Sb-Te-Ti phase-change storage material and Ti-Sb2Te phase-change storage material

An sb-te-ti, ti-sb2te technology, applied in the field of phase change materials and their preparation, can solve the problems of poor thermal stability, doping, and reduced data retention, and achieve enhanced thermal stability, uniform distribution, and data retention. Retention boost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of Sb 60 Te 30 Ti 10 Nanocomposite phase change materials:

[0054] The nanocomposite phase change material in this embodiment adopts Sb 60 Te 30 Co-sputtering alloy target and Ti target. The specific preparation conditions are: during the co-sputtering process, Ar gas with a purity of 99.999% and Sb 60 Te 30 The target adopts radio frequency power supply, the Ti target adopts direct current power supply, the adopted radio frequency power supply power is 25W, and the adopted direct current power supply power is 15W. Sb 2 After the Te target glows, turn on the Ti target power. The co-sputtering time is 20 minutes, and the film thickness is about 170nm.

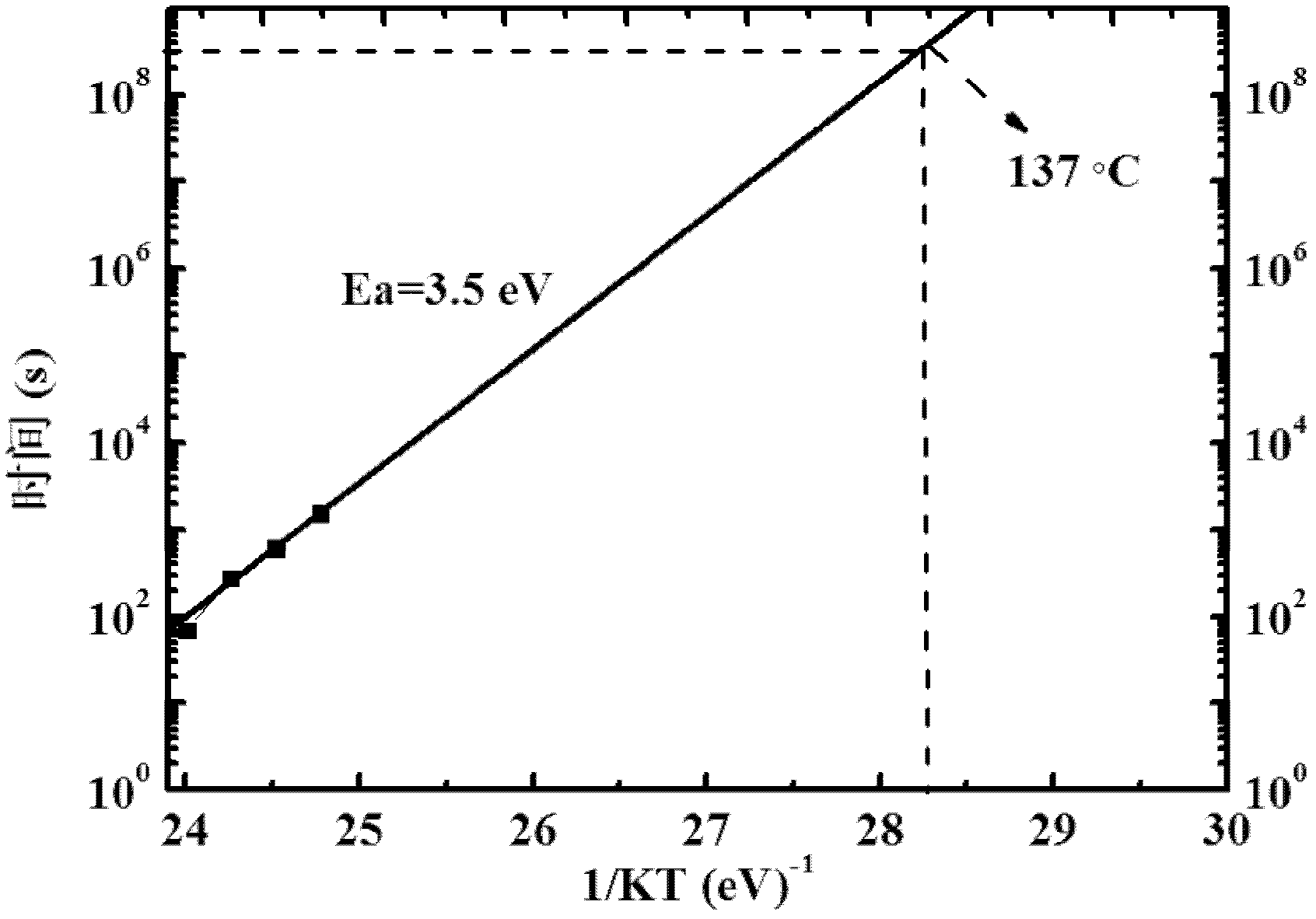

[0055] The Sb obtained in this embodiment 60 Te 30 Ti 10 Nanocomposite phase change materials obtained through testing Figure 1-3 :

[0056] figure 1 Sb with different heating rates 60 Te 30 Ti 10 The graph of the relationship between sheet resistance and temperature. The heating rate used...

Embodiment 2

[0062] Preparation of Sb 72 Te 18 Ti 10 Nanocomposite phase change materials:

[0063] The nanocomposite phase change material in this embodiment adopts Sb 72 Te 18 Co-sputtering alloy target and Ti target. The specific preparation conditions are: during the co-sputtering process, Ar gas with a purity of 99.999% and Sb 72 Te 18 The target adopts radio frequency power supply, the Ti target adopts direct current power supply, the adopted radio frequency power supply power is 25W, and the adopted direct current power supply power is 15W. Sb 72 Te 18 After the target glows, turn on the Ti target power. The co-sputtering time is 30 minutes, and the film thickness is about 200nm.

[0064] The Sb obtained in this embodiment 72 Te 18 Ti 10 Nanocomposite phase change materials have been tested and known:

[0065] Sb obtained from 72 Te 18 Ti 10 Sb at different heating rates of nanocomposite phase change materials 80 Te 10 Ti 10 The graph of the relationship between ...

Embodiment 3

[0070] Preparation of Sb 50 Te 30 Ti 20 Nanocomposite phase change materials:

[0071] The nanocomposite phase change material in this embodiment adopts Sb 50 Te 30 Co-sputtering alloy target and Ti target. The specific preparation conditions are: during the co-sputtering process, Ar gas with a purity of 99.999% and Sb 50 Te 30 The target adopts radio frequency power supply, the Ti target adopts direct current power supply, the adopted radio frequency power supply power is 25W, and the adopted direct current power supply power is 15W. Sb 2 After the Te target glows, turn on the Ti target power. The co-sputtering time is 50 minutes, and the film thickness is about 250nm.

[0072] The Sb obtained in this embodiment 50 Te 30 Ti 20 Nanocomposite phase change materials have been tested and known:

[0073] Sb obtained from 50 Te 30 Ti 20 Sb at different heating rates of nanocomposite phase change materials 50 Te 30 Ti 20 The graph of the relationship between sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com