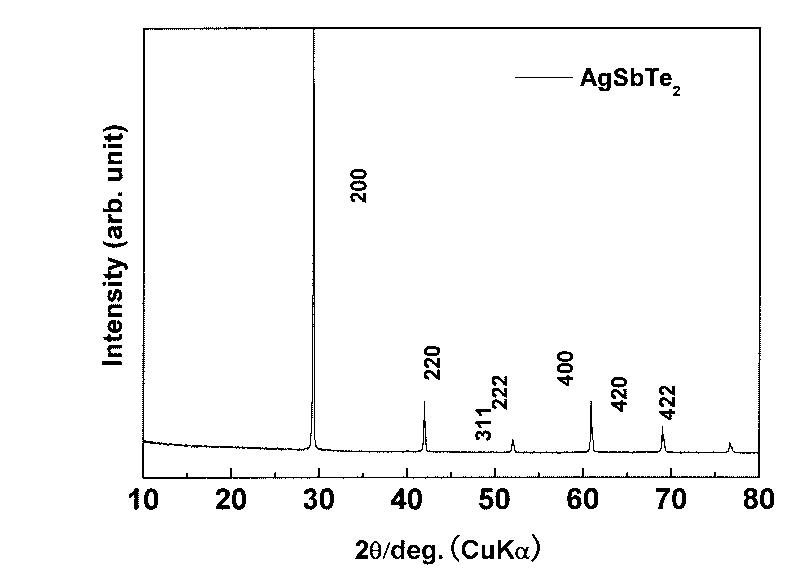

Method for preparing AgSbTe2 thermoelectric material by combining fusant rotatable swinging and spark plasma sintering

A technology of discharge plasma and silver antimony telluride, which is applied in the field of preparation of thermoelectric compounds, can solve problems such as difficult preparation, and achieve the effects of saving preparation cycle, high thermoelectric performance, and high thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

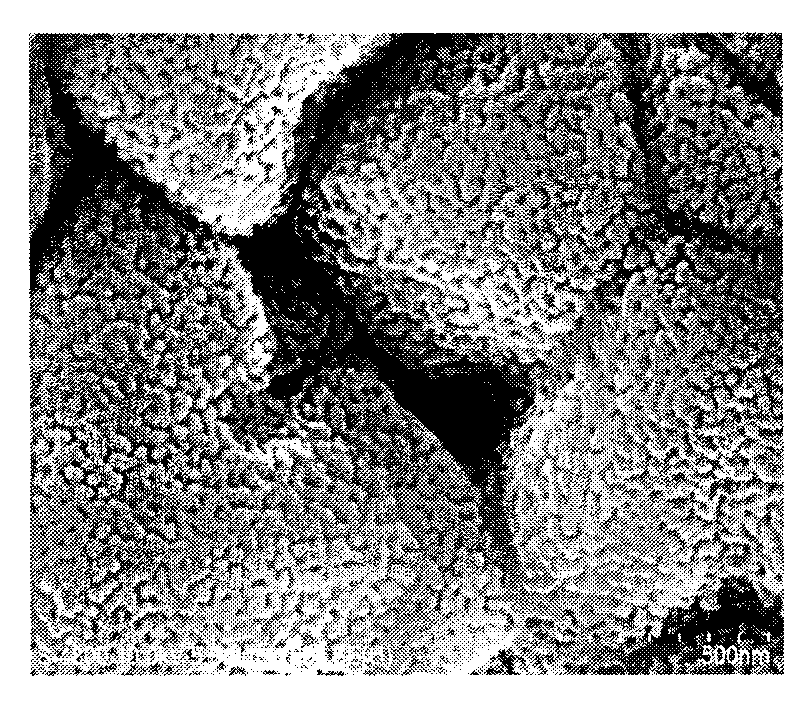

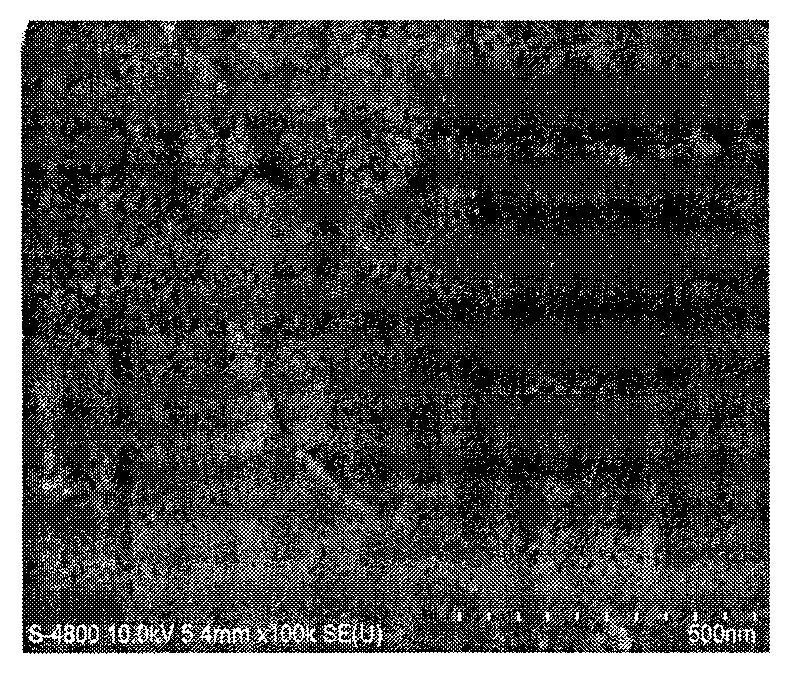

Embodiment 1

[0029] The method for preparing the silver antimony telluride thermoelectric material in combination with the melt spin-spinning and spark plasma sintering comprises the following steps:

[0030] 1) Ingredients: Filamentous Ag, massive Te and granular Sb are used as starting materials, according to the chemical formula AgSbTe 2 Weighing (i.e. x=0), wherein the mass purity of filamentous Ag is ≥99.95%, the mass purity of bulk Te is ≥99.999%, and the mass purity of granular Sb is ≥99.9999%;

[0031] 2) Preparation of master alloy: Mix filamentous Ag, massive Te and granular Sb, then put them into a melting furnace, slowly heat to 700°C at a heating rate of 1°C / min, melt for 9 hours, and then heat at 1°C / min The cooling rate of min is slow to cool down to 550°C and then quenched in supersaturated brine to obtain a master alloy (ingot with dense metallic luster);

[0032] 3) Preparation of strip-shaped product: After rough grinding, the master alloy is pressed into a cylinder wit...

Embodiment 2

[0035] The method for preparing the silver antimony telluride thermoelectric material in combination with the melt spin-spinning and spark plasma sintering comprises the following steps:

[0036] 1) Ingredients: Filamentous Ag, massive Te and granular Sb are used as starting materials, according to the chemical formula AgSbTe 2.02 Weighing (i.e. x=0.02), wherein the mass purity of filamentous Ag is ≥99.95%, the mass purity of bulk Te is ≥99.999%, and the mass purity of granular Sb is ≥99.9999%;

[0037] 2) Preparation of master alloy: Mix filamentous Ag, massive Te and granular Sb, then put them into a melting furnace, slowly heat to 700°C at a heating rate of 1°C / min, melt for 8 hours, and then heat at 1°C / min The cooling rate of min is slow to cool down to 550°C and then quenched in supersaturated brine to obtain a master alloy (ingot with dense metallic luster);

[0038] 3) After the master alloy is ground, press it into a cylinder with a diameter of 15 mm and a height of ...

Embodiment 3

[0042] The method for preparing the silver antimony telluride thermoelectric material in combination with the melt spin-spinning and spark plasma sintering comprises the following steps:

[0043] 1) Ingredients: Filamentous Ag, massive Te and granular Sb are used as starting materials, according to the chemical formula AgSbTe 2.08 Weighing (i.e. x=0.08), wherein the mass purity of filamentous Ag is ≥99.95%, the mass purity of bulk Te is ≥99.999%, and the mass purity of granular Sb is ≥99.9999%;

[0044] 2) Preparation of master alloy: Mix filamentous Ag, massive Te and granular Sb, then put them into a melting furnace, slowly heat to 700°C at a heating rate of 1°C / min, melt for 10 hours, and then heat at 1°C / min The cooling rate of min is slow to cool down to 550°C and then quenched in supersaturated brine to obtain a master alloy (ingot with dense metallic luster);

[0045] 3) After the master alloy is ground, press it into a cylinder with a diameter of 15 mm and a height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com