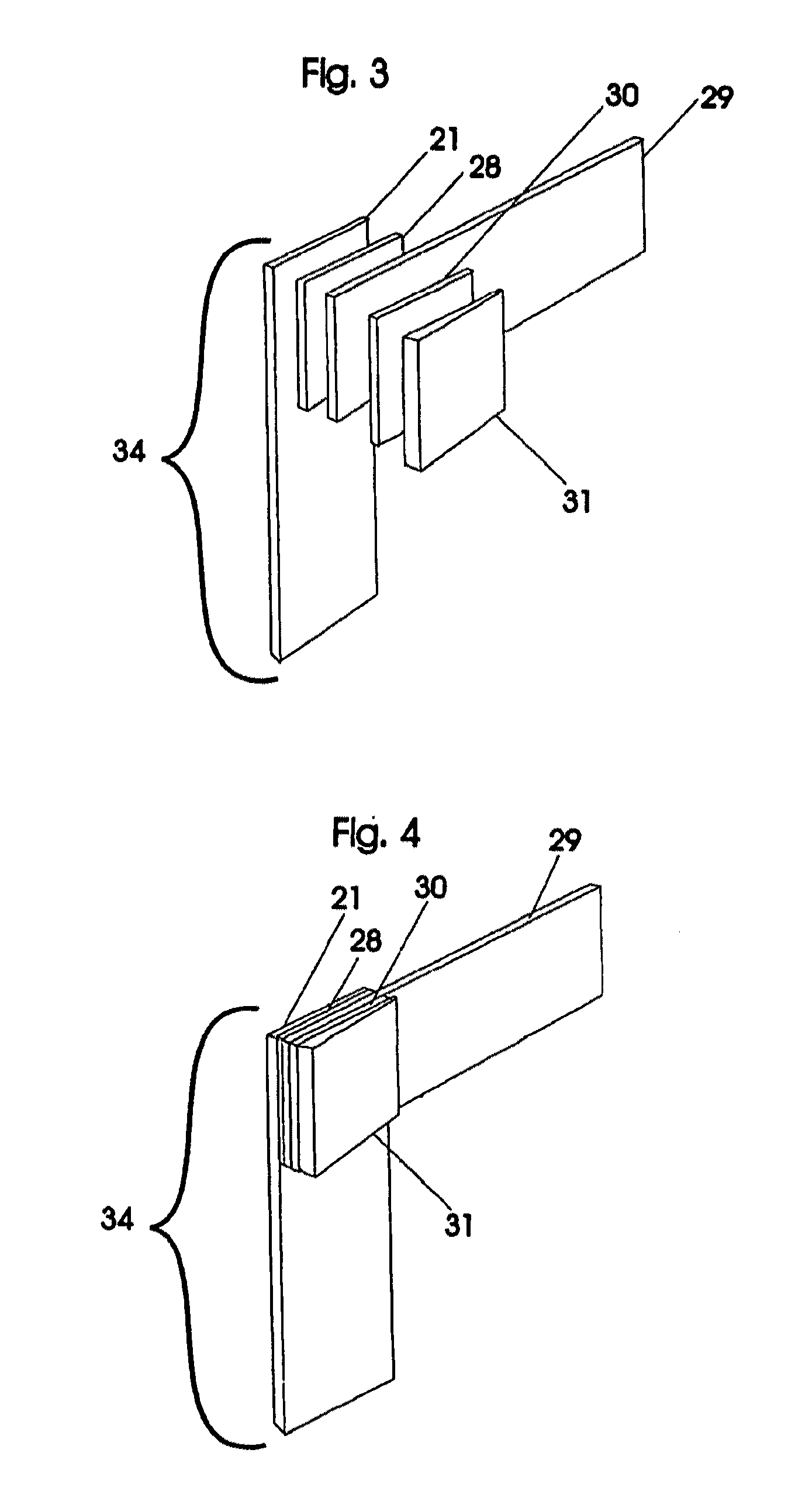

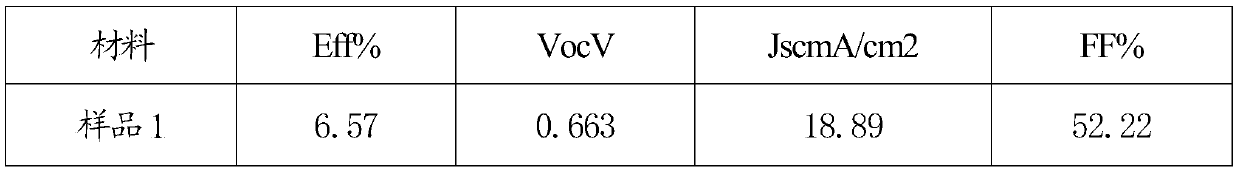

Cadmium telluride thin-film solar cell back contact layer production method and vertical coater

ActiveCN102628163AIncrease profitGuaranteed uniformityFinal product manufactureVacuum evaporation coatingAlloy depositionAlloy

The invention discloses a cadmium telluride thin-film solar cell back contact layer production method, and the production process is carried out in the vacuum environment. The steps are as follows: a substrate is preheated to 160 DEG C to 220 DEG C; after the substrate is heated to 230 DEG C to 320 DEG C, the magnetron sputtering of antimony telluride is carried out; after the substrate is cooled to 80 DEG C to 120 DEG C, the sputtering of nickel-vanadium alloy is carried out; and the substrate is cooled to less than 70 DEG C and then discharged. The coating of a cadmium telluride thin-film solar cell back contact layer produced by the method is uniform, and the number of pinholes is less. The invention also discloses a vertical coater which adopts the method to produce cadmium telluride thin-film solar cell back contact layers, the vertical coater comprises but is not limited to a preheating chamber, a temperature-keeping antimony telluride deposition chamber, a nickel-vanadium alloy deposition chamber, a temperature-decreasing discharge chamber, a vacuum system and the like which are connected in series through vacuum valves, and the vertical coater can simultaneously coat both sides of the substrate, enlarge the effective region of the coating and increase the production efficiency, and is easy to overhaul.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Antimony telluride/poly(3,4-ethylenedioxythiophene)/poly(styrene sulfonate) thermoelectric composite material and manufacturing method thereof

InactiveCN104538540AReduce processing energy consumptionLow costThermoelectric device junction materialsSulfonateMetallurgy

The invention discloses an antimony telluride / poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) thermoelectric composite material and a manufacturing method of the antimony telluride / poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) thermoelectric composite material, and belongs to the technical field of thermoelectric composite material synthesis. The manufacturing method comprises the steps that (1) antimony telluride nanopowder is prepared; (2) under the vacuum condition, spark plasma sintering is performed on the antimony telluride nanopowder prepared in the step (1), and then the antimony telluride nanopowder is cooled, so that an Sb2Te3 block material is obtained; (3) the Sb2Te3 block material prepared in the step (2) is cut, then is soaked in a poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) solution and is stored at the temperature of 3 DEG C-5 DEG C for 20-40 days, so that the antimony telluride / poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) thermoelectric composite material is obtained. The antimony telluride / poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) thermoelectric composite material and the manufacturing method of the antimony telluride / poly(3,4-ethylenedioxythiophene) / poly(styrene sulfonate) thermoelectric composite material have the advantages that the process is low in energy consumption, the cost is low, and the process is simple; the composite material is good in thermoelectric performance and high in ZT value.

Owner:WUHAN UNIV

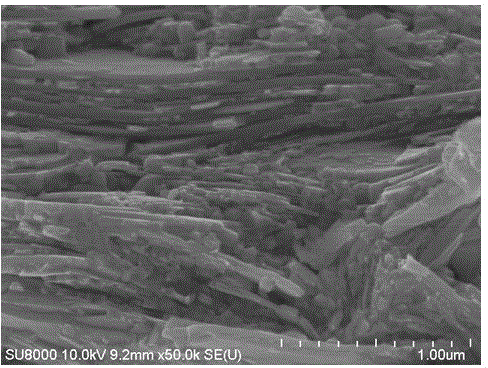

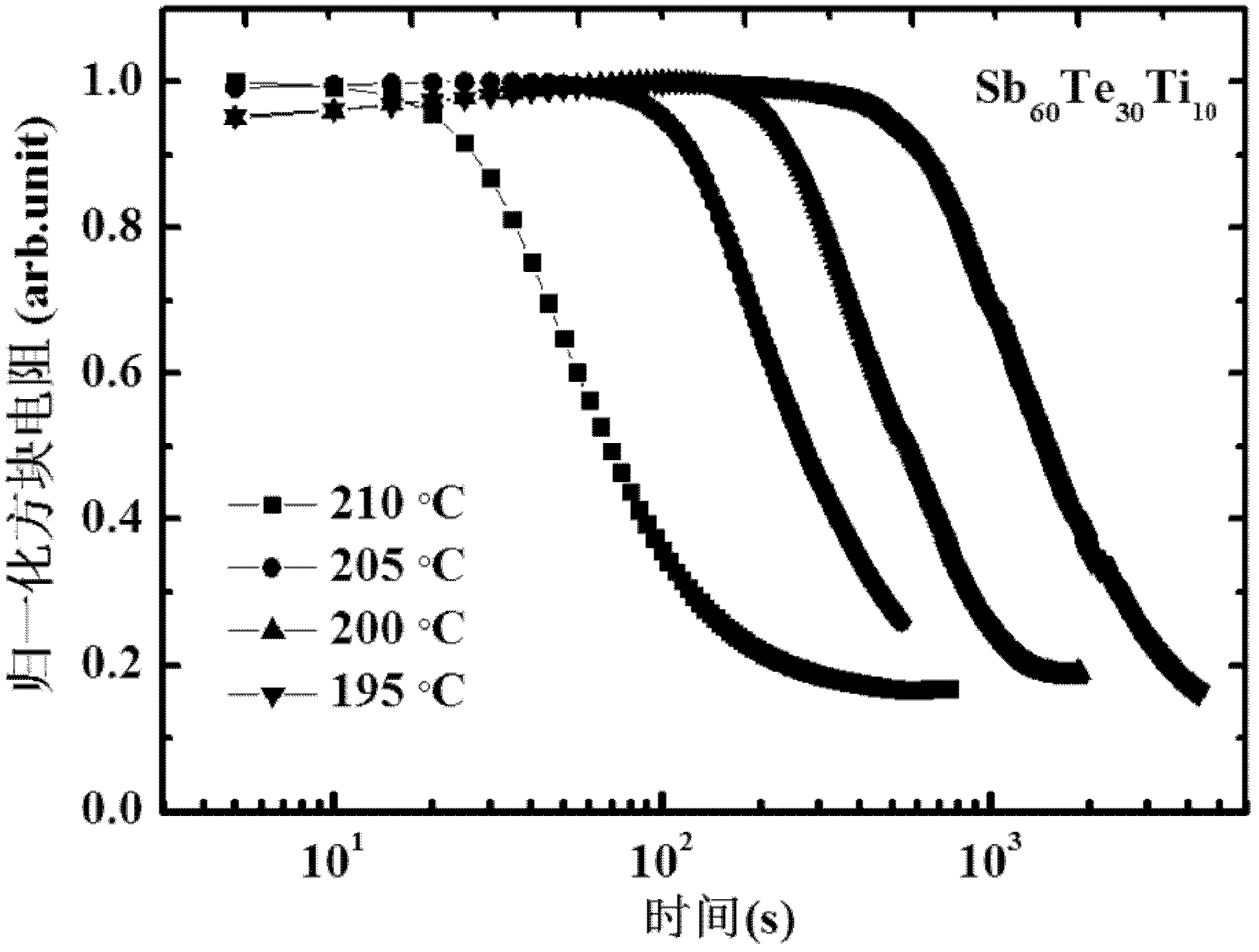

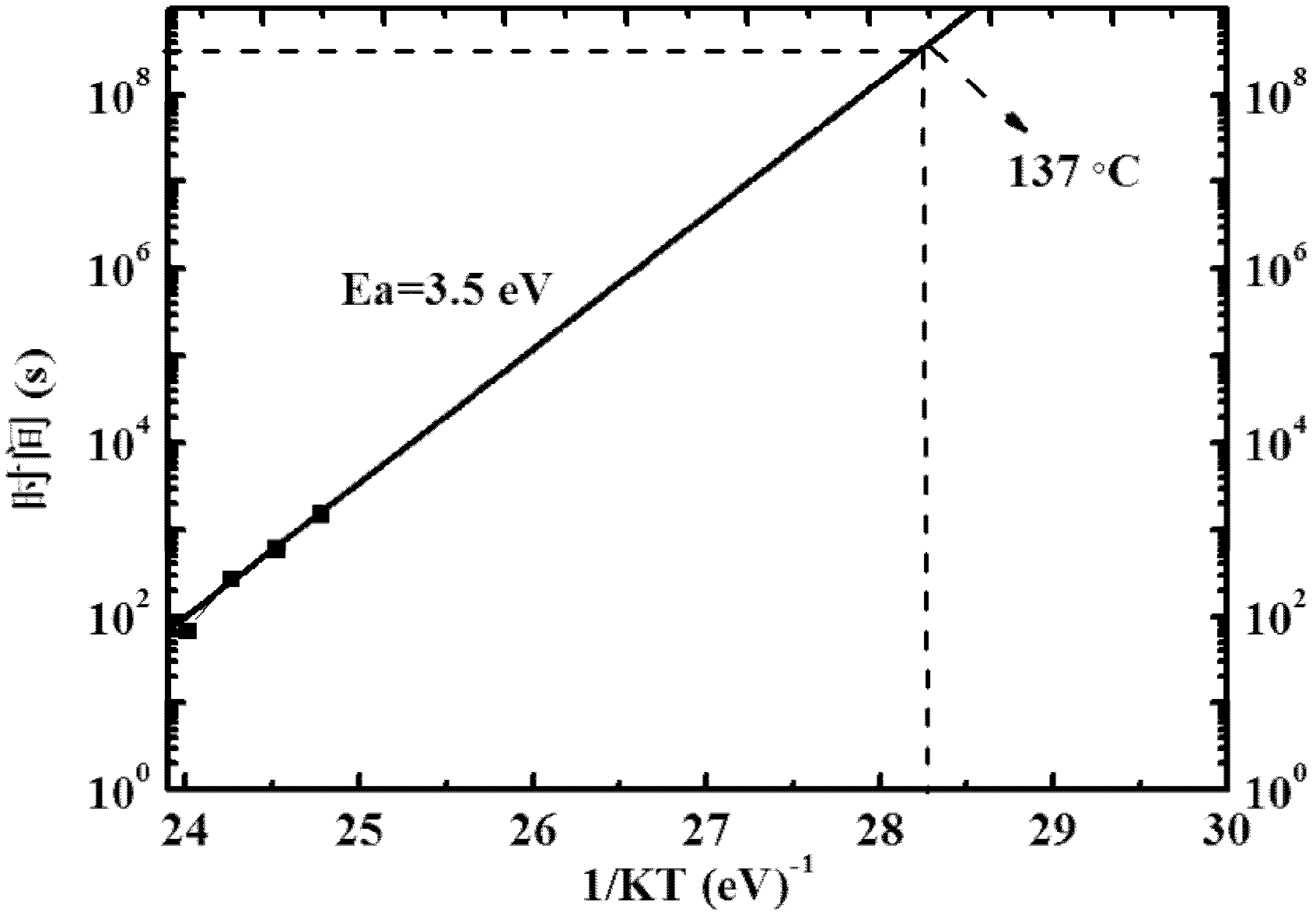

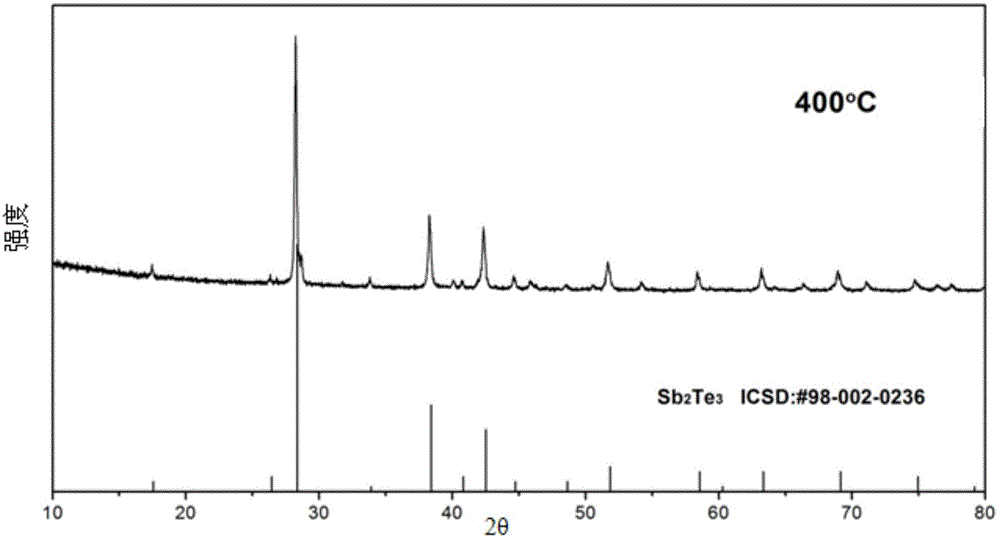

Antimony (Sb)-tellurium (Te)-titanium (Ti) phase-transition storage material and titanium-antimony telluride (Ti-Sb2Te3) phase-transition storage material

ActiveCN102593355AReduce power consumptionRaise the crystallization temperatureElectrical apparatusVacuum evaporation coatingTe elementTitanium

The invention relates to an antimony (Sb)-tellurium (Te)-titanium (Ti) phase-transition film material capable of being used for a phase-transition memory and a preparation method thereof. The novel Sb-Te-Ti phase-transition storage material is formed by doping Ti on the basis of a Sb-Te phase-transition material, the doped Ti is bonded with both the Sb and the Te, a chemical formula of the novel phase-transition material is SbxTeyTi100-x-y, wherein x is more than zero and less than 80, and y is more than zero and less than 100 minus x. When the novel phase-transition storage material is a Ti-Sb2Te3 phase-transition storage material, Ti atoms substitute the positions of Sb atoms, and no phase is split. The present Sb-Te phase-transition material crystallization process is led by the grain growth, so that the phase transition rate is fast, but the maintaining force cannot meet the industrial requirements. The crystallization temperature of the novel Sb-Te-Ti phase-transition storage material is greatly improved, the maintaining force is enhanced, and the thermal stability is enhanced; at the same time, amorphous resistance is reduced, and the crystalline resistance is increased; and the novel Sb-Te-Ti phase-transition storage material can be widely applied to the phase-transition memory.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for quickly preparing antimony telluride thermoelectric material

ActiveCN106145062AQuick responseReduce energy consumptionBinary selenium/tellurium compoundsThermoelectric materialsReaction speed

The invention discloses a method for quickly preparing a Sb2Te3 thermoelectric material. The method comprises the following steps that 1, Sb powder and Te powder are weighed according to the stoichiometric ratio of all elements in Sb2Te3 and then ground and mixed to be uniform to obtain a mixed raw material; 2, discharging plasma activated sintering is conducted on the mixed raw material obtained in the step 1, and the compact single-phase Sb2Te3 thermoelectric material is obtained. The antimony telluride thermoelectric material has the advantages of being high in reaction speed, efficient, economical in energy, good in repeatability and the like and has a very good application prospect.

Owner:WUHAN UNIV OF TECH

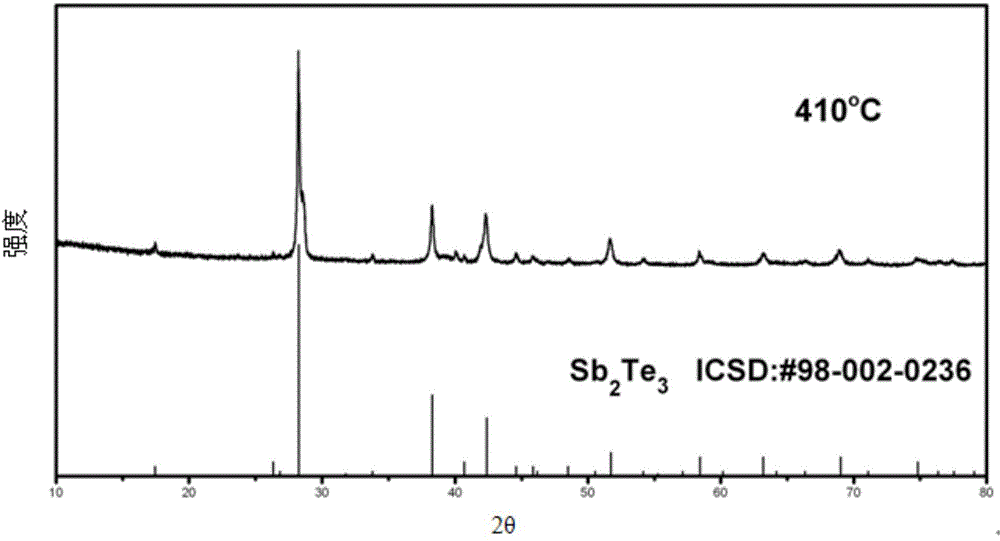

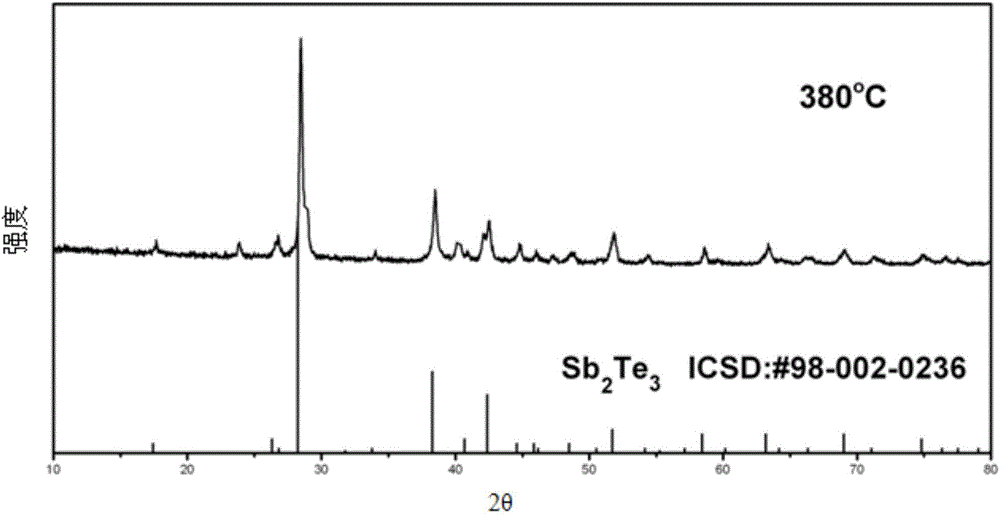

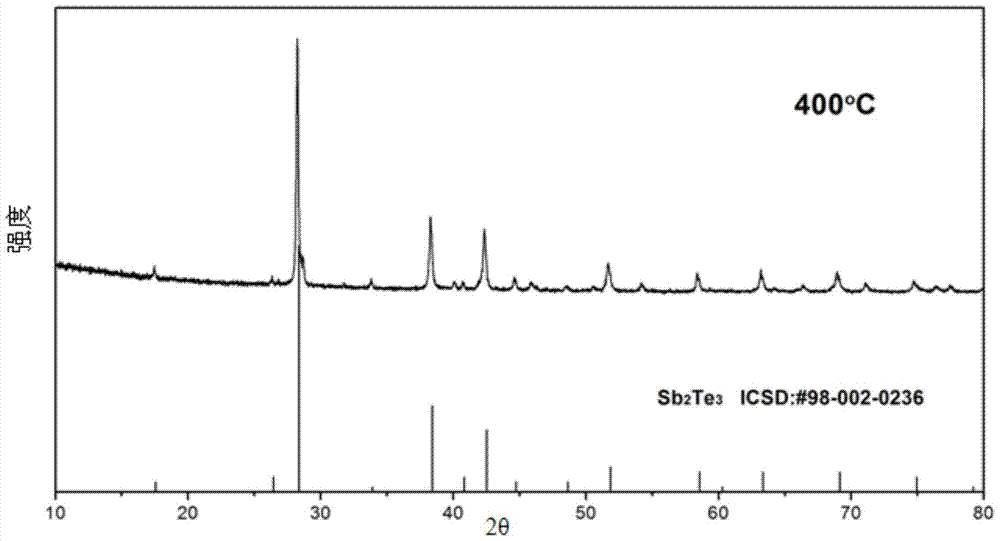

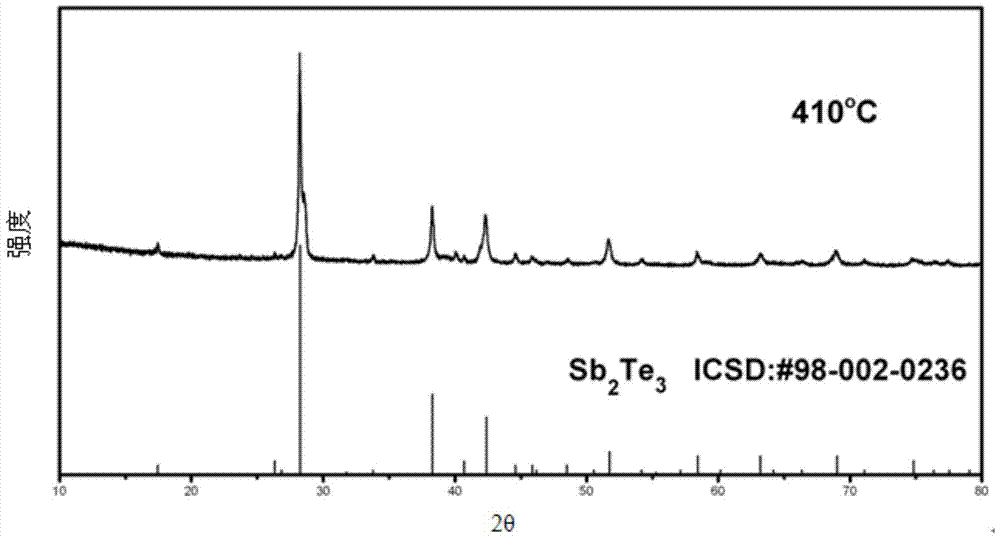

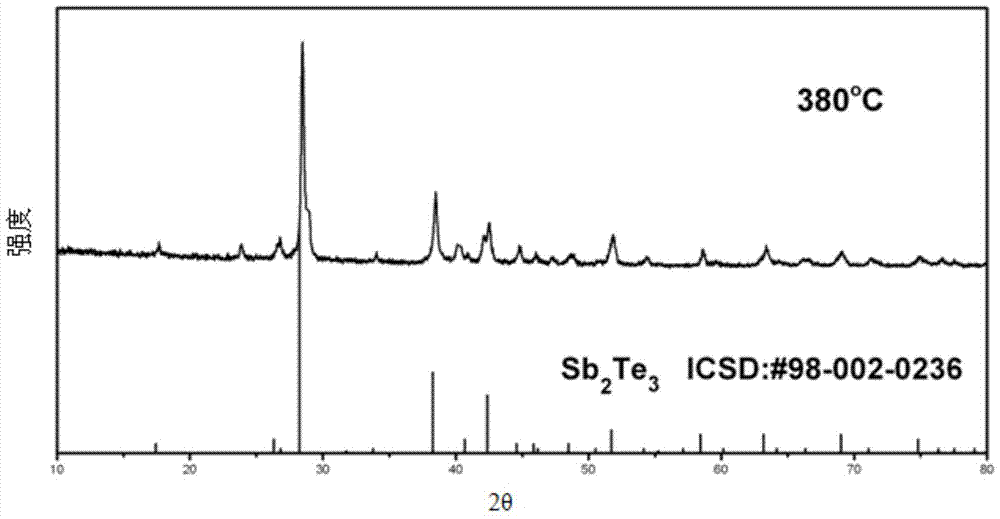

Method for preparing high thermoelectrical antimony telluride micro-nano crystal and block material thereof

InactiveCN104310320AEfficient removalPrevent oxidationMaterial nanotechnologyMetal selenides/telluridesMicro nanoPolyol

The invention discloses a method for preparing a high thermoelectrical antimony telluride micro-nano crystal and a block material thereof. The method comprises the following steps: dissolving an antimony precursor into polyol, then mixing the obtained solution with a tellurium precursor and a complexing agent, heating the mixed solution at a temperature of 140 to 180 under stirring, cooling to a temperature of 100 to 120 DEG C, adding a reducing agent, carrying out reactions at a temperature of 120 to 180 DEG C for 6 to 48 hours so as to obtain precipitate, washing the obtained precipitate by waterless ethanol until the washing liquid is neutral, drying the washed precipitate in vacuum so as to obtain antimony telluride micro-nano crystal, cold-pressing the obtained antimony telluride crystal into a sheet, and then carrying out annealing for 2 to 24 hours at a temperature of 300 to 400 DEG C in an atmosphere of mixed gas composed of Ar and H2 with a volume ratio of 92%:8% so as to obtain an antimony telluride block material. The obtained antimony telluride micro-nano crystal and block material thereof have the characteristics of high purity and good thermoelectrical property. Moreover the preparation method has the advantages of simpleness, low cost, easiness in repeating, and suitability for massive production, and thus has a good commercialization prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Preparation method of quantum dot sensitized solar cell light cathode

ActiveCN105489383APromote productionImprove stabilityLight-sensitive devicesSolid-state devicesIndiumArgon atmosphere

The invention discloses a preparation method of a quantum dot sensitized solar cell light cathode. The preparation method comprises the following steps: firstly dispersing titanium dioxide quantum dots and one of sulfur / selenium / antimony telluride quantum dots, copper-indium sulfide quantum dots, copper-indium-selenium quantum dots, copper-zinc-tin-sulfur quantum dots and copper-zinc-tin-selenium quantum dots which contain an oleic acid or oleylamine stabilizer in a same non-polar solvent respectively to form oil-phase solutions; then uniformly mixing two oil-phase solutions, and adding a solar solvophobic solvent so that the titanium dioxide quantum dots and chalcogenide quantum dots are coprecipitated to form a titanium dioxide-chalcogenide quantum dot aggregate; and finally coating the titanium dioxide-chalcogenide quantum dot aggregate on conducting glass through titanium tetrachloride treatment, and carrying out heat treatment under an argon atmosphere to form the quantum dot sensitized solar cell light cathode. The preparation method disclosed by the invention is simple, the stability and light-induced electron transmission performance of a quantum dot sensitized solar cell can be obviously improved, and the dark reaction of the cell is reduced.

Owner:HUAQIAO UNIVERSITY

Sputtering of thermally resistive materials including metal chalcogenides

ActiveUS8500963B2Reduce heat loadLow thermal conductivityVacuum evaporation coatingSputtering coatingPhase-change memoryMetal chalcogenides

A plasma sputtering method for metal chalcogenides, such as germanium antimony telluride (GST), useful in forming phase-change memories. The substrate is held at a selected temperature at which the material deposits in either an amorphous or crystalline form. GST has a low-temperature amorphous range and a high-temperature crystalline range separated by a transition band of 105-120° C. Bipolar pulsed sputtering with less than 50% positive pulses of less than 10:s pulse width cleans the target while maintain the sputtering plasma. The temperature of chamber shields is maintained at a temperature favoring crystalline deposition or they may be coated with arc-spray aluminum or with crystallographically aligned copper or aluminum.

Owner:APPLIED MATERIALS INC

Solid state thermoelectric power converter

InactiveUS20120090534A1Improve efficiencyReplacement is neededPolycrystalline material growthThermoelectric device with peltier/seeback effectMOSFETEngineering

High efficiency conversion of heat energy to electrical energy is achieved using a ring of metallic components and anodically sliced, reduced barriers, high purity n-type and p-type semiconductor wafers. Energy produced by heating one set of fins and cooling another set is extracted from a ring of bismuth telluride based n-type wafers and antimony telluride based p-type wafers using make-before-break control of MOSfet switch banks. Standard AC frequencies and DC output result from rectification of make-before-break high frequency switched very high currents in the ring and a DC to AC converter. Solar energy stored in porcelain fragments extends the time that solar energy can be used as the heat source for the thermoelectric generator device.

Owner:SCHROEDER JON MURRAY +1

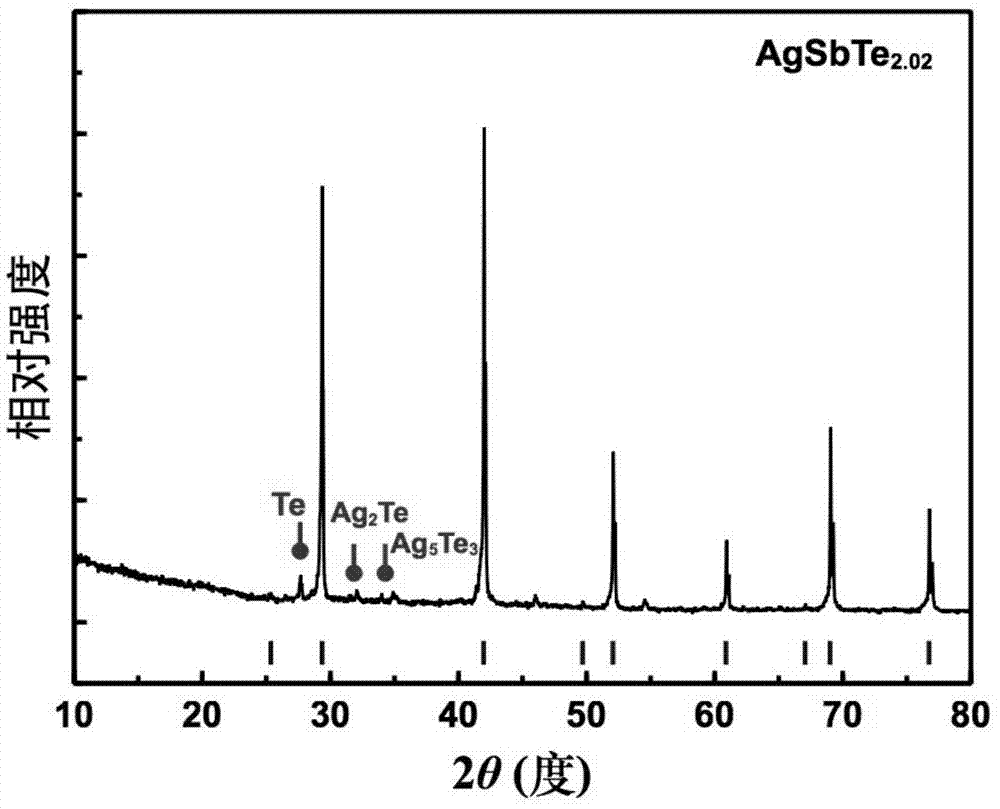

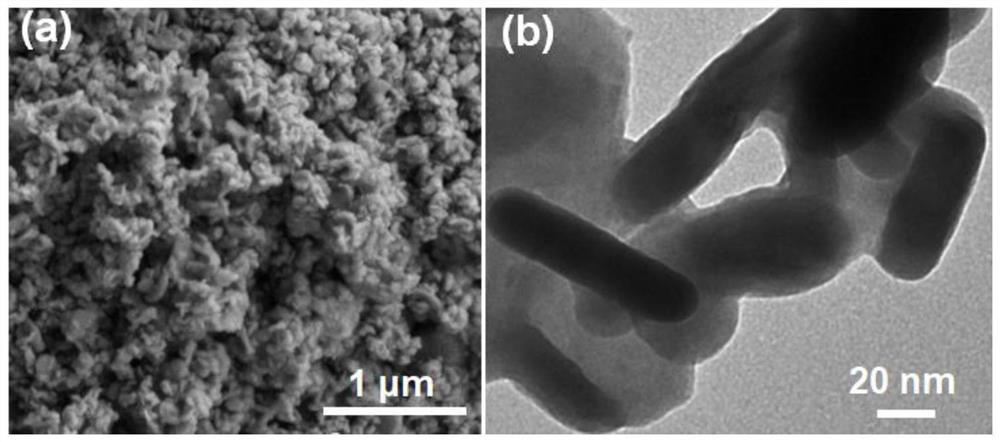

Method used for preparing AgSbTe2 thermoelectric material

InactiveCN104961107AHigh densityGood repeatabilityBinary selenium/tellurium compoundsHigh energyVolumetric Mass Density

The invention relates to a method used for preparing a AgSbTe2 thermoelectric material. The method comprises following steps: 1) material preparation, wherein silver telluride and antimony telluride are taken as main raw materials, trace elemental tellurium is taken as a thermoelectric performance regulating composition, and silver telluride, antimony telluride, and elemental tellurium are weighed at a molar ratio of (0.9-1.1)(0.9-1.1):x as reaction raw materials, and x ranges from 0 to 0.04; 2) high energy ball milling, wherein the raw materials disclosed in step 1) are subjected to high energy ball milling in inert gas protection atmosphere so as to obtain single-phase AgSbTe2 powder; and 3) spark plasma sintering, wherein the single-phase AgSbTe2 powder is subjected to spark plasma sintering so as to obtain the compact AgSbTe2 thermoelectric material. The raw materials are stable in the air; oxidation is not easily caused; the whole technology is simple and controllable; preparation cost is low; repeatability is high; density of the prepared AgSbTe2 block material is high; phase is pure; and thermoelectric performance is excellent.

Owner:HENAN POLYTECHNIC UNIV

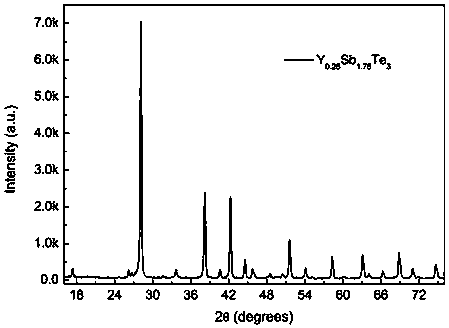

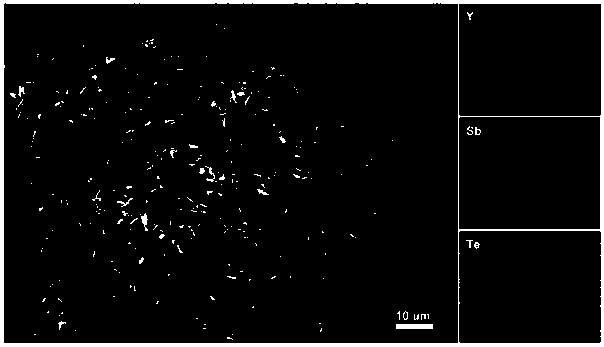

Preparation method of yttrium-doped antimony telluride phase changing material

ActiveCN108389960ARaw materials are cheap and easy to getSimple processElectrical apparatusThermal insulationSolvent

The invention provides a preparation method of an yttrium-doped antimony telluride phase changing material. The preparation method of the yttrium-doped antimony telluride phase changing material Y<x>Sb<2-x>Te<3> comprises the steps of 1) enabling raw materials Y(NO<3>)<3>.6H<2>O, SbCl<3> and TeO<2> to be dissolved into a mixed solvent of dilute ammonia water and absolute ethyl alcohol to obtain aprecursor, wherein the molar ratio of Y(NO<3>)<3>.6H<2>O to SbCl<3> to TeO<2> is x: 2-x: 3 (x is greater than or equal to 0 and less than or equal to 0.33); 2) transferring the precursor obtained in the step 1) into a reaction kettle, adding NaBH<4>, next, heating to 160-200 DEG C, performing thermal insulation for 18-24h, then cooling to the room temperature, and next, separating out precipitates; and 3) performing alternate washing and filtering on the precipitates by deionized water and ethyl alcohol and then carrying out vacuum constant temperature drying to obtain the yttrium-doped antimony telluride phase changing material. The preparation method disclosed in the invention has the characteristics of low cost of raw materials, simple process, low equipment cost, safety and no pollution and the like; and the prepared phase change material is small in granularity, high in purity and uniform in element distribution.

Owner:BEIHANG UNIV

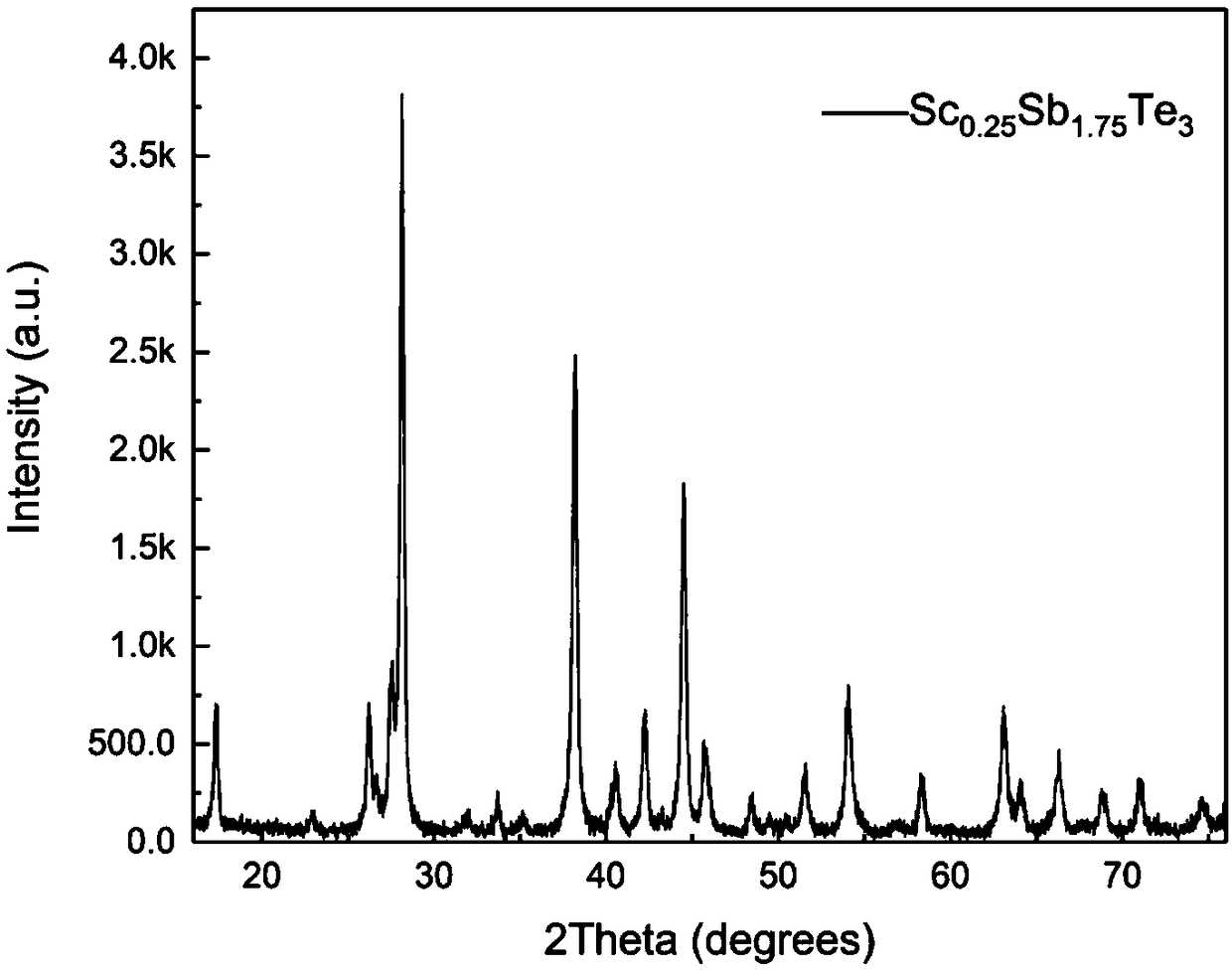

Preparation method for transition metal doped antimony telluride alloy target material

InactiveCN109226768ALow costEasy to operateVacuum evaporation coatingSputtering coatingRoom temperatureAlloy

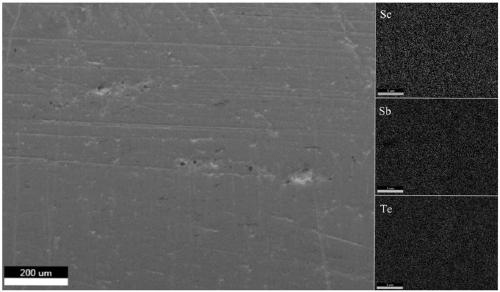

The invention provides a preparation method for a transition metal doped antimony telluride alloy target material. Transition metals comprise Sc, Y, Ti, Cr, Hg, Zn and the like. The preparation methodfor the alloy target material comprises the steps that 1, a proper amount of alloy powder is put into a graphite die, and then the graphite die with the alloy powder is sealed in a vacuum hot press furnace; 2, 70% of target pressure is applied at the room temperature, the pressure is maintained for about 5 minutes, and then the pressure is slowly relieved; 3, the temperature is adjusted to be 200DEG C, then the target pressure is applied, the pressure is maintained for about 5 minutes, and then the pressure is slowly relieved; 4, after heating is conducted to raise the temperature to targettemperature, the target pressure is applied again, and the pressure is maintained for about 5 minutes; 5, after pressure maintaining is finished, natural cooling is conducted, every when the temperature is reduced by 20%, the target pressure is relieved by 20%, and after the temperature is lowered to the room temperature, the target material is obtained. The preparation method has the advantages of being low in cost, simple in operation, environmentally friendly and the like, the target material prepared by using the method is high in purity and high in density, and elements in the target material are uniformly distributed.

Owner:BEIHANG UNIV

Thermoelectric film material and production process

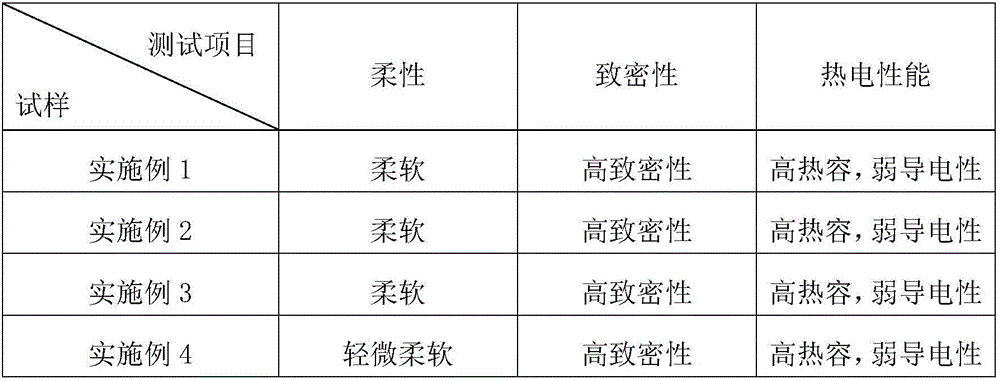

ActiveCN106549096AImprove compactnessImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsScreen printingSlurry

The present invention discloses a thermoelectric thin film material and a production process thereof. The production process of the thermoelectric thin film material comprises the steps of synthesizing a thermoelectric material base material, preparing a slurry, preparing a thermoelectric thin film base body, carrying out sintering treatment and the like. According to the thermoelectric thin film material and the production process thereof of the invention, a silk-screen printing technology is adopted to print the slurry on a flexible bearing base, and therefore, a process bottleneck that a thin film is deposited on a low-melting point flexible bearing base through using a high-melting point thermoelectric material can be broken through; a sectional type sintering treatment mode is adopted to sinter the dried thermoelectric thin film base body, since the sectional type sintering treatment mode has the characteristics of high heating speed, short sintering time and low sintering temperature, the low melting point requirement of the flexible bearing base can be satisfied; secondary crystallization can be realized better, and therefore, the compactness of bismuth telluride and antimony telluride after recrystalization can reach 88% to 90%; and therefore, the material obtained through synthesis is dense in surface, the specific heat capacity of the material is higher, and the material has a good heat end and cold end and can meet market demands.

Owner:SUZHOU KANRONICS ELECTRONICS TECH CO LTD

Cadmium telluride thin film solar battery and preparation method thereof

ActiveCN109801980AIncrease the bandgap widthImprove initial performanceFinal product manufacturePhotovoltaic energy generationMercury cadmium tellurideOhmic contact

The invention discloses a cadmium telluride thin film solar battery. The cadmium telluride thin film solar battery comprises a substrate layer, a light absorbing layer, a back contact layer and a backelectrode layer which are arranged sequentially from bottom to top; the light absorbing layer is a cadmium telluride film layer; and the back contact layer is composed of an antimony telluride and copper selenide composite material. According to the cadmium telluride thin film solar battery of the invention, the back contact layer made of the antimony telluride and copper selenide composite material can form good ohmic contact with the cadmium telluride light absorbing layer, and therefore, potential barriers are lowered, and doped copper selenide can effectively eliminate the defects of thecadmium telluride light absorbing layer, and after selenium diffuses to a cadmium telluride interface, the forbidden band width of the cadmium telluride can be effectively increased, and presents deep-V type gradient change; and the initial performance and long-term stability of the battery are excellent, and the conversion efficiency of the battery is high.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

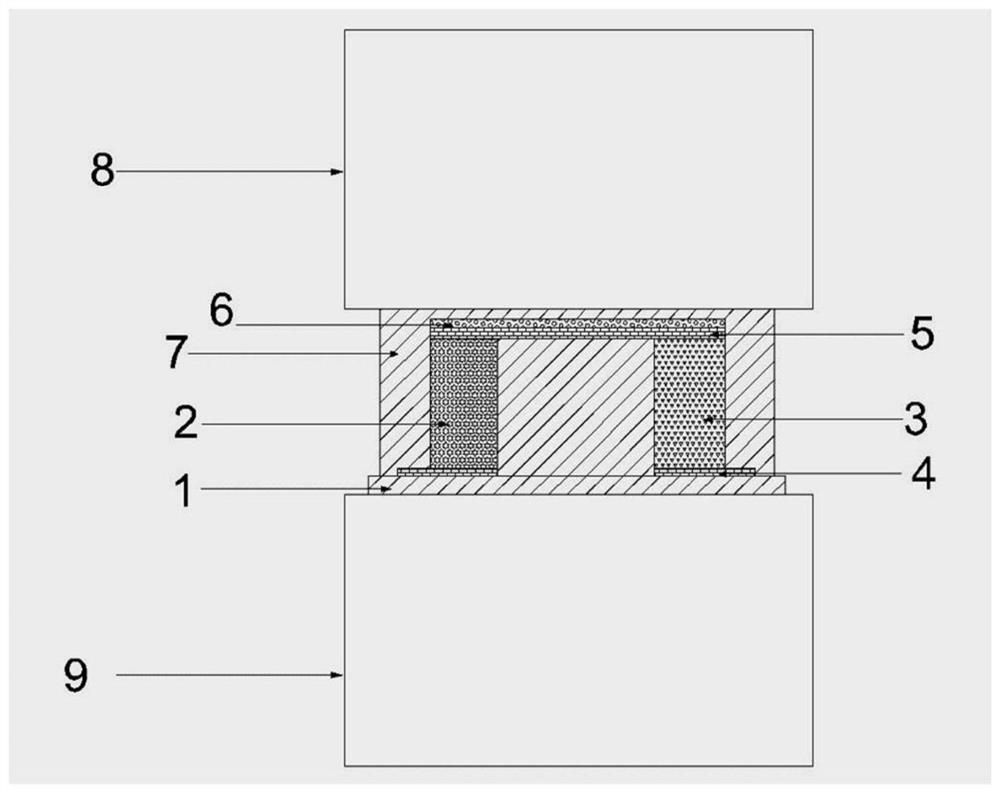

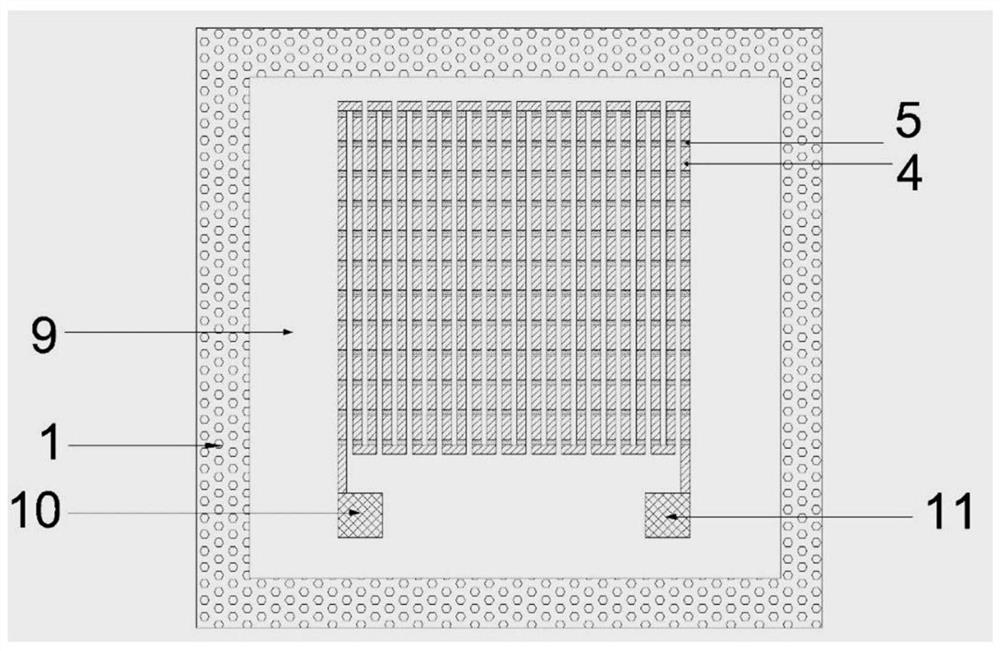

Three-dimensional micro-fluidic chip calorimeter for biochemical reaction detection and preparation method of three-dimensional micro-fluidic chip calorimeter

ActiveCN112710414AReduce volumeHigh sensitivityElectrolytic inorganic material coatingVacuum evaporation coatingPolyimide substrateThermopile

The invention provides a three-dimensional micro-fluidic chip calorimeter for biochemical reaction detection and a preparation method of the three-dimensional micro-fluidic chip calorimeter. The three-dimensional micro-fluidic chip calorimeter comprises a polyimide substrate, a bismuth telluride N type semiconductor column, an antimony telluride P type semiconductor column, a thermopile surface exposed lead end, a bottom Au connection electrode, a top Au connection electrode, a Ni top protection electrode, a polyimide protection layer, a top PDMS micro-channel and a bottom PDMS micro-channel, wherein the bismuth telluride N type semiconductor column, the antimony telluride P type semiconductor column, the thermopile surface exposed lead end, the bottom Au connection electrode, the top Au connection electrode, the Ni top protection electrode, the polyimide protection layer, the top PDMS micro-channel and the bottom PDMS micro-channelare arranged on the polyimide substrate. When biological or chemical liquid is injected from the outside into the top PDMS micro-channel of the calorimeter and room-temperature pure water is injected into the bottom PDMS micro-channel, a temperature difference is formed between the two micro-channels due to a thermal reaction generated by the biological or chemical liquid, so that the upper surface of a thermopile becomes a hot node, and the lower surface of the thermopile becomes a cold node; according to the seebeck effect, a corresponding electric potential is output, and then a thermal reaction condition is obtained according to the electric potential. The calorimeter has very high sensitivity and measurement precision.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparation of silver antimony telluride thermoelectric material by combining low temperature solid phase reaction with hot pressing process

InactiveCN104762501AHigh densityHigh purityThermoelectric device junction materialsThermoelectric materialsReaction temperature

The invention relates to a method for preparation of a silver antimony telluride thermoelectric material by combining low temperature solid phase reaction with hot pressing process. The method comprises the steps of: 1) ingredient compounding: according to the stoichiometric ratio of each element in the chemical formula AgSbTe2+x, weighing elemental silver, elemental tellurium and elemental antimony as raw materials, wherein x is 0-0.02; 2) briquetting sealing; 3) solid phase reaction: raising the temperature of the vacuum-tight block obtained in step 2) to a reaction temperature of 390-450DEG C, and conducting heat preservation for 6-12h to obtain a single phase silver antimony telluride ingot body or approximate single phase silver antimony telluride ingot body; 4) hot-pressing: grinding the obtained ingot and then performing hot pressed sintering, thus obtaining the high density silver antimony telluride thermoelectric material. The method has the characteristics of low reaction temperature, simple and controllable process, low preparation cost, and the prepared silver antimony telluride block material has the advantages of high density, high purity, good repeatability and excellent thermoelectric properties.

Owner:HENAN POLYTECHNIC UNIV

Bismuth antimony telluride/graphene potassium ion battery negative electrode material with high-stability structure and preparation method thereof

ActiveCN113130908AObvious sandwich layered stacking structureImprove conductivitySecondary cellsNegative electrodesMaterials scienceHigh current

The invention discloses a bismuth antimony telluride / graphene potassium ion battery negative electrode material with a high-stability structure and a preparation method thereof. The bismuth antimony telluride / graphene potassium ion battery negative electrode material is prepared by adopting a one-step hydrothermal method, the material is of a sandwich layered stacked structure, and is obtained by modifying Bi0.4Sb1.6Te3 nanoparticles between graphene layers. The preparation method disclosed by the invention is simple and rapid, and the obtained product shows excellent potassium ion storage specific capacity, high-current charge-discharge performance and cycling stability.

Owner:ANHUI UNIVERSITY

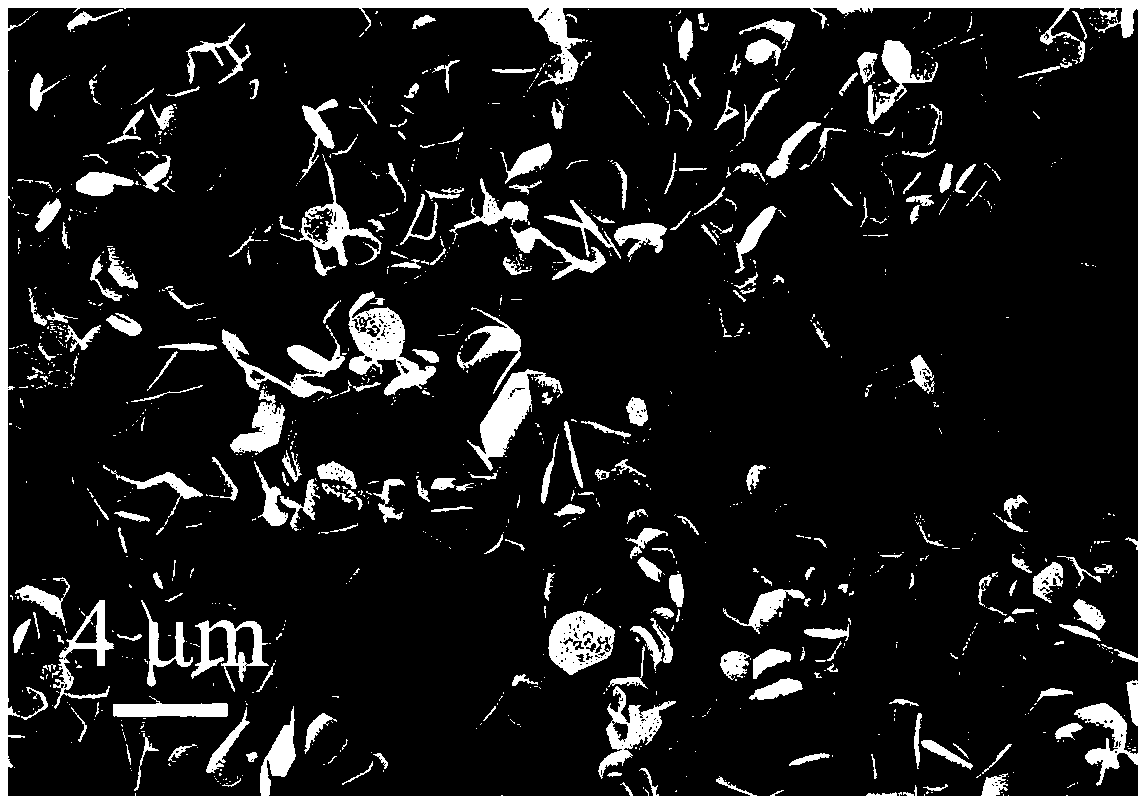

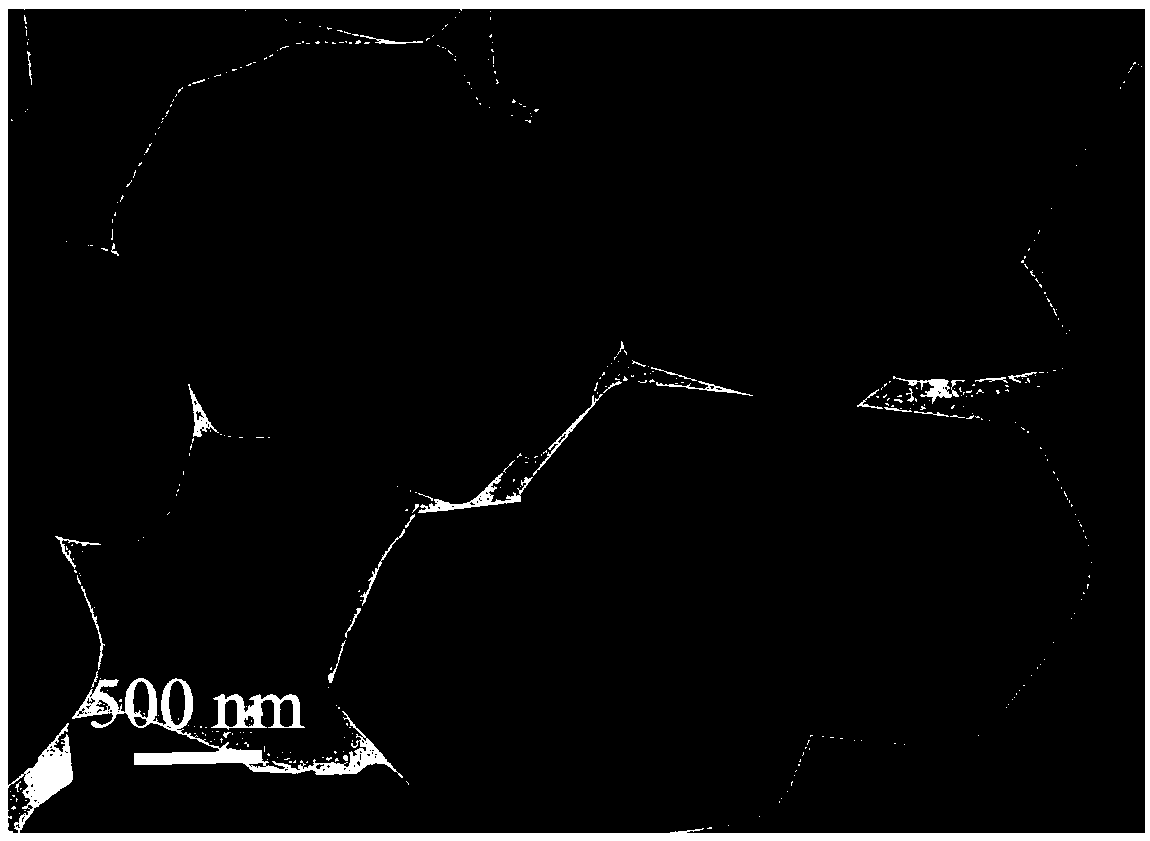

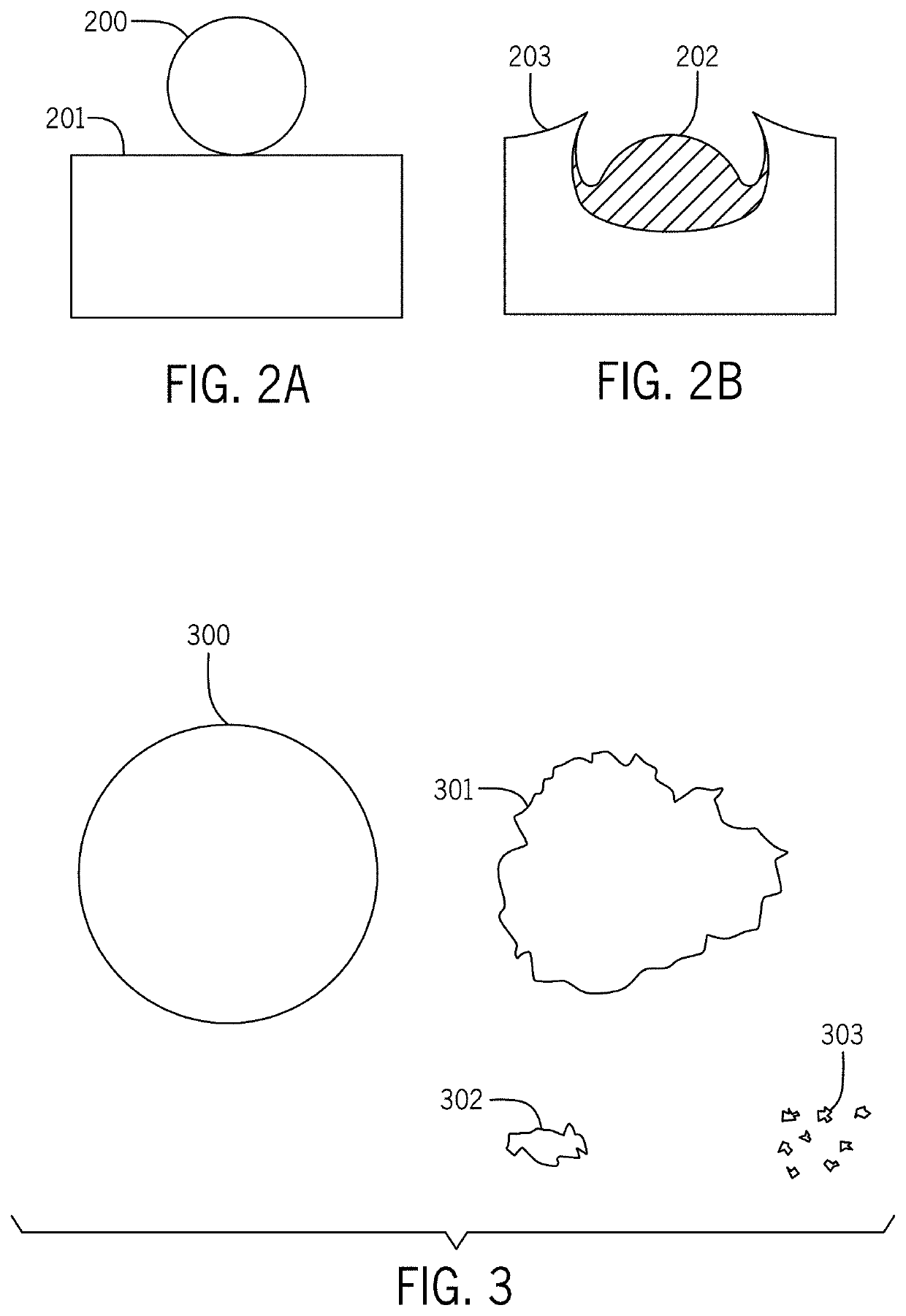

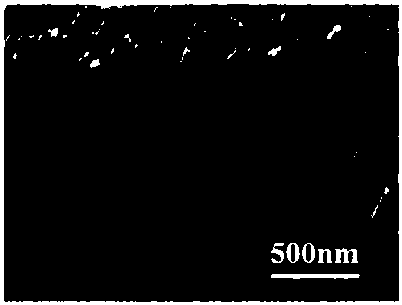

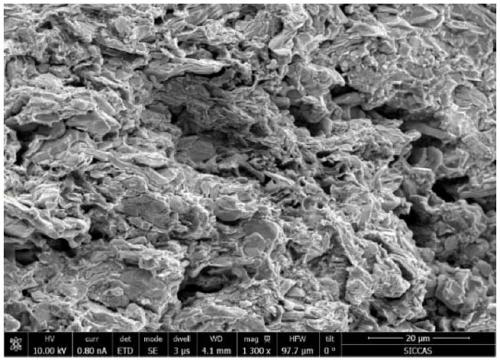

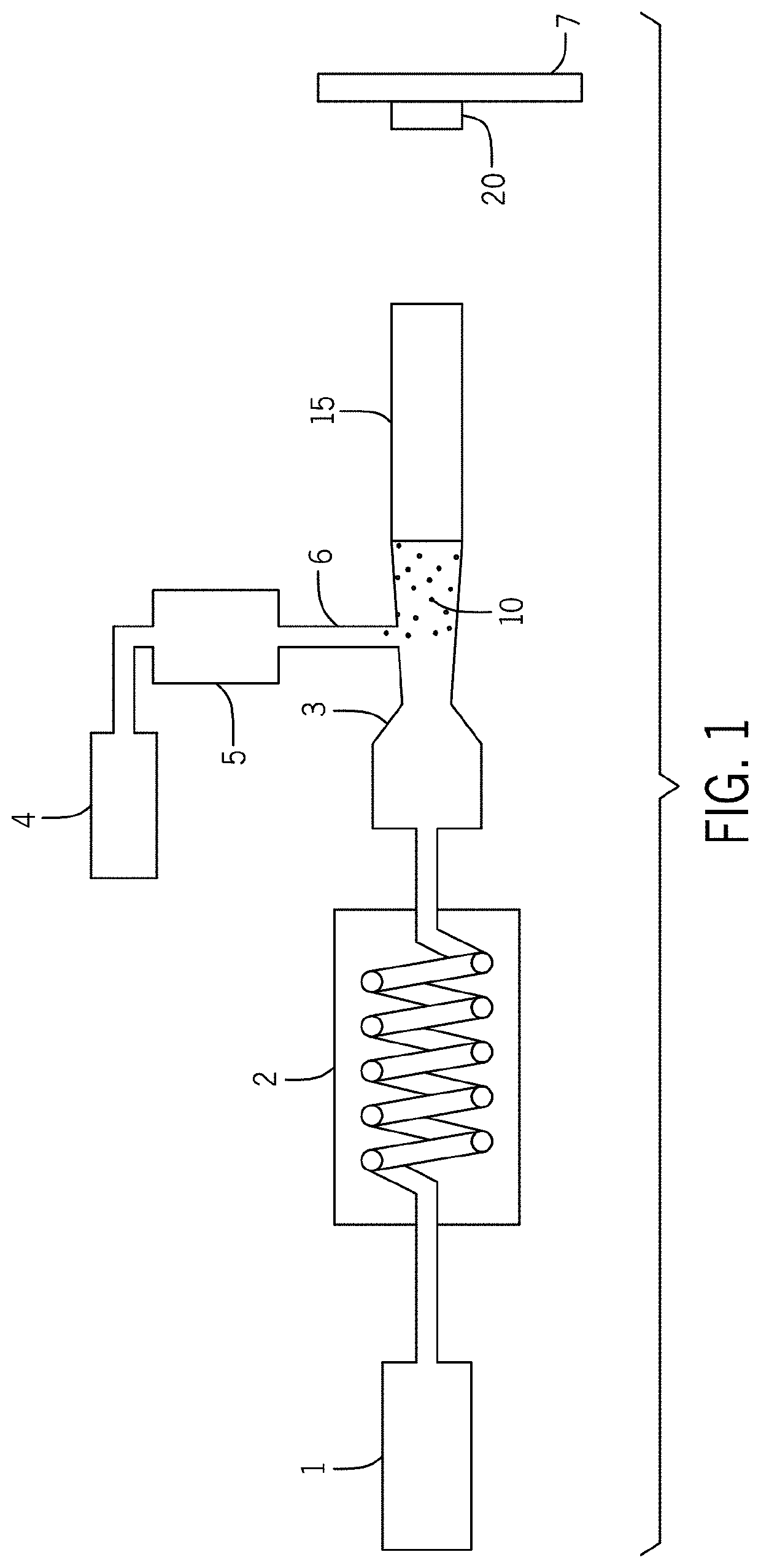

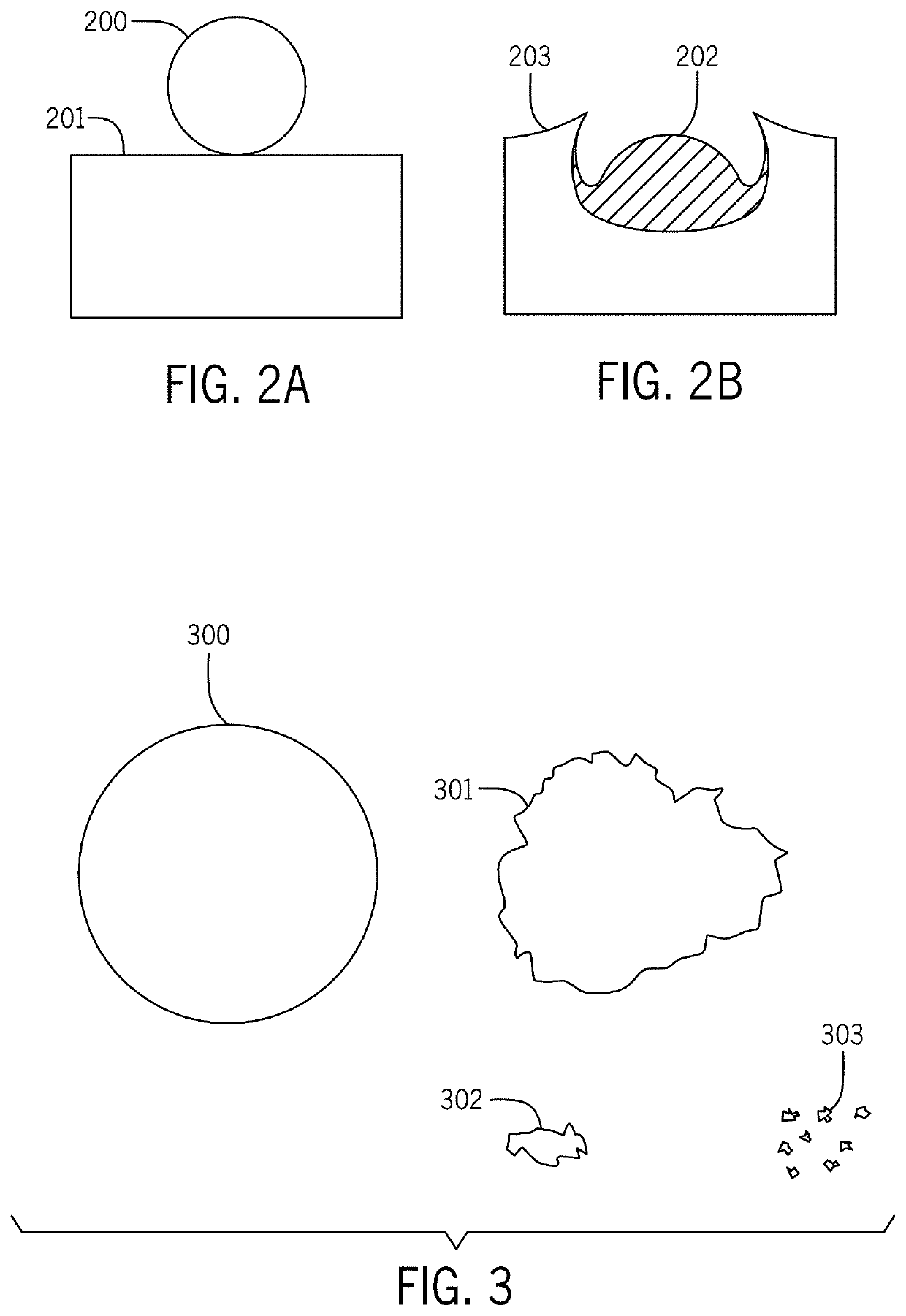

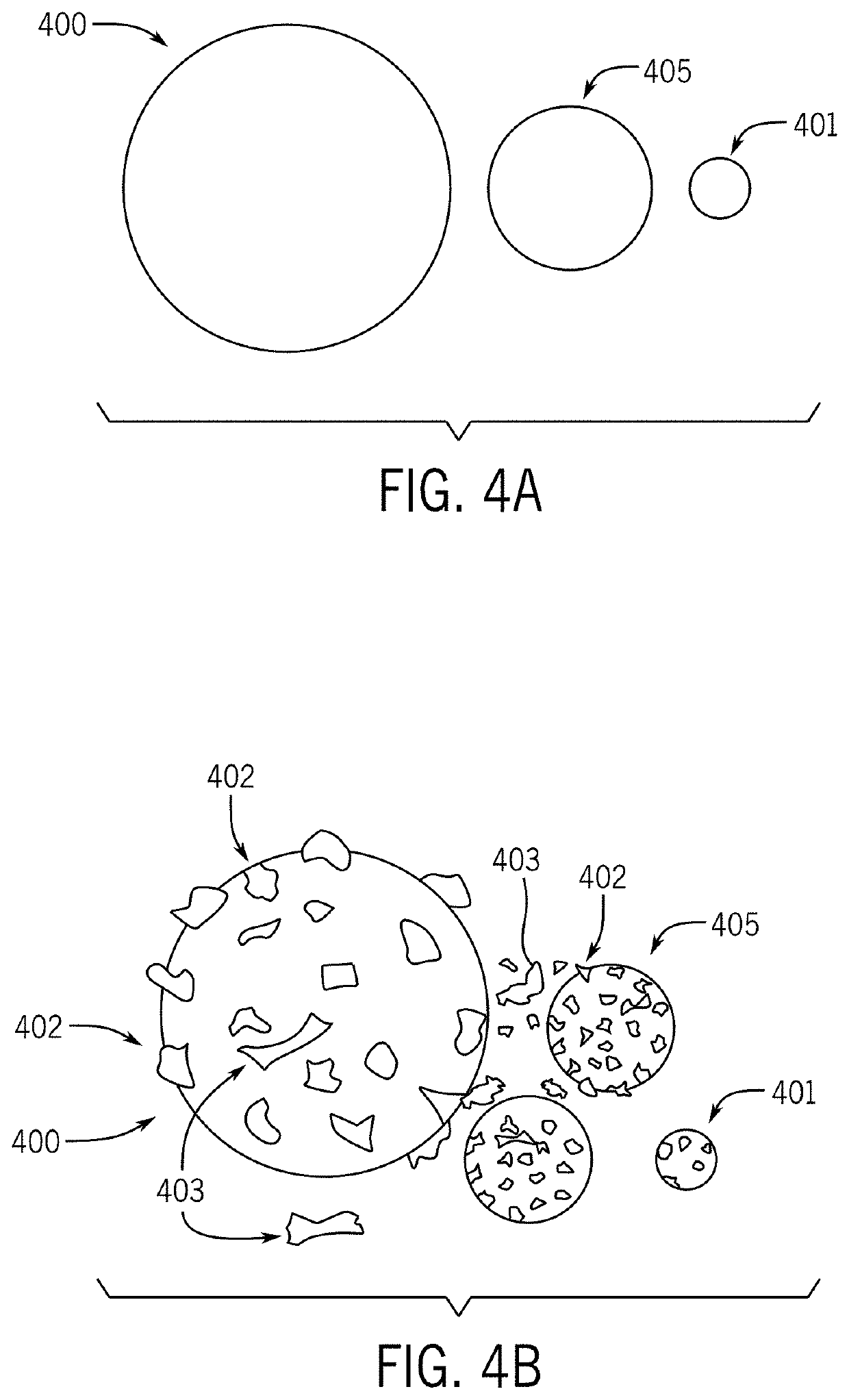

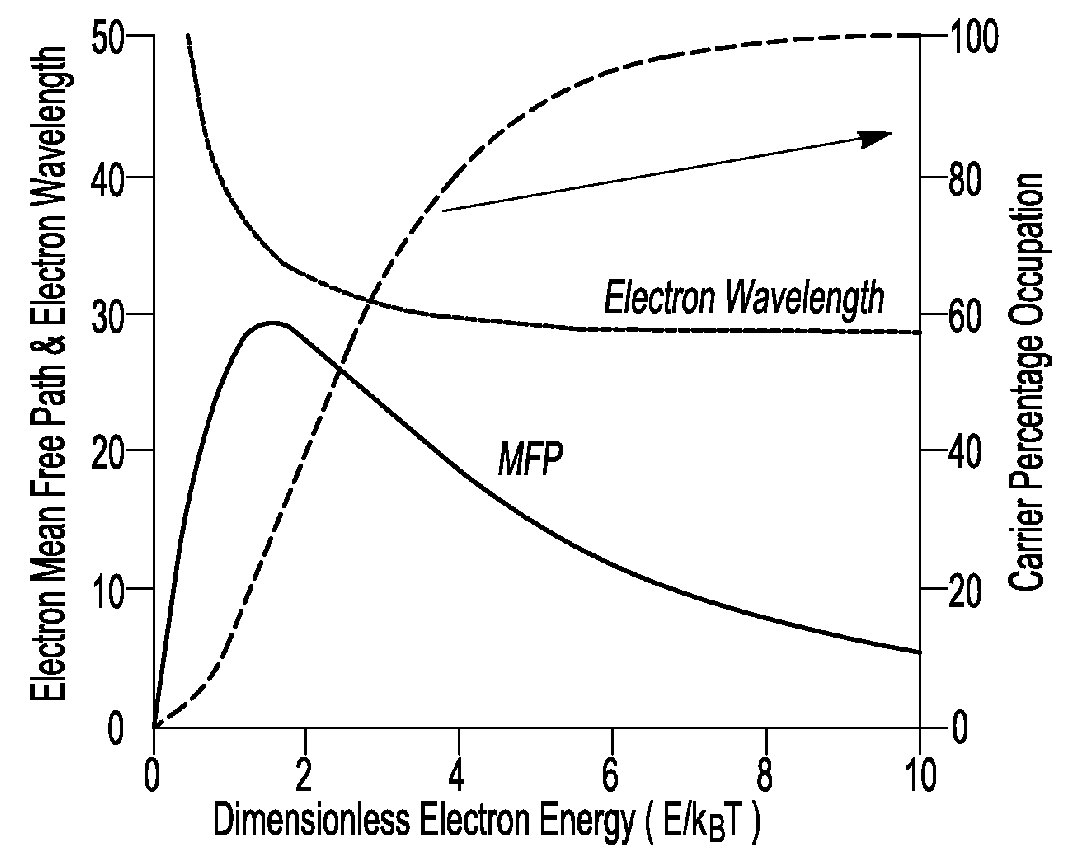

Apparatus, and process for cold spray deposition of thermoelectric semiconductor and other polycrystalline materials and method for making polycrystalline materials for cold spray deposition

ActiveUS20190355891A1Enhance cold-spray depositionIncrease depositionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric coolingSemiconductor materials

An apparatus and method perform supersonic cold-spraying to deposit N and P-type thermoelectric semiconductor, and other polycrystalline materials on other materials of varying complex shapes. The process developed has been demonstrated for bismuth and antimony telluride formulations as well as Tetrahedrite type copper sulfosalt materials. Both thick and thin layer thermoelectric semiconductor material is deposited over small or large areas to flat and highly complex shaped surfaces and will therefore help create a far greater application set for thermoelectric generator (TEG) systems. This process when combined with other manufacturing processes allows the total additive manufacturing of complete thermoelectric generator based waste heat recovery systems. The processes also directly apply to both thermoelectric cooler (TEC) systems, thermopile devices, and other polycrystalline functional material applications.

Owner:THUSS RICHARD C

A method for preparing a tilted nanowire array structural antimony telluride based membrane by evaporation coating

InactiveCN108220879AImprove thermoelectric performanceHigh quality factorVacuum evaporation coatingSputtering coatingEvaporationAlternating current

The invention relates to a method for preparing a tilted nanowire array structural antimony telluride based membrane by evaporation coating. The method includes (1) fully mixing Sb2Te3, Te and Bi powder having purity of 99.99% in a mass percentage manner, with the mass ratio of the Sb2Te3, the Te and the Bi being 10:0.8-1.2:0.8-1.2, and pressing the mixture of the Sb2Te3, the Te and the Bi under 8-10 MPa to obtain a block; (2) subjecting a substrate to ultrasonic cleaning in acetone, absolute ethanol and deionized water respectively and blow-drying the substrate with nitrogen; (3) putting theblock obtained by pressing 0.1-0.2 g of the mixture of the Sb2Te3, the Te and the Bi into a tungsten boat in a vacuum chamber of a vacuum coating machine; (4) feeding nitrogen into the vacuum chamberfor 2-5 min to allow the vacuum degree to range from 2.0*10<-4> Pa to 5.0*10<-4> Pa; (5) setting a heating temperature to be 240-280 DEG C; (6) after the temperature rises, setting a deposition rate to be 10-20 nm / min and deposition time to be 2-3 h on a PID controller; and (7) starting an alternating current power supply, adjusting an output current to be 160-170 A, and preparing the tilted nanowire array structural (Sb,Bi)<2>Te3 membrane. Preparation is simple and effects are significant.

Owner:TIANJIN UNIV OF SCI & TECH

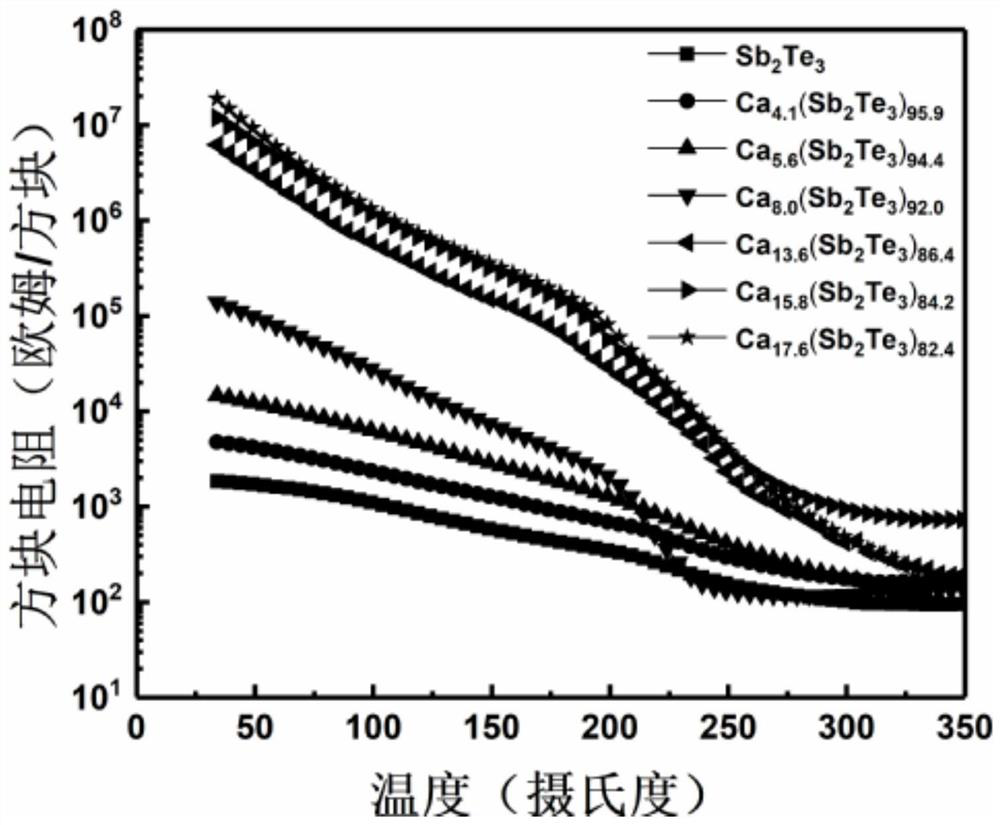

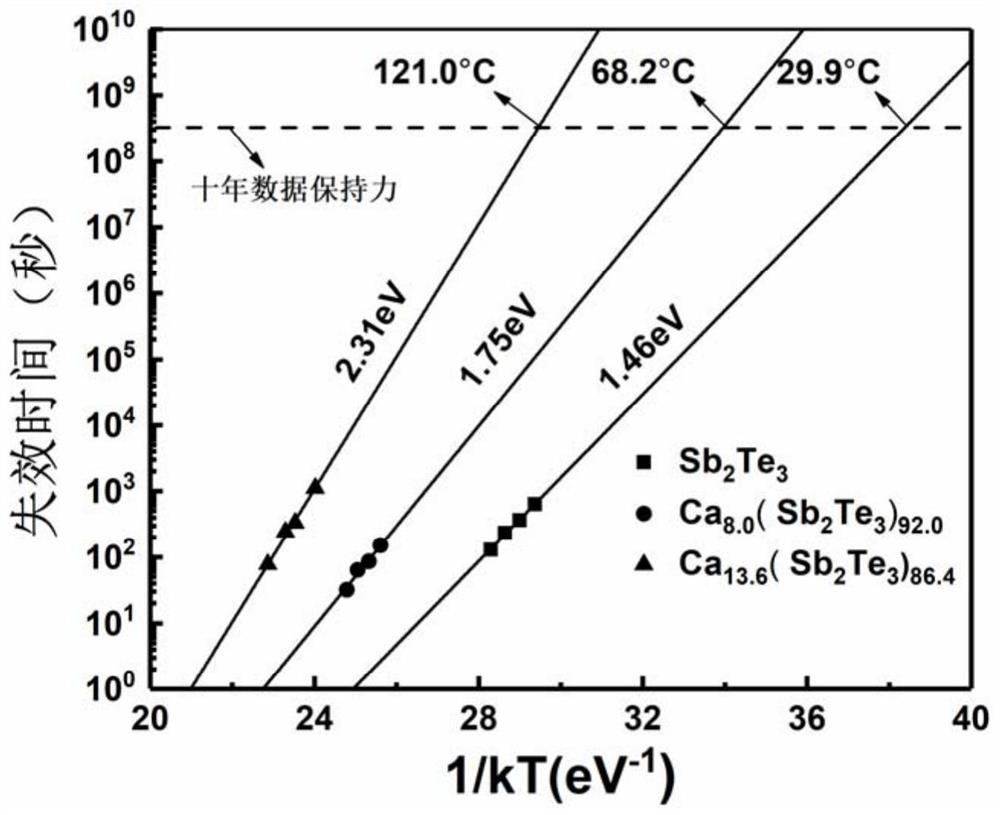

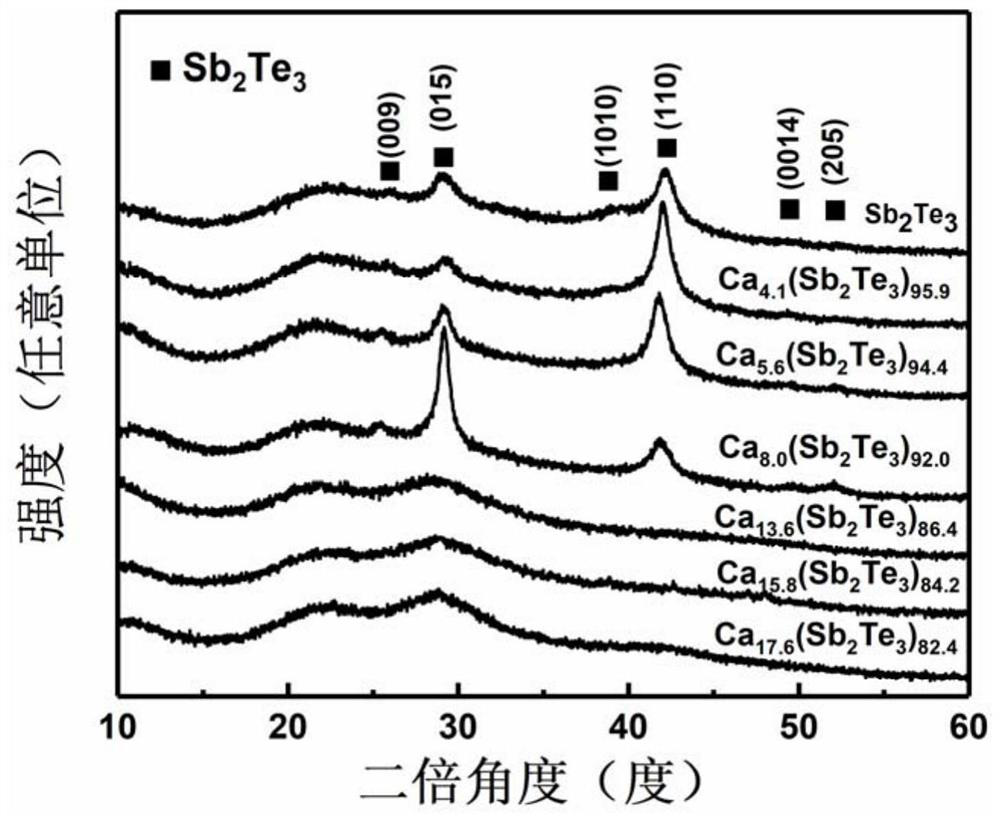

Ca-doped antimony telluride ultra-stable phase change storage film material and preparation method thereof

ActiveCN111876731ARaise the crystallization temperatureLarge crystallization activation energyThermoelectric device manufacture/treatmentVacuum evaporation coatingCoating systemPhysical chemistry

The invention discloses a Ca-doped antimony telluride ultra-stable phase change storage film material and a preparation method thereof. The Ca-doped antimony telluride ultra-stable phase change storage film material and the preparation method are characterized in that the phase change storage film material is a mixture of three elements of calcium, antimony and tellurium, and the chemical structural formula of the phase change storage film material is Cax(Sb2Te3)100-x, wherein x is greater than 0 and less than 17.6 at%; and the Cax(Sb2Te3)100-x phase change storage film material is prepared bya magnetron sputtering coating system in a double-target co-sputtering mode. The phase change storage film material has the advantages that a Ca-Sb2Te3 phase change thin film has high crystallizationtemperature, large crystallization activation energy and good ten-year data retention capacity; and the phase change thin film has the high crystallization temperature, the large crystallization activation energy and the good ten-year data retention capacity, and the resistance drift coefficient is low, so that the resistance drift phenomenon of the phase change material in an amorphous state isimproved.

Owner:NINGBO UNIV

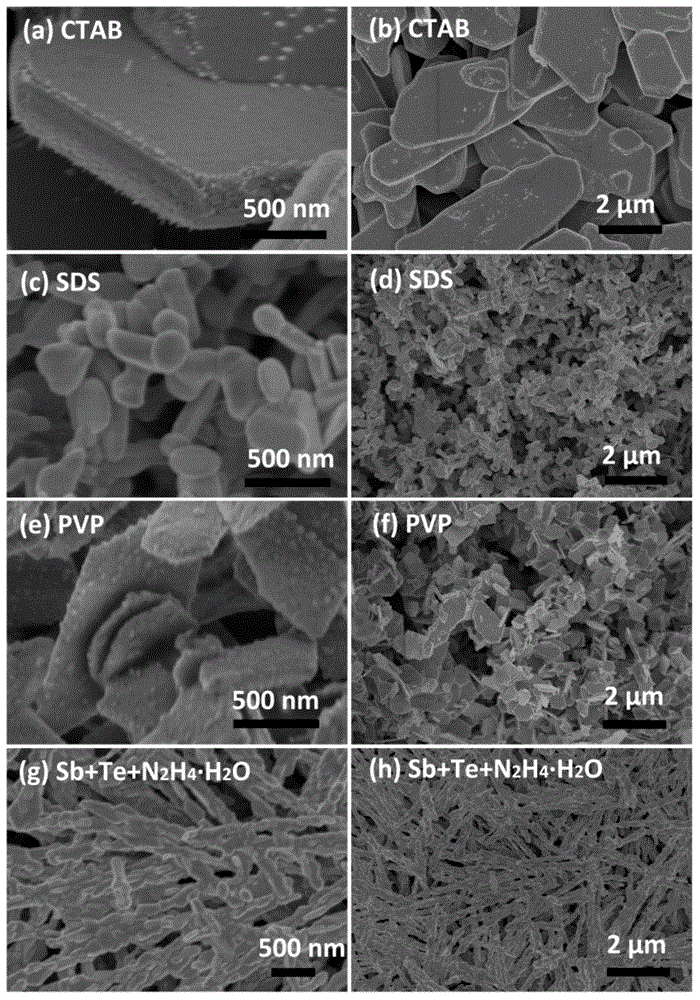

Preparation method of antimony telluride block thermoelectric material

PendingCN111430532AImprove thermoelectric performanceSimple preparation processThermoelectric device manufacture/treatmentThermoelectric device junction materialsPotassium borohydrideTube furnace

The invention discloses a preparation method of an antimony telluride block thermoelectric material. The preparation method is characterized by comprising the following steps: adding SbCl3, TeO2, a surfactant and KOH into deionized water to prepare a precursor solution; stirring to dissolve; adding potassium borohydride; continuing to stir; transferring the solution into a reaction kettle to react; washing with deionized water and absolute ethyl alcohol for multiple times; and carrying out vacuum drying to obtain antimony telluride powder; putting antimony telluride powder into a stainless steel mold; and carrying out cold pressing at room temperature to form a block; and putting the block into a tubular furnace; introducing protective gas; heating; keeping the temperature; carrying out annealing treatment; and cooling to room temperature to obtain the antimony telluride block thermoelectric material. The antimony telluride block thermoelectric material is prepared through a cold pressing and annealing combined method, the prepared p-type antimony telluride block thermoelectric material has good thermoelectric performance, meanwhile, the preparation process is simple and easy to operate; the cost is low; large-scale production is easy to achieve; and the p-type antimony telluride block thermoelectric material has wide application prospects in the fields of thermoelectric powergeneration and refrigeration devices.

Owner:SHANGHAI INST OF TECH

Apparatus, and process for cold spray deposition of thermoelectric semiconductor and other polycrystalline materials and method for making polycrystalline materials for cold spray deposition

ActiveUS10714671B2Increase depositionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric coolingSemiconductor materials

An apparatus and method perform supersonic cold-spraying to deposit N and P-type thermoelectric semiconductor, and other polycrystalline materials on other materials of varying complex shapes. The process developed has been demonstrated for bismuth and antimony telluride formulations as well as Tetrahedrite type copper sulfosalt materials. Both thick and thin layer thermoelectric semiconductor material is deposited over small or large areas to flat and highly complex shaped surfaces and will therefore help create a far greater application set for thermoelectric generator (TEG) systems. This process when combined with other manufacturing processes allows the total additive manufacturing of complete thermoelectric generator based waste heat recovery systems. The processes also directly apply to both thermoelectric cooler (TEC) systems, thermopile devices, and other polycrystalline functional material applications.

Owner:THUSS RICHARD C

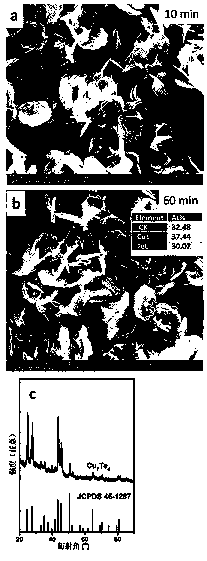

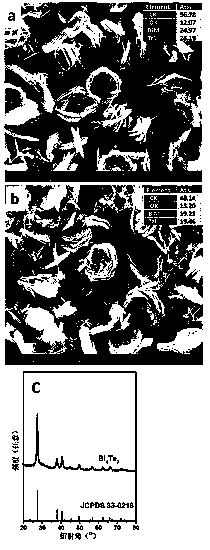

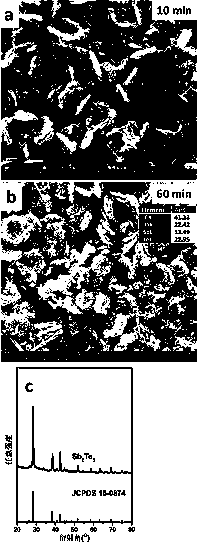

A kind of preparation method of metal telluride flower-like micro-nano structure

ActiveCN107601440BSimple processEasy to operateBinary selenium/tellurium compoundsMicro nanoSodium acetate

The invention discloses a preparation method of flower-like micro-nano structures of metal tellurides. The preparation method belongs to the technical field of preparation of semiconductor materials.The method comprises the steps of dissolving sodium tellurite, polyvinylpyrrolidone, sodium acetate, ethanediamine and zinc acetylacetonate into ethylene glycol, removing oxygen in an obtained solution in an inert environment, and heating to obtain a precursor; then, respectively adding copper acetylacetonate, bismuth acetylacetonate, cadmium acetylacetonate, lead acetylacetonate and antimony acetylacetonate so as to successfully prepare the flower-like micro-nano structures of copper telluride, bismuth telluride, cadmium telluride, lead telluride and antimony telluride. The diameters of the prepared flower-like micro-nano structures of the copper telluride, the bismuth telluride, the cadmium telluride, the lead telluride and the antimony telluride are 8-10 microns. The method has the advantages of being simple in synthetic process, good in repeatability, safe and environmentally friendly, and cost-saving. Based on the characteristics of the preparation method, the preparation method has a very high value in the aspects of laboratory research and industrial applications.

Owner:HENAN INST OF ENG

A method for rapidly preparing antimony telluride thermoelectric materials

ActiveCN106145062BQuick responseReduce energy consumptionBinary selenium/tellurium compoundsThermoelectric materialsMetallurgy

Owner:WUHAN UNIV OF TECH

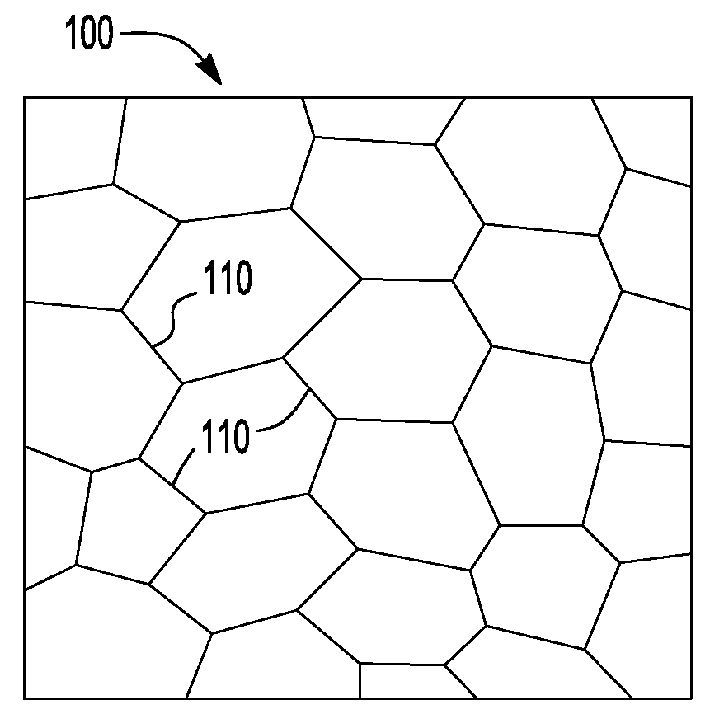

Method of producing thermoelectric material

A thermoelectric material is provided. The material can be a grain boundary modified nanocomposite that has a plurality of bismuth antimony telluride matrix grains and a plurality of zinc oxide nanoparticles within the plurality of bismuth antimony telluride matrix grains. In addition, the material has zinc antimony modified grain boundaries between the plurality of bismuth antimony telluride matrix grains.

Owner:TOYOTA JIDOSHA KK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com