Ca-doped antimony telluride ultra-stable phase change storage film material and preparation method thereof

A thin film material, antimony telluride technology, applied in metal material coating process, thermoelectric device node lead wire material, thermoelectric device manufacturing/processing, etc., can solve the problem of unstable memory amorphous resistance, low data retention temperature, Performance defects cannot be improved, etc., to achieve the effect of improving the resistance drift phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

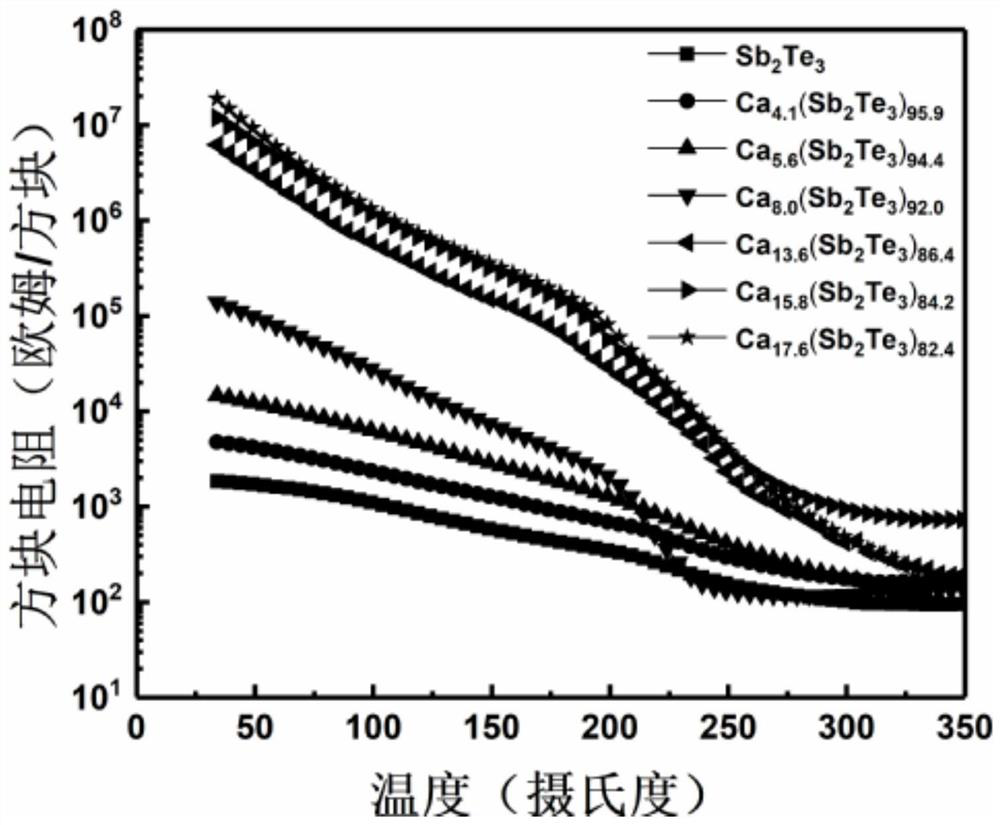

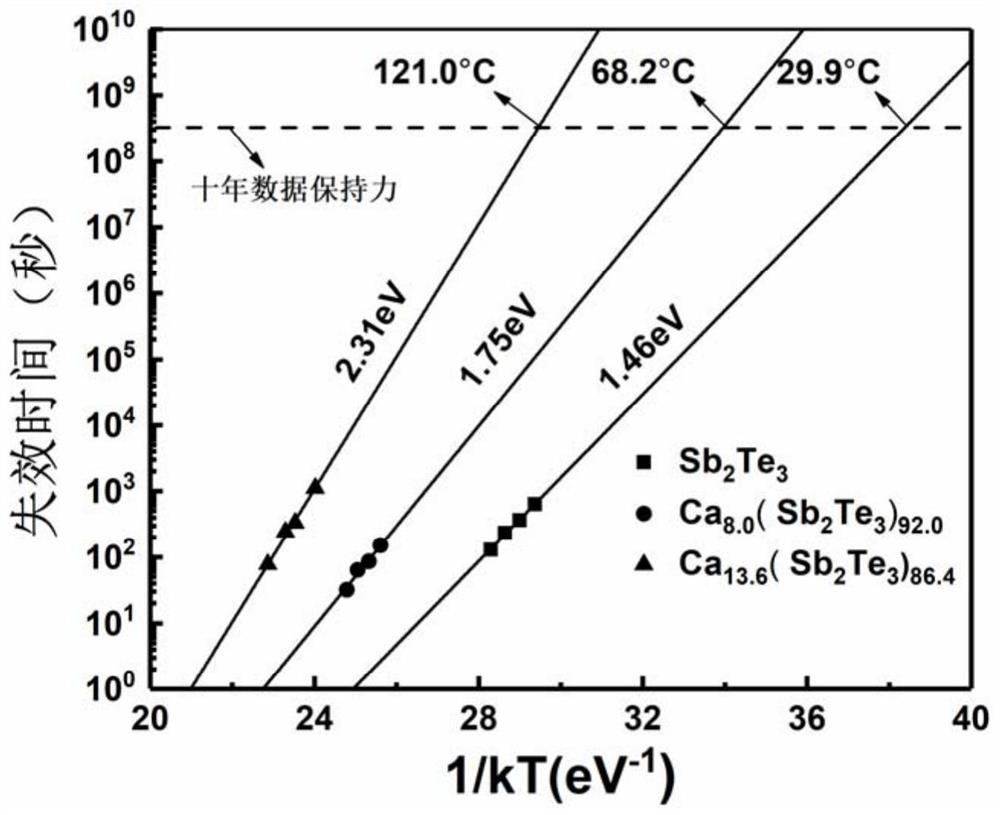

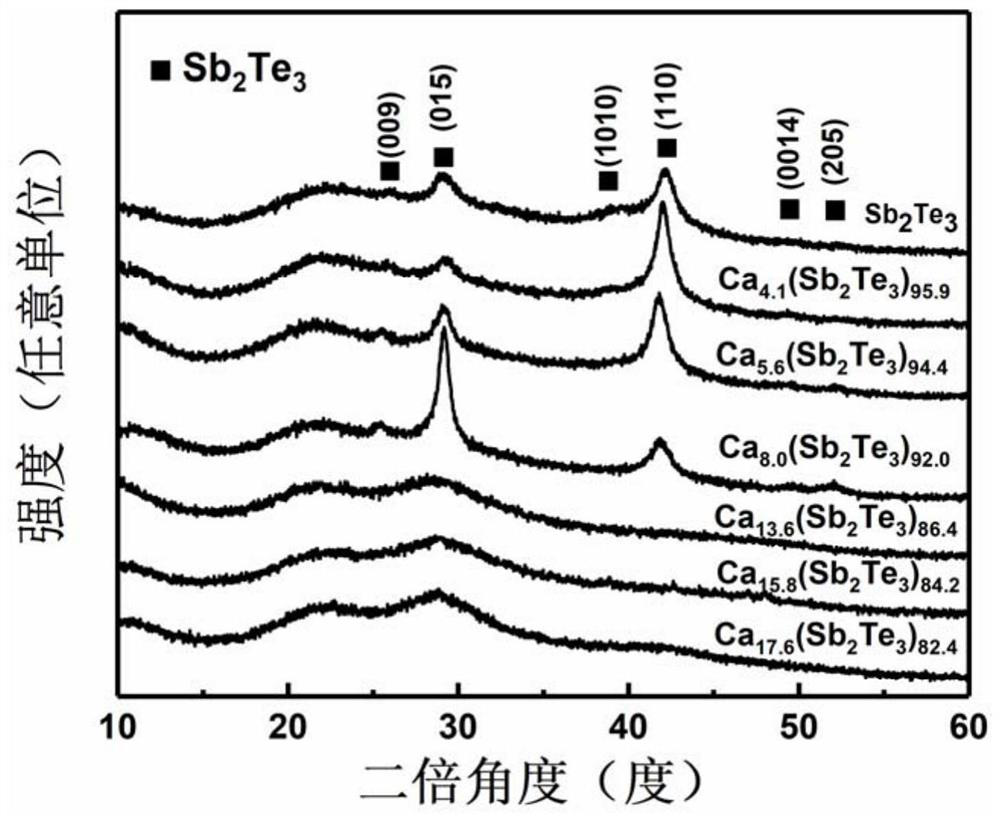

[0026] A Ca-doped antimony telluride ultra-stable phase-change thin film material, whose chemical structural formula is Ca x (Sb 2 Te 3 ) 100-x , where 0<x≤17.6 at%, the specific preparation process is as follows:

[0027] 1. In the magnetron sputtering coating system, silicon wafers and silicon oxide wafers are used as substrates, the Ca target is installed on the magnetron radio frequency sputtering target, and the Sb 2 Te 3 The target is installed on the magnetron DC sputtering target, and the sputtering chamber of the magnetron sputtering coating system is vacuumed until the vacuum degree in the chamber reaches 5.0×10 -5Pa, and then feed high-purity argon gas with a volume flow rate of 50 sccm into the sputtering chamber until the air pressure in the sputtering chamber reaches the required pressure of 0.8 Pa for ignition. After the ignition, adjust the pressure of the chamber to the required pressure of 0.4 Pa for sputtering. Then control the sputtering power of the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com