Antimony telluride/poly(3,4-ethylenedioxythiophene)/poly(styrene sulfonate) thermoelectric composite material and manufacturing method thereof

A technology of ethylenedioxythiophene and polystyrene sulfonate is applied in the field of thermoelectric composite material synthesis, which can solve the problem of high energy consumption and achieve the effects of low energy consumption, simple process and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

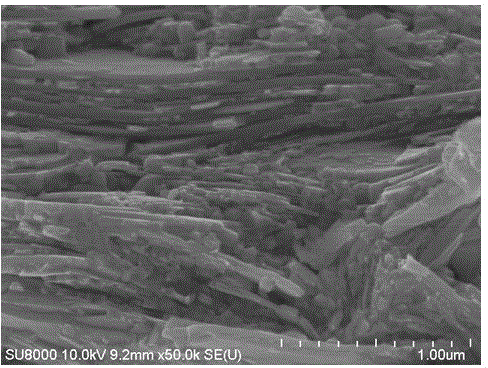

Image

Examples

Embodiment 1

[0033] Embodiment 1: solvothermal synthesis of Sb 2 Te 3 Matrix material

[0034] 1) with SbCl 3 and K 2 TeO 3 As the starting material, according to the stoichiometric ratio of n(SbCl 3 ):n(K 2 TeO 3 )=2:3 Weigh 0.002mol of SbCl 3 and 0.003mol of K 2 TeO 3 , and added to a 250ml two-necked round-bottomed flask, then added 0.5g polyvinylpyrrolidone, 0.5g NaOH and 80ml of diethylene glycol (measured with a measuring cylinder), and placed the two-necked round-bottomed flask in a temperature-controlled heating mantle , set the temperature at 240 ° C, keep warm for 4 hours, and adjust the rotation speed to 500 r / min. When the temperature of the reactants dropped to room temperature, they were transferred to 100 ml centrifuge tubes, centrifuged 3 times with isopropanol and acetone respectively, the speed of the centrifuge was set at 4000 r / min, and the time was 4 min. The lower black precipitate was taken out and placed in an oven at 70°C for drying for 6 hours...

Embodiment 2

[0038] Embodiment 2: solvothermal synthesis of Sb 2 Te 3 Matrix material

[0039] 1) with SbCl 3 and K 2 TeO 3 As the starting material, according to the stoichiometric ratio of n(SbCl 3 ):n(K 2 TeO 3 )=2:3 Weigh 0.002mol of SbCl 3 and 0.003mol of K 2 TeO 3 Add to a 250ml two-necked round-bottomed flask, then add 0.55g polyvinylpyrrolidone, 0.4g NaOH and 80ml of diethylene glycol (measured with a graduated cylinder), place the two-necked round-bottomed flask in a temperature-controlled heating mantle, set 230 DEG C of fixed temperature, insulation 5h, regulate rotating speed 500r / min. When the temperature of the reactants dropped to room temperature, they were transferred to 100 ml centrifuge tubes, centrifuged three times with isopropanol and acetone respectively, and the centrifuge speed was set at 4000 r / min for 4 minutes. The lower black precipitate was taken out and placed in an oven at 70°C for drying for 6 hours to finally obtain black Sb 2 Te 3 N...

Embodiment 3

[0041] Embodiment 3: solvothermal synthesis of Sb 2 Te 3 Matrix material

[0042] 1) with SbCl 3 and K 2 TeO 3 As the starting material, according to the stoichiometric ratio of n(SbCl 3 ):n(K 2 TeO 3 )=2:3 Weigh 0.002mol of SbCl 3 and 0.003mol of K 2 TeO 3 Add to a 250ml two-necked round-bottomed flask, add 0.45g polyvinylpyrrolidone, 0.6g NaOH and 80ml of diethylene glycol (measured with a measuring cylinder), place the two-necked round-bottomed flask in a temperature-controlled heating mantle, set Set the temperature at 250°C, keep warm for 3h, and adjust the rotating speed at 500 r / min. When the temperature of the reactants dropped to room temperature, they were transferred to 100 ml centrifuge tubes, centrifuged 3 times with isopropanol and acetone respectively, the speed of the centrifuge was set at 4000 r / min, and the time was 4 min. The lower black precipitate was taken out and placed in an oven at 70°C for drying for 6 hours to finally obtain blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com