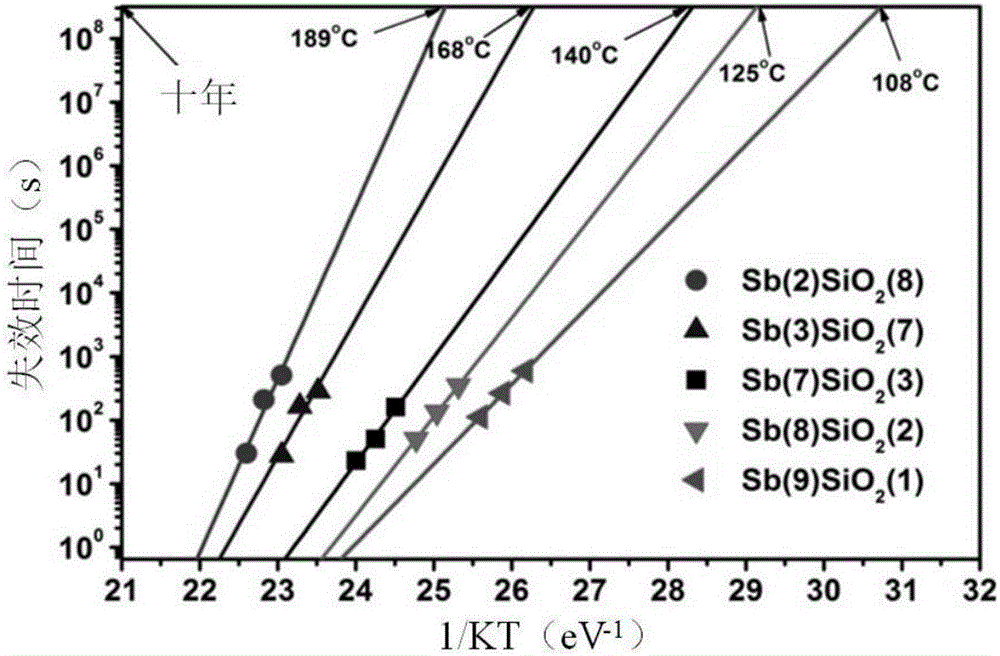

SiO2/Sb superlattice nano phase change thin film material and preparation method and application thereof

A thin-film material and superlattice technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the phase change process of phase change memory with limited operating speed, unable to meet information storage requirements, The problem of high power consumption of RESET achieves excellent data retention ability, shortens crystallization time, and ensures effective resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: preparation [SiO 2 (1) / Sb(9)] 5 Superlattice-like nanophase-change thin film materials.

[0037] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0038] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0039] b) Strong ultrasonic cleaning in ethanol solution for 3 to 5 minutes, rinse with deionized water, and dry the surface and back with high-purity nitrogen;

[0040] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0041] 2. Preparation before preparing multi-layer composite film:

[0042] a) Install SiO separately 2 and Sb sputtering target, the atomic percent purity of the target reaches 99.999%, and the background vacuum is evacuated to 1×10 -4 Pa;

[0043] b) Set the sputtering power to 30W;

[0044] c) Using high-purity argon as the sputtering gas, the volume percent purity reaches 99.999%, setting the arg...

Embodiment 2

[0051] Embodiment 2: preparation [SiO 2 (2) / Sb(8)] 5 Superlattice-like nanophase-change thin film materials.

[0052] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0053] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0054] b) Strong ultrasonic cleaning in ethanol solution for 3 to 5 minutes, rinse with deionized water, and dry the surface and back with high-purity nitrogen;

[0055] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0056] 2. Preparation before preparing multi-layer composite film:

[0057] a) Install SiO separately 2 and Sb sputtering target, the atomic percent purity of the target reaches 99.999%, and the background vacuum is evacuated to 1×10 -4 Pa;

[0058] b) Set the sputtering power to 30W;

[0059] c) Using high-purity argon as the sputtering gas, the volume percent purity reaches 99.999%, setting the arg...

Embodiment 3

[0066] Embodiment 3: preparation [SiO 2 (3) / Sb(7)] 5 Superlattice-like nanophase-change thin film materials.

[0067] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0068] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0069] b) Strong ultrasonic cleaning in ethanol solution for 3 to 5 minutes, rinse with deionized water, and dry the surface and back with high-purity nitrogen;

[0070] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0071] 2. Preparation before preparing multi-layer composite film:

[0072] a) Install SiO separately 2 and Sb sputtering target, the atomic percent purity of the target reaches 99.999%, and the background vacuum is evacuated to 1×10 -4 Pa;

[0073] b) Set the sputtering power to 30W;

[0074] c) Using high-purity argon as the sputtering gas, the volume percent purity reaches 99.999%, setting the arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com