Preparation method of antimony telluride block thermoelectric material

A technology of thermoelectric material and antimony telluride block, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric device nodes, etc., can solve the problems of long time consumption, complex process, high consumption of resources and energy, etc. Low, broad application prospects, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

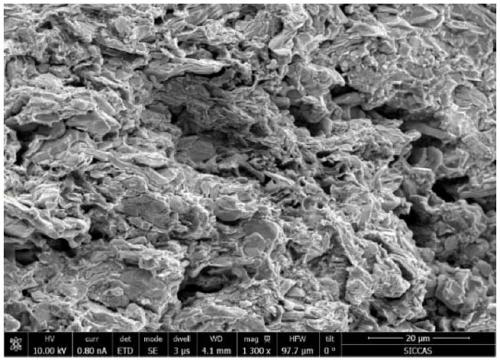

[0025] A preparation method of antimony telluride bulk thermoelectric material includes the following steps:

[0026] (1) Powder synthesis: Add 0.002mol SbCl to 80mL of deionized water in sequence 3 , 0.003mol TeO2, 0.4g PVA and 4.48g KOH, stir for 1h, then add 1.2g KBH 4 , Continue to stir for 30 min. Transfer the above solution to a reaction kettle, heat it to 180°C for 24 hours, then wash it with deionized water and absolute ethanol several times, and dry it under vacuum at 60°C for 8 hours to obtain antimony telluride powder;

[0027] (2) Powder cold pressing: 0.8g of antimony telluride powder is put into a stainless steel mold with a diameter of 12.7mm, and cold pressed at a pressure of 30MPa for 30 minutes at room temperature to form a bulk material of antimony telluride;

[0028] (3) Block annealing: Put the block into a tube furnace, pass in argon as a protective gas, quickly raise it to 275°C at a heating rate of 5°C / min, and keep it at room temperature for 1 hour.

Embodiment 2

[0030] A preparation method of antimony telluride bulk thermoelectric material includes the following steps:

[0031] (1) Powder synthesis: Add 0.002molSbCl to 80mL of deionized water in sequence 3 , 0.003mol TeO2, 0.4g PVA and 4.48g KOH, stir for 1h, then add 1.2g KBH 4 , Continue to stir for 30 min. Transfer the above solution to a reaction kettle, heat it to 180°C for 24 hours, then wash it with deionized water and absolute ethanol several times, and vacuum dry it at 60°C for 8 hours to obtain antimony telluride powder;

[0032] (2) Powder cold pressing: 0.8g of antimony telluride powder is put into a stainless steel mold with a diameter of 12.7mm, and cold pressed at a pressure of 30MPa for 30 minutes at room temperature to form a bulk material of antimony telluride;

[0033] (3) Block annealing: Put the block into a tube furnace, pass in argon as a protective gas, and rapidly increase the temperature to 425°C at a heating rate of 5°C / min for 1 hour, and then cool to room tempera...

Embodiment 3

[0035] A preparation method of antimony telluride bulk thermoelectric material includes the following steps:

[0036] (1) Powder synthesis: add 0.001 mol SbCl to 80 mL of deionized water sequentially 3 , 0.0015mol TeO2, 0.2g sodium dioctyl succinate sulfonate and 2.24g KOH, stir for 1h, then add 0.6g KBH 4 , Continue to stir for 30 min. Transfer the above solution to a reaction kettle, heat it to 150°C for 20 hours, then wash it with deionized water and absolute ethanol several times, and dry it under vacuum at 60°C for 8 hours to obtain antimony telluride powder;

[0037] (2) Powder cold pressing: Put 1.2g of antimony telluride powder into a stainless steel mold with a diameter of 10mm, and press it into a block material of antimony telluride by cold pressing at room temperature at a pressure of 10MPa for 10 minutes;

[0038] (3) Block annealing: Put the block into a tube furnace, pass in nitrogen as a protective gas, and rapidly increase the temperature to 200°C at a heating rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com