A method for preparing a tilted nanowire array structural antimony telluride based membrane by evaporation coating

An antimony telluride base film and tilted nanotechnology are applied in the field of preparing an antimony telluride base film with a tilted nanowire array structure by using evaporation coating, which can solve the problem of no tilted nanowire array structure and the like, achieve the improvement of the thermoelectric quality factor, and the method is simple , the effect of significant practical value and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

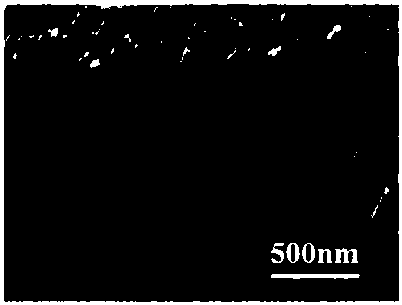

[0043] Fabrication of vertical nanowire array structures (Sb,Bi) by evaporation coating on glass substrates 2 Te 3 membrane:

[0044] (1) the mass percent purity is 99.99% Sb 2 Te 3 , Te and Bi powders (mass ratio Sb 2 Te 3 :Te:Bi=10:0.8:0.8 evenly mixed) press Sb under 8MPa pressure 2 Te 3 , Te and Bi mixed materials into bulk; the Sb 2 Te 3 , The average particle size of Te and Bi powders is less than 50 μm;

[0045] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 5 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0046] (3) Add 0.1g of Sb 2 Te 3 , Te and Bi mixed materials are pressed into the tungsten boat in the vacuum chamber of the vacuum coating machine, the substrate is placed in the center of the sample stage, and the angle θ=0° between the sample stage and the horizontal plane is adjusted; the center of the substrate and the tungsten The boat distance d=8cm;

[0047] (4) Fill the v...

Embodiment 2

[0055] Fabrication of Tilted Nanowire Array Structures by Evaporation Coating on Glass Substrates (Sb, Bi) 2 Te 3 membrane:

[0056] (1) the mass percent purity is 99.99% Sb 2 Te 3 , Te and Bi powders (mass ratio Sb 2 Te 3 :Te:Bi=10:1.0:1.0 evenly mixed) press Sb under 9MPa pressure 2 Te 3 , Te and Bi mixed materials into bulk; the Sb 2 Te 3 , The average particle size of Te and Bi powders is less than 50 μm;

[0057] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 7 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0058] (3) 0.12g of Sb 2 Te 3 , Te and Bi mixed materials are pressed into the tungsten boat in the vacuum chamber of the vacuum coating machine, the substrate is placed in the center of the sample stage, and the angle between the sample stage and the horizontal plane is adjusted to θ=30°; the center of the substrate and the tungsten The boat distance d=9cm;

[0059] (4) Fill the v...

Embodiment 3

[0066] Embodiment 3 (preferred)

[0067]Fabrication of Tilted Nanowire Array Structures by Evaporation Coating on Glass Substrates (Sb, Bi) 2 Te 3 membrane:

[0068] (1) the mass percent purity is 99.99% Sb 2 Te 3 , Te and Bi powders (mass ratio Sb 2 Te 3 :Te:Bi=10:1.0:1.0 evenly mixed) press Sb under 9MPa pressure 2 Te 3 , Te and Bi mixed materials into bulk; the Sb 2 Te 3 , The average particle size of Te and Bi powders is less than 50 μm;

[0069] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 8 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0070] (3) 0.12g of Sb 2 Te 3 , Te and Bi mixed materials are pressed into the tungsten boat in the vacuum chamber of the vacuum coating machine, the substrate is placed in the center of the sample stage, and the angle between the sample stage and the horizontal plane is adjusted to θ = 45°; the center of the substrate and the tungsten The boat dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com